Decoding the code

This malfunction of the Vaillant boiler is usually interpreted as a lack of coolant. It’s easy to verify by looking at a number of thematic sites and forums. Hence the only recommendation is to add water to the system.

Error f22 belongs to the general category: the causes are different, and therefore a set of measures is carried out to identify and eliminate them. Correct interpretation: decrease in pressure in the circuit. Caused by a number of factors caused by problems with the system or Vaillant boiler.

First steps

First steps

Press button number 8 on the Vaillant boiler control panel

This algorithm of actions saves time in troubleshooting problems with heating equipment. A negative result is a reason to look for the reason for the shutdown of the Vailant boiler.

On a note! The instructions for gas equipment contain scant information on faults. The manufacturer, taking into account the complexity of the devices and their danger in terms of ignition (explosion), does not rely on repairs by the user - only a certified technician. A number of Vailant boiler errors are caused by identical factors.

Possible causes of the error

Leak

With error f22 there is no talk of a serious defect. But if, some time after filling the system with coolant, the pressure drops, the conclusion is clear: a microcrack has appeared in the circuit, through which liquid slowly and continuously leaks. The problem area may be on the main line (radiators, pipe connections, expansion tank) or in the Vaillant boiler. It is difficult to identify a defect due to the fact that water droplets from a heated surface evaporate intensively, rather than flow down, forming puddles. And if the coolant in the system is of good quality, no traces in the form of streaks remain in the area of the microcrack.

How to proceed . Wait until the pipe temperature reaches room temperature. There will be no more evaporation, and the location of the leak can be determined by looking at the stains on the floor and walking around the house. It is not difficult to decide how to repair a microcrack (soldering, cold welding, high-temperature sealant).

Air accumulation

When the boiler is operating, gas formation in the circuit occurs continuously. And the higher the Vaillant mode, the faster. With normally functioning air vents, bubbles are removed automatically. Incorrect operation of the device leads to the formation of a bubble, which impedes the circulation of liquid, initiating dry running of the pumping device. The result is the same - error f22 of the Vaillant boiler.

How to proceed . Vent the air wherever possible. You should not rely on the valves, since any of them can fail. There are many reasons: weakening of the spring, contamination of the channel, but the formation of a cluster of bubbles is inevitable. This also applies to the Vaillant boiler pump. There is a plug on the end of the device body. Unscrew the washer until a trickle of water appears, after placing the bath in place. The coolant is drained until clean liquid comes out, without air bubbles. With the measures taken, error f22 is eliminated.

Boiler pump

The 22nd fault code Vailant is evidence of incorrect operation of the pumping device. After bleeding the air, the error is caused by a problem with the pump itself.

What goes away on its own

Incorrect functioning of the pump is also caused by other reasons : deformation of the shaft or impeller, destruction of the bearing, contamination of the internal air removal channel. Repairing the Vailant boiler pump is impractical. And not only because of the search for a part, the need to disassemble the device: the shaft is not sold at retail, you need to order it. The nuance is that you will have to perform alignment, and it requires experience and time.

Recommendation : if an internal defect is suspected, install a new pumping device. Price from 9,700 rubles, the work is performed without contacting a professional.

Electronic board

This is the likely cause of error f22. In order not to waste time, you need to go to the menu (the algorithm is specified in the instructions for Vaillant) and look at the symbols on the display: the letter S and numbers. Using this code, an employee of the service organization, taking into account the boiler model, will give recommendations over the phone or accept an application. If the unit stops for this reason, the arriving technician will replace the board.

Source

What to repair?

If the above steps do not help, there is likely a problem with the heating or control elements. It could be:

- heating element. Its failure causes scale. To avoid this, carefully select the washing powder or liquid or clean the heating element from time to time by running the washing machine idle with special products;

- Temperature sensor or NTC sensor. Replacing one or both of these parts will most likely solve the problem;

- Control block. Failures in the module can also block the heater. Sometimes a flashing is enough, in some cases a deeper repair or replacement is needed.

Self-diagnosis systems in modern heating boilers make it possible to quickly detect malfunctions, notifying users about this. They are present in equipment from almost all brands, including those from Vailant. In this review, we will analyze the typical errors of Vailant boilers and their numerical designations, and give instructions for further actions.

How to correct errors on Vailant boilers - types of malfunctions

Vaillant equipment is one of the safest among similar boiler models sold in the Russian retail chain. The manufacturer has tried and introduced a lot of test checks and settings into the software, which simplifies its maintenance. However, as with any equipment, malfunctions may occur during operation and maintenance of the Vaillant.

A display installed on the boiler control unit helps personnel understand where the failure occurred. When several malfunctions occur simultaneously, the codes are displayed alternately, after approximately 2 seconds, with the error starting with the letter F, and the status information with S.

The boiler owner, in order to understand what to do in a particular situation, will need to decipher the main codes.

Adjustment features

Boilers from this manufacturer are easy to control. However, this does not mean that every person can cope with such a task on their own. It is best to make adjustments together, when one person turns the tap and the other monitors the position of the pressure arrow. To adjust the water or heating temperature, you can use special valves located on the control panel. In this case, how hot the water is will be displayed on the display. Thanks to this, you can increase or decrease the temperature by turning the tap to the desired position.

Also, the fact that the time has come to figure out how to eliminate error F28 in the Vailant boiler can be signaled by special light sensors on the device panel. The green light comes on when heated water is being used. A yellow indicator indicates that gas is burning. If the red LED lights up, this indicates a problem with the system

It is also worth paying attention that only water is poured into the boiler. There is no point in experimenting

Prevention

Like any other equipment, the boiler requires timely prevention.

Cleaning the boiler

Cleaning of soot from the boiler is carried out with a soft brush from the outside. The use of harsh cleaning is unacceptable, since the boiler plates are made of copper, with an anti-corrosion coating that cannot be removed. The disadvantage of the heat exchanger design is that it cannot be internally washed, and the use of antifreeze or feeding the circuit with hard water shortens the service life of the unit.

Fighting deposits and scale

The problem of deposits is even more important when operating secondary hot water boilers, due to the constant circulation of hard water through its circuit. This means that it becomes even more clogged with deposits and scale. The manufacturer took care of this situation and created conditions for periodic washing of the heating surfaces of the DHW circuit. This can be done using a booster with the addition of special agents to the circulation coolant.

Next, the solution is run for several hours, dissolving and washing away the scale.

Note! In addition, it is recommended to maintain a low temperature for hot water supply, which does not require dilution with cold water. In this case, the intensity of scale formation, which begins at 60 °C, will be practically reduced to zero.

Expansion tank maintenance

Expansion tanks are subject to annual maintenance. To do this, the boiler is filled with water to the operating level in the system of 1–1.2 bar. If water appears from the control output of the expander, then the tightness of the tank membrane is broken and it will need to be replaced.

Burner and filters

The filters on the gas line are made in the form of a mesh; for maintenance they are removed and washed with water. The gas burner also becomes clogged with combustion products over time; it should be cleaned with a soft bristle brush and a vacuum cleaner.

Practical recommendations

• The Vaillant boiler should not be connected to the network directly, but through a UPS. A unit is a complex device consisting of a group of batteries, their charging and voltage stabilization circuits. Even if the power line is disconnected or the backup electric generator breaks down, the heating installation will continue to function for several hours (depending on the total battery capacity).

• The “weak link” of the pressure sensors of any imported boiler, and Vaillant is no exception, is the sensitive element (membrane). Foreign developers focus on their customers, without taking into account our specifics. This concerns the quality of the water filling the heating circuit. Over time, with increased rigidity of the coolant, the rubber rubber becomes “oaky” and loses sensitivity to changes in the pressure of the circulating liquid. In fact, the sensor (flow switch) is working, but boiler error F75 appears periodically. The reason is that the membrane does not respond to slight changes in pressure.

It is advisable to order and install a new German sensor of a new modification in the Vaillant boiler (article 0020023721). The price is quite high (around 11,500 rubles), but the warranty for it is 5 years, and the problem with the appearance of error F75 due to the “whims” of the flow switch will be solved forever. It is made in such a way that debris is excluded: special membrane material, polymer filling of voids in the sensor body.

Other possible malfunctions and ways to eliminate them

It happens that the boiler display does not work and does not allow faults to be recorded. If the user is sure that power is supplied to the boiler control panel and it is correctly connected to the network, then the most likely cause will be a malfunction of the board itself.

Note! Unfortunately, the boiler software does not allow you to detect internal failures in the operation of the board. And although the boiler will not be able to function, violations can sometimes be detected visually.

Possible other error codes:

Note! Before calling the service center, you can independently press the “Reset fault” button, on which the image of a “fire with a cross” is installed. If the unit does not work, then you should call a certified specialist, especially if the boiler is under warranty.

The arriving specialists will have to diagnose all boiler equipment, which will require disassembling the boiler. Next, the condition of the electrodes and electrical wiring supplying the electronic board will be analyzed, the reliability of the grounding circuit will be tested, and the gas fuel pressure and operation of the valve on the gas line in front of the boiler will be checked. If these components do not show a malfunction during testing and inspection, it will be necessary to check, repair or replace the electronic board of the boiler control unit.

Why does blood pressure drop?

The pressure drop in the boiler has a single cause - a coolant leak. If, after several attempts to increase the pressure using the supply valve, no positive results appear, you should look for a leak in the boiler itself or in the heating circuit.

Difficulty may arise if the boiler is a condensing boiler and is connected to a floor heating system.

Finding leaks in such conditions is extremely difficult. It may turn out that the fault is hidden in the discharge valve connected to the sewer system.

The optimal way to search for causes is to consistently eliminate possible causes of leaks, so that ultimately only one, the correct one, remains.

NOTE!

Certain information can be obtained if you try to determine the intensity of the leak and analyze the throughput capacity of the boiler elements involved.

Boiler "Vailant" error f28 - user tips

Since error f28 is the most common among boilers of this model, experienced users shared their tips for eliminating it:

Note! The Vaillant boiler belongs to high-quality and highly reliable equipment, but component failures sometimes occur.

The unit's circuit board is its most expensive element, so it is more advisable to have it repaired at a service center rather than buy a new one; this will save the owner significant money.

Source

Repeated breakdown

The music didn’t play for long; my favorite Vaillant gas boiler broke down again. At first I got error f33 and again f28, which means a problem with the gas burner. Since the Vailant display was acting up, naturally the fault was on the control board. However, one should not rush to conclusions. Like last time, we act according to a clear plan:

- Disabling equipment.

- Removing a gas boiler.

- Carrying out diagnostics.

- Analysis of the design.

- Checking elements.

Since I had previously inspected the unit, I decided to check all the main components. I was interested in the condition of the tap, sensors, and pump. I didn’t want to disassemble the unit often, so I thought about how to fix all the problems at once. In a Vaillant gas boiler, some elements are hidden, so it is difficult to get to them without damaging another element.

We are talking about the control board. It is located at the bottom of the structure, and to get there you will have to tinker with the bolts, in my case everything looks flimsy. Finally, the Valiant boiler is open and you can look around. The control board is a regular element, the same as in a computer. When disassembling a gas boiler, it is recommended not to touch the contacts and connecting elements with your fingers again, since greasy stains remain on them. All this can affect the operation of the automation.

Eliminating the error begins with cleaning the contacts. As you know, there are tracks on the control board, and they can be easily cleaned with ordinary office grout. As for the sensors, I just removed the dust from them. Upon inspection, I noticed that the three-way valve was loose and could possibly fail in the near future. This element is located in the upper part of the structure and is responsible for shutting off the gas.

In the store I picked up a similar three-way product, the most interesting thing was with the control board. Finding a similar variation is problematic, fortunately, the exact product code is indicated on it, so I was able to order it online.

Error F28 may also appear due to a gearbox malfunction. The element is responsible for gas pressure and is connected to the meter. When I had suspicions about the gearbox, I initially carried out diagnostics; it was necessary to check the settings. First of all, turn off the gas valve

You need to pay attention to the display. If the error code disappears, it means the element needs to be replaced. It happens that everything is fine with the magnet, but the ignition transformer suffers

Soot often accumulates on it and the gas boiler refuses to work. Checking the pressure is not so easy, since it requires removing the casing. Having reached the distribution box, close the shut-off valve. Inside there are several sealing screws that are fixed to the gas fittings. It is only necessary to loosen them a little; the structure is not as strong as it might seem at first glance

It happens that everything is fine with the magnet, but the ignition transformer suffers. Soot often accumulates on it and the gas boiler refuses to work. Checking the pressure is not so easy, since it requires removing the casing. Having reached the distribution box, close the shut-off valve. Inside there are several sealing screws that are fixed to the gas fittings. They only need to be loosened a little; the structure is not as strong as it might seem at first glance.

A digital tonometer is used to check blood pressure. In the instructions you will find exact indicators of normal pressure depending on the modification.

Typical errors

Knowing the error codes of the Vailant boiler, you can diagnose almost any malfunction. And having experience in repairing heating equipment, nothing prevents you from dealing with the breakdown yourself. The codes are displayed on digital indicators, representing two-digit numbers with the letter F. Let's look at them in more detail.

Error F28

A fairly common error that occurs when the ignition unit cannot be started. As a result, the equipment cannot start working. Error F28 in Vailant boilers can indicate either a breakdown of the system board or a malfunction of other components - the high-voltage ignition transformer, gas magnet, gas valve, ignition sensor and much more. It appears when the conductors break or there is insufficient pressure in the line. Its appearance is often caused by a simply closed gas valve.

To fix error F28, follow these steps:

If all nodes are intact, there is a high probability of an error directly on the system board. In this case, you need to contact Vailant service for its repair or complete replacement.

Error F75 may also indicate problems with the on-board water pressure sensor - it cannot recognize an increase in pressure after the pump starts.

Error F75

Another common sign of breakdown. Error F75 in Vailant boilers indicates problems with pressure in the heating system. It occurs after starting the circulation pump . Usually in this case the pressure rises by about 0.2-0.4 atmospheres. If this does not happen, the problem may lie in improper installation of the system. First, you need to check the functionality and correct connection of the expansion tank (expansomat), and then de-air the circuit.

After this, we check the functionality of the pump - it should drive the coolant along the circuit. A faulty pump must be replaced; they are usually not repaired.

Errors F0, F1, F2, F3 and F4

The first two occur in Vailant heating boilers if the coolant temperature sensor (NTC sensor) fails. It must be replaced with a sensor of a similar model. Despite the absence of vibrations, the connecting conductors may also fail - check their integrity with a multimeter. You should also evaluate the quality of the connections, inspect the connecting plugs - codes often appear due to oxidation of the contacts. Codes F2, F3 and F4 are caused by the accumulator sensor.

Errors F5 and F6 (and F15 and F16)

This code is typical for Vailant Atmo series boilers with atmospheric burners. It indicates a breakdown of the traction sensor or a break in the connecting wires. We recommend checking the integrity of the conductors and testing the sensor itself. If a breakdown occurs after disassembling and reassembling the equipment, we check that all connections are correct. In turbocharged units, codes F15 and F16 occur.

Codes F10 and F11

Their appearance means a short circuit in the supply and return temperature sensor circuits. Not only the wires need to be checked, but also the temperature sensors themselves. We test detachable connections in the same way.

Errors F13 and F14

If one of these codes appears on the digital indicator, it means that the coolant has overheated - it has heated up to a temperature of +130 degrees. For Vailant boilers, this value is critical, so the equipment is immediately turned off. If the water in the circuit is clearly cooler, there is a short circuit in the sensor itself or in the connecting wires.

Code F20

Indicates problems with the supply temperature sensor. It needs to be checked, all connections are checked in the same way. In some cases, the code indicates overheating of the coolant.

If error F22 occurs, you need to test all circuits responsible for the operation of the circulation pump and the coolant pressure sensor in the circuit.

Codes F22, F23 and F24

Error F22 is common, indicating a variety of malfunctions. It appears when there is no water in the heating circuit. Water can leak out through the smallest cracks and cracks, and problems with the pressure switch and circulation pump are also possible. In rare cases, the motherboard is to blame.

How to run self-diagnosis

The self-diagnosis system is a complex of sensors consisting of NTC elements (thermistors) or software products.

All of them operate in continuous mode, monitoring the status of connected elements from the moment the boiler is turned on.

Therefore, the self-diagnosis system does not need to be started - it is always on and operates in constant mode, monitoring the operating mode of components and parts, immediately signaling the occurrence of problems.

In the event of an emergency, a special code will appear on the display indicating the problematic structural element. The user is only required to react appropriately when an error occurs.

How to fix error f28 of a Vaillant gas boiler (Vailant)

German heating systems are available in various modifications. But regardless of the principle of operation or design features of gas boilers, error f28 is typical for all versions of Vaillant, and the reasons that initiate it are identical. Most of them are identified and eliminated on their own, without calling a specialist. The article will help you troubleshoot possible problems and give recommendations on how to restore the functionality of your equipment.

Error interpretation

Code f28 appears on the display after several unsuccessful ignition attempts. The reasons can be divided into four groups:

Understanding this and knowing the specifics of the gas supply to the facility, it is easy to develop an action plan for troubleshooting. In order to reduce the time to eliminate the f28 Vaillant error, you need to start by testing the most problematic areas of the circuit.

Video about how error code F28 is displayed on the Vailant boiler.

“Troubleshooting” button to reset certain faults. Click it.

First steps

On a note!

The recommendation to “turn the plug over” and reinsert it into the socket in order to eliminate the error is not suitable for Vaillant boilers - the experiment will lead to the circuit breaker turning off or the electronic board burning out.

Gas path diagnostics

When connecting a building to a main pipe

If we are talking about a residential building, and “blue fuel” is chosen as the main energy resource, in the house, in addition to Vaillant, there is a gas stove. After the pipes have been laid, there are no devices in the section of the circuit up to the boiler. Therefore, you can control the flow of gas without leaving the kitchen.

The check comes down to igniting all the burners on the stove at maximum mode. Flames with a characteristic shade will indicate the absence of problems with the fuel supply, and their intensity and stability will indicate the constancy of the pressure and its normal value. If the stove does not light up or does not work correctly, you need to look for a fault in the section between the main line and the place where the gas pipes are laid (the method is described below).

With autonomous gas supply

Check what

Another option is the formation of an ice jam on one of the sections of the highway outside the building. But this defect must be dealt with (and eliminated) by specialists.

Diagnostics Vaillant

Ionization sensor

If ignition occurs (there is a spark), but after a short time error f28 appears and the operation of the Vaillant boiler is blocked, the electrode “does not see” the flame.

Ignition system

Its serviceability can be judged by the spark between the igniter electrodes. If the connected wires are in normal condition and the assembly body is intact (the absence of cracks is determined visually), the cause of error f28 of the Vaillant boiler is in the transformer. It is necessary to test its winding to identify a break: the multimeter should show ∞.

Gas valve

It is not difficult to disassemble it yourself: you will need an asterisk key. After dismantling the stepper motor and removing the cap, the rod is visible. It is “responsible” for moving the membrane that regulates the gas supply to the burner of the Vaillant boiler. During operation, it becomes dirty, and layers interfere with its free movement. It is enough to wash it in any alcohol-based liquid, put it in place and reassemble in the reverse order.

Vaillant boiler gas valve

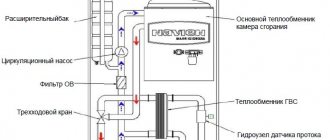

Location of the main units in the Vaillant boiler

This is a theory, but in practice everything is much more complicated.

Other reasons for the error

Useful tips

If you have experience on how to fix error f28 of a Vaillant boiler or what needs to be done based on your experience, write in the comments to this article, we will try to consider your option and analyze it in detail in this article or one of the following articles. You can also send photos and videos with comments and descriptions.

Did you like the article? Like and repost will be the best gratitude.

Most common hardware problems

F20/F22/23/24 (F10|F11) – overheating.

Errors occur when the volume of coolant in the system decreases, a sharp increase in temperature, or an exorbitant difference in temperature at the outlet and inlet to the Vaillant.

Recommendation: fill the circuit with water, bringing the pressure to normal (2±0.5 bar). Reset and start up the boiler. Repeated occurrence of the error is evidence of a problem.

Probable Causes

1. Leak. An autonomous circuit is a closed and closed system: natural evaporation of liquid is excluded. Loss of coolant is possible only in the event of mechanical damage or leakage. It is easy to find the problematic section of the route (device) by inspecting the house for signs of dampness, stains and streaks. Leaks rarely occur in the Vailant boiler itself: more often in the joints of pipes or heating radiators.

2. Reduced circulation rate. The coolant moves more slowly, and the boiler burner operates in the specified mode. Hence the overheating and Vaillant's error. What is the reason?

- Heat exchanger

- Pipe

Airlock. It is easiest to identify and mitigate such a problem. It is necessary to check all radiators for the degree of heating: a sharp temperature drop in individual sections of the circuit will indicate the “culprit”. Even if there are automatic valves, you should bleed them manually - they often fail due to poor quality water treatment.

Pump. The boiler overheating error is caused by stopping the device or reducing the shaft speed.

Vaillant boiler pump

First of all, the supply voltage and the set speed are checked. Incorrect operation of the Vailant pump may be due to salt deposits on the impeller. It is necessary to dismantle the pumping device, perform partial disassembly and wash it. After starting the boiler, the overheating error disappears.

Heat exchanger. The formation of layers in its cavity is one of the probable reasons. A gradual decrease in the diameter of the channel negatively affects the circulation of liquid, hence the overheating of the Vaillant boiler and the error.

Recommendation: if there is an alternative heat source at the site, the device must be removed and sent for service. Self-cleaning is ineffective, and after starting up, the Vailant boiler may start up again in a month or a month and a half. High-quality maintenance involves filling the cavity of the heat exchange device with an aggressive liquid, leaving it for at least a day, followed by flushing under pressure. This cannot be done on site.

F26 (F07) – problem with gas fittings.

You should ensure the integrity of the wires and the reliability of the contacts. It is not advisable to change it yourself - you also need to configure it correctly.

F27 – flame simulation error.

The probable cause is the ionization sensor: shorted wires, dirty electrode, dampness. If the boiler has been idle for a long time, you need to remove the casing and dry it (with a directed stream of warm air).

F28 (F04) – unsuccessful ignition.

There are many reasons for this error to appear. You can independently check only the flow of gas to the boiler burner, its pressure, the reliability of the signal circuits and grounding. Other defects - in the meter, main filter, Vaillant fittings, transformer, electronic board - must be determined by a specialist.

F29 – boiler malfunction, problem with re-ignition.

Probable causes of errors during autonomous gasification: gearbox failure, icing, LPG production. The remaining faults are identical to F28; they cannot be determined independently.

F33 (F05) – incorrect fan operation.

The error is caused by its breakdown, failure of the flow switch, or a malfunction in the electronic module of the boiler. If the power and signal lines are not damaged, you need to contact a specialist.

F68 – unstable flame.

Probable Causes

- Unstable pressure in the line.

- Air leak. If Vaillant runs on LPG from a cylinder group, check all connections.

- Problem with the boiler ionization sensor. Its contamination may be the cause of error F68: remove carbon deposits.

- Vaillant boiler gas valve is clogged

- Debris in gas valve

Everything else is due to incorrect operation of the gas fittings and boiler burner. You can service the nozzles yourself: a vacuum cleaner, a toothbrush. If after this the Vaillant error does not disappear, call a technician.

– Pressures greater than 50 mbar are not detected.

What to do with error F20 on a Vaillant gas boiler (Vailant)

The diagnostic function of heating installations in automatic mode allows the user to solve almost all problems without contacting service. For Vaillant gas boilers, error f20 is a rare occurrence. Understanding the reasons why it is caused, it is easy to identify the problem and fix it on your own.

Decoding the code

Recommendations for eliminating the f20 Vaillant error found on forums and thematic sites are different. It appears when the boiler overheats, and there are several reasons for this. The nuance is that the instructions indicate different codes for them: f0 (high supply temperature), f22 (sharp drop in coolant pressure) and a number of others.

Error f20 is displayed on the control panel of the Vaillant boiler

Not everyone understands the difference between Vaillant boiler sensors. Devices installed on the forward and return lines monitor the current temperature. The overheating thermostat is activated at a value of t˃ 95 0 C at the output of the heat exchanger and turns off the heating installation upon an alarm signal with error f20. Therefore, it is necessary to deal with it.

Procedure

Step 1

Perform a reset by pressing the button on the Vaillant control panel. Imported boilers are sensitive to the supply voltage, and if the network is unstable, they malfunction with an indication of some error. If it is false, it is easily reset.

Button

8 “Troubleshooting” for resetting specific faults

Step 2

Bring the thermostat into working position. In Vaillant boilers, it is “cocked” manually by pressing the rod (painted red). If error f20 is caused by a pump malfunction or other reason, it will disappear. To access the overheating thermostat, you need to fold back the front panel - in most Vaillant models, a protective device (fuse) is installed at the heat exchanger outlet, under the NTC sensor.

Location of the NTC sensor of the Vailant boiler

Step 3 – diagnostics of signal circuits. Defects are determined visually: line break, insulation melting, short circuit - the causes of error f20 and emergency stop of the Vaillant boiler. The reliability of the contacts and the absence of oxides are checked.

Step 4 – testing the overheat sensor. It is easy to determine serviceability with a multimeter by measuring the resistance. In the initial state, the contacts of the working device are closed, R = 0. The protective thermostat cannot be repaired - it is replaced.

The last reason that causes error f20 is the electronic board of the Vaillant boiler. It generates a fault code based on a signal from the overheating sensor. It will not be possible to identify a defect on your own without diagrams, experience, or appropriate equipment. If the measures taken to eliminate error f20 are unsuccessful, you need to contact a service center. After replacing the board, the boiler's performance will be restored.

Source

Ignition transformer

Failure to start the Vailant boiler is due to the lack of a spark or its insufficient power. If there are no wire defects, the Tr winding is checked with a multimeter: open – R = ∞, short circuit – R = 0. With interturn, the device will show resistance, but if the value does not correspond to the passport data, the spark is weak, insufficient to ignite the burner. Error f29 can be eliminated by replacing the transformer.

Burnt ignition electrode of Vaillant boiler

Control board

Self-repair is possible for a user with specialized education, but it will take time. Error f29 can be eliminated by replacing the Vaillant boiler assembly.

Useful tips

What checks are carried out before the first start-up of the boiler?

For further normal and safe operation, as well as maintaining the warranty, any equipment requires compliance with a number of conditions:

The installation manual also requires installing a coarse filter on the cold water supply to the boiler and on the return pipe of the heating system, as well as a gas filter.

It is better to study the commissioning process in more detail in the instructions for a specific boiler model.

The selection of the test program (airing, filling the system) is started by turning on the boiler and simultaneously holding the “+” button for 5 seconds. The selected program is activated with the “i” button. For TEC series boilers, five programs are preinstalled.

Bosch machine repair and parts replacement

If you are unable to fix the problem yourself, contact the service center for the services of a technician. It is not possible to determine the location of the breakdown on your own; professional diagnostics are needed. At risk:

Pressure and water supply sensor

If the pressure sensor (pressostat) fails, the failure cannot be corrected: the part needs to be replaced. A breakdown can result in an endless cycle of draining and filling water.

But if a blockage occurs, then the pressure switch simply needs to be cleaned. There is no need to disassemble the machine, just disconnect the tube from the pressure switch and rinse thoroughly under running water. This part is located in the central part of the left side wall.

The flow sensor monitors the throughput of the machine. If water does not enter the tank, do the following:

Inlet (fill) valve

If there is a malfunction, the valve must be replaced. Open the top cover of the machine. There are two hoses connected to the fill valve - disconnect them. Then you should disconnect the wires from the burnt valve and remove it. After this, you can install a new one.

On a note! When replacing any valves in a washing machine, you should first turn off the water supply in the water supply, otherwise it will flow onto the floor.

A malfunction of the fill valve can lead to flooding of the neighbors below if the Aqua Stop is missing or is faulty in the machine.

Water intake sensor

If the electronic module is broken, the sensor does not detect the liquid intake. Because of this, the machine cannot start washing. If the sensor completely fails, it is cheaper to buy a new washing machine. In other cases, the technician can help with repairs.