The greatest disadvantage of solid fuel boilers is their cyclical nature: at maximum load and combustion, a peak (often excessive) thermal power is reached, which constantly decreases to 0 (complete attenuation) and is resumed with a new addition of fuel. Such cycling does not allow for a stable, quickly and accurately regulated heating system.

The uneven heat transfer of TT boilers can be smoothed out by a buffer tank (also known as a heat accumulator), which accumulates excess heat during peak operation of the boiler unit. However, there are many nuances in choosing and calculating the required volume of a heat accumulator.

What is a buffer tank for a solid fuel boiler?

A buffer tank (also a heat accumulator) is a tank of a certain volume filled with coolant, the purpose of which is to accumulate excess thermal power and subsequently distribute it more rationally for the purpose of heating a house or providing hot water supply (DHW).

What is it for and how effective is it?

Most often, a buffer tank is used for solid fuel boilers that have a certain cyclicity, and this also applies to long-burning TT boilers. After ignition, the heat transfer of the fuel in the combustion chamber quickly increases and reaches peak values, after which the generation of thermal energy fades, and when it fades, when a new batch of fuel is not added, it stops altogether.

The only exceptions are bunker boilers with automatic supply, where due to the regular uniform supply of fuel, combustion occurs with the same heat transfer.

With such cyclicality, during the period of cooling or attenuation, thermal energy may not be enough to maintain a comfortable temperature in the house. At the same time, during the period of peak thermal power, the temperature in the house is much higher than comfortable, and part of the excess heat from the combustion chamber simply flies out into the chimney, which is not the most efficient and economical use of fuel.

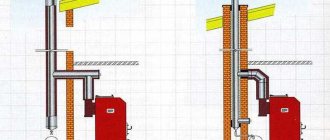

A visual diagram of connecting a buffer tank, showing the principle of its operation.

The effectiveness of a buffer tank is most clearly understood using a specific example. One m3 of water (1000 l) when cooled by 1°C releases 1-1.16 kW of heat. Let's take as an example an average house with a conventional 2-brick masonry with an area of 100 m2, the heat loss of which is approximately 10 kW. A 750 liter heat accumulator, heated by several loads to 80°C and cooled to 40°C, will release about 30 kW of heat to the heating system. For the above-mentioned house, this equates to 3 additional hours of radiator heat.

Sometimes a buffer tank is used in combination with an electric boiler; this is justified when heating at night: at reduced electricity rates. However, such a scheme is rarely justified, since in order to accumulate a sufficient amount of heat overnight for daytime heating, a tank of not 2 or even 3 thousand liters is needed.

Design and principle of operation

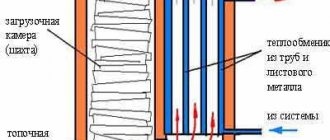

A heat accumulator is a sealed, usually vertical, cylindrical tank, sometimes additionally thermally insulated. He is an intermediary between the boiler and heating appliances. Standard models are equipped with an insert of 2 pairs of pipes: the first pair is the boiler supply and return (small circuit); the second pair is the supply and return of the heating circuit distributed throughout the house. The small circuit and the heating circuit do not intersect with each other.

The principle of operation of a heat accumulator in conjunction with a solid fuel boiler is simple:

- After the boiler is fired up, the circulation pump constantly pumps the coolant in a small circuit (between the boiler heat exchanger and the tank). The boiler supply is connected to the top pipe of the heat accumulator, and the return pipe to the bottom. Thanks to this, the entire buffer tank is smoothly filled with heated water, without pronounced vertical movement of warm water.

- On the other hand, the supply to the heating radiators is connected from above to the buffer tank, and the return is connected from below. The coolant can circulate both without a pump (if the heating system is designed for natural circulation) and forcibly. Again, this connection scheme minimizes vertical mixing, so the buffer tank releases accumulated heat to the batteries gradually and more evenly.

If you correctly select the volume and other characteristics of the buffer tank for a solid fuel boiler, heat loss can be minimized, which will affect not only fuel economy, but also the comfort of the firebox. The accumulated heat in a well-insulated heat accumulator is retained for 30-40 hours or more.

Moreover, due to a sufficient volume, much larger than in the heating system, absolutely all the generated heat is accumulated (in accordance with the efficiency of the boiler). After only 1-3 hours of heating, even with complete extinguishing, a fully “charged” heat accumulator is available.

Types of structures

| Photo | Buffer tank device | Description of distinctive features |

| Standard, previously described, buffer tank with direct connection at the top and bottom. | Such designs are the cheapest and most frequently used. Suitable for standard heating systems, where all circuits have the same maximum permissible operating pressure, the same coolant, and the temperature of the water heated by the boiler does not exceed the maximum permissible for radiators. | |

| A buffer tank with an additional internal heat exchanger (usually in the form of a coil). | A device with an additional heat exchanger is necessary at a higher pressure of the small circuit, which is unacceptable for heating radiators. If the additional heat exchanger is connected with a separate pair of pipes, you can connect an additional (second) heat source, for example, a TT boiler + electric boiler. It is also possible to separate the coolant (for example: water in an additional circuit; antifreeze in the heating system) | |

| Storage tank with an additional circuit and another circuit for domestic hot water. The heat exchanger for hot water supply is made of alloys that do not violate sanitary standards and requirements for water used for cooking. | Used as a replacement for a double-circuit boiler. In addition, it has the advantage of almost instantaneous supply of hot water, while a double-circuit boiler requires 15-20 seconds to prepare it and deliver it to the point of consumption. | |

| The design is similar to the previous one, however, the DHW heat exchanger is not made in the form of a coil, but in the form of a separate internal tank. | In addition to the benefits described above, the internal tank eliminates limitations in hot water production. The entire volume of the DHW tank can be used for unlimited simultaneous consumption, after which time is required for heating. Typically, the volume of the internal tank is enough for at least 2-4 people to bathe in a row. |

Any of the above-described types of buffer tanks can have a larger number of pairs of pipes, which allows you to differentiate the parameters of the heating system into zones, additionally connect a water-heated floor, etc.

Features of the structural device

A storage tank for a heat supply system in its simplest design looks like a tall container with a cylindrical or square cross-section and several pipes located at different heights from the base. Its volume can range from 200 to 3000 liters, with the most popular products being 0.3 - 2.0 cubic meters.

The list of options for the heat accumulator produced for heating and its inherent options is as follows:

- The number of pipes can range from four to several dozen. This circumstance depends on the configuration of the heat supply system and the number of independent heating circuits.

- The storage tank is thermally insulated. Applying a 5-10 cm layer of polyurethane foam can greatly reduce heat loss in cases where the device is installed outside a heated room. Even when the tank is installed in the house, thermal insulation will not be a hindrance. The fact is that a device with a volume of 0.3 - 2 cubic meters gives off a significant amount of heat.

- For the manufacture of walls, both black and stainless steel are used. In the second case, the service life of the tank will be longer, but the cost will also be higher. By the way, being in a closed system, water becomes chemically inert, as a result of which the corrosion process of a metal such as black steel slows down significantly.

- A storage tank for heating may have several internal horizontal partitions that divide it into communicating sections. The device also has flanges for installing tubular electric heaters. If they have sufficient performance, a hydraulic accumulator for heat supply systems can perform the function of a full-fledged electric boiler.

- A container that accumulates heat is sometimes equipped with a heat exchanger for heating drinking water, the function of which can be performed by a storage tank located inside the main container, as well as a plate flow element. The cost of heating the liquid in this case, compared to the amount of thermal energy accumulated by the tank, will be insignificant.

- At the bottom of the heat accumulator there may also be an additional heat exchanger intended for connecting the solar collector. It is installed exclusively at the bottom, since this ensures the highest possible heat transfer from the collector, even with its low efficiency.

Reviews of household heat accumulators for boilers: advantages and disadvantages

| Advantages | Flaws |

| Much more efficient use of solid fuel, which increases savings | The system is justified only with constant use. If you don't live in the house all the time and only light the fire, for example, on weekends, the system needs time to heat up. In case of short-term operation, the effectiveness will be questionable. |

| Extending the cycle and reducing the frequency of solid fuel loading | The system requires forced circulation, which is provided by a circulation pump. Accordingly, such a system is energy dependent. |

| Increased comfort due to more stable and customizable heating system operation | To install a heating system using an indirect heating boiler, additional funds are required. The cost of inexpensive buffer tanks starts from 25 thousand rubles + safety costs (a generator in case of a power outage and a voltage stabilizer, otherwise, in the absence of coolant circulation, overheating and burnout of the boiler may occur at best). |

| Possibility of providing hot water supply | A buffer tank, especially one of 750 liters or more, is quite large and requires an additional 2-4 m2 of space in the boiler room. |

| Possibility of connecting several heat sources, ability to differentiate coolant | To ensure maximum efficiency, the boiler must have at least 40-60% more power than the minimum required to heat the house. |

| Connecting a buffer tank is a simple process, it can be done without the involvement of specialists |

Rating of heat accumulators

Manufacturers produce different types of buffer tanks. The market offers simple models with a hollow structure, devices with one or two heat exchangers, and built-in boilers. Our VyborExperta.ru team analyzed heat accumulators for heating systems from leading manufacturers.

Reliability, maintainability, and resistance to external influences were studied. Experts checked the functionality, effectiveness of thermal insulation, and compliance of technical characteristics with passport data. Feedback from owners, opinions of heating engineers, and availability of service were taken into account.

We paid special attention to the following equipment parameters:

- Capacity volume - the greater the heat loss in the house and the lower the efficiency of the boiler, the more coolant will be required;

- Maximum and operating heating temperature - the efficiency of the boiler operation depends on these indicators;

- Maximum permissible pressure in the system - the recommended pressure in the heating system of a small country house and a luxurious mansion of 2-3 levels has different values. The battery characteristics must correspond to these indicators;

- Dimensions of equipment - the possibility of installing heating equipment in a home boiler room depends on the parameters of the container;

- The presence of a heat exchanger improves the overall efficiency of the system;

- The materials used depend on the weight of the buffer tank, resistance to corrosion and temperature changes.

Not all heat accumulators met the requirements for reliable heating equipment. Lack of protection against overheating, high heat loss coefficient, poor thermal insulation, short warranty period - equipment with such characteristics was excluded from the rating.

How to choose a buffer capacity

Calculation of the minimum required volume

The most important parameter that you should decide on right away is the volume of the container. It should be as large as possible to maximize efficiency, but up to a certain threshold so that the boiler has enough power to “charge” it.

The volume of the buffer tank for a solid fuel boiler is calculated using the formula:

m = Q / (k*c*Δt)

- where m is the mass of the coolant, after calculation it is not difficult to convert it into liters (1 kg of water ~ 1 dm3);

- Q – required amount of heat, calculated as: boiler power * period of its activity - heat loss at home * period of boiler activity;

- k – boiler efficiency;

- c – specific heat capacity of the coolant (for water this is a known value - 4.19 kJ/kg*°C = 1.16 kW/m3*°C);

- Δt – temperature difference in the boiler supply and return pipes; indicators are taken during steady operation of the system.

For example, for an average house with 2 bricks and an area of 100 m2, the heat loss is roughly 10 kW/hour. Accordingly, the required amount of heat (Q) to maintain balance = 10 kW. The house is heated by a boiler with a power of 14 kW and an efficiency of 88%, the firewood in which burns out in 3 hours (the period of boiler activity). The temperature in the supply pipe is 85°C, and in the return pipe – 50°C.

First you need to calculate the required amount of heat.

Q = 14*3-10*3 = 12 kW.

As a result, m = 12 / 0.88 * 1.16 * (85-50) = 0.336 t = 0.336 cubic meters or 336 liters . This is the minimum required volume of buffer capacity. With such a capacity, after burning out the fill (3 hours), the heat accumulator will accumulate and distribute further 12 kW of heat. For the example house, this is more than 1 additional hour of warm radiators on one tab.

Accordingly, the indicators depend on the quality of the fuel, the purity of the coolant, and the accuracy of the initial data, so in practice the result may differ by 10-15%.

Calculator for calculating the minimum required capacity of a heat accumulator

Number of heat exchangers

Copper internal heat exchangers of the storage tank.

After selecting the volume, the second thing you should pay attention to is the presence of heat exchangers and their number. The choice depends on desires, requirements for CO and the tank connection diagram. For the simplest heating system, an empty model without heat exchangers is sufficient.

However, if natural circulation is planned in the heating circuit, an additional heat exchanger is needed, since the small boiler circuit can only function with forced circulation. The pressure in this case is higher than in a heating circuit with natural circulation. To provide hot water supply or connect underfloor heating, additional heat exchangers will also be required.

Maximum allowable pressure

When choosing a buffer tank with an additional heat exchanger, you should pay attention to the maximum permissible operating pressure, which should not be lower than in any of the heating circuits. Tank models without heat exchangers are in most cases designed for an internal pressure of up to 6 bar, which is more than enough for average CO.

Inner container material

At the moment, there are 2 options for manufacturing an internal tank:

- mild carbon steel – coated with a waterproof anti-corrosion coating, has a lower cost, and is used in inexpensive models;

- Stainless steel is more expensive, but more reliable and durable.

Some manufacturers also install additional wall protection in the container. Most often, this is, for example, a magnesium anoid rod in the center of the tank, which protects the tank walls and heat exchangers from the build-up of a layer of solid salts. However, such elements require periodic cleaning.

Other selection criteria

After determining the basic technical criteria, you can pay attention to additional parameters that increase efficiency and comfort of use:

- the ability to connect a heating element for additional heating from the electrical network, as well as additional control and measuring instruments that are mounted with a threaded or coupling (but in no case welded) connection;

- the presence of a layer of thermal insulation - in more expensive models of heat accumulators, between the inner tank and the outer shell there is a layer of thermal insulation material that promotes even longer heat retention (up to 4-5 days);

- weight and dimensions - all of the above parameters affect the weight and dimensions of the buffer tank, so it is worth deciding in advance how it will be brought into the boiler room.

Calculation

The power accumulated by a heat accumulator (TA) is calculated based on the volume of the container, more precisely the mass of the liquid in it, the specific heat capacity of the liquid used to fill it, and the temperature difference, the maximum to which the liquid can be heated, and the minimum target at which it can still be carried out. heat intake from the heat accumulator to the heating circuit.

Formula:

- Q = m*C*(T2-T1);

- m – mass, kg;

- C – specific heat capacity W/kg*K;

- (T2-T1) – temperature delta, final and initial.

If the water in the boiler and, accordingly, in the heating element is heated to 90ºС, and the lower threshold is taken equal to 50ºС, then the delta is equal to 40ºС. If we take TA water as filling, then one ton of water, when cooled to 40ºC, releases approximately 46 kW*hours of heat.

| Volume | 0,5 | 1 | 1,5 | 2 | 3 | 5 |

| Accumulated heat at ΔT = 40ºC, kW/h | 23 | 46 | 69 | 92 | 138 | 230 |

The stored energy must be sufficient for the intended use of the heat accumulator.

To select the required volume of the heat accumulator, it is necessary to determine:

- The time during which the accumulated energy in the heat exchanger should be enough to cover the heat loss of the house;

- The time during which the coolant in the heat exchanger must heat up;

- Power of the main heat source.

For periodic operation of the boiler during the day

If it is needed to switch the boiler operation only to night or day mode, when heat is supplied for a limited time, then the TA power should be enough to cover the heat loss of the house for the remaining time. At the same time, the boiler’s power should be enough to heat the heating unit in a timely manner and, again, to heat the house.

Let's assume that a solid fuel boiler is used with firewood only during the day for 10 hours, the estimated heat loss of the house for the coldest period of the year is 5 kW. 120 kW*hours are required per day for full heating.

The battery is used for 14 hours, which means that it needs to accumulate 5 kW * 14 hours = 70 kW * hours of heat. If you take water as a coolant, you will need 1.75 tons or a heat exchange volume of 1.75 m3. It is important that the boiler must produce all the necessary heat within just 10 hours, that is, its power must be more than 120/10 = 12 kW.

If the heat accumulator is used as a backup option in case of boiler failure, then the stored energy should be enough for at least a day or two to cover all heat losses in the house. If we take the same 100 m2 house as an example, then heating it will require 240 kW*hours in two days, and a heat accumulator filled with water must have a volume of at least 5.3 m3.

But in this case, the TA does not necessarily have to heat up in a short period of time. A boiler power reserve of one and a half is enough to accumulate the required amount of heat in a week or two.

The calculation is approximate, without taking into account the reduction in the thermal power of radiators depending on the temperature of the coolant and air in the room.

The best known manufacturers and models: characteristics and prices

Sunsystem PS 200

A standard inexpensive heat accumulator, perfect for a solid fuel boiler in a small private house with an area of up to 100-120 m2. By design, this is a regular tank, without heat exchangers. The capacity of the container is 200 l at a maximum permissible pressure of 3 bar. For a low cost, the model has a 50 mm layer of polyurethane thermal insulation and the ability to connect a heating element.

Hajdu AQ PT 500 C

One of the best buffer tank models for its price, equipped with one built-in heat exchanger. Volume – 500 l, permissible pressure – 3 bar. An excellent option for a house with an area of 150-300 m2 with a large power reserve of a solid fuel boiler. The line includes models of different sizes.

Starting with a volume of 500 l, models (optional) are equipped with a layer of polyurethane thermal insulation + an artificial leather casing. Installation of heating elements is possible. The model is known for extremely positive reviews from owners, reliability and durability. Country of origin: Hungary.

S-TANK AT PRESTIGE 300

Another inexpensive buffer tank with a capacity of 300 liters. The design is a storage tank without additional heat exchangers with a maximum permissible operating pressure of 6 bar. The internal walls, as in previous cases, are made of carbon steel. The main difference is a significant, environmentally friendly layer of thermal insulation made of polyester material using NOFIRE technology, i.e. high class thermal and fire resistance. Country of origin: Belarus

ACV (ATsV) LCA 750 1 CO TP

A productive, expensive buffer tank with a volume of 750 liters with an additional tubular heat exchanger for domestic hot water, designed for boilers with a large power reserve.

The internal walls are covered with protective enamel and there is a high-quality 100 mm layer of thermal insulation. A magnesium anode is installed inside the tank, which prevents the accumulation of a layer of solid salts (the kit includes 3 spare anodes). It is possible to install heating elements and additional instrumentation. Country of origin: Belgium.

Homemade heat accumulator: advantages, design, connection diagram to the heating system

Among craftsmen, improving the heating system has recently become one of the most popular topics. The material used for the heat accumulator is 200 liter metal barrels, containers for technical fluids and even ready-made solutions - barrels from decommissioned fire trucks and army water-oil heaters. At the same time, the latter options are considered the most preferable - the containers already have thermal insulation and sufficient volume. So, from an AC-40 fire truck, the tank has a capacity of 1.5 tons, an army trailer holds 1 ton of water.

When designing, different calculation methods are used, but the fastest and easiest is to use an online calculator, into which you just need to substitute the requested indicators.

At the same time, despite the apparent simplicity of correctly calculating and installing a heat accumulator for a solid fuel boiler, it is also important to correctly select other equipment - pumps, valves, taps, electronic control devices.

Prices: summary table

| Model | Volume, l | Allowable operating pressure, bar | Cost, rub |

| Sunsystem PS 200, Bulgaria | 200 | 3 | 38 000 |

| Hajdu AQ PT 500 C, Hungary | 500 | 3 | 33 000 |

| S-TANK AT PRESTIGE 300, Belarus | 300 | 6 | 39 000 |

| ACV (ATsV) LCA 750 1 CO TP, Belgium | 750 | 8 | 178 000 |

Wiring and connection diagrams

| Simplified visual diagram (click to enlarge) | Description |

| Standard diagram for connecting “empty” buffer tanks to a solid fuel boiler. It is used when the heating system (in both circuits: before and after the tank) has a single coolant and a single permissible operating pressure. | |

| The scheme is similar to the previous one, but involves the installation of a thermostatic three-way valve. With this arrangement, the temperature of the heating devices can be adjusted, which allows you to use the heat accumulated in the tank even more economically. | |

| Connection diagram for heat accumulators with additional heat exchangers. As has been mentioned more than once, it is used in the case where a different coolant or higher operating pressure is expected to be used in a small circuit. | |

| Scheme of organizing hot water supply (if there is an appropriate heat exchanger in the tank). | |

| A scheme that involves the use of 2 sources of thermal energy independent from each other. In the example, this is an electric boiler. Sources are connected in descending order of thermal pressure (top to bottom). In the example, first comes the main source - a solid fuel boiler, and below - an auxiliary electric boiler. |

As an additional heat source, for example, instead of an electric boiler, a tubular electric heater (TEN) can be used. Most modern models already provide for its installation via flange or coupling mounting. By installing a heating element in the corresponding pipe, you can partially replace an electric boiler or once again do without lighting a solid fuel boiler.

It is important to understand that these are simplified, not complete connection diagrams. To ensure control, accounting and security of the system, a security group is installed at the boiler supply. In addition, it is important to take care of the operation of the CO in the event of a power outage, because The energy generated by the thermocouple of non-volatile boilers is not enough to power the circulation pump. Lack of coolant circulation and heat accumulation in the boiler heat exchanger will most likely lead to a rupture of the circuit and emergency emptying of the system; it is possible that the boiler will burn out.

Therefore, for safety reasons, it is necessary to ensure that the system operates at least until the filling is completely burned out. For this, a generator is used, the power of which is selected depending on the characteristics of the boiler and the duration of combustion of 1 load of fuel.

Which heat accumulator is better

The buffer tank should take up little space and fully correspond in its technical characteristics to the parameters of the boiler. The equipment should not have a complex connection system. The thermal insulation of the best equipment fully complies with fire safety requirements and has a positive effect on the efficiency of the heating system and does not allow you to burn your hand if accidentally touched. This storage capacity will help reduce annual fuel costs by 30-50%.

Our experts have analyzed the proposals of the world's best manufacturers and, depending on the operating conditions, recommend the following models of thermal accumulators:

- Hajdu AQ PT6 500 – a compact model for a small country house;

- S-Tank Hfwt Duo -1000 - a practical tank for the heating system of a mansion;

- Electricboiler Heat Tank – storage tank for a small manufacturing enterprise4

- Oso Accu AS is a compact heat accumulator for a country house.

What kind of buffer tank should be capable of maintaining warmth and comfort in the house every day and protecting the boiler from overheating throughout the long winter? Only the best drives with good thermal insulation can cope with the task.