Home / Gas boilers

Back

Published: 07/26/2019

Reading time: 4 min

0

3840

Many boiler owners have no idea what a parapet boiler is, although they have been using them for a long time. This modern unit belongs to the class of energy-efficient devices and removes flue gases using a coaxial chimney mounted in a through hole in the wall of the building.

The units are equipped with a closed firebox and can be installed in small rooms. Since the oxygen necessary for combustion is not taken from the living area, it is not dangerous. The heating unit is so compact that it can easily fit even in the kitchen under the windowsill.

- 1 What is a parapet boiler

- 2 Operating principle of parapet gas equipment

- 3 Types and prices

- 4 Installation of a parapet boiler

What is a parapet gas boiler?

Parapet gas boilers are heating units that combine the features of atmospheric and turbocharged models. They are completely energy independent, but are equipped with a closed combustion chamber.

A special feature of this design is the use of a coaxial chimney, which is connected to the rear of the unit and vented to the street. Smoke removal and fresh air intake occur as a result of convection processes.

When the boiler is put into operation, no odors are felt in the room; there are not even traces of soot or other combustion products .

In addition, oxygen does not burn out in the room, which allows you to maintain a normal microclimate.

Another feature of parapet boilers is the ability to be used as independent heating elements. There are special holes in the lower part of the case through which hot air escapes.

It circulates in the room and provides it with the desired temperature.

Under what conditions is it most advisable to use such boilers?

Parapet models are used to organize heating and hot water supply (DHW) systems in buildings whose design does not involve the construction of a full-fledged chimney, as well as with problems in power supply and other aspects: stable pressure, soft water and high-quality fuel.

However, it is necessary to take into account the power limitation in the range from 4 to 46 kW, i.e., in terms of similar indicators, “parapets” are seriously inferior to both wall-mounted and, even more so, floor-standing units.

This means that it is reasonable to install them only in relatively small rooms (from 30 to 250 m2), such as private and country houses, retail sites, offices in shopping centers and, of course, high-rise apartments, in which they fit perfectly into the niche under the windowsill in the kitchen. How to choose a room thermostat and save up to 30% per month on heating

Possibility of installing a parapet boiler in a wooden house

Almost any wooden house can be equipped with a parapet boiler: the exception is barracks and other old-style apartment buildings.

Installation is carried out according to the current SNiP rules 42-101-2003:

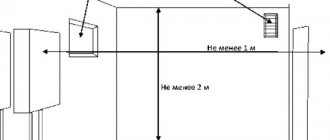

- the unit is placed on an external wall, while an empty gap should remain outside - from 0.3 to 3.1 m (depending on the power), without facade elements;

- The chimney outlet must not be installed near or directly in enclosed spaces (entry, attics, entrances, balconies, loggias, etc.);

- the mounting wall is sheathed with fire-resistant material and covered with a sheet of steel so that there is a distance of 10–25 cm to difficult and easily flammable areas;

In wooden houses, internal and external thermal insulation of a coaxial chimney is mandatory - porous wood, in order to increase fire safety, is prepared in advance for overlapping, treated with special mastics and impregnations in 2-3 layers.

Many companies still use asbestos to protect walls from fire, although today it is officially recognized as a material hazardous to health. Ceramic or silicate bricks, GVP-slabs, mineral wool, basalt insulation, foam and aerated concrete panels, and even gypsum plaster can help replace it.

The positive side of the issue

The main advantage of gas heating systems is the low price of energy. Indeed, gas on the domestic market is much cheaper than coal, electricity and firewood.

As for parapet gas boilers, they have some additional advantages:

- High efficiency.

- Possibility to refuse additional space for storing fuel. The gas heating system is the cleanest, second only to electrical equipment in this indicator. But among appliances that burn fuel, gas boilers produce the least amount of pollution.

- Easy maintenance during use.

- The coolant heats up very quickly.

- Minimum level of environmental pollution.

- Excellent controllability of the equipment due to dosing of consumed fuel.

The only disadvantage of parapet boilers is the need to obtain numerous permits for their installation. To do this, you have to knock on the thresholds of gas services and design bureaus for more than one day. However, by obtaining all the necessary permits and paying numerous taxes, the result can be a very convenient heating system that will make your home as comfortable and cozy as possible.

In addition, some models of this type of equipment are quite sensitive to the chemical composition of the coolant. To avoid breakdowns, the jumper connecting the heating system and the water supply system is equipped with a filter to soften the water. If this is not done, the device will quickly fail due to salts. If installing a filter is impossible for some reason, you will need to inspect the boiler and clean the heat exchanger annually at the end of the heating season.

Advantages and features of parapet units

The main advantage of the equipment is its compactness: a parapet boiler running on gas can easily fit in the kitchen under a window sill or in any other room, since during operation it does not consume oxygen from the room and does not pose a danger to residents. A coaxial chimney is a reliable and safe smoke removal system, which also offers a choice in favor of such equipment.

The correct choice of product should be based on the following parameters (except for consumer reviews and catalogs from selling companies):

- Installation technology: the parapet boiler is made for mounting on walls and floors; there are also left- and right-hand models;

- A gas parapet boiler can be equipped with one or two circuits. One circuit is for heating only, the second circuit is for domestic hot water;

- Also, parapet boilers can be energy-dependent (with an automatic monitoring, adjustment and control system) and non-volatile (with or without manual adjustment).

Technical characteristics of universal boilers

The thermal power possessed by parapet boilers varies between 15 kW-40 kW for a unit with one circuit. If you choose to install parapet equipment with two water heating circuits, then the capacity for heating water for domestic needs should also be added to the rated power. For example, parapet boilers with a power of 12 kW -15 kW easily heat the volume of water up to 180 l/h, which, according to the standards, is four water points (faucets, toilets, faucets, showers, etc.).

- The single-circuit unit has a standard heat exchanger (jacket) of a plate design, which speeds up the process of heat exchange between the gas burner and the working fluid of the heating system. The material of the shirt is thick 3 mm steel.

- Double-circuit gas parapet boilers contain, in addition to the heat exchanger, a copper or brass coil for hot water supply, in which water is heated only by the flow method. If you increase the productivity of the hot water supply due to an additional hot water tank, then such a boiler will no longer be able to be installed in the kitchen.

Also, in addition to wall-mounted and floor-mounted models, there are products with differences in installation: with left-side connection of the gas pipe, hot water supply and heating circuit, and with right-side connection. This convenience should not be overlooked when choosing a boiler for an apartment or house. The dimensions of the unit are determined by its performance and the number of water heating circuits. For example, if a boiler has one circuit, then its dimensions will be smaller than that of a double-circuit one.

Types of boilers by power

Basic rules for connection

First, a filter for rough water purification must be installed on the pipeline pipe, which prevents the boiler from clogging with debris formed in the battery due to contact of metal with water. If this filter is not installed, the device will soon stop working normally. Correct installation involves screwing the filter onto the return pipe so that the arrow points towards the boiler.

If you connect a shut-off valve to the return line of the unit, then in the event of equipment failure, all the liquid in the heating system will have to be aired. Therefore, the installation diagram of a double-circuit gas boiler necessarily involves the installation of a shut-off valve with a detachable connection - this will make it possible, if necessary, to disconnect it without cutting the pipes.

The heating design with natural circulation is considered the easiest to maintain and most economical. It is controlled entirely manually, but it is perfect for those populated areas where power outages often occur.

An automatic circulation system is more convenient because it can operate without human intervention. In this case, it is enough to set the required temperature level, and it will be constantly maintained automatically. But you need to take into account that if the electricity is turned off, the system will stop working and the coolant will stop circulating through the pipes.

The choice of a double-circuit gas boiler primarily depends on the area of the house - the larger it is, the more powerful the equipment should be. The higher the power of the device, the more gas it consumes. Low-power devices are not capable of heating large houses well. The latest models have a system for automatically shutting off the equipment from gas, which will prevent its leakage if the flame in the boiler goes out.

Connection diagram for a double-circuit gas boiler in the video:

What is the difference from the usual?

The main difference between parapet models and conventional boilers is the ability to obtain increased safety from a non-volatile design and no impact on the internal atmosphere of residential premises.

If a conventional atmospheric boiler consumes ambient air, actively burning oxygen and requiring constant ventilation, then parapet models are completely separate and do not disturb the air exchange regime.

Another difference is the ability to independently heat air, making a parapet boiler similar to a stove.

Operating principle of parapet gas equipment

- The burner device is ignited with a wick or igniter.

- Gas, when burned, releases heat, which heats the boiler.

- Network water, using a circulation pump or with natural circulation, heats up, leaves the boiler and enters heating devices located in residential, public or industrial premises.

- The gas combustion process will continue until the water in the heating circuit heats up to a predetermined level, after which it will be automatically turned off by a gas valve installed in front of the boiler.

- The wick continues to function and will re-ignite the burner when the mains water temperature drops.

Pros and cons of parapet boilers:

- Possibility of indoor use.

- Affordable prices.

- Small geometric dimensions of the installation.

- Speed and ease of installation work.

- Possibility of use without installing additional radiators.

- Large power range.

There is only one drawback - energy dependence.

Design and operating principle

In terms of design features and technical characteristics, parapet boilers are similar to wall-mounted gas heaters. The boilers are equipped with:

- body made of sheet steel with a minimum thickness of 3 mm;

- closed combustion chamber;

- gas burner and igniter;

- a heat exchanger made of steel (if the device has two circuits, then the secondary coil is copper);

- coaxial chimney;

- safe use system (thermometer, thermocouple, draft sensor).

Such boilers consist of 6 elements

The inside and outside of the case is treated with a special powder coating that protects it from corrosion. Thick steel prevents mechanical damage. All this ensures a decent appearance and reliability of the unit.

The principle of operation of a parapet boiler is simple: the burner is ignited by the ignition device, the flame is directed to the heat exchange device, inside which the coolant circulates. As soon as its temperature reaches the required limit, the automatic heating element is activated. The gas valve closes automatically, the burner goes out, and the igniter continues to operate. When the water cools to the lower critical level, the gas supply to the burner will resume, the burner will light up from the igniter, and the water will begin to heat up.

Single and Dual Circuit Devices

Parapet boilers are produced in a standard rectangular shape, single- and double-circuit, left- and right-handed, which makes their installation easy and convenient.

Single-circuit ones are intended only for heating. They are equipped with a plate heat exchanger, which ensures the rate of heat exchange between the gas burner flame and the coolant.

The double-circuit parapet boiler has an additional copper coil, which provides the house with hot water supply. Water is heated only by flow. If you use a storage tank, the size of the equipment will increase significantly, which will make it impossible to install it in an ordinary apartment.

Rules and installation locations

Equipment of this type is used in rooms where a traditional chimney is not provided. A parapet gas boiler can be installed anywhere in the house thanks to a closed combustion chamber and a coaxial chimney, but the main condition is its location near the wall. This ensures that the coaxial pipe is brought out to the street.

A coaxial chimney is a stainless steel structure consisting of two pipes of different diameters located one inside the other. Thanks to this design, a space is provided through which air mass flows to ensure gas combustion. Combustion products are removed through a pipe of smaller diameter. The coaxial chimney is directed through the wall to the street, and wind protection must be installed. After this, the installation of flue pipes, heating circuits and hot water supply is carried out.

Installing the equipment is quite simple, but doing it yourself is strictly prohibited. You should contact licensed specialists. Connection to the gas main is made exclusively by gas service employees.

This is important: what standards exist for installing heating boilers in a private home.

Installation process

Installation of a parapet gas boiler is carried out in the following steps:

- If the covering of the wall on which the device will be hung is flammable, it should be removed at least in an area equal to the projection of the boiler onto the wall.

- A hole is made in the wall in accordance with the diameter of the chimney. It is necessary to ensure that the pipe is placed with a slight slope towards the street to remove condensate.

- A coaxial pipe is inserted into the resulting hole and fixed. The presence of a certain slope should be checked. For example, for a wall of one and a half bricks, the outside of the pipe should be 4 mm lower than the inside.

- In accordance with the position of the installed chimney, places for fastenings are marked on the wall. Then the holes are drilled and the fasteners are installed on the wall.

- The boiler, depending on the model, is hung on the wall or installed on the floor.

- The pipe connection is attached to the unit. Heating sections are being installed.

- Heating and water supply pipelines are supplied to the boiler nozzles (depending on the model).

- The gas connection to the device and the first start-up must be carried out by a gas specialist.

Depending on the unit model, some installation points may differ slightly.

Note! In order for the heat exchanger of the parapet unit to work as long as possible, it is recommended to install a filter on the tap water inlet pipe.

Rules for choosing parapet gas boilers

Before purchasing, the user should decide on the type of model - wall-mounted or floor-mounted, calculate the heated area, and assess the degree of insulation of the object.

Equipment is selected taking into account the following nuances:

- Heat exchanger wall thickness. The steel must be at least 3 mm thick, otherwise the efficiency of the device decreases due to the slowdown of thermal processes.

- Working pressure indicator. The parameter is stated in the technical data sheet and should be higher than 4–5 bar. The higher the number, the better the quality of the heat exchanger steel.

- Efficiency The optimal size is from 92%. The efficiency and performance of the device depends on the indicator.

- Dimensions. The compact wall-mounted gas parapet boiler does not limit the installation area; models are installed in the kitchen, bathroom, and other rooms. Floor-standing ones require free access to the equipment, which means that there must be at least 30 cm of space between the device body and the nearest equipment.

- Connection type. Models with side and bottom connections are available for sale.

- Power. This is an important parameter. If the power of the device is low, the thermal energy will not be enough; if it is excessive, the unit will not work at full capacity, which will lead to rapid wear of the equipment.

Advice! To calculate power, the area of the room is divided by 10, the final figure means the number of kW. For example, for houses of 50 m2 you need a boiler with a power of 5 kW. The parameter is average, so in case of poor insulation, harsh winters, or an extensive network, another 35–50% is added.

Types of turbo boilers

There are 2 types of devices available:

- convection;

- condensation

It is known from physics that a substance gives or absorbs the greatest amount of energy when its state of aggregation changes.

Condensing boilers only work with “warm floors” and other low-temperature systems. The moisture formed in the heat exchanger is an acidic solution, therefore it is not allowed to be drained into an autonomous sewer system - this will lead to the death of bacteria. It is necessary to dispose of the condensate separately or first neutralize it with alkali. This ban does not apply to centralized sewerage.

Heaters also differ in heat exchanger material. Available options:

- steel;

- silumin (an alloy of aluminum and silicon);

- cast iron;

- copper.

The first 2 metals are used in budget boilers. It is not recommended to purchase models with silumin heat exchangers. They do not last long and fail abruptly - they crack.

Copper products, due to their good thermal conductivity, contribute to increased efficiency. But at the same time, they are more expensive than all other options.

Cast iron heat exchangers are the most durable and at the same time have a low price. Their disadvantage is their large mass.

According to the installation method, heaters are divided into types:

- wall or hanging;

- floor

The advantage of models of the first type is that they do not take up space on the floor. Such a device can be installed in the kitchen between cabinets, and it will not interfere. But it also has disadvantages due to its low weight:

- Power does not exceed 30 kW. This is enough for most apartments and houses.

- They install either the cheapest and short-lived steel heat exchanger, or an expensive copper one. Cast iron is too heavy for a wall-mounted boiler.

The type of burner matters. A boiler with a simple 1-stage device operates in start-stop mode, which negatively affects its service life. A modulated burner with the ability to adjust power over a wide range (10%-100%) does not have this drawback. Having selected the desired heat output, the heater reaches a stable mode, using less gas.

Functionality and equipment of gas wall-mounted parapet-type boilers

The devices can be equipped with gas burner devices of various designs:

- single-stage,

- two-stage,

- modulated.

Operating modes are also different. There are devices only for heating, but there are models capable of preparing hot water to meet economic and domestic needs.

Gas wall-mounted boilers of this type are equipped with heat exchangers made of cast iron, copper and steel. Each type has its own pros and cons and should be selected based on operating conditions. To ignite the gas apparatus, an electronic or piezoelectric ignition system is usually provided.

Project

When there are technical conditions, you should start developing an installation plan.

The project represents an installation diagram, as well as laying a gas main from the point of connection to the city gas communication network. For the private sector, a drawing of the passage of gas communications throughout the entire site is additionally required. The entry point to the house must be marked. The project will be developed by engineers. In this case, all provisions of the GOS are taken into account. The design company must have a license for this type of service.

Advantages and disadvantages of parapet models

The positive features of the equipment are as follows:

- wide scope of application due to the absence of the need for additional structures;

- small dimensions and weight;

- very affordable cost, especially compared to other devices;

- Possibility of use without a heating circuit for one room due to the presence of convection holes in the housing.

The disadvantage of heating with parapet gas boilers is the same as with other heat generators using “blue fuel”: the need to obtain permission from regulatory organizations. It may take several months to agree on all installation details, obtain a positive decision and seal the equipment.

How to calculate the minimum required power

In most cases, to determine power (Q), a simplified formula is used, where 1 * kW of thermal energy is taken per 10 m 2 of heated area.

- * approximate heat loss of a brick building with ceilings of 2.7 m from the central climatic zone of Russia.

For example, for a residential building of 120 m 2 located in the Moscow region, the minimum required power of a parapet gas boiler will be Q=120÷10×1=12 kW.

We also recommend making a reserve of 15–20% of the power so as not to operate the heat generator at its limit for a long time, i.e. for the same object Q≈14–15 kW. Also, if we are talking about a double-circuit model, then you will have to add about 15–20% more to provide hot water supply, the total result will be Q≈16–17 kW.

In an apartment of 120 m2 (not corner), heat loss is a priori 10–15% less, so for a unit with one circuit Q≈12.5–13 kW, with two circuits Q≈14.5–15 kW.

How to accurately calculate the required boiler power Individual calculation, formula and correction factors

Rating of the TOP best parapet gas boilers

Lemax Patriot 12.5

Lemax Patriot 12.5 is a high-performance single-circuit gas boiler with a power of 12.5 kW and designed for heating a room with an area of 120 m2.

The device is equipped with a smoke removal kit and a sealed chamber, ensuring that there is no risk of combustion products entering the heated room.

The design is highly durable thanks to high-quality steel heat exchanger walls with a thickness of 2 mm.

The operating life of the boiler reaches record levels due to the use of a reliable gas valve manufactured by the Italian company SIT and an overheating protection system.

Specifications

| Power | 12.5 kW |

| Efficiency | 87% |

| Heat exchanger material | Steel |

| Maximum heating temperature | 80° |

| Manufacturer country | Russia |

| Weight | 50 kg |

| Guarantee | 36 months |

pros

- Availability of a protective system;

- Smoke removal system;

- Convection effect achieved due to the presence of holes on the boiler panel;

- Long service life;

- Reliability and comfort;

- Energy independence

Minuses

- No

Lemax Patriot 20

Floor-standing gas boiler with high power and a guarantee of reliability . The device is equipped with a smoke removal system.

The manufacturing is based on 2 mm thick steel, the production of which belongs to

Magnitogorsk Iron and Steel Works. The heat exchanger has an enamel coating, which helps protect the boiler components from unwanted influences.

The Lemax Patriot 20 model includes a security system and overheating protection.

Gas heating boiler, contour. The parameters of the device (H*W*D) are 790*710*410 mm.

Specifications

| Power | 20 kW |

| Efficiency | 87% |

| Maximum heating temperature | 90° |

| Number of circuits | One |

| Manufacturer country | Russia |

| Weight | 67 kg |

| Guarantee | 36 months |

pros

- High efficiency;

- Convection effect;

- High reliability and quality;

- Long service life;

- Overheat protection;

- Energy independence

Minuses

- No

TERMOMAX S-12E

Another unit, devoid of any hints of design. Despite this circumstance, you should not write it off, because the lack of external attractiveness is compensated by economy, efficiency and real comfort of operation: the main control elements are located directly on the front of the outer panel.

On request, the boiler can be supplemented with an expansion tank and a circular pump (not included in the basic package), which will make it suitable for connection to complex heating systems, including those with high hydraulic resistance. Maximum gas consumption at a power of 12.0 kW is 1.39 m3/h.

Cost: 15,860 – 20,340 rubles.

Manufacturer: TERMOMAX (TERMOMAX), Ukraine.

Hephaestus VPR KSG-10S

Perhaps this option is one of the best parapet gas boilers for heating a private home: it is clear, almost silent (distinctively quiet at start-up) and quite highly efficient, given the ability to operate in the “small flame” mode, which allows reducing the average gas consumption to 0.60 m3/h.

Despite the fact that the unit itself has a Russian-made assembly, it contains the well-known Italian automation of the “SIT” type, which, based on the current heat losses, maintains an optimal power level (within 10 kW), as well as a slot burner of the “BRAY” type , which does not require air flow adjustment.

Cost: 19,680 – 23,840 rubles.

Manufacturer: Gefest WPR (Hephaestus VPR), Russia.

Lemax Patriot 6

Lemax Patriot 6 is a parapet gas boiler that includes the functions of a convector and a wall-mounted boiler.

The coaxial pipe combines the roles of air intake and chimney.

The heating area of the boiler is 60 m2. The unit is suitable for heating residential and public premises.

The presence of an opening in the lower part of the boiler ensures high efficiency due to the symbiosis of the functions of a water heater and a stove, which are assumed by the gas boiler of the Lemax Patriot 6 model.

The device is notable for its compactness and, as a result, low weight. Boiler parameters: 730*550*310 mm.

Specifications

| Power | 6 kW |

| Efficiency | 87% |

| Maximum heating temperature | 90° |

| Number of circuits | One |

| Manufacturer country | Russia |

| Weight | 41 kg |

| Guarantee | 24 months |

pros

- High efficiency;

- Energy independence;

- Availability of a protective housing;

- Availability of a protective system;

- Reliability

Minuses

- Low power rating

Lemax Patriot 16

This model is a floor-standing single-circuit gas boiler with a rectangular heat exchanger, which is based on high-quality steel material 2 mm thick.

The power of the device is 16 kW, which is why it is designed to heat a room with an area of 160 m2.

The boiler is equipped with a chimneyless design, which allows it to be used both in apartments and private houses.

Product parameters: 790*670*400 mm.

Specifications

| Power | 16 kW |

| Efficiency | 87% |

| Maximum heating temperature | 80° |

| Number of circuits | One |

| Manufacturer country | Russia |

| Weight | 67 kg |

| Guarantee | 36 months |

pros

- High efficiency;

- Energy independence;

- Compactness;

- Overheating protection system;

- Availability of inspection window

Minuses

- No

Lemax Patriot 7.5

Gas single-circuit boiler with a power of 7.5 kW . The device runs on natural gas and is equipped with a closed combustion chamber.

The walls of the heat exchanger are made of steel and have a thickness of 2 mm.

The unit is equipped with automatic safety, an overheat protection system and an easily removable top panel.

The heat exchanger is covered with anti-corrosion enamel, which protects it from harmful influences.

The device is non-volatile and has the following parameters - 730*550*310 mm.

Specifications

| Power | 7.5 kW |

| Efficiency | 87% |

| Maximum heating temperature | 90° |

| Number of circuits | One |

| Manufacturer country | Russia |

| Weight | 42 kg |

| Guarantee | 36 months |

pros

- High efficiency;

- Convenience and reliability;

- Long-term operation;

- Compactness;

- Energy independence;

- Overheat protection system

Minuses

- Low power rating

ATON Compact 12.5E

Floor-standing parapet gas boiler with a power of 12.5 kW . Designed for heating a room with an area of 160 m2.

The device is equipped with a tubular flow coil made of copper.

The device has only one circuit and is not intended for heating water.

The operation of the boiler does not depend on electricity. Type of construction: gas, convection. The equipment is easy to use.

Boiler parameters: 700*630*275 mm.

Specifications

| Power | 12.5 kW |

| Efficiency | 90% |

| Maximum heating temperature | 90° |

| Number of circuits | Two |

| Manufacturer country | Ukraine |

| Weight | 70 kg |

| Guarantee | 12 months |

pros

- No dependence of operation on electricity;

- High efficiency;

- Combination of heating and water heating functions;

- Compactness;

- Versatility of use regarding installation locations;

Minuses

- Heavy weight;

- Low warranty period

Prices: summary table

Rating of the most popular models of parapet gas boilers:

| Model name | DHW, l/min | power, kWt | Efficiency, % | Consumption, m 3 / h | price, rub. |

| LEMAX Patriot-12.5 | —— | 12,5 | 87 | 0,75 | 18 500 |

| ATON Compact-12.5EB | 5–6 | 12,5 | 90 | 1,53 | 25 000 |

| TERMO MAX C-12E | —— | 12,0 | 90 | 1,39 | 18 000 |

| Hephaestus VPR KSG-10S | —— | 10,0 | 92 | 0,60 | 21 500 |