When installing a heating system, sooner or later you get to installing a boiler room. Very often in Russia and the CIS countries, wall-mounted gas boilers are installed in private homes and beyond. This is primarily due to good gasification and ease of use of such boilers in comparison with solid fuel ones.

Ideally, when installing a wall-mounted gas boiler, you need to involve a certified specialist. But what to do if a problem arises with such personnel? Let's look into this issue in detail.

Types of gas boilers

Many companies involved in the production of gas equipment offer users various types of heating boilers, the designs of which are designed exclusively for working with blue fuel. They can be used for absolutely any scale and area.

Speaking about installation types, boilers are divided into:

Floor-standing

They are characterized by such indicators as high power, durability and reliability. Their purpose is installation in buildings with an area above the average size and area. However, flagship models also have their drawbacks: the need for a separately installed and equipped room.

Wall mounted

This type of boiler is a great option for small private homes. Consequently, there is no need to build a separate room for them, and they are multifunctional models. They contain a built-in expansion tank, a circulation pump, a safety group, and sophisticated automation. Assembly and installation do not require special elevated conditions.

This type of boiler is installed everywhere and is widely used in modern apartments, dachas, houses and cottages, which is due to the provision of maximum comfortable environmental conditions and minimal effort and expense for assembly and installation. Currently, they are created using design solutions and compact resolutions. We also wrote detailed material on the topic of comparing these types of boilers.

There is also a division according to the type of combustion chambers of boilers.

Open combustion chamber

This model is prone to natural traction. One way or another, air is produced and penetrates from the interior of the room, and the combustion products themselves are discharged exclusively through the chimney. If there is insufficient ventilation, there will be a lack of oxygen. The performance of heating units with an open combustion chamber depends on the draft. It is important to install chimneys correctly and not skimp on their insulation. In this case, there is a high probability of risk of combustion products entering the interior of the room. Based on this, the price categories are much lower than average.

Closed chamber

They are characterized by forced traction. Electric fans (smoke exhausters) are installed in them, with the help of which it becomes possible to remove substances formed during the combustion process through the chimney. Air enters the chamber by sucking it through the outer, external pipe, and exiting through the internal one.

Connection to the gas main

You need to know that according to the standards for installing gas floor-standing boilers, only a qualified specialist can perform this operation. You can do the work yourself, but an invited professional will still check the assembly and do the first start-up.

Connection work is carried out extremely carefully and accurately. They start by connecting the gas pipe to the corresponding element of the heating boiler.

Only tow can be used as a sealant. No other material will provide the required tightness of the connection. It is necessary to install a shut-off valve, which is additionally equipped with a filter.

At the same time, gas workers strongly recommend installing a high-quality system here. An insufficiently efficient filter can cause boiler failure.

For connection, it is recommended to use copper pipes, the diameter of which can vary from 1.5 to 3.2 cm, or special corrugated hoses. In any case, special attention should be paid to the quality of sealing of connections. Because gas tends to leak from loose connections and accumulate in the room, which can create an explosive situation.

There must be a flexible connection behind the filter, which can only be done using a corrugated hose. Rubber parts are strictly prohibited because over time they develop cracks, creating channels for gas leakage.

The corrugated parts are secured to the boiler pipe using a union nut. A mandatory element of such a connection is a paronite gasket.

After installing and connecting the gas heating unit, it is necessary to check the quality of connections and components. The simplest way to control is to apply a soap solution to the connection. If it bubbles, there is a leak.

Difference between closed and open chambers

The answer is quite simple and clear: in their design features, the method of oxygen absorption.

It is worth understanding that in a residential building you need to resort to an option such as a closed one, since only this will be acceptable for use in private buildings. Open spaces require a separate room.

Studying the process diagram, it can be noted that the air, which ensures normal and stable operation, is absorbed through a coaxial chimney from the external space. In the future, the already processed substances also move from the premises to the street. So there is no need for extra costs and expenses for additional ventilation devices.

It is worth resorting to purchasing an open version only for their installation in boiler rooms. Its operating principle is the absorption of oxygen from the oxygen contained in the room. Therefore, it is important that regular and stable ventilation of the building is ensured.

The main rule is to install a gas boiler completely separately from the house, which ensures safety, since the likelihood of leakage of gas and substances formed during combustion is reduced to a minimum, which is due to the non-use of air from the house. To completely eliminate the possibility of emergency situations, it is worthwhile to first undergo a thorough inspection of the pipeline for the presence of various types of distortions, scratches and damage.

Look at an example of converting a boiler room from an open boiler to a closed one:

The advantage of installing a boiler with a closed chamber

- When getting rid of the products consumed in the isothermal process, a reverse reaction occurs - cooling, which dramatically increases the safety and reliability of such boilers.

- The room equipped for this device does not overheat and is protected from various and numerous air pollutants, since combustion occurs only on the street, that is, not within the house.

- High efficiency

- Air enters the room, the pressure increases, as a result of which its temperature increases. Thus, the closed chamber is environmentally friendly and clean.

There are also disadvantages:

An installed gas boiler with a closed chamber will not be able to operate without electricity. But as soon as electricity appears, all work starts automatically.

Features of the device and principle of operation

A gas boiler with a closed combustion chamber is a device that operates regardless of the presence of natural ventilation. Structurally, it is a metal casing, inside of which there is a burner, a heat exchanger and a coaxial pipe. Some models can be equipped with a built-in boiler and circulation pump.

A coaxial chimney is a must for closed boilers. It consists of pipes of different diameters inserted into one another. Through the larger one, air from the street enters the boiler; the smaller pipe serves to remove exhaust gases from the room. This arrangement of boilers made it possible to use them even where there is no natural ventilation.

The coaxial pipe is laid horizontally through the wall and brought out. In this case, a vertically routed pipe is not necessary, because Air injection is performed forcibly due to the operation of the built-in fan. He is also responsible for removing combustion products.

Gas combustion is carried out by forced-air burners. The combustion intensity is adjusted in parallel with the fan rotation speed. Gas consumption is minimized due to the optimal ratio of the mixture of gas and air, which is achieved taking into account the pressure in the overall gas pipeline system.

The heat exchanger can be steel, cast iron or copper. Through it, the energy from the burned fuel is transferred to the coolant. The best performance indicators are shown by cast iron elements, because... They are resistant to high temperatures and are not subject to corrosion, so they will last longer than steel or copper.

Control sensors for a closed gas boiler

Using control sensors, the necessary parameters are set: temperature, amount of water used for heating, power, etc. The built-in protection system will prevent the boiler from burning out if there are interruptions in water supply or the burner flame is blown out.

Requirements for a boiler room with a gas boiler

Much depends on the performance of the boiler: if it reaches more than 30 kilowatts, then there is a need for a separate room. It is on the basis of the provisions of the 'Building Codes and Rules' that specific instructions are built and created for the arrangement of a boiler house specialized in heating for the combustion of products.

- It is possible to place a boiler room in attics, basements, that is, in special rooms of houses. But it is worth considering that a cleared corridor and sufficient illumination are required.

- The installed volume is at least 14 square meters, taking into account a power of 30-60 kilowatts and above 15 square meters intended for boilers of higher productivity.

- Comfortable and unhindered access to the device.

- Covering the walls with non-flammable material.

- Providing a ventilation process with three times the amount of air exchange.

Criteria for choosing heating equipment

Since heating equipment is installed for a long period of time, its choice must be approached responsibly.

When purchasing a closed gas boiler, take into account the following parameters:

- Device power. It depends on the total area of the house.

- Types of stabilization of electrical energy supply. To avoid interruptions, use a stabilizer or generator.

- The need to heat water. A double-circuit closed gas boiler is installed if the house does not have a boiler. This takes into account the number of residents.

- Water hardness level. If necessary, install a device with a bithermal heat exchanger.

To calculate the power of a closed boiler, the possible heat loss in the room is first assessed.

Three options for installing a gas boiler

When installing a wall-mounted gas boiler in a private home, you have three options:

1. You contact the company yourself and order the service of installing a gas boiler at home. The company’s employees not only install the boiler, but also provide post-warranty service, and also place the boiler for servicing. 2. If you do not have the opportunity to order boiler service and installation directly from the company, you will order a specialist to install the boiler. Then the company that sold you the boiler itself sends a service department. It carries out commissioning work and also supplies equipment for service. 3. If you live in a rural area and there are no service centers nearby, then you can do the installation yourself, following the instructions. Moreover, instructions for installing a wall-mounted gas boiler in a private house should be exclusively from the manufacturer. You also need to consider your heating system when installing.

What needs to be done before purchasing a gas water heater?

Before purchasing a floor-standing gas boiler, you need to find out whether it is even possible to install such a device in your home. Thanks to this, an application is written to the gas service to obtain technical conditions and permission to use the device. First of all, it indicates the volume of gas that you plan to consume in a year.

The document will be reviewed, and the applicant will receive permission for the installation process simultaneously with the Technical Conditions or a refusal with a detailed explanation.

Another stage involves drawing up a project for subsequent installation . It is being developed taking into account all the parameters of the future gas water heater. It is done on the basis of ready-made technical conditions and permits. The document must contain diagrams for connecting equipment and passage from inside the house from the place where gas communications are connected.

You need to pay attention! The boiler installation project must be developed by a company that has a specialized license to carry out similar work.

The project should be approved by the gas service that serves your home. After checking it, the applicant receives a coherent project. If the document has not received the consent of the gas service, then corrections must be included. After correcting the project, the applicant again sends it for approval.

Possibility of installing a gas boiler with your own hands

In short, installation of a gas boiler in a private house is possible for everyone. Follow the installation diagram and installation rules and everything will work properly. But the exception is the input, which must be carried out by gas service specialists. Also, boiler testing is carried out only by a specialized company, since they have certificates and licenses for this.

However, it would be safer to rely on the qualified employees of a professional company. After all, only they will be able to carry out the necessary work with excellent accuracy and competence and provide the necessary safety during operation of the equipment.

Conducting a trial run

At this point, the main work on connecting the gas boiler has been completed. The exception is appliances with a closed firebox. They require a connection to the electrical network. It is better to do this through a stabilizer.

After which the system can be filled with coolant. This is done as slowly as possible to displace most of the air present in it. The liquid is pumped until a pressure of 2 atm is reached.

All connections are carefully checked for possible leaks. After a gas service representative inspects the connection and allows gas to flow, you should also carefully inspect all connections on this pipeline. They need to be coated with soapy water and make sure there are no bubbles. Now you can carry out the first start-up of the equipment.

A service agreement should be concluded with the representative of the gas company that installed the equipment, according to which the organization undertakes to conduct regular inspections to study the technical condition and repair the unit as necessary.

Gas boiler installation steps

Chimney hole

Before installing the pipe under the chimney, it is necessary to create a hole with the exact size (usually 120 mm) and place a specific protective and sealing apron, onto which the chimney is connected.

Boiler installation

The boiler package usually includes, first of all, the boiler itself and the operating instructions, a warranty service coupon, a mounting strip, and an installation diagram.

First of all, you need to decide on the installation location of the boiler. In European countries, boilers are usually installed in the kitchen. They do not violate harmony and fit into almost every kitchen interior. The equipment operates quietly.

You can mount a wall-mounted gas boiler in a basement or basement. In this case, certain standards must be observed. The boiler must be installed by at least two people, even if it is not too heavy. A distance of at least 30 cm must be provided on all sides of the boiler. Regarding the height of the boiler: it is important that the control panel is located depending on the height of the owner.

Important! Keep the control panel out of reach of children. You should not place the boiler obviously high above the floor, because in case of repair or service work it will be inconvenient for specialists and they will have to use a stepladder or stool .

Next, we take the installation template (it is attached to the boiler), which is developed for several types of boilers. Using the template, you can mark the pipe outlets, chimney and fastenings and then install a wall-mounted gas boiler without any problems. In Europe, during the construction of a house, pipes are laid in accordance with a pre-selected gas boiler.

Chimney installation

The coaxial chimney has a diameter of about 100 mm, but the hole is made with a diameter of 120 mm or more. The play is necessary so that the chimney is directed towards the street at an angle of approximately 5 degrees. Condensation that forms during operation must be drained outside. After installing the chimney, the hole can be foamed with foam. A coaxial pipe consists of two pipes. A pipe with a diameter of 60 mm removes combustion products, and air from the atmosphere is sucked into the space between 60 and 100 mm. This is why the walls of the pipe are slightly warm.

The mounting bolts have plastic dowels. They can be used for various walls.

Connecting pipes to the boiler

There are two options for connecting hot and cold water supply pipes, as well as the heating system. The first is that the pipes are supplied during the construction or renovation phase, taking into account the boiler you choose. However, it may be necessary to install a wall-mounted gas boiler if a heating system already exists.

The supply pipeline is connected to the boiler supply, return to return. When installing a double-circuit boiler, it is necessary to connect a cold water supply circuit to the boiler. Connect the hot pipeline to the remaining connection and install it in the hot water supply riser.

Do not forget to install a dirt filter on the return, a check valve on the supply, as well as ball valves on each connection.

A dirt filter is necessary to prevent large debris from entering the boiler. A check valve is needed to protect against sudden pressure of coolant into the supply. The taps will be useful when servicing the boiler.

As you understand, there is nothing complicated in installing a wall-mounted gas boiler and you can do the installation yourself.

Gas connection

This action can only be performed by a gas service employee. He will install a pipe for you in accordance with the design, and the gas hose from the pipe to the boiler is installed independently.

It is advisable to use cardboard spacers. Rubber gaskets can tear when clamped, which is very unsafe. Today, paronite cardboard gaskets are in high demand.

Electrical installation

Produced for boilers with modern automation and for models with a closed combustion chamber, as they are equipped with electronic devices. Usually limited to supplying electricity closer to the boiler and installing a plug to the boiler wire. Don't forget about phase dependence. If suddenly the boiler does not turn on, try simply turning the plug over and plugging it in again.

Sockets and other connections must be located at a distance from the boiler so that in the event of an emergency, splashes do not get on the electrical wiring. The gas hose must have a yellow metal braid. It is necessary to prevent a breakdown of the hose in the event of lightning or overvoltage.

In order to ensure the safe operation of a gas boiler, it is better to install a network voltage stabilizer.

Starting a gas boiler

After the wall-mounted gas boiler is installed, it must be filled with coolant. If the system is new, the pressure should be approximately 1.8 bar. When you first start, set the temperature at 45-50 degrees. Modern boilers quickly accelerate the system. Try to increase the temperature gradually to avoid temperature shock. If the boiler power is 24 kilowatts, then this is enough to heat a house of 300 square meters. meters if the house is well insulated. Try not to buy boilers of lower power, because even if the area of the house is approximately 160 square meters. meters, but it is poorly insulated, then even 24 kilowatts may not be enough. It should also be taken into account that gas has different calorie content.

Connection to the heating system

At the bottom of the boiler there are tubes for connecting hot and cold water supplies. Return and hot water supply to radiators should be connected, carefully observing all requirements and rules. When piping, sealants are used to insulate the system and prevent water leaks when starting the system.

When connecting the heating system, a filter is used in the water supply pipe to help prevent contaminants from entering the boiler. Be sure to take care of the shut-off valves. This will help make repairs and dismantling of equipment easier.

Installation cost

When contacting gas boiler installation specialists, many clients are interested in the cost of the work. It is important to understand that pricing policies may differ in different regions.

A comprehensive boiler connection with a hole and start-up starts from 5,000 rubles. This amount will be asked from you provided that there is no additional work. If the heating system is made of metal pipes, then the cost of installing wall-mounted gas boilers will be higher. Around 6000-8000 rubles.

Also budget 3000-4000 rubles for the purchase of materials (hose, pipes, taps, fittings, etc.)

Only competent people who have access to this type of work can install a gas boiler. Even if the boiler is installed by company specialists, you need to know its operating system. The boiler itself is as safe as possible in operation as it has many degrees of protection.

Chimney requirements

The building codes also specify the requirements for the chimney:

- the cross-section of the outlet pipe must correspond to or be larger than the cross-section of the boiler outlet pipe;

- the material of the chimney outlet pipe is stainless or carbon sheet steel, the use of asbestos and other layered materials is possible only at a distance of more than 50 cm from the boiler outlet pipe;

- gas boilers, in which the outlet pipe is located at the top, must be connected by a vertical section at least 25 cm long, only after which bends are possible;

- no more than 3 bends are allowed along the entire length of the chimney;

- there must be at least 20 cm between the chimney outlet through the wall and the ceiling;

- the height of the chimney must ensure the proper force of natural draft (see photo).

The optimal height of the chimney according to SNiP 41-01-2003.

How to choose the right gas wall-mounted single-circuit boiler

Furnace room arrangement

According to the conditions of SNiP, for the installation of a floor-standing gas boiler, a specially equipped room must be allocated - a boiler room or furnace room. This rule should not be ignored, since gas units are flammable appliances and should be handled with care.

The boiler room where the floor-standing gas boiler will be installed must be isolated from living rooms and equipped with good ventilation.

Note! The placement of single-circuit appliances with a closed firebox and a power of up to 58 kW is allowed in any room of the house.

If the power of the unit is not higher than 145 kW, then it can be installed on any floor. If the boilers are more powerful, then they are allowed to be installed only on the ground floor or in the basement.

The room that will serve as a combustion chamber must have certain dimensions. Its minimum volume is calculated using the formula:

V= 0.2 * M , m³

where M is the power of the gas unit.

…

The minimum permissible room volume is 14 m³.

The walls of the combustion room must be made of non-combustible materials. If this is not the case, then the surfaces are covered with special fire shields. There are also a number of other requirements for the boiler room:

- ceiling height of at least 2.45 m;

- door passage width – from 0.8 m;

- availability of sufficient natural light;

- effective ventilation device;

- doors to the furnace room must have a ventilation hole;

- ensuring free access to the equipment for maintenance and settings.

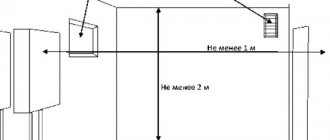

The horizontal section of the gas pipe located inside the combustion chamber should not be longer than 3 m. The number of turns cannot be made more than 3. There must be free space in front of the heating boiler, providing easy access to it. The surface of the floor and walls located next to the unit must be covered with a sheet of metal measuring 1x1m.

The room for installing a floor-standing gas boiler must have a device to shut off the gas supply in case of a leak.

Find out which floor standing boiler is the best

How to choose a floor-standing gas boiler and not make a mistake?

https://oteple.com/kak-vybrat-napolnyj-gazovyj-kotel-i-ne-oshibitsya/