Ecology of consumption. Estate: Such systems have now reached a fairly high technical level and can not only significantly increase the comfort of a home, but also significantly reduce heating costs.

When planning a heating system, very few consider the possibility of operating boiler units with modern intelligent control systems. But such systems have now reached a fairly high technical level and can not only significantly increase the comfort of a home, but also significantly reduce heating costs.

Design and principle of operation of weather-compensated automation

The mechanical part of the heating automation is a pump with an adjustment valve. The equipment is controlled by a computer based on data from 4 temperature sensors that respond to indoor and outdoor temperatures. The smart regulation program for weather-dependent boiler control is built into the controller. The circuit is adjusted according to operating conditions and type of room.

Existing regulatory schemes are based on three principles:

- The hydraulic elevator uses return water, mixing it with the water heated in the boiler. The device is controlled by a weather-dependent heating regulator, sending a command to move the cone valve according to sensor readings.

- A circuit with a circulation pump and a three-position valve limits the heated flow and returns waste coolant to the system. The three-way valve is controlled by a processor according to a given program.

- The shut-off valve on the return pipeline is closed by a valve. The device is controlled by a weather-dependent heating system controller based on data from temperature sensors.

Weather-dependent automation sensors for heating systems of an apartment building (ABC) are installed in the living room.

The individual heating point (IHP) is located in the basement, where it is easier to maintain the equipment.

Installation Features

Weather-compensated automation has a number of installation features. The main ones are the choice of installation location for the external and internal temperature sensor.

The external sensor is mounted so that it is protected from direct sunlight. It should also not be blocked from the wind by any building structures. Most often, the north-eastern side of the building is chosen, at a height of approximately a meter and a half from the ground. The sensor must be removed from the wall of the house so that heat loss does not affect its readings.

The internal sensor is installed in the so-called reference room. It should have the average temperature in the house, and its fluctuations should be minimal. There should not be many people in the room; it is not advisable to use the fireplace. It should not be in direct sunlight or near the front door. A bedroom or children's room is best suited for these conditions.

The indoor sensor must be mounted in a reference room

If in private houses the system directly controls the boiler power, then in large apartment or public buildings the system controls the operation of the return valve, which releases a larger or smaller part of the waste coolant back into the heating circuit.

Types of automatic control systems

Apartment owners who use individual heating often encounter problems with temperature control. The manual adjustment method is inaccurate and consumes fuel excessively. The use of automatic weather-compensated control of the heating system saves resources and frees up personal time.

Types of automation:

- a thermostat connected by a wire to a dependent mechanism;

- wireless control of the heat preservation system depending on the weather.

Functions of control devices:

- The thermostat keeps the room temperature at a given level;

- programmatic setting of the heating level by time of day for up to one week.

Types of devices:

- mechanical thermostat – turns on the electrical network when the ambient temperature changes;

- electronic device – precisely regulates heating based on sensor signals;

- electromechanical device - a temperature relay controls the valve drive.

Thermostats that control heating can be connected to a pump, boiler or mechanical shut-off actuator.

Operating principle

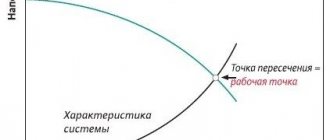

When setting up the controller, a “curve” is specified.

With its help, the program calculates the need to heat the room. The initial position of the curve is the point at which the temperatures of the coolant and the environment are equal. Typically this is 20 degrees Celsius. After calibration, the device independently monitors the need for temperature changes. Manufacturers specify several curves in the PA so that setup does not take extra time. Having selected the program, the specialist starts the system. Further, it functions independently.

For better synchronization, it is necessary to install two sensors - one outside, the second inside.

By checking the readings, the system will not produce additional heating at a comfortable room temperature.

For this reason, it is necessary to correctly select the room in which the sensor will be installed.

Warming up or cooling the coolant takes time, so the heating cannot adapt sharply to temperature changes.

Controller

The controller is the core of the hardware device. It monitors sensor readings and sets the room temperature. The factory functions of the device are responsible for heating, and also inform the owner about problems. Custom settings are designed to maintain maximum comfort.

Rules for operating weather-compensated heating

Heating control systems have a self-diagnosis function. Error messages appear on the display, and the owner can choose how to eliminate them.

If the temperature controller is not working, you need to check the electricity first.

Frequent problems:

- crackling noise during operation – poor contact with the power supply;

- weak heating of the room at a high set level - possible extraneous thermal influence on the sensor;

- the device connected according to the rules does not turn on - the reason is in the design, replacement will be required;

- LED blinking – temperature sensor is broken;

- The thermostat does not provide the specified mode - the device is faulty.

For long-term operation without failures, it is enough to comply with the operating requirements established by the manufacturer. Installation and configuration of the system are carried out according to the instructions.

Features of climate automation in a Smart Home

To create control, you will need to spend a large amount on installing controllers and sensors. They will also have to be included in the system, which is not difficult, but labor-intensive. This is followed by setting up the devices and establishing the principles of operation.

Some automated Smart Homes include heating controls. It can be standard, with separately connected devices, or centralized, in which commands are issued to the entire system. The latter is preferable because it reduces the amount of resources spent on work.

Attention! For full operation of control devices, it is necessary to install two types of sensors. The first ones are placed in a heated room, the second ones - on the street

By combining the readings, the system better manages fuel consumption, which leads to savings on automation operation.

Using automatic heating control

Heating control systems differ in function and price. Simple models are controlled by a remote control or touch screen. Complex systems have their own software with remote control access. Weather-compensated automation is available in different types of heating boilers:

- wall-mounted, located in one of the rooms;

- floor-mounted, installed in the boiler room;

- electric boiler

In the controller program setting, the initial value is set when the inside and outside temperatures coincide. Then calibration is performed, coolant parameters are selected for each type of weather. The manufacturer programs its own options by default, one of which can be selected for operation.

To configure the system, you need to install temperature sensors outside and in the room so that the data is transmitted without distortion.

The advantages of control are the presence of autonomous operation and resource saving. Disadvantages of weather-compensated automation - maintenance and repairs can be expensive due to the replacement of faulty electronics.

Custom Functions

User functions primarily include various heating programs that allow you to adapt the heating mode of the house to the rhythm of life of its inhabitants (sleep and wakefulness, vacations, shift work). Programs for hot water supply are selected in the same way. If the user is not satisfied with any of the standard set offered by the manufacturer, you can create your own individual one - both for heating and for hot water supply.

Good night mode. Almost all systems have the ability to set the so-called night temperature. Scientists have proven that a sleeping person feels much more comfortable when the room temperature drops slightly (usually by 4°C) relative to the daytime room temperature (obviously, this reaction was formed in people during evolution and reflects their adaptation to natural temperature changes during the day and night hours). At the same time, all thermal processes are inertial, and if, for example, you set the start time of the day program at the time of your awakening, then when you get out of bed, you will feel some discomfort due to the fact that the room has not yet had time to warm up after the night. To overcome this shortcoming, many modern controllers use a room pre-heating mode (sometimes called a soft exit from night mode), according to which the temperature in the house begins to gradually rise a few hours before you wake up. For example, controllers of the Diematic family from DE DIETRICH or Logamatic 4000 from BUDERUS have a similar function.

Low temperature systems. At the current level of development of heating technology, there is a tendency to switch to low-temperature heating modes. In other words, to a decrease in the operating temperature of heating devices. This leads to a more comfortable perception of thermal radiation by humans. The most important advantage of the low-temperature mode is the reduction in fuel consumption. The installation of automation also allows you to operate the heating system in low-temperature mode.

By the way, here we should separate concepts such as low-temperature mode and low-temperature boiler. A low-temperature boiler is a device in which, due to the specific properties of the materials used in its manufacture, or thanks to original technical solutions, it is possible to maintain the flow temperature at a level of up to + 40 ° C (as, for example, iroVIT VKO boilers from VAILLANT) and even less - up to + 30°C (for GT 210 boilers from DE DIETRICH). In this case, the return line temperature is not regulated at all.

Low-temperature heating mode can be achieved without using a low-temperature boiler, but for this you will need actuators - three or four-way mixing valves with a servo drive, which will be discussed separately. In combination with them, the heating boiler will operate in constant mode with a high boiler water temperature, and the temperature in the heating circuits will depend on the degree of opening of the mixing valve, in which hot water is mixed with cold, return water.

Priority system. One of the important functions of automatic control systems is the ability to organize hot water supply control. It can be priority, mixed and non-priority. The most common, priority method is not without its drawbacks: when hot water is consumed, the heating system simply turns off. This usually does not cause the house to become colder. The mixed priority method allows you to use for heating the house that part of the boiler power that is not used for preparing hot water. However, if there is insufficient power, the entire resource is spent on the latter. And what “non-priority hot water supply” is can be understood already from the name.

Disinfection. The software of many control panels allows thermal disinfection of the boiler once a week. This is done by raising the temperature in the boiler to 80°C for 20-30 minutes. This procedure eliminates the possible presence of legionellosis bacteria in the water, which causes pneumonia.

Frost protection. As soon as the outside temperature drops below a certain value, the automation itself will start the boiler and maintain a certain temperature in the heating system to prevent it from defrosting.

"Smart House". The latest models of controllers provide the ability to both remotely access themselves via a telephone line or GSM mobile connection, as well as their integration into the Smart Home system. This option is available in devices from such heating equipment manufacturers as VIESSMANN, BUDERUS, DE DIETRICH, etc. Such devices allow you to remotely control the temperature in the house and find out about any problems in time.

Weather-compensated Vaillant automatic

Vaillant's Multimatic VRC 700 controls underfloor heating and up to 10 mixed heating circuits.

Characteristics of Vaillant VRC 700 Multimatic:

- setting parameters using the rotary knob;

- work with solar heating of coolant and forced ventilation;

- preset Vaillant heating curves - night, guest, day and ventilation;

- recording an individual control program;

- remote diagnostics of the system by the service department.

Control circuits for weather-compensated automation VRC 700:

- One direct heating circuit and recirculation pump with additional module.

- Two lines with mixing coolant, expansion VR 70, boiler pump.

- Direct coolant flow control.

- Circuits - direct and with mixing, two VR 70 modules, recirculation pump.

- Control of two lines with mixing of coolant with expansion VR 70, module VR 91 regulates the process.

- Regulation of two mixing circuits using the VR 70 extension and the boiler via the condensing boiler board.

- Three mixing lines with VR 71 module and recirculation pump.

- Control of more than 3 circuits, one of which is direct. The circuit includes extensions VR 60, VR 32, VR 90.

The Vaillant VRC 700/6 weather-compensated automation version can connect several boilers, and with the VR 900 unit, control the cascade remotely in a special application.

ADJUST WHAT?

You can regulate the temperature at the boiler outlet, if the boiler can do this. The trick is that not all boilers have weather-dependent regulation “by default”. More often, a controller will need to be built into an inexpensive boiler, which costs as much as half the boiler. What if, in addition to radiators, we have heated floors? It is wrong to place radiators and heated floors on the same circuit, since floors and radiators need completely different temperatures. Accordingly, a second control loop appears. A boiler controller that can control two or more circuits can easily cost as much as a whole boiler. And inexpensive Air Conditioners will come in handy for you. But there are also solid fuel boilers - their outlet temperature greatly depends on how much firewood you threw in, and depends little on what temperature you want. Well, how do you connect heated floors to such a boiler without Climatic?

Includes outdoor temperature sensor and supply temperature sensor

Baxi boilers with weather-dependent control

Gas boilers, even in normal mode, consume fuel, since the burner continues to operate when there are no people in the house. If the house is well insulated, turning off the heating reduces the temperature by 2°C in 6 hours, and turning on the heating gives an increase of 2°C in one hour. Boilers of the Baxi Luna 3 Comfort model have remote control via a mobile application. You can link an automatic heating control script to the calendar.

The Baxi Slim series boilers have the following functions:

- remote temperature request in the apartment and outside;

- remote control of water temperature in forward and return circuits;

- gas meter reading;

- pressure control in the system;

- notification of errors and emergency stop of the boiler;

- remote activation of the boiler.

Advantages of wall-mounted boilers:

- separate heating and water heating circuit;

- constant coolant temperature;

- silent operation;

- electronic flame modulation;

- boiler operation at reduced gas pressure in the system;

- Possibility of connecting underfloor heating.

Baxi boilers from an Italian manufacturer are unpretentious.

Service functions

Fresh air. To reduce the amount of harmful emissions into the air, multifunctional automation can optimize the operation of the burner. In the installation parameters of modern controllers, the minimum combustion duration is set initially. This eliminates the operation of the burner in the “start-stop” mode, which has a bad effect on both the service life of the equipment and the environment. The fact is that most harmful emissions are generated precisely at the moment of ignition. This occurs due to incomplete combustion of fuel. By default, the minimum burner operating time is usually at least one minute. So, by purchasing a modern management system, you take care not only of your wallet, but also of your health.

Smooth start. An interesting feature is the so-called start-up relief. When the boiler is turned on for the first time (cold) or after a long period of inactivity, increased condensation formation is usually observed in the furnace. As a rule, this is a mixture of acids that adversely affect the internal elements of the device. It is to eliminate this unpleasant phenomenon that many control systems allow for starting unloading. Its essence lies in the fact that immediately at the moment the heating is turned on, the circulation pumps are not yet working, so the coolant in the boiler quickly heats up to 40-60°C. It is this range that is considered safe in terms of condensation formation, which means that the time of the harmful effects of the latter is significantly reduced. After reaching the desired temperature, the heating circuit pumps are turned on and the system begins to operate in the specified mode.

Pump run-out. In many modern systems, it is possible to set the pump run-on time. This function allows you to prevent possible overheating of the boiler. The fact is that in boilers (especially cast iron) there is an increase in the temperature of the boiler water after the burner is turned off. This is due to the heat exchange occurring inside the metal, directed from the surface facing the firebox to the one that is washed by the coolant. The process will continue until the temperatures of the internal and external surfaces are equal, and the boiler may overheat. This is why it is important not to stop the circulation pumps immediately, but to let them run for some time.

An interesting way to solve this problem was proposed by BUDERUS specialists in the Logamatic 4000 series panels, creating the “use of residual heat” function. When heating the coolant, the boiler does not reach a maximum temperature, but only a certain design temperature, at which the automation turns off the burner, and heating continues due to the effect described above. The energy released, of course, is not wasted, but is used to produce hot water in the boiler.

Summer maintenance. Many control systems have a pump release feature. It is implemented, for example, in the E6 series controllers from KROMSCHRODER (cost € 382), in Vitotronic control panels from VIESSMANN, Honeywell Smile, Immergas Viktrix and many others. A circulation pump and mixing valve that does not work for a long time can jam, which is why in the summer, during prolonged inactivity, it is advisable to turn them on for a while.

Automatic control of Protherm boilers

Boilers without regulation turn on heating depending on the parameters of the coolant. Weather-dependent Protherm equipment controls heating based on data from street and room sensors. Thermostats save up to 30% fuel, reducing the frequency of boiler switching on.

Room regulators that are used with the Proterm Skat electric boiler:

- Instat Plus with a wired connection, maintains temperatures from 5 to 30°C, and has a night heating reduction mode.

- Termolink B – room air heating controller in the range from 8 to 30°C, programmable operating mode for 24 hours, frost protection function.

Electric heating is a safe source of heat in the home without emissions. No ventilation system is required for installation. The equipment of a Protherm electric boiler is simpler than that of a gas boiler.

Temperature regulators on the eBus are used with Protherm Medved floor-standing cast iron boilers:

- Termolink P - there is a modulation mode, adjustment of air and hot water heating, a heating control curve depending on temperature sensors.

- Termolink S – can change the boiler operating mode according to the time of day, programmed for a week. Vacation mode and frost protection are preset.

Boilers of the Bear series change the water temperature using an injection burner. The heating element is made of cast iron. The display on the panel informs about the parameters of the coolant.

Automation equipment for boiler rooms

Automation technical means:

- sensors of technological process parameters;

- actuators that move regulatory bodies according to commands in the desired direction;

- control equipment that processes information from sensors in accordance with the algorithms and programs embedded in it and generates commands for actuators;

- devices for selecting control modes and for remote control of actuators;

- means of displaying and presenting information to operational personnel;

- devices for documenting and archiving technological information;

- means of collective presentation of information.

All this technology has undergone revolutionary changes over the second half of the last century, not least thanks to the achievements of Soviet science. For example, pressure gauge instruments, widely used in measuring pressure, flow, speed and level of liquids and gases, as well as in measuring force and mass, have changed the physical principle of the sensing element.

Instead of a membrane that bends under the influence of force and moves the rod of an electromechanical transducer, they began to use a strain gauge method. Its essence is that some materials, when subjected to mechanical action, change their electrical parameters. A sensitive measuring circuit detects these changes, and a computing device built into the device converts them into a process parameter value.

Boiler automation diagram

Devices have become more compact, more reliable, and more accurate. And more technologically advanced in production. Modern actuators don't just accept "on" and "off" commands, as they did for many years. They can accept commands in digital code, independently decipher them, execute them and report on their actions and their condition. Control technology has evolved from tube regulators and relay-contact circuits to microprocessor-based control, logic and demonstration controllers.

Abroad, the use of such controllers in automation systems for various objects began a little earlier. A microprocessor controller is a computing device designed specifically to control a technological object located in its immediate vicinity.

The controller consists of the following blocks and devices:

- power unit;

- calculator;

- block for input of analog signals of different ratings with galvanic separation;

- device for inputting discrete active (in the form of voltage) and passive (in the form of a dry contact) signals;

- block for outputting analog signals of different ratings with galvanic separation;

- device for outputting discrete active and passive signals;

- an interface communication device for connecting the controller to the system information field.

Signal input and output blocks - blocks of the ICD group (communication devices with the object) - are all multi-channel, have from 8 to 16 channels. The controller is assembled for a specific task using the design layout method. The composition and number of USO blocks is selected based on the number of corresponding signals in the system. The computer block contains a processor, random access memory (RAM) and read-only memory (ROM). A library of algorithms is stored in ROM. Its composition covers almost all control tasks used in such systems - regulation, arithmetic calculations, dynamic transformations, logical actions.

Home automation

Programming of controllers is carried out using the technological programming method. For modern controller models, this method is an assembly of a functional diagram of a control task on the monitor screen.

After a simple check for errors, the program circuit is loaded into the controller’s RAM. The intuitive accessibility of the method for traditional machine gunners contributed to the rapid and widespread spread of RemiKonts.

Weather-compensated automatic Meibes

The weather-dependent thermostat HZR-M Meibes controls the coolant mixing circuit independently in combination with other controllers. Characteristics of the Maybes device:

- interface with icons;

- built-in heating mode programs;

- integration with other controllers on the eBUS bus;

- Autonomous battery power supply;

- display backlight;

- connector for connecting a computer.

Weather-compensated automation for heating systems of a private home - devices with remote access Meibes LE HZ made in Germany.

The thermostat controls two circuits or a cascade of 2 boilers and recirculation pumps. Features of Meibes LE HZ:

- connecting controllers remotely;

- expansion of control to 8 circuits via eBUS;

- character menu;

Advantages: easy installation on the wall.

Efficient modern heating systems in an apartment building: pros and cons

Since ancient times, people have tried to make their homes cozy and warm with the help of fireplaces.

A modern person living in his own apartment has practically no choice on how to heat it.

In most cases, residents are “warmed” by a centralized heating system in an apartment in a multi-story building.

Heating system in an apartment building

Few people like having no choice in anything. When they return to their apartments in winter, they want not only warmth in them, but also the ability to control its quality and quantity. The modern heating system in an apartment building does not always justify their trust, especially in Soviet buildings. What heating system is used in an apartment building today?

Today, the following heating schemes are used in high-rise buildings:

- Vertical system one-pipe or two-pipe.

- Two-pipe horizontal circuit.

A single-pipe heating system in an apartment building is considered the most economical and simplest in technical terms, but not convenient. It was mainly used in Soviet buildings and the fact that it cannot be regulated, for example, turned off when it is hot in the apartment or warmer outside, is a big disadvantage.

The vertical two-pipe installation of a heating system in an apartment is very popular, since the heating of the medium in it is better and more uniform. An important role is played by the ability to regulate the heat in the apartment.

The horizontal two-pipe system is recognized not only as the most efficient, but also expensive. Despite this, more and more private and apartment buildings are using it.

When you can choose what kind of heating to install in an apartment, there is no better option than a radiant heating system in an apartment building. This is due to the positive qualities that she possesses.

Collector heating system

The principle of radiant heating is that the coolant is distributed over all radiators from one collector. This scheme is best suited for high-rise buildings or private houses with several floors and a large number of rooms.

As a rule, collectors are installed on all floors, and the supply and return pipes are distributed from them.

The collector heating system in an apartment is a complex mechanism that includes the following elements:

- A boiler responsible for supplying hot media to the pipes.

- Circulation pump providing the required pressure. The quality of indoor heating largely depends on it.

- The collector itself, which is the main “distributor” of heat.

- A cabinet that hides the main elements of the system.

The positive qualities of the beam system include:

- Aesthetic appearance, since all pipes, locking mechanisms and manifold are hidden in a special cabinet.

- The system is not subject to hydraulic shocks, which significantly increases its service life.

- If necessary, individual structural elements can be turned off or set to a minimum heat supply using control valves, without interfering with the rest from working efficiently. This is especially beneficial when the premises are not in use, which creates significant cost savings. This is also convenient if you need to repair or replace radiators.

- Easy to install and reliable. As a rule, a radiant heating system in an apartment can operate for 50 years or more.

The disadvantages of the system are its cost and the fact that, despite its apparent simplicity, its installation requires certain skills.

Pros and cons of top spill

The quality of home heating also depends on how the heating pipes are routed. The heating system of an apartment building with a top spill is most often found in high-rise buildings. Its peculiarity is that the carrier is supplied from the attic or technical floor of the building. Its elements include an expansion tank and valves on each of the risers.

The features of this centralized heating scheme are:

- A certain slope of the elements allows water to be drained from the heating system of an apartment building in a matter of minutes.

- Simultaneous filling of all risers when starting the system, which is achieved by opening the valves and air vent in the expansion tank.

- In order to discharge the media in a separate riser, it is enough to close its valves in the attic and basement, and then open the plug.

Among the disadvantages of the upper spill is a gradual decrease in the heating of radiators from the upper floor to the lower.

The decrease in heating of the coolant on the lower floors is easily compensated by increasing the number of heating elements of the batteries.

Reasons for media drainage

Any, even the most efficient heating systems for private houses and apartments require draining the media from time to time.

There are a number of reasons for this:

- Replacement of heating network elements.

- Repair work, for example, to eliminate leaks.

- System maintenance, such as cleaning radiators.

- When replacing media.

- When an air lock appears in the system.

For the latter reason, there is no need to take permission or notify heating network workers about draining the media. It is enough to prepare the containers and open the Mayevsky tap. When the whistling and hissing stops coming from the pipes, it means that the air has left it and you can tighten the valve.

Any repair or maintenance work on the heating system requires permission from the management company. In this case, all work on draining the media will be carried out by its technicians. This service is often paid and hourly.

Technical characteristics of the coolant

The coolant parameters of the heating system of an apartment building must comply with the following standards:

- Transfer heated media through the system as quickly as possible with minimal heat loss.

- Be fluid enough to achieve similar speeds under pressure.

- Do not cause corrosion to network elements.

- The coolant must be safe and, when heated, not release toxic substances or ignite.

- It should have a low cost.

Based on the above parameters, the best carrier for multi-storey buildings is water.

It is used not only because it is cheap and environmentally friendly, but also in the event of an emergency, its reserves in the system are easy to replenish.

Tap water is not suitable as a coolant, as it contains a large amount of salts, which have a bad effect on the operation of the system, gradually settling on the walls of the pipes. Typically, distilled water is used.

In regions with harsh winters, antifreeze is often used as a coolant, which does not freeze at -30 degrees. Even if the system fails and the antifreeze freezes, its elements are not in danger of losing their integrity. This is due to the property of the substance at subzero temperatures to take a gel-like form, which again changes to liquid when heated.

Regardless of how the heating system in an apartment building is designed, the presence of antifreeze in it requires the use of a high-power pump. It is also necessary to remember that not all types of pipes and radiators “get along” with this substance.

Weather-compensated automation

Automation of heating systems has recently become very popular. This is due to the fact that tariffs are constantly growing, and any assistants that allow you to save energy costs are becoming in demand.

Weather-dependent automation for heating systems in an apartment building is a means of regulating the indoor microclimate during temperature changes outside. As practice shows, these devices for the heating system of an apartment building are really useful in regions where frequent daily temperature changes occur in winter.

Such devices are equipped with programs that allow you to set the necessary parameters in advance. For example, at -10, the heating of the batteries reaches one level, but when the temperature outside drops to -15 degrees, it reaches another, hotter level, and vice versa.

Where the temperature regime in winter is not subject to sudden changes, but remains at approximately the same level, such devices are a waste of money.

Washing of heating networks

When a situation arises that buildings located in the immediate vicinity of the boiler room receive increased heating in the radiators, and residents are forced to open the windows and give off excess heat to the street, and more distant objects freeze, then heating network technicians carry out work to distribute heat evenly to all consumers.

Washing the heating system of an apartment building is the installation of special washers with a hole of the required caliber on the branches of heating networks.

At the same time, less heat flows to nearby buildings, since it flows freely to distant objects. This work makes it possible to reduce the carrier flow through the pipes by 3 times.

Washing allows you to reduce the number of boilers, reducing electricity and fuel consumption. They are applicable not only for external work, but also for uniform distribution of coolant inside apartment buildings.

The cost of washer is low, so installing them on the risers of a high-rise building will allow residents to significantly save money on heating.

Making corrections

Any change to the heating system in an apartment building is an encroachment on property owned by the management company. This applies to houses with central heating.

Any work on the system, be it replacing old radiators with new ones, an emergency situation or flushing pipes, must be agreed upon with the management of the heating network. Otherwise, making independent changes to the system is a violation and may result in legal proceedings, dismantling of new elements and fines.

The same applies to the situation when abandoning central heating in favor of switching to autonomous heating. Any reconstruction of the heating system of an apartment building must first have a project, listing the work and purchase of materials, a statement indicating the reason for its replacement, and the approval of the commission.

In conclusion, we can conclude that multi-apartment buildings often have outdated heating systems, which cannot be said about modern new buildings. The radiant heating scheme for apartments is by far the best and most popular, despite its high cost.

Any breakdowns, changes and even draining of water from pipes must be agreed upon with the heating network workers. Installing automation on heating systems is not always advisable, so before purchasing it it is better to consult with specialists.

Useful video

Heating systems of an apartment building - video:

netholodu.com

Thermostat ZONT

Weather-compensated heating regulator ZONT H-1 is an intelligent system, remotely controlled via GSM or the Internet. The device is connected via a mobile application, personal account on the manufacturer’s website or via SMS commands. Thermostat capabilities:

- 2G SIM card management;

- transmission of temperature sensor readings and boiler operating mode;

- selection of heating control curve;

- programming room heating for a week;

- notification of errors and emergencies;

- message about a power outage in the house;

- transaction history for 3 months;

- software update via the Internet.

The thermostat is connected in 2 ways - through the terminals on the boiler or with an adapter to the digital bus. Heating control can be performed in relay mode, with periodic switching on of the gas burner. Digital control is possible via an adapter - electronic flame modulation.

Technical characteristics of ZONT H-1:

- operating voltage 10-28 V;

- analog and digital inputs;

- connection of 10 wired and radio sensors;

- operating range from –30 to +55°C;

- exit to mode – 50 seconds;

- plastic case, universal surface mounting.

Weather-sensitive controller SALUS Multi-Mix

The weather-dependent thermostat Multi-Mix is a universal device for monitoring and weather-dependent control of the temperature of the medium in the heating system. With a standard installation, the regulator can control: one unregulated circuit, two regulated (using 3- and 4-way valves) circuits, and a DHW preparation circuit. In addition, it is possible to control the solar collector circuit and the DHW recirculation pump. The heat sources in the system are also monitored and controlled: the main one (gas, electric, diesel, etc. boilers, heat pump) and additional (fireplace, solid fuel boiler, etc.). The controller supports connection diagrams using a hydraulic arrow and a heat accumulator. It is possible to connect room thermostats; in this case, the heating circuits are adjusted and turned on taking into account their readings. The advantage of the Multi-Mix thermostat is its unique design, ease of installation, ease of maintenance and operation, and intuitive interface.

Basic properties

- Integrated heating control

- Many possibilities of use, the regulator is compatible with many installations (many hydraulic circuits to use)

- Intuitive operation via color touch panel

- Weather-compensated control based on heating curves

- Automatic heating season detection

- Possibility of working with a conventional room thermostat

- Monitoring the operation of pumps and heat sources

- Smooth control of 3-way valves

- Maintenance of installations with a heat accumulator or hydraulic valve

- Wall installation

Included:

— external temperature sensor CT6-P — 1 pc.

— clip-on temperature sensor CT10-X — 5 pcs.

Connection diagram SALUS Multi-Mix

Characteristics

| Nutrition: | 230 V AC 50 Hz; 3(3)A |

| Pace. inputs: | T1 – external temp. T2 – temp. main heat source (water gun) T3 – temp. additional heat source T4 - temp. mixer 1 T5 - temp. mixer 2 T6 - temp. DHW T7 - temp. collector T8 – temp. heat accumulator |

| Potential-free inputs: | TP1, TP2, TP3 – room thermostats or switching centers |

| Outputs with voltage 230 V: | — 6 circulation pumps 230 V — 2 drives with mixing valves 230 V — 4 controlled outputs 230 V |

| Potential-free outputs NO/COM/NC: | - main source of heat |

| Control outputs 0-10 V: | - main source of heat |

| Dimensions: | 340 x 210 x 60 |

Boiler operation with heated floors

For comfort in the house, a heated floor system is used, where the coolant is water or a liquid with a low freezing point. The circulation pump is regulated by weather-compensated automation.

Composition of the heated floor scheme:

- weather-compensated control controller;

- outdoor temperature sensor installed in the shade;

- mixing unit servo drive;

- circulating water temperature sensor;

- underfloor heating pipeline;

- thermostat in the heated room.

The Russian-made TRC-03 controller maintains the temperature according to the heating control curve.

Warm floors are used with other types of room heating. Four types of weather-compensating controllers are designed to work together:

- Main – controls 8 types of hydraulic circuits, 6 of which include the boiler.

- Expansion for 2 hydraulic systems in addition to the main regulator.

- Independent loop control with mixing, can independently regulate one system.

- Heating control device with buffer tank and timer.

Heated floors have significant inertia, so the room thermostat reacts more accurately to the weather.

Scope of use

In small and medium-sized private houses, it makes sense to install such systems if the owners are often absent for a long time. If you live permanently, it’s easier to go to the stake (or log into the application on your smartphone) and adjust the power in case of cold weather, strong winds or warming.

In large cottages, mansions, multi-apartment, commercial or public buildings, automation of heating control based on a weather-dependent controller is becoming an urgent need. In public buildings with a large glass area, it was possible to achieve double or more savings in energy resources spent on heating.

It is recommended to use such systems in centralized boiler houses serving several geographically distributed facilities.

Weather-compensated automation for greenhouses

Growing crops year-round in a northern climate is a difficult task. To ensure the growing season of plants, weather-dependent heating is used. The best option is a piped soil heating system, which stimulates root development and reduces energy consumption.

The temperature in the greenhouse is different at night and during the day, and the soil should be 2-3°C warmer. Aries TRM-32 automation or Aries PLC 100 controllers integrated into a system with a control center can cope with this task.

Characteristics of the Aries TRM-32 control system:

- control of coolant heating based on the signal from four external sensors;

- connection to a computer via an adapter;

- control range from –50 to +200°C;

- wired communication length – 1200 m;

- temperature in the greenhouse from +1 to +50°C;

- push-button control, information display;

- programming a heating schedule based on a given temperature value;

- switching from day to night operating mode.

Remote control of the microclimate of greenhouses is carried out by ventilation and changing the speed of the pumps.

Boiler room piping diagrams and principles of circuit control

In order to organize the operation of one or more heating circuits in a hydraulic system, they must be connected to a heat generator-boiler. This problem can be solved in different ways; experts call them boiler room piping schemes. Let's consider the most common of them, as well as the principles of organizing the corresponding management process with all their advantages and disadvantages.

Heating circuits are divided into direct and mixing according to the method of achieving temperature in them. The water temperature in the direct circuit is achieved only by the burner and depends on the duration of its operation.

In the mixing circuit, the temperature of the coolant is determined both by the operation of the burner and by the position of the damper of the actuator - a three-way mixing valve with a servo drive. By resorting to the first option, you can easily connect a low-temperature boiler with one radiator heating circuit and ensure automated control of it depending on the outside temperature. This is a very simple and relatively inexpensive task. If, in addition to heating, it is necessary to organize hot water supply, without resorting to mixing units, two types of schemes are used. The first is with a three-way valve, the second scheme is with two pumps.

The simplest is the circuit with a three-way switch valve equipped with a servo drive. Water from the boiler is directed to the tap, which, in turn, directs it either to the heating circuit or to the boiler heating circuit. Switching can be carried out by command from the boiler control panel. The water temperature in the boiler is controlled automatically using a temperature sensor installed in it. As soon as the water cools below the required level, a command is given to switch the three-way tap. It is necessary to take into account that with such a piping and control scheme, while heating water in the boiler, the heating is turned off (that is, it is impossible to organize control of hot water supply with mixed priority).

The collector circuit, as the name suggests, involves the use of collectors for piping the boiler room, which are pipes with leads to the required number of circuits. This scheme, being quite simple, has become widespread due to the advent of so-called quick installation components. They include pumping and mixing groups. These devices allow you to quickly assemble a system with several heating circuits (it takes a few days to install a boiler room). However, it should be noted that such modules are used mainly for boiler houses of small power - up to 85 kW.

Nevertheless, they are extremely convenient for installation and significantly reduce the risk of error due to the notorious human factor, since they are assembled and tested for functionality and tightness in the factory.

There is an interesting option for piping boiler rooms using a hydraulic separator (hydraulic arrow). This refers to a scheme of primary and secondary rings, the operating principle of which is as follows: boiler water constantly circulates through a small circuit (primary ring), from which other heat consumers (various circuits) take the coolant with the help of circulation pumps. The advantage of this scheme is the ability to connect a large number of secondary circuits while ensuring the nominal flow rate through the boiler and the relative simplicity of the design.

The DE DIETRICH company (France) recommends using a thermohydraulic distributor (abbreviated as THR) for piping its boilers. When using it, a constant flow of coolant through the heating device is achieved - regardless of the value of water flow in the heating circuits, where this indicator may vary. As a result, it is possible to achieve optimal balanced operation of the boiler and heating circuits.

It is important to note that automation from many manufacturers allows you to control the boiler and circuits in a wide variety of boiler room piping schemes. However, it is still better to entrust the search for the most suitable option and the selection of automation to a specialist.

Do-it-yourself automatic regulation

Weather regulation is used to maintain comfort and economy. They install weather-compensated heating in small private houses and dachas with their own hands. For stable operation of the system, factory-assembled devices are suitable. Homemade devices will not work stably; they are unsafe.

The Ochag universal boiler, which runs on solid fuel, is suitable for a country house. The control circuit has three temperature sensors - coolant in the boiler, waste gases and water in the boiler. The actuators are an air flow gate and a damper on the pipeline. Automatic control is organized using the Arduino Nano controller.

Actuators

In order to organize the operation of several heating circuits with different, not always constant temperatures, actuators are required. The most common are three- and four-way mixing valves (mixers). The principle of their operation is to regulate the temperature of the coolant in a separate heating circuit by mixing water from the boiler with water from the return line. Thus, the temperature of the coolant in the supply line of the circuit can vary from a minimum, for example equal to room temperature, to a maximum, equal to the temperature of the boiler water, but not higher than it. The crane can be turned manually (but then there is no need to talk about any automation of control!) or using a special motor - a servo drive.

Typically, several parameters of servo drives are indicated in the technical data sheet. This is the power supply voltage, the maximum torque generated on the shaft, and the speed of the drive. The last indicator reflects the time it takes for the servo drive to transition from one extreme position to another. This is usually from 60 to 300 seconds. It is worth keeping in mind that a shorter response time of the servo drive does not at all guarantee a rapid change in temperature in the heating circuit. Let us remember that all thermal processes are very inertial. It is for this reason that drives with operating speeds of less than 60 seconds are not usually used. Approximately this amount of time is required for the sensor installed on the supply pipe, the temperature of which cannot change instantly, to respond to changes in the temperature of the coolant. In the service menu of many control panels there is a setting parameter that takes into account the speed of the servo drive. For example, in the control panels of the Logamatic 4000 series from BUDERUS, costing € 1,270, the opening time of the three-way mixing valve in seconds is directly set as standard. This indicator characterizes the response of a particular servo drive and is reflected in the data sheet.

Mixing taps and actuators for them are produced by a number of manufacturers, for example ROCA, Honeywell, WOLF. The valve body can be made of either cast iron or brass. Both materials are well suited for use in heating systems. Mixers from the Swedish company ESBE have proven themselves to be excellent. A three-way mixing valve with a diameter of 32 mm, manufactured by this company, can be purchased for € 60-70, a servo drive for it will cost € 150-170.

How necessary is a weather-compensated heating system?

Automation of heat management is not always necessary. Regulation occurs with a deviation of 2°C from the norm in the room with the sensor; in other rooms the variation is greater. The cost of installing automation installed separately reaches 2 thousand euros.

If the equipment is supplied with a heating boiler, the use of weather-dependent automation is justified. In other cases, the costs will not cover the possible savings.

Thermostatic radiator heads are sufficient for heating regulation.

Advantages of automatic heating control

Due to its high cost, weather-dependent control is more often used in apartment buildings and industrial buildings, where it is economically justified. Advantages of automation:

- constant temperature;

- reduction of fuel consumption during temperature changes;

- automatic environmental control by sensors;

- maintaining a low temperature;

- lack of human factor.

Boilers of new models are equipped with automatic adjustment. The functions of these systems are sufficient for comfort in the home without unnecessary investments.

How it works

Control using a heating boiler

With this approach, all heating control comes down to setting the temperature of the coolant on the boiler. In this case, the automation built into it begins to work; for heating that works in this way, control on the boiler is quite sufficient. It will maintain the required coolant temperature regardless of its value in the premises.

More details in the article - automation for a heating boiler.

Thermostatic valve

Perhaps this is the simplest automatic heating temperature controller. It is placed on each radiator, and on it (on its head) you can set the desired value. In cases where it becomes too hot, the regulator operates and cuts off the flow of coolant into the battery. When the temperature drops below the set value, the valve opens and water begins to flow into the radiator, heating the room.

Automation for gas heating boilers

Thermostatic valve

The disadvantage of this approach is the lack of savings due to the inability to control the boiler and fuel consumption.

Room temperature controller

In this case, a special temperature controller is installed in the room - essentially a heating controller. It changes the heating of the coolant (turning on or off the burners, adjusting the water supply, etc.), providing the desired mode.

Room temperature controller

In fact, in this case, the control is completely electronic; the heating of the house operates according to commands from a special center and can implement any given operating mode. If such a control and regulation structure is equipped with remote communication units and a GSM module, an automated heating system control unit with remote access will be formed.