In search of ways to reduce the negative impact on the environment, scientists and engineers are developing new ways to increase the efficiency of heating systems. One of them is weather-dependent automation for heating systems. It allows you to control fuel consumption in a heating boiler taking into account current weather conditions, predict cold weather or overheating in residential premises and quickly compensate for them. At the same time, a reasonable balance is maintained between comfortable living conditions and energy saving.

WHAT'S COOL?

The main thing is that Klimatic is the most inexpensive of the cool ones.

Or the coolest inexpensive one - whatever you like. It is easy to set up - large screen and clear menu.

It can work with wireless temperature sensors (radio communication). Moreover, one outdoor air temperature sensor can be used by several Climatics. This is in case you have several heating circuits.

It has 9 "factory" time programs such as "morning, evening and weekend". This saves a lot of time when setting up.

You can manually switch the Climate control to comfortable or economical mode at any time. And return it back to automatic.

The heating schedule can be adjusted (this is more for specialists).

The climate control system intelligently controls the pump and drive: if heat is not needed, the pump will turn off and the drive will close.

The climate control is always on guard! In any mode, frost protection is provided (if the coolant temperature drops below 10 degrees, the controller will turn on the pump and maintain 10 degrees).

Controls any three-position drives

Adjusting the heating system using pumps

Among the well-known schemes for installing heating systems controlled from a weather-dependent automation unit, the optimal option for regulating the heating temperature of rooms is a scheme using circulation pumps. This scheme is more used for heat supply to district heating buildings, when additional pumps are installed at heating points to pump coolant from the main to a specific consumer. In this scheme, in addition to the pumps themselves, other equally important elements are used, for example, a heat accumulator and a hydraulic separator - a hydraulic arrow.

The essence of this method is to quickly increase the flow rate of coolant to the radiators by switching the pump operation. After receiving information from external and internal sensors, the control unit, according to the program, selects the operating mode of the circulation pump. By increasing or decreasing the coolant supply rate, the automation regulates the flow pumped into the radiators. To achieve the desired temperature, the automation opens, or vice versa, closes the three-way mixing valve and the liquid heated to the desired temperature, under the action of the pump, enters the battery circuit.

This option for controlling the heating system using pumps allows you to bring the room temperature to the desired value in a very short time without adjusting the burner of the heating boiler. It is simple and reliable, and heating boilers do not need to be constantly adjusted, setting the temperature to 40-45 degrees.

Pump control from an external signal

Connecting the controller to the smart home system significantly expands the heating control capabilities.

In addition to the heating operation under the control of a weather-compensated automation controller, the system’s owners have the opportunity to remotely adjust the temperature in the premises. The main condition here is connecting the controller to the Internet and installing a special application on mobile devices to control life support systems at home.

Principle of weather-compensated heating control

Let us explain how room temperature is maintained taking into account changes in outside temperature. When setting up the controller, a so-called temperature curve is established, reflecting the dependence of the temperature of the coolant in the heating circuit on changes in weather conditions outside. This curve is a line, one point of which corresponds to +20°C outside (in this case, the temperature of the coolant in the heating circuit is also +20°C, since it is believed that under such conditions there is no need for heating). The second point is the coolant temperature (say, 70°C), at which even on the coldest day of the heating season the temperature in the room will remain set (for example, 23°C). If the building is not insulated sufficiently, a slightly higher temperature of the coolant in the heating circuit will be required to compensate for heat loss. Accordingly, the slope of the curve will be steep. And vice versa, if everything is in order with the thermal insulation of the house. When making a controller, many similar curves are entered into the device’s memory so that you can then select from the entire family the appropriate line specifically for the conditions of your home.

As a rule, to create the maximum level of thermal comfort, as well as to save fuel, a single street sensor is not enough. Therefore, an additional sensor is often installed inside a heated room. The presence of two sensors at once, both indoor and outdoor, allows you to accurately monitor and quickly adjust the temperature in the premises of the house.

Typically, a room temperature sensor is installed in the so-called reference room - the temperature in it will correspond to your concept of a comfortable thermal background. This room should not be heated by direct sunlight or exposed to drafts. As a rule, children's and bedrooms are chosen as a standard. Installing a room sensor makes it possible to enable the self-adaptation mode, in which the heating curve is selected for the appropriate room automatically - by the microcomputer of the control panel itself. In addition, a room sensor is often integrated into a thermostat, with which you can set the desired temperature and its average level throughout the house. Local temperature control in a single room is achieved by installing thermostatic valves with thermal heads on radiators.

A very important aspect of using a thermostat is, again, fuel economy. Let us explain how it is carried out. Let’s say that guests gathered in the room where the sensor is installed and the temperature increased by 2°C due to the natural heat generation of people. The control panel detects these changes and gives a command to reduce the temperature of the coolant in this circuit, although the street sensor may require just the opposite. Reducing the heat consumption to heat this room naturally saves fuel. But there are also problems here. Flooding the fireplace in the room where the thermostat is set, or leaving a window open for too long, can change the temperature throughout the house. To take into account such factors, many systems provide the possibility of making amendments to the control algorithm by setting the coefficient of influence of the room sensor on the nature of the heating curve. But in general, experts simply do not recommend installing room temperature measuring devices near fireplaces, entrance doors, windows and other sources of heat or cold that can introduce an error in the measurement results.

It should also be noted that installing only a room thermostat, without an outside temperature sensor, significantly increases the inertia of the temperature control system. Changes in the thermal background will occur with a delay, since the automation will begin to operate only when the temperature in the house, for example, drops, and this will happen later than the actual cold snap outside

Modern controllers not only monitor the weather, but also have a fairly large number of functions, some of which are user, and some are service. If the former guard comfort, the latter monitor the condition of the system and ensure the correct and safe operation of the equipment.

Weather climate control system for multi-apartment high-rise buildings Housing and communal services

Call:8

Automation of housing and communal services is an urgent task in saving thermal energy for management companies in the housing and communal services sector. The weather control system for heating is justified only if a heat meter (thermal energy metering unit) is already installed in the house.

The Moscow United Energy Company (MOEK) never complies with the temperature schedule (they themselves claim it and do not comply with it) and therefore overestimation of the coolant temperature is observed everywhere. Their goal is to take as much money as possible from the consumer, and at any cost, therefore, at a temperature of -5Cº, MOEK gives the temperature that they should give at a temperature of -15Cº, etc.

Tired of overpaying? There is a way out!

The weather control system for heating allows saving up to 35% of thermal energy consumption. If you consider that an apartment building (management company, housing cooperative, HOA) pays about 1 million rubles per month for heating during the heating season, then residents will feel the savings within a month!

Call by phone in Moscow and in 10 minutes you will learn more than in 3 hours of searching on the Internet

How it works?

The outside air sensor (located on the shady side of the street) measures the outside temperature. Two sensors on the supply and return pipelines measure the temperature of the heating network. A logical programmable controller calculates the required delta and, by controlling the valve (KZR), regulates the flow rate of the coolant.

In order to protect against complete blocking, the valve is equipped with protection. To prevent stagnation of the risers (air ingress), the internal circulation pump circulates the coolant in the system through a check valve. The weather control unit is also equipped with an automatic air vent.

If the heating network does not have the required differential (which is extremely rare), then the problem can be easily eliminated by installing an automatic balancing valve.

The system has a full-bore bypass and 100% guarantees no interruptions in heat supply in winter.

In the event of an unplanned pump stop and other emergency situations affecting automatic weather control of heating, the system sends an SMS via GSM module to a mobile phone.

Need help calculating your weather control system?

Call

How much does a weather control system cost?

The price of a weather control system largely depends on the equipment used (foreign or domestic). All the pros and cons of using foreign or domestic equipment can be found out from VNT specialists. When requesting a price, you must send a printout for heating (monthly, which you submit to MOEK) and indicate the diameter of the heating pipes.

As an example, we will give several cost options for installing a weather controller on a heating system based on imported equipment for apartment buildings (300 apartments or more). Prices at the beginning of 2016

- Circulation pump - 40,000 rubles

- Control valve with electric drive - 60,000 rubles

- Control cabinet for two pumps assembled - 85,000 rubles

- Iron (pipes, couplings, flanges, taps, valves, bolts, nuts, filter, etc.) - 85,000 rubles

Total: 270,000 rubles - equipment Cost of installation and commissioning works: 290,000 rubles

TOTAL TURNKEY: 560,000 rubles

Commercial proposal for the installation of a weather controller on the heating system of a private house with no more than 10 apartments. Prices at the beginning of 2016

This version of the weather control system is fully automatic and regulates heat depending on the outside temperature. It is relevant in small residential buildings with no more than 10 apartments.

- Circulation pump within the range - 10,000 rubles

- Valve with drive within - 60,000 rubles (maybe less with a discount)

- Electrical cabinet assembled with thermal converters and installation kit - 40,000 rubles

- Iron (pipes, couplings, flanges, taps, valves, bolts, nuts, filter, etc.) - 30,000 rubles

Total: 140,000 rubles - equipment Cost of installation and commissioning works: 160,000 rubles.

TOTAL TURNKEY: 300,000 rubles

Savings from using an automatic weather control system will be about 50%!

This version of the system uses manual regulation using a balancing valve.

Total: 50,000 rubles - equipment Cost of installation and commissioning works: 80,000 rubles.

TOTAL TURNKEY: 130,000 rubles

*Prices for both options are indicated when paying in cash. When paying by bank transfer, the cost will be 20% higher.

We will help you save Call

Weather-compensated heating control

At first glance, everything is logical, but I had a question about the advisability of constantly adjusting the temperature of the coolant in the heating system. There is an opinion that a one-time adjustment of the heating system over a period of time is sufficient in the event of a sudden change in outside air temperature. In this case, adjustment can be made manually using various remote control systems, while avoiding unnecessary “bells and whistles” in engineering systems and thereby simplifying their operation. In order to understand this, let's look at the second function that requires weather-dependent heating control - saving energy resources. I am sure that you don’t have to be an academic to answer the question of what type of coolant supply control will be the most energy efficient. Naturally, it's automatic. But the question immediately arises: by how much are the costs of generating thermal energy reduced if you use weather-dependent heating control, and how reasonable are the costs for it?

Actuators

In order to organize the operation of several heating circuits with different, not always constant temperatures, actuators are required.

The most common are three- and four-way mixing valves (mixers). The principle of their operation is to regulate the temperature of the coolant in a separate heating circuit by mixing water from the boiler with water from the return line. Thus, the temperature of the coolant in the supply line of the circuit can vary from a minimum, for example equal to room temperature, to a maximum, equal to the temperature of the boiler water, but not higher than it. The crane can be turned manually (but then there is no need to talk about any automation of control!) or using a special motor - a servo drive. Typically, several parameters of servo drives are indicated in the technical data sheet. This is the power supply voltage, the maximum torque generated on the shaft, and the speed of the drive. The last indicator reflects the time it takes for the servo drive to transition from one extreme position to another. This is usually from 60 to 300 seconds. It is worth keeping in mind that a shorter response time of the servo drive does not at all guarantee a rapid change in temperature in the heating circuit. Let us remember that all thermal processes are very inertial. It is for this reason that drives with operating speeds of less than 60 seconds are not usually used. Approximately this amount of time is required for the sensor installed on the supply pipe, the temperature of which cannot change instantly, to respond to changes in the temperature of the coolant. In the service menu of many control panels there is a setting parameter that takes into account the speed of the servo drive. For example, in the control panels of the Logamatic 4000 series from BUDERUS, costing € 1,270, the opening time of the three-way mixing valve in seconds is directly set as standard. This indicator characterizes the response of a particular servo drive and is reflected in the data sheet.

Mixing taps and actuators for them are produced by a number of manufacturers, for example ROCA, Honeywell, WOLF. The valve body can be made of either cast iron or brass. Both materials are well suited for use in heating systems. Mixers from the Swedish company ESBE have proven themselves to be excellent. A three-way mixing valve with a diameter of 32 mm, manufactured by this company, can be purchased for € 60-70, a servo drive for it will cost € 150-170.

Autonomous heating boilers - non-volatile automation.

Boilers equipped with non-volatile automation are protected from sudden power outages. As a rule, they operate without the use of forced coolant circulation, which means they can work autonomously. Such a heating device is controlled by boiler automation, the operation of which is based on the use of gases that can expand significantly under the influence of temperature.

A special sensor with such gas is installed at the top of the heat exchanger, where the temperature is highest. As the temperature of the coolant increases, it increases in volume and its pressure increases. The sensor, using a copper tube, communicates with the membrane, which, in turn, is mechanically connected to the valve that controls the fuel supply to the burners. With approximately the same type of action, a sensor is installed on Galan electrode boilers.

Using the controls, you can adjust the valve cut-off threshold, and thus control the water temperature in the heating circuit.

Non-volatile automation for boilers is installed, as a rule, in domestically produced parapet heating installations.

Modern control devices are electronic automation systems.

Modern automation devices for wall-mounted boilers operate on a different principle. They use a solenoid valve that is controlled by a microprocessor unit. This is explained by the fact that this control method makes it possible to more accurately regulate the operating mode and is more convenient for the consumer. The boiler is usually equipped with a display and buttons for controlling operating modes. Just a few clicks are enough to set the required mode, and then the smart electronic system itself will maintain optimal operating parameters.

Technically, the electronics in such boilers control a three-way valve and a circulation pump. A three-way valve with an electric drive allows you to switch the flow of coolant to provide hot heating of DHW water or to completely turn off the heating circuit. This is necessary, for example, in the summer when there is no need for heating. If the boiler operates only in the DHW supply mode, and there is no water flow, then the automation stops the circulation pump and turns off the burner.

Automation equipment for boiler rooms

Automation technical means:

- sensors of technological process parameters;

- actuators that move regulatory bodies according to commands in the desired direction;

- control equipment that processes information from sensors in accordance with the algorithms and programs embedded in it and generates commands for actuators;

- devices for selecting control modes and for remote control of actuators;

- means of displaying and presenting information to operational personnel;

- devices for documenting and archiving technological information;

- means of collective presentation of information.

All this technology has undergone revolutionary changes over the second half of the last century, not least thanks to the achievements of Soviet science. For example, pressure gauge instruments, widely used in measuring pressure, flow, speed and level of liquids and gases, as well as in measuring force and mass, have changed the physical principle of the sensing element.

Instead of a membrane that bends under the influence of force and moves the rod of an electromechanical transducer, they began to use a strain gauge method. Its essence is that some materials, when subjected to mechanical action, change their electrical parameters. A sensitive measuring circuit detects these changes, and a computing device built into the device converts them into a process parameter value.

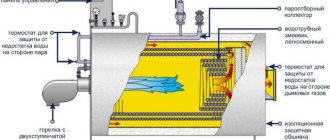

Boiler automation diagram

Devices have become more compact, more reliable, and more accurate. And more technologically advanced in production. Modern actuators don't just accept "on" and "off" commands, as they did for many years. They can accept commands in digital code, independently decipher them, execute them and report on their actions and their condition. Control technology has evolved from tube regulators and relay-contact circuits to microprocessor-based control, logic and demonstration controllers.

Abroad, the use of such controllers in automation systems for various objects began a little earlier. A microprocessor controller is a computing device designed specifically to control a technological object located in its immediate vicinity.

The controller consists of the following blocks and devices:

- power unit;

- calculator;

- block for input of analog signals of different ratings with galvanic separation;

- device for inputting discrete active (in the form of voltage) and passive (in the form of a dry contact) signals;

- block for outputting analog signals of different ratings with galvanic separation;

- device for outputting discrete active and passive signals;

- an interface communication device for connecting the controller to the system information field.

Signal input and output blocks - blocks of the ICD group (communication devices with the object) - are all multi-channel, have from 8 to 16 channels. The controller is assembled for a specific task using the design layout method. The composition and number of USO blocks is selected based on the number of corresponding signals in the system. The computer block contains a processor, random access memory (RAM) and read-only memory (ROM). A library of algorithms is stored in ROM. Its composition covers almost all control tasks used in such systems - regulation, arithmetic calculations, dynamic transformations, logical actions.

Home automation

Programming of controllers is carried out using the technological programming method. For modern controller models, this method is an assembly of a functional diagram of a control task on the monitor screen.

After a simple check for errors, the program circuit is loaded into the controller’s RAM. The intuitive accessibility of the method for traditional machine gunners contributed to the rapid and widespread spread of RemiKonts.

Disadvantages of weather-sensitive automation

Here, oddly enough, there are much more significant positions

- Price if we are talking about a floor-standing boiler.

- The main disadvantage of external weather-compensating automation that is not built into the boiler is the difficulty of maintenance. Often, people call repairmen without even knowing the model of their controller. There are a lot of controllers, so they don’t carry them with them, except in cases where they know exactly for what purpose and model of boiler they are going. The controller cannot be repaired on site. You have to pull out the wires that are connected to the controller and connect them directly. This is the worst case scenario. At best, they take the controller away, check it, and buy a new one. The result is unnecessary spending and worry. In contrast to the lack of weather-compensated automation. As a rule, nothing breaks there due to regular maintenance.

- With automation, which is connected to a large number of electronic devices, there are problems and it is impossible to eliminate them, you just need to change them.

Installation Features

Weather-compensated automation has a number of installation features. The main ones are the choice of installation location for the external and internal temperature sensor.

The external sensor is mounted so that it is protected from direct sunlight. It should also not be blocked from the wind by any building structures. Most often, the north-eastern side of the building is chosen, at a height of approximately a meter and a half from the ground. The sensor must be removed from the wall of the house so that heat loss does not affect its readings.

The internal sensor is installed in the so-called reference room. It should have the average temperature in the house, and its fluctuations should be minimal. There should not be many people in the room; it is not advisable to use the fireplace. It should not be in direct sunlight or near the front door. A bedroom or children's room is best suited for these conditions.

The indoor sensor must be mounted in a reference room

If in private houses the system directly controls the boiler power, then in large apartment or public buildings the system controls the operation of the return valve, which releases a larger or smaller part of the waste coolant back into the heating circuit.

Operating principle

When setting up the controller, a “curve” is specified. With its help, the program calculates the need to heat the room. The initial position of the curve is the point at which the temperatures of the coolant and the environment are equal. Typically this is 20 degrees Celsius. After calibration, the device independently monitors the need for temperature changes.

Manufacturers specify several curves in the PA so that setup does not take extra time. Having selected the program, the specialist starts the system. Further, it functions independently.

For better synchronization, it is necessary to install two sensors - one outside, the second inside.

By checking the readings, the system will not produce additional heating at a comfortable room temperature.

For this reason, it is necessary to correctly select the room in which the sensor will be installed.

Warming up or cooling the coolant takes time, so the heating cannot adapt sharply to temperature changes.

Controller

The controller is the core of the hardware device. It monitors sensor readings and sets the room temperature. The factory functions of the device are responsible for heating, and also inform the owner about problems. Custom settings are designed to maintain maximum comfort.

Operating rules

During operation, you must comply with all requirements and recommendations of the manufacturer. Self-diagnostic tools are built into modern systems, and they themselves can inform the owner about any problems that have arisen. This does not replace the need for periodic inspections and preventative maintenance. During preventive maintenance, the reliability of fastening and cleanliness of sensors, especially external ones, should be checked, and the actuators of the system should be tested. During quarterly prevention, it is also convenient to change the seasonal algorithm of the device.

WEATHER DEPENDENT - HOW IS IT?

Heating system designers design systems for the coldest days of the year (the coldest five-day period). And it is on these days that the boiler must produce the calculated coolant temperature - as a rule, the maximum it is capable of. If we maintain this temperature all year, we will overheat the premises. What should I do?

It is necessary to somehow change the boiler temperature. Scientists have long carried out observations and found that the best solution is to measure the air temperature “overboard” and change the temperature “in the supply” according to the “heating schedule”.

Observations were carried out on a variety of buildings, and it turned out that the graph is almost the same for any building, be it stone or frame. And this graph depends only on the difference in air temperatures inside and outside - this difference is also called temperature pressure.

IS FUEL ECONOMY A MYTH?

Not a myth. Don't believe me? Let's do the math. The situation is the simplest - during the day we maintain the temperature at 22 degrees, at night 18. We have healthy sleep - 8 hours, i.e. 1/3 of the day. The heat loss of any home is directly proportional to the temperature pressure... Remember? The temperature difference is just the difference in temperature in the room and “outside”.

First, let’s calculate on the coldest day - for Yekaterinburg the temperature “overboard” will be -32 degrees. Temperature pressure during the day: 22 - (-32) = 54 degrees. At night - 50 gr. If heat loss during the day is taken as 100%, then at night it will be (50 /54 * 100) = 92.6%, saving 7.4%. This is if you compare an hour during the day and an hour at night, and on average per day the figure is even lower - 2.5%. It seems like the game is not worth the candle. Let's recalculate to the beginning of the heating season - according to the law, this is the day when the average daily temperature is below +8 degrees. We calculate and see that “night” heat losses already amount to 71.4% of “daytime” ones, and the average daily savings are almost 10% (you can check the calculations yourself). Isn't it wonderful? What about the average for the heating season?

For Yekaterinburg, the average temperature during the heating period is -5.4 degrees, so on average we will save about 5% every day. You shouldn't be grinning - we've only just begun. Let’s lower the temperature while we are at work - then out of the entire day we will only maintain a comfortable temperature for 2 hours in the morning and 4 in the evening. Using the same logic, we calculate savings - voila, 5% turns into 9%. And this is in the Urals, where it is very cold - for Moscow in the same situation we will save about 11%.

What if you reduce it not by 4 degrees, but more? What if we reduce it for the entire vacation, when we go away as a family? How much will this be in rubles per year? That's it.

What automatic settings are there?

Currently, the market offers consumers a wide selection of control devices. Therefore, you need to know what automation systems for home heating systems generally exist, and what to give preference to.

Room thermostat

According to installation criteria, there are:

- Wired thermostats. The advantage of this type is the ability to supply power up to approximately 50 meters via wires.

- Wireless thermostats. The advantage is that it is not necessary to create holes for the wires. However, they have a significant drawback - reinforced concrete walls reduce the signal power.

According to functionality they are distinguished:

- Simple thermostats. They retain the desired level of warmth.

- Programmable thermostats. Such devices are capable of setting a certain number of degrees for a whole week in advance (the period depends on the model) with maximum accuracy down to seconds. The advantages also include cost savings due to weekly programming.

Thermostats are also distinguished:

- Electronic thermostats. The kit contains three components: temperature sensor, signal transmitter, relay. The main advantage of the device is the maximum accuracy of the equipment. Don't forget ease of use.

- Mechanical thermostats. The basis of the devices is the ability to change properties under the influence of temperature levels. Due to temperature changes in the gas membrane, a circuit is closed or opened, causing certain mechanisms to work.

- Electromechanical thermostats. The mechanism of the device is much simpler than an electronic one. The main element is the relay. The node looks like a tube, which is filled with a special substance that reacts to temperature. If the boiler heats up, the substance expands; similarly, when the boiler cools, the substance contracts. And the drive, dependent on the substance, regulates the temperature thanks to an electrical circuit.

Connection can be made to:

- Kotlu;

- To the pump;

- Servo drive;

Thermal head

This is a thermostatic element that, under the influence of the external environment, slightly opens or closes the radiator. An inexpensive type of automation for heating a home. A significant advantage is that the thermal head is very convenient for local heating, and there are also significant cost savings. Of the minuses: firstly, the adjustment occurs according to standards consisting of abstract numbers, not degrees. Secondly, the sensor measures the degree of heat around the installation, but not the room, which reduces the accuracy of the device.

Weather-compensated automation

The design of weather-dependent automation for heating a house is simple: as the weather outside decreases, the temperature of the coolant increases. However, a weather-dependent installation has a very significant drawback - the system sometimes does not have time to adapt to the temperature, and, therefore, the effect is delayed. The especially mentioned disadvantage manifests itself if an addition is connected - heated floors. The disadvantages include the fact that the devices do not operate entirely correctly, approximately, so the change is noticeable only during seasonal climate changes. It is worth noting that the prices for the unit are relatively high. But the units will be very convenient in production, large-scale houses (over 500 square meters).

Types of control devices

To ensure control of the temperature regime of the heat generator or consumer, the same device equipped with a temperature sensor is used.

These devices are divided into three categories, which can work either individually or in combination:

- Thermostat

. This device is the simplest control device in the heating system. Being located in a building, it monitors changes in air temperature. When the required temperature is reached, the thermostat sends a signal to the boiler or radiator tap, as a result of which the heating of the coolant stops or the flow of liquid to the radiator is blocked. Installing a thermostat yourself is not particularly difficult: just look at the photo, which shows the diagram of its connection and operation, to be convinced of the simplicity of this design. - Coolant temperature regulator

. Such a device can work independently or together with a thermostat. The design works due to temperature sensors that are installed inside the heating circuit. They constantly monitor temperature changes in the system and transmit this data to the control module, which controls the circuit's mixing valve. If it is necessary to increase the temperature, the controller can perform this task using a valve. - Weather-compensated automation of heating systems

. This type of device can be classified as the most complex, since such a system has to work not only with the heating circuit, but also with the environment, thereby ensuring the most accurate and rational temperature control.

The basic design of weather-compensated automation includes an outdoor thermometer, a thermal circuit controller and a thermostat located in the room. Despite the high cost, such a system is considered the most popular, since it is capable of providing maximum comfort that can only be squeezed out of heating. Weather-dependent automation of heating systems uses complex software systems that ensure maximum efficiency and cost-effectiveness.

Weather-dependent automation can be controlled either from its own remote control or remotely by installing the necessary software on a smartphone or tablet (more details: “

How to choose remote heating control - characteristics, capabilities

"). In this case, you can regulate the temperature in the house while being away from it.

Conclusion

Automation for heating boilers is expensive, but immediately after installation these devices will begin to save fuel, which will affect the economic situation after some time. In addition, it is the automatic temperature control system that allows you to ensure maximum comfort in the home.