Home / Boiler automation

Back

Published: 05/24/2019

Reading time: 3 min

1

3082

Modern scientists, together with engineers, are searching for increased efficiency of heating systems in order to reduce the negative consequences affecting our environment. One way to solve this problem is weather-dependent automation that can control heating systems.

This group of devices is capable of monitoring fuel consumption in a running unit, taking into account current weather changes. In this case, it is possible to predict excessive cooling or excess temperature in a heated room in order to immediately compensate for possible deviations.

It is important to understand that the work carried out by weather-compensated automation is aimed at maintaining the optimal balance between a comfortable microclimate and an economical heating mode.

- 1 Weather-compensating automation device

- 2 Operating principle

- 3 Advantages and disadvantages

- 4 When weather-compensated automation comes in handy

Weather-dependent automation device

One of the leading manufacturers of high-tech heating equipment is BAXI. In addition, the company produces weather-dependent automation systems suitable not only for BAXI boilers, but also for equipment from other manufacturers.

A system capable of controlling heating based on data from changes in the current weather is presented in the form of a number of basic elements:

- control controller;

- temperature sensors;

- elevator - a control valve equipped with a pump.

The control controller, which regulates the temperature, changes the heating mode based on data transmitted by 4 sensors that record temperature changes:

- outside temperature sensor;

- in room;

- at the boiler feed;

- on the return line.

Taking into account the difference in temperature readings of all controlled sensors, the control system selects the optimal operating mode of the heating unit.

Features of use

Weather-compensating automation (PA) is used in two types of boilers.

Wall

Automation is built into most of these devices by the manufacturer. They are hung on a vertical surface during installation, which is why they got the corresponding name. A medium-sized device takes up little space. Recommended for use in small private houses where it is impossible to allocate a separate room for the boiler room. Compared to the floor version, the wall version is cheaper. PA involves installing a sensor that measures outdoor temperature.

Photo 1. Wall-mounted boiler installed in the kitchen. Typically, such devices are equipped with weather-sensitive automation.

Floor

The use of a floor-standing boiler is justified in a large country house. The cost of the device is higher than that of its wall-mounted counterpart, but operation is cheaper.

Rare models have a built-in controller - you will have to buy it separately. You will also need to purchase and install a lot of additional equipment: mixing units, terminals, hydraulic system. For strapping you need a place, preferably a separate room. In addition, you will need to hire a specialist for connection and debugging. The total amount will be 100 - 150 thousand rubles.

Principle of operation

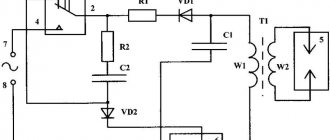

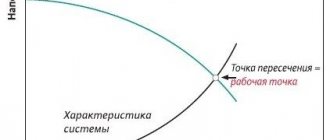

Weather-dependent automation for heating systems is controlled by a controller, the operation of which is adjusted using a special algorithm. The sequence of actions is determined by the temperature curve, which reflects the dependence of the heating of the coolant on the temperature outside.

The amplitude of the calculated curve has two starting points. The first such point corresponds to a temperature of 20 degrees on all 4 temperature sensors. The second is determined by the readings of the sensor at the boiler supply; the 80 degree mark corresponds to the maximum power of the unit.

The difference in the curve between the base points depends on the reliability of the room’s thermal insulation. Thus, the better the building is insulated, the lower the rate of change in internal temperature, which means the curve will have a smoother amplitude.

The controller program contains several initial algorithms, from which it is recommended to choose the one that best suits the environmental conditions. Subsequently, a mode is activated that allows you to draw your own conclusions (learning mode) based on the data obtained at the end of the day and at the end of the week. Thus, after some time the system fully adapts to the local conditions that are inherent in every house, for example a brick one.

It is important to remember that the sensor that reflects the internal temperature of the room must be installed in a neutral location. Its readings should not be affected by drafts or exposed to sunlight. Otherwise, the readings of the internal temperature of the room will not correspond to reality, and the principle of operation of the automatic system will be based on incorrect information.

Temperature sensors for radiators

Sometimes one temperature sensor has several heating radiators. This is influenced, first of all, by the installation diagram. But it is much more common to mount the regulator on each heating device separately.

Many owners install a system familiar to many, called the “Leningradka”, the principle of which is to use one pipe encircling the house or one floor, which has a rather impressive diameter, and heating radiators or convectors are built in parallel to it. It is worth noting that in order to adjust the heating temperature, you can use not only standard devices. Common mechanisms of this type include:

- thermostatic head. It is an automatic sensor that monitors the temperature of the coolant in the battery. The principle of its operation is as follows: during the heating process, liquid and gaseous substances expand (for more details: “Which thermal head for a heating radiator is better - selection and installation”). This, as a consequence, leads to the fact that the heated product squeezes out a special rod, thereby blocking the access of the coolant;

- devices called chokes are no less often used. They are special screw-type taps, with which you can manually regulate the flow of coolant. Their cost is more affordable, and in addition, they can be used to control two-pipe heating systems;

- The least expensive and simplest mechanism to help regulate temperature is a traditional valve. Of course, in this case, only modern models should be used, and not outdated screw devices, since in old mechanisms valves very often come off, and there is also a risk of oil seals leaking. The situation is completely different with ball valves: even in a half-open position, they function reliably and efficiently over a long period of time.

In order for the installation of temperature controllers to be as convenient as possible, many experts recommend first studying various photos of these devices and detailed videos on their correct connection.

Example of heating temperature controllers in the video:

Advantages and disadvantages

Weather-dependent automation allows its users to avoid excessive heating of the room during warm periods and to avoid loading heating boilers in advance during cold periods.

The presented system has a number of advantages that allow heating to operate in optimal mode:

- sudden changes in temperature outside do not affect the microclimate of the room;

- maximum economical fuel consumption;

- smooth transitions between operating modes eliminate long-term loads on heating equipment;

- the amount of harmful emissions into the chimney is reduced;

- the service life of the heating system increases.

Installing automatic heating control will allow you to significantly save money, get maximum comfort and not be distracted by independently adjusting heating modes.

However, the disadvantages of this equipment should also be taken into account:

- High price.

- The placement of the sensor indoors seriously affects the overall operation of the system.

- Installation, configuration and repair of automation is possible only with the help of qualified specialists.

Weather-dependent automation perfectly controls heating in high-rise buildings, whose facades are exposed to all winds. Application in the private sector largely depends on environmental conditions.

Automation of the process of regulating the heat supply of MKD

The existing system of transportation and distribution of thermal energy is far from ideal. Its imperfection is especially acute during the off-season. It often happens that the weather outside is consistently warm, and the radiators stubbornly heat the already warm rooms. This situation is due to the fact that the only link in the chain of enterprises, communications and coolant supply devices that has the ability to influence the heat supply process is the boiler house or thermal power plant. But even they do not have the possibility of flexible regulation; they do not have mechanisms that allow them to instantly respond to weather changes.

The ideal option for regulating the heat supply in an apartment building would be a project in which, when implemented, it becomes possible to regulate the temperature of each room separately. This solution allows for individual metering of heat supply, which in turn allows residents not to pay for heat that simply escapes through open vents.

Individual metering of heat supply allows the consumer to independently regulate the amount of thermal energy consumed . This can be achieved by setting the temperature of rooms that are not in use lower, raising it as needed.

When does weather-compensating automation come in handy?

In private houses, if they are of medium or smaller size, the need to install this automation mainly arises when the owners are absent from the house for a long time. In other cases, adjustments are not difficult to make manually or using gadgets.

A different situation arises in large cottages or mansions, as well as in public buildings with a large area. Here, organizing automatic heating control using automation for boilers becomes a direct necessity.

Based on the results of a control test that checked the operation of the new system, it was found that fuel consumption for heating in a high-rise apartment building with a large number of glazed surfaces was reduced by 2 times.

In addition, weather-compensated automation produced high efficiency in a residential central heating boiler room configured to serve a number of buildings.

Single-pipe heat supply option MKD

The simplest option for heating an apartment building is a single-pipe system. The coolant is supplied from the bottom up, it fills the radiators, gives off heat and moves to the next consumer. This system has a number of significant disadvantages. One of the main ones is significant heat loss during transportation. The last consumers in the chain receive a slightly heated liquid.

In addition, a single-pipe system makes it almost impossible to regulate the heat supply in an apartment building. It is not possible to install valves or automatic control devices on the supply pipelines, since a decrease in the flow rate within any of them will affect the entire system. You also need to remember about possible emergency situations. A single-pipe system does not allow the replacement of one of its components without completely draining the system. A minor breakdown can result in a stop in the heat supply to all consumers.

Characteristics of automatic heating system control systems

At the moment, there is a wide range of heating automatics on the market. Despite the differences in design, functionality and parameters, all automation is subject to the same requirements, the fulfillment of which is mandatory.

The first and most important requirement is reliable and effective feedback, which is achieved through the presence of highly sensitive thermal sensors. When the automation is operating, minimal temperature differences will still appear, and the task of the sensors is to prevent a noticeable difference.

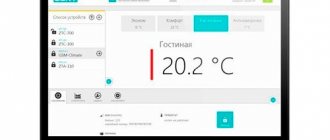

In addition, an important parameter when choosing automation for heating is a clear and pleasant interface, which will allow you to make adjustments without any effort or knowledge (more details: “

Adjusting the heating system - details from practice

"). You will have to pay for such simplicity, since even the simplest control panel hides a complex controller for the heating system. The reliability of these devices is very high, but the cost corresponds to the high quality.

All devices must be safe and reliable - this is a prerequisite. Installation of such systems is usually carried out by qualified specialists, but there are also models that you can install yourself.