The electronic thermostat can be programmed in any order.

Any modern heating boiler, regardless of the type of energy carrier used, must meet a number of requirements. This includes functionality, ergonomics, safety and the last quality, the relevance of which is growing every year - energy efficiency. When choosing a boiler, the buyer thinks about how much the equipment will help save his budget. Reducing energy costs for heating a house will allow not only the high efficiency of the heating element, but also additional components of the heating system. This is a thermostat and thermostat for an electric heating boiler, which control the operation of the boiler depending on the ambient temperature.

In addition, when it comes to electrical equipment, you need to think about purchasing a voltage stabilizer. It will not affect the energy efficiency of the heating device, but will also help save your budget by maintaining the operation of the electric boiler during power surges in the network.

Electric boiler for heating a house

Advantages of installing an electric central heater:

- The use of other types of fuel in parallel with electricity.

- Possibility to integrate into an existing heating system.

- Saving on heaters.

- Simplicity of design and maintainability.

- Savings with differentiated heating tariffs.

- Low cost of equipment , possibility of remote control.

- Availability of technology, the ability to assemble the heater with your own hands.

- Possibility of installation in the heating system of a private house and utility rooms.

- The optimal solution if alternative energy sources are available: a solar panel or a wind generator.

There are various methods for implementing an electric boiler, but each one contains three components:

- Heater.

- Frame.

- Management and Security Group.

Differences in electric boilers are usually variations of these parameters and options.

Safety valve

Modern automatic models of solid fuel boilers include ignition control, an ignition system, and even a continuous fuel supply.

Source oteple.com

For self-ignition, a special electric incandescent element is provided, which is turned on after the pallets are fed into the auger container or burner. The signal to turn off the electric ignition is a stable flame, which is detected by the photosensor and transmitted to the controller in the form of a pulse.

During operation, granules from the hopper are fed into the auger. The volume of the latter allows you to provide heat to the entire room for several days without additional human intervention.

New models of solid fuel boilers are equipped with devices for controlling the heating system, as well as newer safety devices, one of which is a safety valve.

This device is needed to discharge water from the boiler tank if the coolant overheats. This is done to protect the casing from destruction and stabilize pressure.

Additionally, the unit may include an overheating sensor, which will signal if the temperature is exceeded at the initial stage.

Source graviterm.com.ua

Let's summarize. Modern solid fuel boilers are equipped with the best automation: a draft control sensor, pressure recorders, a fan, a smoke exhauster, water level sensors in the jacket, level sensors for pellets or coal in a container, and a circular pump. All these devices are connected to a controller, thanks to which control and notification of emergency situations are carried out. The most sophisticated models can have a remote control function - the automation of a solid fuel boiler is controlled via mobile applications and the Internet.

How does it work

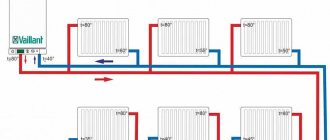

The device is connected to a liquid heating system . The system is filled with coolant, which is heated by a heating element. A pump or gravity constantly forces the fluid to circulate.

The liquid transfers heat to the room through heat exchangers - batteries. The cold liquid is supplied again to the boiler.

along the highway or at certain points in the room. They send a signal to the controller, which reduces or increases the voltage or turns off the boiler.

The control of an electric boiler, depending on the connection diagram and the components used, can be stepped or smooth.

The selection of heater power depends on the size of the heater tank and the power of the radiators. Installing too powerful heaters can lead to boiling of the coolant and rupture of the system.

Attention! To increase safety, use a limit mechanical thermostat with a relay , which will prevent the liquid from boiling if the controller electronics fail.

How to choose a room thermostat for an electric boiler

Mounting and connection method

According to the technique of fastening and connecting to the electric boiler, wired and wireless devices are distinguished.

Wired thermostats can still be installed in any room, can have any functionality, but require a wired connection directly to the electric boiler. Their cost is lower, and in most cases the connection wire is included.

Wireless temperature controllers consist of a control panel and a radio signal receiver connected to the electric boiler by wire. The advantages are obvious: when placing the thermostat in a room remote from the installation site of the electric boiler, there is no need to lay an additional electrical wire through the entire house.

According to practice, a radio signal with a frequency of 433 or 868 MHz intended for household appliances does not affect other electronics in the house and is transmitted without problems through any walls at a distance of 20 and even 30 meters. The disadvantage is the need for additional power for the control panel, usually 2 standard AA batteries.

Functionality

Standard simple models only have an on/off switch and a rotator (or “+” “-“ buttons) to set the temperature.

For significant savings, it is better to choose a more expensive programmable thermostat, which will pay for itself in the first few months of use. With its help, you can reduce the room temperature to 15-16°C when everyone has gone to work, or to 18-19°C at night. It is enough to set up several electric boiler operating patterns once, the duration of which can range from 8 hours to 7 days.

In addition, programmable models, in addition to the built-in temperature sensor, are often equipped with additional remote ones, including those for heated floors.

Availability of Wi-Fi or GSM module

The built-in GSM module allows you to receive notifications via SMS messages about the operation of the heating system or about an emergency situation that has occurred, which you can immediately solve. This way the coolant will not freeze during a long absence of the owners.

The presence of Wi-Fi allows you to control the operation of the electric boiler through an application on your smartphone. Also, via a Wi-Fi network, you can connect a thermostat to a smart home system or connect several additional temperature sensors (including underfloor heating). The presence of Wi-Fi and GSM does not affect the efficiency and economy of the heating system, but increases the comfort of its use.

Protection and safety

Budget and even some models of electric boilers in the mid-price segment may lack basic safety elements such as overheating protection, frost prevention mode, or protection against stopping the circulation pump. However, all these elements are found even in many simple models of thermostats in the price range of 1,000-1,500 rubles.

Such security systems especially should not be neglected when temporarily living in a house, when the owners are absent for days or weeks, but the heating system maintains a positive temperature.

Network connection and control unit

To connect to the network securely you will need:

- Wires of the appropriate section . The cross-section is calculated based on power and length; for a powerful system, it is better to connect a power cable and 380 volts.

- Grounding : metal parts should be connected to a ground loop.

- A separate automatic circuit breaker will turn off the consumer if the protective tube becomes rusty and “pierces” into the house.

To regulate the current, purchase:

- Controller or control unit.

- Ammeter.

- GPS module.

- Mechanical valve that turns off the electricity when the liquid boils in the boiler (reliable mechanism, operates on pressure).

Why does an electric boiler need a thermostat?

There are many types of products, some types of design are simple, while others allow you to configure more than 50 parameters for a comfortable stay in a house or apartment.

There are models that allow you to program equipment performance for one day or even a whole week; the main functions include:

- Temperature maintenance and control.

- Protection against freezing or overheating of the device.

- Saving resources.

- Remote control of the boiler.

A small device is capable of adjusting all functions of electrical equipment as accurately as possible, because comfort in each room is an important indicator for any owner.

Managing such devices is quite simple; modern models can connect to the phone using special programs, which allows manipulations to be carried out remotely.

Schemes of homemade electric boilers

A home craftsman can easily assemble an electric heater in his workshop . There are a number of schemes and solutions that are optimal for various conditions.

From a cast iron battery with TEN

If you plan to heat a small insulated room (house, garage, isolated room), a cheap option would be to convert a cast-iron battery into an electric heater. This option acts as an electric boiler and heat exchanger.

For assembly you will need:

- Cast iron battery. The length of the battery is selected based on the heat loss of the room. One standard fin is capable of releasing 0.1-0.2 kW/h.

The heating element must be liquid, with the possibility of a sealed threaded connection. The length of the heater, if possible, is the length of the battery - then you will achieve maximum efficiency .

The power of the heating element is less than the heat transfer capability of the battery - you don’t have to use a regulator.

- Power regulator . PWM can handle a small amount of power; if there are several batteries, you can purchase a multi-band controller.

- Electrical wires of the required cross-section.

The heating element is installed in the bottom plug of the battery. an additional expansion tank is cut into the plug above the heating element which also serves as a “watering can” for filling and venting the battery.

If the battery will serve as an electric boiler, the cold water supply is connected to the opposite side of the battery at the bottom, and the cold water supply is connected to the top of the battery.

What tools will you need?

To assemble homemade electric heating and encounter a minimum of difficulties, you must have high-quality tools at your disposal.

To work you will need:

Electric boiler on heating elements

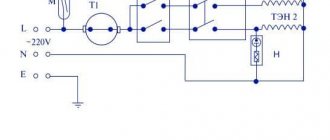

The do-it-yourself electric boiler circuit with a heater is the easiest to implement and has been known for quite a long time.

Operating principle of a heating element boiler

The design of all household appliances in which heating elements (heating elements) are installed is the same. When the power is turned on, voltage is applied to the heating element, which gradually heats up and transfers thermal energy to the liquid located around it.

The advantages of such devices:

- a wide range of heating elements of various shapes and power;

- Possibility of use in any heating system with liquid coolants;

- insulation is installed on the boiler body, so that voltage is supplied exclusively to the heating element;

- do not require complex maintenance;

- The heating level is very easy to control, even with a minimal set of automatic controls.

Among the disadvantages of a homemade electric boiler of this type are:

- “gluttony” in electricity consumption, since heating 10 m2 of area requires 1 kW of power;

- impurities in the coolant accumulate on the heating element in the form of scale, so it needs to be cleaned approximately once a year;

- The heating element can only function in the presence of liquid; it is recommended to install an idle speed sensor with it.

Automation for a solid fuel boiler using improvised means

A thermostat, which is used as an automatic device for regulating the operation of the heating system, can be purchased at any electrical goods retail chain. The device will have a heat removal plate on the back, which will need to be pressed against the bare part of the boiler.

Inside the device there will be three contacts - normally closed, normally open and common. While rotating the handle, you can change the position of these contacts. Therefore, next you need to set the handle to the minimum mark, and then make the connection to the open contacts as follows:

- A phase must be connected to the common contact.

- One wire from the turbine is connected to the open one.

- A direct zero is connected to the second wire from the turbine.

Source hyperauto.ru

I recommend the following video, in which the author makes automation for a solid fuel boiler:

The procedure for assembling a boiler with heating elements with its own rivers

Before you make an electric boiler with your own hands, you should make sure that you have a reliable power supply line. Only equipment with a power of no more than 6 kW can be connected to ordinary networks with a voltage of 220 V and a frequency of 50 Hz. If a more powerful boiler is required, it needs a three-phase wiring and a separate input.

So, we begin assembling a homemade electric heating boiler from a pipe with a cross-section of 159 mm and a wall thickness of 10 mm. This pipe will serve as the boiler body. It will require either a factory-made hemisphere with a cross-section of 159 mm and a thickness of 10 mm, or sheet metal with a thickness of 8 mm or more of a similar section.

The boiler roof, into which the heating elements will subsequently be embedded, can be made from an 8 mm thick channel.

We cut a ¾-inch coupling into the boiler dome. We will screw the drain valve into this coupling. In addition, you will need 2 pipes with a cross-section of 1 inch for inflow and return. The threads on the pipes can be made both internal and external. It all depends on which one you are more comfortable working with.

To relieve excess pressure, you need to prepare a pipe for inserting the bypass channel. You will also need 3 adapters, each of which will have a heating element for the electric boiler screwed into it. Another adapter will be needed for the temperature sensor. In addition, you will need holders for automation.

Please note that it is advisable to cut the threads on the pipes and adapters immediately.

Prepared pipes with threads, the same as on heating elements, must be immediately screwed into the adapters. This is necessary so that the threads are not damaged during welding to the arch. To mark the insertion points of the heating elements, the outer diameter of the pipe must be divided into 6 equal sectors according to the radius size. Then we draw three identical sectors strictly at an angle of 120°.

The next step is to start cutting. Having finished with the markings, using a plasma cutter we cut out holes for the pipes for the heating elements. They should be cut only along the outer contour. With all other pipes this is not of fundamental importance.

Assembling a heating boiler on electrodes

Devices of this type have become actively used only in the last 10-15 years. These are more technologically advanced devices compared to heating elements.

Design

In electronic electric boilers, the liquid plays the role of a heating element. A self-assembled electric boiler of this type is a metal casing, inside of which there is an insulated steel electrode.

0 is supplied to the housing, and phase is supplied to the electrode. When voltage is applied, water ions begin to vibrate with a frequency of 50 hertz. In this case, the liquid gradually heats up. Due to this property, such boilers are also called ion boilers.

The dimensions of electrode boilers are small. They can be made from a pipe with a cross-section of up to 320 mm and a length of up to 60 cm. However, an electric boiler for heating a house with your own hands can be made much smaller.

- small dimensions, thanks to which the ion boiler can be placed even in a small apartment;

- the absence of the so-called “dry running”, which guarantees the serviceability of the boiler, since without liquid inside it will not work;

- resistance to voltage surges;

- high heating and cooling speed, which means ease of adjustment;

- efficiency in energy consumption compared to devices using heating elements.

Among the disadvantages of such boilers are the following:

- An important condition for the effective functioning of an electrode boiler is the level of thermal conductivity and the quality of the coolant;

- the device must be reliably grounded, since there is a high risk of electric shock;

- It is important to exclude the possibility of air getting inside the system, otherwise the electrodes will become unusable due to corrosion.

Designation on electrical circuits

The transistor has an accepted designation: “VT” or “Q”. After the letters you need to indicate the position index. For example, VT 2. On old drawings you can find symbols: “T”, “PP” or “PT”, which are no longer used. The transistor is drawn in the form of certain segments indicating the electrode contacts. Sometimes they are circled. The direction of the electric current in the emitter area is indicated by a special arrow.

Scheme of operation of the simplest radio element

Based on their operating principle and structure, the following semiconductor triodes are distinguished:

- Field type;

- Bipolar;

- Combined.

They all have similar functionality and differ in operating technology.

Field

Such triodes are also called unipolar, because of their electrical properties - they flow current of only one polarity. This type is also divided into several types according to its structure and type of adjustment:

- Transistors with PN control transition;

- Elements with an insulated shutter;

- The same transistors of a different structure (metal-dielectric-conductor).

Important! An insulated gate has one distinctive feature - the presence of a dielectric layer between it and the channel. Diagram of an element with an insulated gate

Diagram of an element with an insulated gate

Another feature of field-effect transistors is low power consumption. For example, such an element can function for more than one year on one battery. Field radio elements are quite independent: they consume extremely little electricity. Such a device can operate for years on a AA battery or a small battery. This is what led to their widespread use in electrical circuits and devices.

Electron-hole transition

Bipolar

These elements got their name because they are capable of passing plus and minus electric charges through one passage channel. They also have low input impedance. Such devices work as signal amplifiers and switches. Thanks to them, you can connect a fairly strong load to the electrical circuit and reduce the effect of its resistance. Bipolars are the most popular active-type semiconductor devices.

The principle of operation of a bipolar transistor in a circuit

Combined

Combined elements are invented in order to achieve the required electrical parameters using one discrete state. They are:

- Bipolar with resistors embedded in their circuit;

- Two triodes of one or more structure structures in a single part;

- Lambda diodes - a combination of two field control triodes that create resistance with a minus sign;

- Elements in which field components control bipolar ones.

Combination transistor

Instructions for assembling a homemade electrode boiler

As a body for an electric heating boiler with our own hands, we use a pipe with an internal cross-section of about 50 mm and a length of 40 cm. In addition, you will need a solid rod with a diameter of 20 mm and a length of 30 cm, as well as two adapters with cut internal threads. At the end of the rod we drill a blind hole with a thread for a Ø10 mm bolt.

We prepare the pipes. We will weld 1 at the end of the pipe, and the other at the side. To ensure that the side pipe fits perfectly to the pipe, it is trimmed with a grinder and then sanded with a round file.

We cut holes for the pipes. If you don’t have a cutter, you can drill many small holes around the circumference. The work is brought to perfection with a needle file and a round file. The hole for the side pipe must be located 10-15 mm from the edge of the pipe.

The next step is to weld the pipes to the pipe. To prevent them from being led away, they first make spot welding in several places, and then apply a continuous seam.

We prepare the platform for the electric boiler. To do this, you can take a sheet of fiberglass 2 cm thick and cut a piece of 120x120 mm using a hacksaw. Then in this platform you need to drill one hole in the center, and four around the perimeter. The cross-section of the holes should be 10-12 mm.

Fastenings of the boiler body will be passed through the holes along the perimeter, and the central hole is intended for fixing the steel electrode.

We proceed to fixing the casing for the boiler to the platform. To ensure a secure fit, four Ø12 mm nuts can be welded on the body on 4 sides. Bolts Ø10 mm will easily pass through them.

Working principle of electric induction boiler

If we omit the details, then the operation of an induction boiler is based on heating the coolant through a magnetic field.

Among the advantages of such units:

- high efficiency;

- safety;

- possibility of using any coolant;

- no scale.

Disadvantages can be considered:

- high cost of factory boilers;

- complexity of the structure of the automatic control unit. Without preparation it will be difficult to assemble it.

Instructions for assembling a homemade induction boiler

It is worth noting that often the instructions on how to make an induction-type electric boiler are so complex and contain such labor-intensive drawings that self-assembly of the equipment looks rather doubtful. However, we found a non-standard solution.

Before you make an electric boiler for heating yourself, you will need to purchase an induction furnace with a power of 2.4 kW and 3 meters of profiled pipes Ø25x50 mm with walls 2.5 mm thick.

If we consider how this design will work, then first we assemble a flat container from the profile - liquid will move along it. And then we fix the induction stove to the pipe and connect it to the network. Everything together will look something like a saucepan on the stove.

Pipe cutting must be done as accurately as possible. You will need several 400 mm pieces, carefully cleaned of burrs at the ends.

Since the liquid inside such a boiler will move like a snake, it is advisable to take an even number of pieces of pipe so that the inlet and outlet holes are located on the same side - this makes it more convenient to connect them to the heating circuit.

Next, you need to cut the connecting holes, placing them strictly opposite each other. For convenience, you can first drill 2 holes along the edges with a Ø10 mm drill, and use a grinder to cut a gap between them.

Since the profile pipes are not perfectly straight, they must first be joined with blunt edges to sharp ones and numbered so as not to be confused later.

At the next stage, the joints between the pipes need to be welded. We lay the structure on a flat surface, tighten it with a clamp and weld it. First we do spot welding so that the structure does not move, and then we make permanent seams.

Now we need to close the end part of our container. For this we use a steel strip cut from profiled pipes. We perform welding using a similar method - first spot welding and then complete welding.

We also weld the strip on the opposite side, not forgetting to install the inlet and return pipes on the outer pipes. To ensure maximum contact area between the container and the stove, all seams must be thoroughly cleaned.

So that our boiler can be hung on the wall, 2 corners need to be welded on its back, in which the induction stove will be placed, as well as loops for hanging.

The last stage of work is painting. You can use heat-resistant paint. This completes the assembly work. You can hang the boiler and connect it to the heating and electrical network.

When purchasing an induction furnace, make sure that it is designed for continuous operation. Otherwise, the system will need to be restarted every 2 hours.

Results

Each of the listed models is fully functional and reliable. Everyone will make their own choice in favor of any of them. The main thing is to pay attention to the work and, in case of difficulties, consult with knowledgeable people.

Need to know before assembly

The design includes mechanisms to protect people and wiring from overload or short circuit. as well as a counter. The cable goes from the power line to the house to the electrical panel and all the electrical groups of the house are routed from it.

In fact, the correct name for this device is an input distribution device (IDU). But according to the law, you must divide this unit into two and one of them will be input, and the second distribution.

The input device is usually installed on an electrical pole and is an electrical panel. in which there is a window made for the convenience of taking readings. There is an electricity meter inside. general RCD. input circuit breaker. arresters (they are rarely installed), elements for overvoltage protection. This design should be installed at a height of no more than 2 meters.

A cable is led from the input panel to the distribution installation. In private homes, the use of devices and protective shutdown devices is implied. To save space in the switchboard, differential devices are installed, which include a circuit breaker and an RCD.

The material from which the house is made, as well as where the shield itself is located, determines which of its options will be chosen.

Metal mounted electrical panels are used in wooden houses, and in stone houses, where it is drier, you can install a plastic box or a built-in panel.

The place for installing one single-phase circuit breaker is called a module. Each shield has a different number of modules. therefore, it is necessary to know what and how many devices will be installed in the panel.

The distribution block should be installed in a safe place, preferably in a separate nook.