Polystyrene foam (expanded polystyrene) is used in repair and construction. It is environmentally friendly and is used for thermal insulation. Properly selected adhesive for polystyrene foam will reliably bond it to any surface and extend the service life of the insulating structure.

Even a beginner can work with glue at home. Polystyrene foam can be glued to metal, wood, concrete, plastic, and connected to each other. Often attached to the ceiling in the form of ceiling skirting boards and tiles.

Requirements

Expanded polystyrene (polystyrene) is a material that can be destroyed by solvents and other aggressive substances. Therefore, the composition should not contain:

- ketone solvents;

- acetone;

- nitrogen compounds (nitromethane, nitrobenzene);

- chlorine derivatives;

- gasoline, white spirit, kerosene;

- alcohol and ether components.

The scope of application must also be taken into account: for external or internal work. Outdoors and for facades you will need frost-resistant adhesive.

The packaging of each composition contains instructions for use. It indicates which substrates can be glued.

Features of the adhesive composition

The use of solvents always poses a safety risk, so it is important to take all precautions. Gasoline and acetone are flammable materials and are easily flammable. Work is carried out away from sources of fire; smoking nearby is strictly prohibited! It is advisable to work in the fresh air or in a well-ventilated room

Otherwise, there is a risk of inhaling solvent vapors

Work is carried out away from sources of fire; smoking nearby is strictly prohibited! It is advisable to work in the fresh air or in a well-ventilated room. Otherwise, there is a risk of inhaling solvent vapors.

You can also use glue as a protective film on wood products and other materials. You will have to make the solution more liquid, without adding too much foam to it. It is not worth preparing a large portion of the product, it instantly hardens and loses its properties. The drying speed depends on the thickness of the adhesive layer: for quick gluing, apply the mass with a thin stroke.

Types and brands of adhesives

For gluing are used:

- dry (powder, plaster-adhesive) and ready-made liquid mixtures;

- liquid Nails;

- adhesive foam (polyurethane);

- sealants.

Dry (powder)

These are plaster and adhesive mixtures. Packaged in large bags up to 30 kg per package. To prepare, the powder is diluted with water in the proportions specified in the instructions. The composition is based on the inclusion of cement, gypsum and polymer components. Externally, the powder is similar to putty or plaster, but the gluing result is more durable.

Suitable for indoor and outdoor use. Adhere well to concrete, wood and other substrates. Used as a seal for cracks, joints and seams. Consumption per 1 m2 ranges from one and a half to two kilograms.

For a reliable result, the walls are processed before gluing: they are cleaned of dirt, dust, dried and primed.

When diluting the powder with water, the liquid is added gradually in small quantities, and the water itself is constantly stirred. This will prevent lumps from forming. Application is possible in a continuous layer over the entire surface or in separate lines with a small distance between each.

Powder adhesives:

- Ceresit ST-83;

- Knauf Perlfix;

- Avangard-K;

- Primus;

- Volma";

- Armierungs-Gewebekleber.

Avangard-K allows gluing not only to concrete, but also to brick walls. Packaging 25 kg in one package. There is a frost-resistant option for the street.

Another Bergauf ISOFIX cement-sand mixture, which contains fillers and special additives, plasticizers. Apply a layer up to 3 mm thick. After mixing the solution, it can be used for one and a half hours, and the position of the EPS can be adjusted for a quarter of an hour. Can be used indoors and outdoors.

Polyurethane adhesive foam

Polyurethane adhesive in the form of foam (foam glue) connects all types of plastic, including polystyrene foam, with any substrate (OSB, metal, concrete, plaster, wood, aerated concrete and foam blocks). You can glue the foam together.

There are specialized formulations on the market. They are marked with an inscription on the packaging (for polystyrene foam).

The gluing plane is not important. Both horizontal and vertical surfaces are glued. The connection holds firmly both indoors and outdoors.

Installation is possible only with a construction gun, on which a cylinder is placed on top of the legs. The application technology is shown in the figure.

It is convenient to use foam adhesive. The work is done quickly. Has low consumption per sq. m. The cylinder is enough for 10-15 m2. Foam adhesives are resistant to moisture, do not freeze, and have high adhesion.

There is no need to prepare, the cylinder is ready to use. The maximum result of the coupling is evident after half an hour, while pressing the parts is enough for only 20 seconds.

Popular brands:

- Tytan Styro 753;

- Penosil;

- Ceresit CT-84 Express.

PVA

PVA is cheap, so it is often chosen for gluing extruded polystyrene foam (EPS). The reliability of the adhesion is not the highest, so it is more suitable for gluing crafts. It is better to give preference to specialized mixtures.

PVA fills voids in walls well. Additionally, foam plates are attached to dowels. Usually PVA is applied in two layers.

Suitable polyvinyl acetate adhesives include Moment Stolyar and PVA-MB.

- Moment Joiner. Universal composition for repair. Supplied in packages of different volumes, from 100 g to 30 kg. The drying time is fast and the seam is reliable. It does not destroy the structure of polystyrene.

- PVA-MB. The composition contains special plasticizers that improve the quality of adhesion. The hardening time of the seam is longer than that of conventional PVA.

Polyurethane foam

An effective composition, but it has another purpose - sealing seams, cracks, strengthening concrete structures.

If you glue with polyurethane foam, the following consequences may occur:

- the foam after complete drying increases in volume, which can damage the foam and deform the entire structure;

- Foam can increase in volume in different ways, so voids form in some places and the thermal insulation properties decrease.

Polyurethane foam has a high consumption per square meter. m of surface, which increases the cost of gluing.

Recommendations for use:

- make sure that the foam is suitable for gluing foam and does not destroy it;

- install the polystyrene itself with a different composition;

- seal the joints with polyurethane foam;

- the foam dries quickly, so you need to work in the same way;

- Reducing consumption is possible with a glue gun.

Liquid Nails

They have a high price, but the gluing result is very high quality. The best choice would be specialized polyurethane adhesives.

Liquid nails have an optimal balance of qualities (ease of use, service life, adhesion). Polystyrene foam attaches perfectly to polystyrene foam, metal, plastic, concrete, wood, and other materials.

Professionals recommend gluing metal using a combination of liquid nails and polyurethane mixtures.

Increasing adhesion to the surface is achieved by preparing it: cleaning, degreasing, priming.

the high price causes the use of nails only on small bases.

The most popular composition is “Moment Montage”.

Effective products for bonding polystyrene foam

There are many different products that can be used to bond polystyrene foam:

- One-component polyurethane adhesive that does not damage the material;

- Dry adhesives that require dilution in warm water and must be warmed before use;

- Polyurethane foam. It is used not only for sealing holes, but also for gluing materials;

- Liquid foam;

- The most popular glue in the former Soviet Union is PVA. If you buy it, then the question “how to glue the foam to the plane?” will not even arise.

- Hot melt adhesive. To use it, you must additionally purchase a heat gun;

- Two-component compounds based on epoxy resins;

- Compositions containing acrylic or bitumen.

There are many types of glue for working with the material. The choice should be based on price and availability of the formulation. Before choosing a specific brand, read reviews and ratings from builders and people who have used the substance.

A glue gun can be used for precise application of a solution, for example, when making crafts or securing small parts. Important: Only low temperature models are suitable. Expanded polystyrene is sensitive to high temperatures and may melt. Therefore, the colder the glue melts, the better. This method is suitable if you need to choose how to glue the foam element to iron, ceramic, brick, etc.

Description of brands

Among the highest quality brands:

- Ceresit Ct 83 Strong Fix;

- Ceresit Express Ct 84;

- Tytan Styro 753 Gun;

- Knauf Klebespachtel;

- Prospectors Teploizol;

- TechnoNIKOL Professional;

- Penoplex Fastfix;

- Bitumast.

Ceresit CT 83

Ceresit ST 83 brand adhesive is very durable, can withstand heavy loads, and has high adhesion. The mixture is vapor-permeable, so moisture does not linger in the room where the heat-insulating boards were attached with the plaster-adhesive mixture. Does not ignite when exposed to fire. The composition is used to attach heavy slabs of large thickness (up to 20 cm) to the wall outside the house.

You can work with the ST 83 brand at zero temperatures, but then the powder is diluted in heated water to +30 °C.

Advantages:

- environmental friendliness;

- low consumption;

- vapor permeability;

- speed of preparation.

Flaws:

- price;

- inadmissibility of gluing on other paints and varnishes;

- sticker on concrete only three months after it is poured;

- You can mix a good solution without lumps only with a mixer or a drill with a mixing attachment at 400-800 rpm.

Ceresit CT 84

This is polyurethane foam, the basis of the composition is polyurethane and flammable gas. ST 84 – frost-resistant glue. Used at sub-zero temperatures down to -10 °C. In cold weather, the composition hardens several times longer, up to 7-10 hours. While in warm weather, hardening takes only 2 hours.

ST 84 is applied first along the perimeter of the heat-insulating sheet, then diagonally. Presses against the surface. Exposed mixture residues can only be removed with a solvent.

Advantages:

- absence of freons;

- moisture and water resistance;

- consumption;

- simplicity and speed of installation.

Flaws:

- poor adhesion to paint and varnish coatings;

- mandatory fastening with dowels;

- Before applying to foam blocks, the latter require priming.

Tytan Styro 753 Gun

Titan Styro foam in 750 g cans. Application requires a construction gun, which speeds up installation.

The foam layer is no more than 5 mm, this is a drawback, because outside the house such fastening is unreliable. Additionally, fastening with dowels is required.

Bonds EPS sheets to brick, concrete, mastic, plaster and cement bases.

Advantages:

- economical consumption;

- the foam is ready to use, does not require preparation;

- simplicity and speed of application (with a construction gun);

- good adhesion to metal, concrete, brick, plastic and wooden surfaces.

Flaws:

- price;

- requires additional fastening with dowels;

- operation only at t °C above zero.

Knauf Klebespachtel

Powder that is diluted with water. Packaging: 25 kg. For interior and exterior work.

Application is possible by machine using G4 and Monojet pumps. This significantly speeds up coverage of large areas.

Suitable for EPPS.

Advantages:

- Can be used for reinforcement;

- setting time – 1 hour;

- the presence of a machine application method;

- operating temperature range.

Flaws:

- consumption;

- packaging is heavy, inconvenient for transportation;

- takes a long time to apply by hand.

Prospectors Teploizol

Manufacturer – Russia. Release form: powder. Fixing foam plastic to the wall outside the house. In original packaging the shelf life is up to one year.

Advantages:

- no need to pre-treat the surface;

- low consumption;

- used for reinforcement;

- After mixing, the solution is suitable for three hours.

Flaws:

- high price;

- discomfort during transportation;

- slow period of complete hardening (three days);

- operating temperature only above +10 °C.

TechnoNIKOL Professional

TechnoNIKOL Professional adhesive foam has a polyurethane-based composition. Used as a sealant. Fastens all types of polystyrene foam.

Operating temperature up to 30 degrees Celsius, but not below zero.

Advantages:

- price;

- resistance to water, moisture, fungi and mold;

- the ability to correct the position of the slabs within 20 minutes after fixing;

- high adhesion;

- Suitable for external and internal installations.

Flaws:

- installation only at positive temperatures °C;

- installation only with a construction gun;

- chem. reaction when interacting with silicone and polyethylene;

- the required humidity level is 50% for rapid hardening.

Penoplex Fastfix

Penoplex is produced in 750 g cylinders, inside of which there is foam material. Used in conjunction with a mounting gun for fastening extruded and foamed polystyrene foam. Fixation is possible on concrete, brick, ceramic surfaces, and aerated concrete blocks.

It is used both outside and indoors for insulating loggias, rooms, and roofs.

Has a light blue tint. Dries in 10 hours and withstands 100 frost cycles. Installation temperature from -10 °C to +40 °C.

Apply with a construction gun in vertical continuous strips with a distance of 5 cm between each. Press the insulation sheet after 5-7 minutes and strengthen it with dowels.

Bitumast

Resinous bitumen for extruded polystyrene foam. Half a kg of mixture is consumed per 1 m2. Bitumast dries for two days. Withstands 100 freezing cycles. The gluing temperature is only above zero, up to +30 °C.

Cannot be applied to facades or inside rooms or buildings.

Bitumen adhesive needs to be pre-diluted with water. Has good adhesion to any type of substrate. The setting time is long compared to other mixtures. The sheets will have to be pressed until the polystyrene holds on itself and does not slide off. Very high price.

Main varieties

When choosing an adhesive for splicing plywood, you must take into account the requirements for the following compositions:

- ease of use;

- viscous or semi-viscous consistency;

- fast hardening;

- absence of volatile toxic substances in the composition;

- resistance to moisture;

- presence of antiseptic properties (not affected by bacteria).

For plywood that is located indoors, any compositions can be used. For splicing materials used outdoors, synthetic glue is suitable; for moisture-resistant boards, it is based on urea resin.

Aqueous or water-dispersed

Among similar adhesive compositions, PVA is most popular. These products do not contain toxic substances or components that emit unpleasant odors. The glue gains sufficient strength within a day, but it takes 2-3 days to completely harden. Due to the fact that PVA and other similar products are water based, these products cannot be used to bond plywood sheets with a porous surface that absorbs moisture.

Carpentry

The basis of carpentry compositions are fats of animal origin: casein and albumin. Both products are available in the form of a dry mixture, which must first be diluted in water. Albumin compounds are used for hot gluing, due to which the created joint gains strength faster.

Based on urea and phenol formaldehyde

Adhesives based on this type contain natural resins that are less toxic than epoxy ones. Compositions of this type are used exclusively for joining wooden products. Glue with such a base creates a transparent seam, so similar products are used to repair decorative elements.

Epoxy and polyurethane

The basis of such compositions are solvents containing toxic substances and emitting a pungent odor. Therefore, it is recommended to work with such products in ventilated areas or outdoors.

Epoxy adhesives are divided into one- and two-component. Compositions of the first type are immediately ready for use. Two-component products consist of an adhesive and a solvent, which must be mixed before starting work. Such compositions are used for rapid joining of various materials, including wood.

Consumption per 1m2

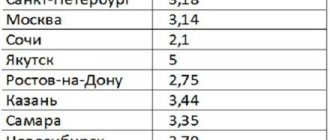

Calculation of consumption per sq. m. is needed to determine the required amount of material to purchase. It is impossible to calculate the exact amount. This is influenced by factors:

- material, its density and ability to absorb;

- consumption of a specific type and brand of mixture.

The average data is shown in the table.

| Type of composition | Consumption |

| Dry | 500 gr. / m² |

| Bituminous | 800-1000 gr. / m² |

| Polyurethane | 1 cylinder per 8-10 m² |

Working with single-part materials

Often in repair work there is a need to glue extruded polystyrene foam and ball or regular foam. For this, the same adhesive components are used, but with certain nuances:

- the glossy surface of polystyrene is treated with a needle-type roller to improve adhesion and glue is applied;

- The foam ball is covered with long-fiber paper.

Otherwise the process is identical to that described above.

VIDEO: Secrets of polyurethane foam - tricky tricks, useful tips

How to glue foam

The gluing technology depends on the installation conditions of the foam and the material to which it is attached.

To the foam

Polystyrene foam is attached to other foam plastic using the adhesives described above.

There is a specialized brand called Styroglue. It will best glue together two parts of foam plastic and other substrates. It is not as widespread on the market as other brands, but the price is not the highest.

Advantages:

- Styroglue is transparent in structure and will be invisible on light or white polystyrene;

- it dries quickly (from 20 seconds to 1 minute);

- resistant to moisture, frost, fungal formations, used indoors and outdoors.

Flaws:

- It is necessary to work with protective gloves, the glue sets quickly and is difficult to remove from your hands;

- cold affects the properties of the glue, it becomes thicker. In cold weather, keep the container in heated water.

When using PVA, it is applied to both parts/surfaces. Allow time to dry slightly, then apply another layer and squeeze the parts for a few minutes.

The parts are also fixed:

- epoxy resin with hardener;

- glue sticks and a heat gun.

The heat gun is suitable for fastening several parts of polystyrene foam into one structure. Extremely hot hot melt adhesive can burn through the material. It hardens quickly, you have to work the same way.

The method does not require professional skills. A beginner can work at home.

When attaching regular foam to extruded foam, the latter is treated with a needle roller for better adhesion.

To concrete

It can be attached to concrete without lathing. Tools and consumables you will need:

- primer mixture;

- spatula (for application);

- electric drill with a mixing attachment (for mixing the solution);

- glue.

A powder mixture is selected for gluing . It is diluted with ordinary water. The proportions are indicated in the instructions. The water in the container is mixed with a drill with a mixing attachment and powder is gradually added. If you don't have a drill, replace it with a construction mixer. The mixture must be allowed to brew so that it acquires adhesive qualities.

The effectiveness of adhesion is achieved by preparing the concrete base. The surface is thoroughly cleaned, all dirt, dust, stains are removed, and a primer is applied.

Next, apply the mass onto the foam block:

- if the walls have slight unevenness and defects, the glue is applied in continuous lines, with indentations of 2 cm made from the edges of the sheet;

- when the walls are curved more than 2 cm, apply with dotted lines (to get rid of excess air);

- the middle of the slab is also lubricated with the solution.

The sheet is then pressed tightly against the concrete wall or floor. Excess glue that appears along the edges is removed with a rag.

Builders advise fastening polystyrene slabs with dowels in each corner and in the center.

In addition to the dry mixture, you can use adhesive-sealant, liquid nails and dowels, and a polyurethane-based composition.

To metal

It will be possible to properly glue the foam to the metal if you lay burlap between them.

The metal must be clean and free of traces of corrosion (rust).

For gluing the following are used:

- adhesive sprays (aerosol, in cans);

- silicone sealants;

- polyurethane foam or polyurethane based;

- powder dry compositions;

- small areas can be glued with double-sided tape.

The best option would be polyurethane aerosol adhesive, available in cans, or foam adhesive. The foam adhesive composition is especially good when installing foam plastic on surfaces that are located at an angle or have uneven surfaces. Foam is applied pointwise (minimum 5 points). Solid strips are smeared with powder solutions.

To the tree

Polystyrene foam can be attached to plywood, boards, lining, OSB boards. Polystyrene sheets are glued to wooden bases in the same way.

The only thing is that nuances are observed due to the characteristics of the tree.

- The wood is cleaned, dirt, dust, grease stains are removed, and completely dried.

- The wood is primed in two or three layers. It is advisable to apply an antifungal primer.

- When fastening under windows, a reinforcing mesh is applied to a wooden base using a stapler.

- The cracks and empty spaces are sealed with polyurethane foam. After the foam has hardened, excess parts are removed.

- Any protrusions and irregularities are corrected.

- If the wood is varnished, it must be removed, since the composition of the varnish coating can corrode the foam.

- It is better to attach polystyrene foam to wood using anti-fungal and anti-mold additives.

The adhesive mixture is applied in strips along the sheet. Indentations of 2 cm are made from the edges. Then diagonal stripes are drawn. The sheet is pressed against the wood, and any residual glue that appears is removed with a rag.

Only for him

Specialized adhesive for polystyrene foam is made on the basis of polyurethane foam. In combination with thickening additives it is a translucent thick liquid. Most often they are used to decorate interior walls and ceilings of rooms with foam products.

Suitable for outdoor use. Frost-resistant, does not absorb moisture. Sold in polyethylene containers. The downside of the application is the difficulty of applying it to the surfaces to be bonded, especially at air temperatures close to zero. Alternatively, you can preheat the composition by placing the container in hot water.

Apply to the insulation in stripes, dots, wavy lines depending on the width of the surface to be glued. Firm pressure is required for 15-20 seconds.

IMPORTANT

To speed up the process, fasten the sheets 2-3 minutes after applying the glue. This allows you to reduce the retention time of the material and improve the quality of gluing.

General information

Characteristics of penoplex

Penoplex can also be called extruded polystyrene foam. This is a popular material in the construction market. It has high thermal insulation properties. It is widely used for insulating facades and roofs, as well as for interior work. The production of expanded polystyrene began in 1941 in the USA. It obtained its technical properties thanks to the most complex processing using extrusion.

Feedstock is placed into the reactor and subjected to high temperatures and pressure. As a result, the existing components are saturated with a gaseous component. When the pressure is released, the mass begins to expand, forming foam. At the same time, the temperature decreases, which turns the substance into a solid. The mass is passed through extruders. It becomes like multilayer plastic. Most of the extruded polystyrene foam is occupied by air, purified from water vapor and having low thermal conductivity.

High production technology makes it possible to obtain a material that does not allow gases and water vapor to pass through, even if the installation of penoplex was carried out incorrectly. Closed cells of penoplex measuring 0.1–0.2 mm are filled with liquid when exposed to moisture. The water does not pass further and remains in the pores.

Advantages and disadvantages of penoplex

Extruded polystyrene foam

EPP does not deform and serves reliably for a long time. He is not afraid of temperature changes. It does not lose its properties from – 100 to + 75 degrees. It can be installed even in the harsh North.

The antiseptic properties of polystyrene foam lie in the fact that it is not at all susceptible to rotting. Working with him is a pleasure: installation is easy. Penoplex slabs do not cause allergic reactions upon contact with it.

Penoplex

The material is light and has a small thickness from 20 to 150 mm. The price-quality ratio pleases consumers. Extruded polystyrene foam is inexpensive and can be purchased by many who decide to renovate a private home or build a new residential building.

Comparison results

But extruded polystyrene foam also has a number of disadvantages: it is susceptible to combustion, is susceptible to exposure to infrared rays, and at temperatures above + 75 degrees it releases substances harmful to human health. One of the important disadvantages of expanded polystyrene is its destruction under the influence of solvents and abrasives. Therefore, a number of requirements are imposed on adhesives for extruded polystyrene.

What kind of glue should be used for extruded polystyrene foam?

Adhesive for penoplex must have the following qualities:

- moisture resistance;

- resistance to temperature changes;

- high adhesion;

- do not emit harmful substances;

- do not be too liquid so as not to leave drips.

Prohibited components of polystyrene foam adhesive

Penoplex adhesive should not contain certain components that negatively affect the structure of the materials, corroding it.

The composition of the adhesive for extruded polystyrene foam should not include:

- solvents;

- formaldehyde and formaldehyde;

- aromatics such as benzene and toluene;

- polyester and coal tars;

- flammable substances: gasoline, kerosene, diesel fuel.

Useful tips

Recommendations from experts will help you choose the most suitable adhesive composition and glue the insulation as firmly and efficiently as possible:

- Do not buy cheap glue produced by a dubious manufacturer.

- Pay attention to quality certificates.

- The glue sold on promotion may be expired - be sure to check the numbers on the packaging.

- The mixture should be stored in a dry place in pallets and sealed. If storage conditions are violated, the technological properties of the product will suffer. If saturated with moisture, it will become unsuitable for use.

- Do not dilute the hardened mixture with water, as this will cause the surface to subsequently crack and lose the properties of the product. Any unusable material must be discarded.

- During fixation, air circulation must be ensured indoors.

- Before installing insulation on metal surfaces, it is recommended to cover them with burlap. This will make it easier to attach the slabs and improve the quality of the connection.

It is better to insulate a house in the warm months of the year, when the weather is good outside, since it is difficult to work in rain and wind.

Linoleum

It is very convenient and reliable to fix linoleum on a concrete floor with glue. The managers of the store where the flooring will be purchased will tell you how to glue linoleum to concrete. Linoleum manufacturers strongly recommend purchasing glue along with it.

Typically, linoleum is fixed to concrete using mastic. Its advantages:

- You can choose the right quality according to the type of linoleum. The fabric base of linoleum requires the use of dispersion glue, and in the absence of a base, synthetic mastic is used.

- The compositions of all adhesives have excellent characteristics in terms of waterproofing properties, strength, and water resistance.

- Resistant to environmental influences.

In addition to their composition, mastics also differ in purpose. There is a mastic for fixing that has increased stickiness and is economical in consumption, and for continuous gluing, the one that should be applied to the floor in an even layer over the entire area is suitable. The thickness of the layer depends on the brand of mastic.

Results

In our article, we talked about the advantages and disadvantages of extruded polystyrene foam, how this building material is produced, and why it is considered the most popular of insulation materials.

Together with you, we found out what extruded polystyrene foam can be glued to, what adhesive compositions to use and how to use them. We introduced you to the types of adhesive mixtures for penoplex and characterized each of them.

You learned how to install slabs to the ceiling using the example of “Fast fix” glue. Which adhesive to choose is up to you. The main thing is to take into account the rules for choosing glue for extruded polystyrene foam, the requirements for adhesive compositions, and follow the instructions for installing polystyrene foam boards.