Home » Equipment » Warm floor

A water underfloor heating system requires a boiler with a heat exchanger in which the coolant is heated. Hot water from the boiler enters the main line, which is located on the floor. Passing through the water circuit, the coolant cools down and returns again to the heat exchanger.

Galvanized, copper and plastic pipes that can withstand high temperatures are used for the main line. The water leaving the boiler has a temperature of 80 0C.

For underfloor heating, it is recommended to use PEX lines made of cross-linked polyethylene. They have unique characteristics. They are easy to lay on the subfloor. What features do PEX pipes have? How to install a water main?

Which pipes are best to use?

For floor lines, only those circuits that can withstand high temperatures are suitable.

Today on the market there is a variety of products made from the following materials: copper, metal-plastic, cross-linked polyethylene. Separately, we will talk about galvanized pipe materials.

Each type has its own characteristics and is intended for use in specific conditions.

PEX pipes made of cross-linked polyethylene

Pipes made of cross-linked polyethylene have excellent performance characteristics, which give them an undeniable advantage over other materials, and are therefore popular both for cold water supply and for installation in heated floor structures.

The material for their manufacture is polyethylene with a certain density. Stitching of products is carried out using several methods.

Depending on the production process, the pipeline is of different classes:

- PEX-a - high-density polyethylene is used in production. The production method is peroxide, which involves melting polyethylene under high temperature. After which, the resulting amorphous mixture is squeezed out through a special forming hole, this method is called extrusion.

PEX-a is a multi-layer construction, with an aluminum insert placed between the layers, which helps maintain the shape of the product. A special glue is used to connect the layers; it does not change its properties under the influence of temperature.

For your information! The product is capable of transmitting oxygen to the coolant. To eliminate penetration, manufacturers began to equip it with an EVOH protective coating on the outside - this is a layer of thin plastic (polyvinylethylene).

- PEX-b - for its production, medium-density polyethylene is taken, which is softened to a solid consistency. With this method, crosslinking is done after extrusion.

- PEX-c - the raw material in this case is also medium-density polyethylene. Crosslinking is carried out at a temperature equal to the environment, while the state of the material is solid.

Hoses made of cross-linked polyethylene are widely used in the installation of heated floors, but PEX-a is more often used, as they have good elasticity and allow laying a line with a bend of up to 5 diameters.

PEX-b is harder and therefore breaks easily. And PEX-c does not tolerate high temperatures well, and therefore is more often used for cold water. In addition, products made from this material are durable and lightweight, which is a plus when installing it yourself.

PEX-a pipes have memory - when deformed, they are able to completely restore their shape; for this they need to be heated. PEX-b does not have such properties, while PEX-c has this property reduced.

Polyethylene PE-RT

PE-RT pipes are modified; they differ from PEX in the absence of seams. A system made from such tubes is practically silent and withstands sub-zero temperatures, but although it tolerates high positive temperatures well, it does not last long.

In addition, this material is susceptible to the action of aggressive substances, and there is no structural memory. But, despite this, heat-resistant polyethylene is widely used in heated floors, as it has a reasonable price.

Metal-plastic

A metal-plastic pipe for underfloor heating is an excellent option. It is flexible and plastic, and can be bent even without heating. In addition, the material is durable, tolerates temperature changes well and is environmentally friendly.

The metal-plastic pipeline consists of several layers - cross-linked polyethylene inside, then metallized foil, and a polymer coating on the outside, which protects against mechanical damage. In this design, corrosion does not form and scale deposits do not occur. If installed correctly, the pipeline will last more than 50 years.

If we compare which is better - metal-plastic or cross-linked polyethylene for heated floors, we can note the high thermal conductivity of plastic. But at the same time, there is a high risk of the coil breaking, and since such a product does not have the ability to restore its shape, this section will have to be removed.

Metal

Metal pipes for warm water floors are available in the following types:

- Copper ones have a high cost, so they are not very popular when installing hydrofloors. In addition, laying such a pipeline is not easy; special equipment is required, and it is unlikely that it will be possible to install it yourself.

However, it is worth noting that a copper pipe is an ideal option for heated floors, as it has excellent characteristics:

- high thermal conductivity;

- durability;

- not susceptible to corrosion;

- ductility and strength.

- Stainless steel corrugated steel is a relatively new type that is well suited for heated floors, but due to its high price it is not used often. The product has a protective polymer coating, and the stainless metal is not subject to corrosion and is resistant to mechanical, chemical and temperature influences.

In addition, this model has increased flexibility; installation in the most complex patterns is possible, without the risk of creasing.

To summarize , we can say that the most popular models that are used for heated floors are a metal-plastic pipe or a cross-linked polyethylene pipe .

They have good performance characteristics and are affordable. But if financial resources allow, then it is better to use a metal (copper) pipeline; it has high thermal conductivity and durability.

Climate

Despite the fact that pipes made of metal, metal-plastic and polypropylene are presented on the construction market for heating and water supply systems, in recent years another new type of material has appeared - cross-linked polyethylene. The article will discuss what kind of material this is and what its advantages are. Instructions will also be given for installing cross-linked polyethylene with your own hands.

Content:

What are cross-linked polyethylene pipes?

The main raw material is dense polyethylene. Making pipes from it is a complex technological process. When chemical compounds are added and under the influence of high temperature, pressure, and electron irradiation, a dense raw material with a three-dimensional structure is formed. It is subsequently cross-linked in an extruder.

All this makes it possible to create a unique material that has properties inaccessible to metal and plastic.

Tip: cross-linked polyethylene itself is resistant to expansion from the inside, but the water supply inevitably consists of metal parts. Therefore, it is not worth deliberately leaving water in the heating system, at the risk of sub-zero temperatures. But they will become a safety net in case of force majeure, for example, when the heating boiler is turned off.

Important: cross-linked polyethylene pipes have low resistance to direct exposure to ultraviolet rays. Therefore, they are recommended to be used for hidden wiring or in rooms without windows.

Tip: if they are used for repairs, you first need to make sure that the pressure and temperature in the home heating system corresponds to the recommended values that are indicated for specific pipes.

Types of cross-linked polyethylene pipes

There are 2 types of cross-linked polyethylene pipes:

Important: pipes intended for heating can withstand temperatures up to +95 °C and pressure up to 10 atmospheres. But in an emergency situation, when the pressure can jump to 20 atmospheres and the temperature is 100-100 °C, they can also cope without losing their technical characteristics.

According to the method of processing the raw materials, they are divided into 4 categories with appropriate markings:

Major manufacturers of cross-linked polyethylene pipes

The cost of the pipes themselves from the most popular brands is almost the same, the only difference is in the price of fittings and components, which can reach 10-15%.

Methods for joining cross-linked polyethylene

There are 3 ways in which you can connect cross-linked polyethylene pipes.

Important: the connection method must be selected based on the pressure expected in the pipes during operation. Each of the above methods can withstand the load only within certain limits.

DIY tool for connecting cross-linked polyethylene pipes

The list is small and consists of:

Preparatory work

How to work correctly with cross-linked polyethylene

Installation of cross-linked polyethylene pipes using the compression method

Crimping of cross-linked polyethylene pipes is equally suitable for cold water supply and heating systems. If necessary, it can be easily dismantled.

Stages of work

This method is especially good if the question is how to join cross-linked polyethylene without a special press.

DIY installation of cross-linked polyethylene pipes video

Installation of cross-linked polyethylene pipes using press fittings

This non-compressive method guarantees a seamless and highly durable connection. But if necessary, it will no longer be possible to dismantle it.

Stages of work

Installation of cross-linked polyethylene pipes using the electric welding method

At this point, the installation is complete and all that remains is to connect the cross-linked polyethylene pipes to the collector.

Source

Is it possible to connect underfloor heating pipes or not?

When laying a pipeline for a heated floor, often the length of the circuit is not enough to make a solid loop. In this case, the question arises: is it possible to connect the pipes to each other, and how to do this? There are several methods for connecting contours, which depend on the type of material.

Important! When choosing a method to join floor pipes, you should take into account the operating pressure, since each connection is designed to withstand a certain load.

Let's take a closer look at the methods of how to connect underfloor heating pipes.

Connection of cross-linked polyethylene and metal-plastic pipes

Mini-review: how to install fittings?

Contours made of polyethylene or metal-plastic can be sewn together using fittings (brass, bronze and plastic); they can withstand high temperatures. Fittings are:

- Electric welding ones are effective, but their installation requires special equipment, so they are rarely used. The process looks like this:

- An electric welding fitting is placed on the pipe cut;

- welding equipment is connected to the terminals, it will supply voltage to the element, which will lead to heating and fusion of the joints;

- the device turns off, the resulting connection can withstand pressure up to 12 Amp.

- Pressing - the main advantage is that when pressing, the entire space is filled with polymer, thereby creating a high-strength connection.

Sequencing:

- A nut is placed on the edge of the crimp tube, with the thread facing the connection;

- the split ring is put on with an indentation of 1 cm from the cut and fixed;

- the hose with the fitting device is stretched;

- The crimp nut is tightened tightly using two wrenches.

- Crimp fittings - these fittings are the easiest to install at home:

- a clamping sleeve is placed on the polymer hose;

- the end of the contour is stretched in diameter using an expander;

- with the stretched edge, the tube is pulled all the way onto the fitting fitting;

- the connection point is fixed in this position for several minutes, this is enough for the fitting to be tightly spliced.

Copper pipe stitching

Just as when installing a plastic circuit, copper can be joined using press or push fittings. This method is recommended in open areas, so that in case of leakage the part can be easily changed.

But the most reliable and practical way is to solder copper pipes. This is a more labor-intensive process, but the connection is durable and reliable. Sequencing:

- contour sections are cleaned from the outside and inside;

- a special connector for soldering copper floor heating pipes is used to lubricate the edges of the parts - only from the top;

- the products are joined, and the excess mixture is removed;

- the joint is heated with a gas burner and solder fills the gaps.

How to connect underfloor heating pipes (press fitting)

As mentioned above, the pipeline can be joined using press fittings. This part consists of:

- housings - come in different shapes (angle, tee, coupling);

- sleeves are the basis of the fitting, the raw material for its production is stainless steel;

- clips - an elastic ring (gasket) that connects the body and the sleeve.

For your information! The fitting body is equipped with a “window” to control the correct insertion of the tubular product. Only when the tube is visible in this hole can you begin pressing.

Pressing is carried out using special press jaws. The essence of the procedure is to compress the handles of the tool. The process is quick and easy, and no special skills are required to carry out this work.

The advantage of using such a connection is strength, long service life and the design does not require maintenance.

Features of the material

Pipelines for heated floors are made from various raw materials: copper, metal-plastic, but the most modern type is considered to be a cross-linked polyethylene pipe.

Cross-linked polyethylene is a type of ethylene obtained by chemical and physical exposure to it. During production, a three-dimensional cellular network is formed from ethylene molecules. This model is called PEX.

Strength

The strength of this product is given by the transverse connections formed during the production process, in addition to the longitudinal ones. The expansion rate of PEX tubing ranges from 250 to 800%.

In addition, unlike polypropylene, the material has increased durability and does not collapse even with significant temperature changes.

Temperature resistance

When using cross-linked polyethylene hoses, a maximum temperature of 140 degrees is recommended. But melting processes begin when heated from +190 degrees.

For your information! Cross-linked polyethylene has increased resistance to short-term temperature extremes.

Therefore, it is recommended to use it in a low-temperature heating system, where heating is not significant and frequent temperature changes occur. But polyethylene should be used where the pipeline is constantly hot.

Physical properties

Despite the high density of PEX tubes, the material is soft and elastic, and has the following properties:

Chemical properties

An improved production process - cross-linking - has made polyethylene more resistant to organic and inorganic influences, and it is also not subject to the destructive effects of solvents.

In addition, the material is resistant to the negative effects of the environment: sunlight and oxygen. This quality is due to the presence of a protective anti-diffusion coating on most models.

Other characteristics

Polyethylene contours have a diameter from 10 to 200 mm. For water heated floors, the recommended size is 16 mm.

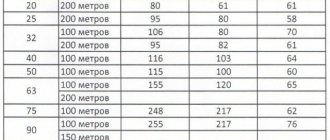

Main technical characteristics:

Connection of underfloor heating pipes in a screed

Although experts advise laying a water-heated floor under a screed without joints, it is not prohibited to do so.

But it is worth noting that it is impossible to connect the floor contours using a threaded method: “American” or PRH. It is better if the pipes are connected using a press fitting or coupling.

Important! When filling such areas with screed, fittings or couplings should be isolated from the concrete solution. This can be done by wrapping them in plastic film.

Types of fittings for joining cross-linked polyethylene

Today, to sew polyethylene pipes together, the following types of fittings are used.

Compression

Compression, also called crimp, is a detachable connection method. Fitting - a nut, a split ring and a fitting, most often the elements are made of brass.

Press fittings

With this type of fitting, a non-detachable connection is formed; it is strong and durable. Recommended for use in a structure with a screed, in a system with a high level of pressure and high temperature.

The press fitting includes a body, a ferrule and a sleeve.

Axial

An axial fitting is a device that has a fitting and a sleeve. It is installed using expansion and tension tools.

How to solder a heated floor pipe

Soldering is a common method of connecting plastic pipes for underfloor heating. The technology is simple and does not require large financial investments. There are two soldering techniques:

- Coupling - for this, a shaped part is used (coupling or contour with a large diameter). This method is suitable for tubes measuring 63 mm. The welding process consists of melting the edge of the product on the outside and part of the coupling on the inside. After which, the parts are joined, forming a tight connection.

- Direct - involves melting small sections of two plastic pipes, which are then joined at the ends. This fairly simple method reliably combines two parts into a single outline.

For your information! Along with hot technologies, the method of “cold” soldering is practiced. A special solvent is used that softens the plastic.

Advantages and disadvantages of cross-linked polyethylene

Pipeline made of cross-linked polyethylene, like any other type, has its pros and cons.

One cannot help but mention the minor disadvantages that cross-linked polyethylene pipes have. First of all, this concerns some difficulties during installation.

Pipe bends require reliable fixation. In addition, when laying them in a heated floor structure, you need to be extremely careful so as not to damage the protective coating.

Another disadvantage is the negative impact of direct ultraviolet rays, under which the material becomes fragile.

How to connect a heated floor pipe with a metal-plastic pipe

Although experts recommend using a pipeline made of one material when installing a heated floor, sometimes it becomes necessary to connect a metal-plastic circuit with products made from other raw materials.

For example, when connecting this circuit to steel (copper) parts of the plumbing or heating system. To do this, you will need a compression fitting and a calibrator. When joining products made of different materials, the thread should be selected according to the size of the steel pipe, and the cuffs and washers should be selected according to the metal-plastic pipeline.

Tow is wound onto the copper pipe, and then the fitting is screwed on. The edge of the product is pushed onto the cone and the nut is tightened.

If it is necessary to connect a metal-plastic circuit with polyethylene products, special threaded fittings can be used as a connector for underfloor heating pipes. This joint is most often made when connecting a heated floor to a boiler.

Rules for working with cross-linked polyethylene

When laying a heated floor made of cross-linked polyethylene, it is important to firmly fix all bends with special clips on the dowels, since the material will try to return to its original state, especially at small bending angles. By following the rules for working with the material at the installation stage, you can avoid problems when using heated floors in the future:

Note! For a one-time installation, you can purchase an inexpensive pipe cutter or rent a professional tool.

Source

What to do if a heated floor pipe is broken?

If there are warm water floors in a house or apartment, there are times when the floor pipeline may be broken. First of all, if the floor is functioning, you should disconnect it from the water supply. But more often, such damage occurs during installation or repair of the system, when the topcoat is not laid and the screed is not poured - this is a huge plus.

If there is a concrete screed, in order to find the location of the damage, you will need a hammer drill, a chisel and a hammer to destroy the concrete. This should be done carefully so as not to damage the entire circuit.

What to do if the floor heating pipe is damaged. Repair of "warm floor". Installation of press fitting.

When pipes made of metal-plastic or polyethylene are pierced, they are repaired using press couplings using a special press.

For your information! If the heating element is filled with screed after repair, then the use of threaded fittings is not possible.

Having calculated the location of the breakdown, you should remove the damaged area and install a whole circuit in its place. The connection is made using press couplings, which should be wrapped in plastic film to protect them from cement mortar.

Water heating circuit

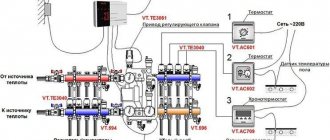

Let's look at the water heating diagram for the place where we will install the heated floor.

The batteries in the kitchen are powered by a supply circuit that runs along the perimeter of the second floor. The battery output is sent to the so-called return circuit, which is installed in the basement. We will connect the heated floor to the second output of the battery and direct it to the return circuit.

To turn off the battery and the heated floor, install taps 1 and 2, respectively.

Additionally, we will install a circulation pump at the entrance to the return circuit. This is how we implement all the requirements of the owners.

Is it possible to extend pipes if they are not long enough?

As you know, it is better to make a loop of a warm water floor than a solid one, this gives the system reliability, and connections are made at the points of attachment with the collector. If the heated room is large, it is recommended to divide the area into several branches.

In order not to make a mistake in the size of the loop, you should make the calculation correctly. To do this, you can use an online calculator.

However, if necessary, it is still possible to lengthen the contour of the heated floor by connecting the missing section of pipe to it, which, by the way, is allowed according to GOST. It is possible to extend heated floor loops using various methods; for this, butt joints are used, most often press fittings.

For your information! In such cases, it is recommended to use pipelines and fittings from the same manufacturer.

To summarize, we can say that connecting underfloor heating pipes is acceptable, and there are various ways. But it is more practical and reliable to lay a single loop, especially under the screed, so that in case of leakage you do not have to destroy the concrete layer.

In addition, preference should be given to high-quality pipe products and connecting parts from trusted manufacturers. In such cases, the heating floor will serve you for a long time and will create a comfortable atmosphere in the house.

Installing damper tape and laying multifoil

Before connecting the pipes, we will do some preparatory work: along the perimeter of the walls we will install a so-called damper tape, which compensates for the expansion of the warm water floor when heated.

It is easy to make such a tape yourself from ordinary foil isofol with a thickness of at least 5 mm. To keep the tape against the wall, you can lightly glue it or use regular tape.

The height of the tape should be slightly higher than the future floor screed. We installed tape around the entire perimeter of our kitchen. Now let's lay down multifoil - a special foam insulation for heated floors.

The branded insulation has a special marking grid, which can help when calculating the distances between pipes. The multifoil is laid directly on the rough screed, and the joints are taped. To lay out, level and fasten the water pipes, we will use a metal reinforcing mesh with a cell width of 10 cm.

Having laid out the mesh around the perimeter of the room, we connect the individual elements using ordinary wire.

The reinforcing mesh is installed throughout the floor and has certain irregularities, but we will press it against the screed later, ensuring more convenient work on fastening the pipes. So, we have completed all the necessary work to begin installing the pipes - there are exits from the battery, we will use the current supply.