The modern market offers 4 types of radiators: cast iron, aluminum, steel and bimetallic. Such batteries are durable, have good heat dissipation and an attractive design. When choosing a model, consider the size of bimetallic radiators, their energy intensity and quantity. But, more about everything.

Bimetallic radiator

Advantages of bimetallic heating radiators

The popularity of this type of battery can be explained very simply. Cast iron radiators are quite reliable, but they do not look very aesthetically pleasing. In addition, they are difficult to install. Aluminum batteries look modern and attractive. However, this metal does not tolerate contact with oxygen in the coolant very well. Therefore, aluminum radiators quickly fail and begin to leak. Steel batteries last longer. However, at the same time they do not look so aesthetically pleasing.

Bimetallic models combine the advantages of aluminum and steel radiators. Such batteries fit perfectly into a modern interior. The sections in them are made of aluminum. At the same time, they last a long time, since the pipes through which the coolant flows through them are made of steel.

Types and design features

Any bimetallic heating radiator is made of two main elements:

- metal pipes;

- aluminum panels.

Due to this combination of components, very efficient heat transfer occurs. The hot coolant moves along a steel core made of metal pipes. The aluminum shell heats up quickly and heats the room well.

The shaped aluminum shell of such a core has a beautiful appearance. It plays an important role in uniform heat distribution.

Thanks to aluminum panels, the radiator is quite light when compared to similar cast-iron batteries. This greatly simplifies installation work. The original shape of the case always attracts attention. In addition to its stylish appearance, a bimetallic radiator increases heat transfer many times over.

The metal pipes from which the core is made are characterized by increased strength. They can easily withstand a pressure of 40 atmospheres and a coolant temperature of over 130 degrees.

Each device is accompanied by a passport, which indicates the maximum parameters of the coolant temperature and maximum pressure.

Battery sizes

The dimensions of the device are important, since with the required power parameters it must fit in a niche under the window. What sizes can bimetallic batteries have?

Bimetallic heating radiators are characterized by standard height dimensions. The device has a marking that indicates the center distance of the device - 200, 350 or 500 mm.

Important! When choosing a radiator, it is necessary to take into account that the center distance is the gap between the inlet and outlet holes of the battery, which does not correspond to the entire height of the case. To find out the actual height of the device, you need to add 80 mm to the center distance

Full height of the device with different markings:

- marking 200 – actual height 280 mm;

- 350 – device height 430 mm;

- 500 – height 580 mm.

The width of the heating device will depend on the number of sections, which is calculated based on the parameters of the room and the power of the individual section.

Attention! When choosing the size of the radiator, do not forget that, in accordance with technical standards, the device must be installed at a distance of at least 10 cm from the window sill and 6 cm from the floor

Design and Key Benefits

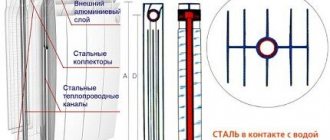

A distinctive feature of bimetallic heating radiators from other analogues on the market is that the internal part of such a device contains steel collectors and heat-conducting channels, and the outer part is an aluminum casing. Thanks to this design, bimetallic radiators are significantly superior in their characteristics to aluminum models, as well as cast iron and steel:

- Resistant to aggressive substances , which are present in significant quantities in central heating systems. This is especially important for networks in which flushing is carried out with the addition of a 5% phosphoric acid solution.

- Durable - the service life of bimetallic models is from 20 to 25 years, due to the presence of high-strength and wear-resistant steel elements. For comparison, steel radiators last about 15 years, aluminum radiators - no more than 20, provided that the pH of the water does not exceed 7-8.

- Resistant to strong hydraulic shocks - the possible operating pressure reaches 40 Atm.

The excellent technical characteristics of bimetallic radiators are not the only advantage; they are also distinguished by their stylish appearance. The combination of efficiency and aesthetics ensures the continued popularity of such heating devices among buyers.

The best bimetallic radiators with a center distance of 500 mm

The choice of heating equipment with a center distance of 500 mm for the rating was not accidental. The vast majority of modern residential premises have fairly large window openings, and the distance between the window sill and the floor is, as a rule, at least 60 cm. Therefore, bimetallic radiators of this qualification are most popular among the population.

Royal Thermo PianoForte 500

Many positive user ratings for this Italian radiator on Yandex.market, which fully confirm the reliability of the design, long service life, and original design, put it in first place in the rating.

- heat output from 740 W to 2590 W (depending on the number of sections);

- the number of sections varies from 4 to 14;

- Power Shift technology, which increases heat transfer;

- steel collectors are designed for pressure surges in the system up to 30 atmospheres;

- resistant to the most aggressive coolants;

- wall and floor installation possible;

- original design;

- Manufacturer's warranty – 10 years.

quite high cost.

In general, as the British say, we are not rich enough to buy cheap things. Therefore, in this case, the price corresponds to the quality. Particular emphasis is placed on the presence of Power Shift technology - the presence of additional fins on the vertical manifold, which significantly increase the heat transfer of the model. In addition, in addition to the basic white and black colors, the buyer can order other tones or RAL palettes.

Rifar Monolit 500

A domestic development that deservedly ranks second in the ranking in terms of the number of laudatory reviews collected in its favor. Features include the technology of the same name used in the production process - sections are connected using contact butt welding.

- monolithic design allowing operation in the harshest conditions;

- heat transfer from 784 W to 2744 W;

- complete set of sections – from 4 to 14;

- high resistance to aggressive coolants (pH 7 – 9);

- there is a bottom connection;

- Manufacturer's warranty – 25 years.

- a bit expensive for a domestic product;

- there are no odd sections - for example, 5 or 7.

However, in general, the radiator of this model receives extremely positive reviews. Moreover, management companies strongly recommend it for use, due to the model’s high resistance to corrosion and long guaranteed service life.

Global Style Plus 500

Once again, an Italian model who has collected a significant number of admiring reviews addressed to her. The inner part of the radiator is made of alloy steel, and the outer part is coated with aluminum alloy.

- high strength;

- maximum working pressure 35 atmospheres;

- crimping pressure – 5.25 MPa;

- heat output in the range from 740 W to 2590 W;

- complete set – from 4 to 14 sections;

- pH value (coolant aggressiveness) – from 6.5 to 8.5;

- Manufacturer's warranty – 10 years.

Heat transfer drops slightly as the coolant temperature decreases.

Satisfied with the purchase, owners shower this model with extremely positive assessments - high resistance to pressure changes in the system, the presence of silicone gaskets between sectional joints prevent leaks, adjustment works stably, and so on.

Sira RS Bimetal 500

Another Italian, appreciated by domestic users, as the reviews eloquently speak about.

- high strength – working pressure up to 40 bar;

- heat transfer from 804 W to 2412 W;

- complete set – from 4 to 12 sections;

- resistance to coolant is expressed in pH - from 7.5 to 8.5;

- Manufacturer's warranty – 20 years.

Well, that’s what premium class is for! In addition to satisfactory ratings regarding the technical characteristics of this radiator model, owners satisfied with the purchase note the unique design - smooth, curved shapes, complete absence of sharp corners.

Fondital Alustal 500/100

Also an Italian miracle of engineering, which won the approval of Russian users, which was reflected in the number of positive reviews.

- heat transfer from 191 W to 2674 W;

- complete set from 1 to 14 sections;

- high strength – working pressure up to 40 bar;

- the most aggressive coolants (pH 7 – 10) are not scary;

- Manufacturer's warranty – 20 years.

In general, this is a minor disadvantage due to the fact that this model is a continuous water chamber. On the other hand, there is an internal anti-corrosion coating, as noted by the owners of this radiator, and a stroke pattern that prevents airing of the system.

Classification of heating devices

Depending on the material used for manufacturing, heating radiators can be:

- steel;

- aluminum;

- bimetallic;

- cast iron

Each of these types of radiators has its own advantages and disadvantages, so it is necessary to study their technical characteristics in more detail.

Cast iron batteries - time-tested heating devices

The main advantages of these devices are high inertness and fairly good heat transfer. Cast iron batteries take a long time to heat up and are also able to release the accumulated heat for a long time. The heat output of cast iron radiators is 80-160 W per section.

These devices have many disadvantages, among which the most serious are:

- a large difference between the flow area of the risers and batteries, as a result of which the coolant moves slowly through the radiators, which leads to their rapid contamination;

- low resistance to water hammer, operating pressure 9 kg/cm2;

- heavy weight;

- requirement for regular care.

Aluminum radiators

Batteries made of aluminum alloys have a lot of advantages. They are attractive, do not require regular maintenance, and are not brittle, which makes them better resistant to water hammer than their cast iron counterparts. Working pressure varies depending on the model and can be from 12 to 16 kg/cm2. Another undeniable advantage of aluminum batteries is the flow area, which is less than or equal to the internal diameter of the risers. Thanks to this, the coolant moves inside the sections at high speed, which makes it almost impossible for dirt to accumulate inside the device.

Many people believe that a small cross-section of radiators leads to low heat transfer. This statement is incorrect, since the heat transfer of aluminum is higher than, for example, that of cast iron, and the small cross-section in the batteries is more than compensated by the area of the radiator fins. According to the table below, the heat output of aluminum radiators depends on the model and can range from 138 to 210 W.

But, despite all the advantages, most experts do not recommend them for installation in apartments, since aluminum batteries may not withstand sudden pressure surges when testing central heating. Another disadvantage of aluminum batteries is the rapid destruction of the material when other metals are used in conjunction with it. For example, connecting to radiator risers through brass or copper pipes can lead to oxidation of their inner surface.

Bimetallic heating devices

These batteries do not have the disadvantages of their cast iron and aluminum “competitors”. A design feature of such radiators is the presence of a steel core in the aluminum fins of the radiator. As a result of this “fusion”, the device can withstand colossal pressure of 16-100 kg/cm2.

The flow area of the device is, as a rule, smaller than that of risers, so bimetallic radiators are practically not contaminated.

Despite its many advantages, this product has a significant drawback - its high cost.

Steel radiators

Steel radiators are perfect for heating rooms powered by an autonomous heating system. However, such radiators are not the best choice for central heating as they may not withstand the pressure. They are quite light and resistant to corrosion, with high inertia and good heat transfer rates. Their flow area is most often smaller than that of standard risers, so they rarely become clogged.

Among the disadvantages are the rather low operating pressure of 6-8 kg/cm2 and resistance to water hammer, up to 13 kg/cm2. The heat transfer rate for steel batteries is 150 W per section.

The table shows the average heat transfer and operating pressure for heating radiators.

What you need to know about radiator sizes

Heating radiators are produced in different sizes, which allows you to choose the optimal place in the room for their installation.

An error in choosing the size of heating radiators will lead to excessively low, or, conversely, high temperatures in the heated room.

Knowing the dimensions of heating radiators, their power and the area of the room where you are going to install them, it is easy to calculate the optimal number of heating devices needed. The choice of radiator height depends on the intended installation location. Often, radiators are installed under the window, so to calculate the height of the heating radiator, you need to measure the distance from the floor to the window sill. Also, all heating devices must be on the same level. Heating radiators are divided into three types according to their height:

- Standard height.

- Low heating radiators.

- Tall heating radiators.

The length of the radiator depends on the number of sections.

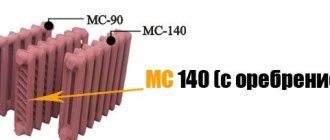

Dimensions of cast iron heating radiators

- Standard dimensions of cast iron heating radiators: section length 93 mm, depth 140 mm, height 588 mm.

- Low heating radiators dimensions: height 388 mm, other parameters are the same.

- Tall cast iron radiators: height from 661 to 954 mm, section length 76 mm, depth - 203 mm.

Cast iron heating radiators can last up to 50 years without replacement

Dimensions of aluminum heating radiators

- Standard sizes of aluminum heating radiators. height 575-585 mm, section length – 80 mm, depth – 80-100 mm.

- Low: height from 200 to 400 mm, section length from 40 mm, depth up to 180 mm.

- High: height 590 mm, depth 95 mm, section length 80 mm.

Aluminum radiators have good heat dissipation

Dimensions of bimetallic heating radiators

- Standard dimensions of bimetallic heating radiators: height 550 – 580 mm, section length 80-82 mm, depth 75-100 mm.

- Low: height 30 -500 mm, section length 80 mm, depth – 95 mm.

- High: height 880 mm, section length 80 mm, depth 95 mm.

Bimetallic radiators combine all the best qualities of steel and aluminum radiators

Dimensions of steel heating radiators

- Standard dimensions of sectional tubular radiators: height 600 mm, radiator length 400-3000 mm.

- Low: height 400-500 mm, radiator length 400-3000 mm

- High: height 700-900 mm, length the same.

Steel radiators are most often used in individual heating systems

General information

The market offers a wide range of heating radiators, which differ in height and length. The size range of these devices is a significant factor when purchasing them.

Every buyer should definitely pay attention to this, because the amount of heat that the room will receive depends on this characteristic. As well as placing the battery in the room.

Main dimensions

Dimensions mean:

The center-to-center distance (also called inter-nipple or center-to-center) should not be confused with the height of the heating radiator. The first indicator indicates how many centimeters are between the upper and lower collectors (holes). Height is the distance between the lowest and highest point of the section.

Aluminum heating radiators have the following dimensions:

- The center distance ranges from 150 to 2,000 mm. Very tall radiators are rare. The most popular are radiators with an inter-nipple distance of 500 mm. This is because the current heating network pipe system was created for cast iron batteries, which have the same center-to-center distance. Since many owners did not and do not have the desire to digest pipes, they simply selected/are selecting a suitable radiator and, thereby, increased the popularity of a battery with an interaxial distance of 0.5 cm. This indicator is very important, and therefore manufacturers indicate it in the name of the battery (RAP-500, Rococo 790, Magica 400, etc.).

- The height is in the range of 245-2000 mm. According to this criterion, batteries can be divided into low, medium and high. The features of each type will be discussed below.

- The section depth ranges from 52 to 180 mm. Some models may have greater depth, however, this is rare.

- The section width is 40-80 mm.

Rating of popular manufacturers

The review includes high-quality foreign heating systems and domestic products adapted to the changing conditions of heating networks.

In practice, the company’s products have proven themselves well:

- Global Style (Italy);

- Sira (Italy);

- Rifar (Russia);

- Tenrad (Germany).

Place #1 - Global

This is a generally recognized leader in the production of heating radiators.

The company produces three series of bimetallic batteries:

- Style – basic characteristics;

- Style Extra – compact dimensions;

- Style Plus – maximum heat transfer.

The sections are connected by paronite gaskets, ensuring the tightness of the joints. Efficient heat transfer between metals is achieved through injection molding of an aluminum “jacket”.

Additional characteristics: pressure – up to 35 atm, connection diameter – ¾ or ½ inch, coolant temperature – up to 110°C, outer shell – double painted

Place #2 - Sira

The Italian manufacturer positions its products as premium products. The devices have gained popularity among consumers due to their durability and attractive design. The manufacturer provides a 20-year guarantee for a series of full-fledged bimetallic radiators Sira Ali Metal.

Characteristics of Ali Metal products: center distance – 350/500 mm, heat transfer of models – 187/141 W (according to the center distance), pressure in the heating network – 35 atmospheres

Place #3 – Rifar

A domestic manufacturer has developed a wide range of bimetallic radiators:

- Base – models with center distances of 200/350/500 mm, warranty from Rifar – 10 years;

- Forza – reinforced external coating, resistant to scratches and mechanical damage;

- Alp – shallow depth (75 mm);

- Monolit is a one-piece radiator.

Monolit series batteries are characterized by the highest performance indicator at high coolant pressure.

Technical data: operating pressure – 10 MPa, destruction pressure – 25 MPa, maximum temperature – 135°C, warranty period – 25 years

Location #4 - Tenrad

Bimetal of German quality is suitable for centralized and independent heating networks. Suitable for use in gravity, elevator and pump systems with one- and two-pipe wiring.

Distinctive features:

- the thickness of the vertical tubes is 1.8 mm, the thickness of the collector walls is 3.6 mm;

- three-row fins;

- the side panels are located at a slope, which creates a diffuser effect for convective flow.

Two-layer enamel coating made of high-quality paints and varnishes - when heated, the device does not emit harmful fumes.

Tenrad products are designed for operation in a system with a coolant pressure of up to 35 atmospheres. Bimetallic radiators are certified and comply with the European standard EN442

The following article will introduce you to the rules for calculating the power and number of radiators for a heating device, which you should read before purchasing devices.

Bimetallic heating radiators, which ones are better, selection instructions

The first heating radiators made from two metals (bimetallic) appeared in European countries more than sixty years ago. Such radiators coped well with the assigned function of maintaining a comfortable room temperature during the cold season. Currently, the production of bimetallic radiators has been resumed in Russia; the European market, in turn, is dominated by various radiators made of aluminum alloy.

Which bimetallic heating radiators are better?

Bimetallic radiators are a frame made of steel or copper hollow pipes (horizontal and vertical), inside which coolant circulates. Aluminum radiator fins are attached to the pipes outside. They are attached using spot welding or special injection molding. Each section of the radiator is connected to another by steel nipples with heat-resistant (up to two hundred degrees) rubber gaskets.

Bimetallic radiator design

In Russian city apartments with centralized heating, radiators of this type can withstand pressure up to 25 atmospheres (with pressure testing up to 37 atmospheres) and, thanks to their high heat transfer, perform their function much better than their cast-iron predecessors.

Radiator - photo

Externally, it is quite difficult to distinguish bimetallic and aluminum radiators. You can make sure that your choice is correct only by comparing the weight of the specified radiators. Due to the steel core, the bimetallic one will be approximately 60% heavier than its aluminum counterpart and you will make an unmistakable purchase.

The structure of a bimetallic radiator from the inside

Positive aspects of using bimetallic radiators

- Bimetallic panel-type radiators fit perfectly into the design of any interior (residential buildings, offices, etc.) without taking up much space. The front side of the radiator can be one or both; the size and color scheme of the sections are varied (self-painting is allowed). The absence of sharp corners and overly hot panels makes aluminum and steel radiators suitable even for children's rooms. In addition, there are models on the market that are installed vertically without the use of brackets due to additionally present stiffening ribs.

- The service life of radiators made from an alloy of two metals reaches 25 years.

- Bimetal is suitable for all heating systems, including central heating. As is known, low-quality coolant in municipal heating systems negatively affects radiators, reducing their service life, but bimetal radiators are not afraid of increased acidity and low quality coolant due to the high corrosion resistance of steel.

- Bimetallic radiators are the standard of strength and reliability. Even if the pressure in the system reaches 35-37 atmospheres, this will not damage the batteries.

- High heat transfer is one of the main advantages of bimetal radiators.

- Regulating the heating temperature using a thermostat occurs almost at lightning speed due to the small cross-section of the channels in the radiator. The same factor allows you to halve the volume of coolant used.

- Even if there is a need to repair one of the radiator sections, thanks to the well-thought-out design of the nipples, the work will take a minimum of time and effort.

- The number of radiator sections required to heat a room can be easily calculated mathematically. This eliminates unnecessary financial costs when purchasing, installing and operating radiators.

Negative aspects of using bimetallic radiators

- As mentioned above, bimetallic radiators are suitable for use with low-quality coolant, however, the latter significantly reduces the service life of the radiator.

- The main disadvantage of a bimetallic battery is the different expansion coefficient of aluminum alloy and steel. After prolonged use, creaking may occur and a decrease in the strength and durability of the radiator.

- When operating radiators with low-quality coolant, steel tubes can quickly become clogged, corrosion can occur, and the level of heat transfer can decrease.

- A contested disadvantage includes the cost of bimetal radiators. It is higher than that of radiators made of cast iron, steel and aluminum, but considering all the advantages, the price is completely justified.

Design Features

Water contains a large number of impurities. When in contact with aluminum, they cause corrosion. Over several years of use, these processes will lead to leakage of the device.

The design feature of these radiators is the presence of an internal stainless steel core, which is surrounded on the outside by an aluminum alloy. This way, water does not come into contact with aluminum, which significantly extends the service life of the system.

There are two manufacturing options:

- Pseudobimetal. In this case, the steel core is located only inside the vertical channels. So aluminum is not completely protected, but only in the weakest places. These models are cheaper and have a standard service life of up to 10 years if used in systems with high water pressure (for example, in city apartments).

- Bimetal. It has a solid inner casing made of steel, which is filled with aluminum alloy under pressure. Here the aluminum is protected on all sides. These are more expensive models and their service life under similar operating conditions is up to 30 years.

Design of a bimetallic battery The manufacturing method directly affects the volume of water in the section of the bimetallic radiator.

If we compare it with any other battery, the volume of one section here will be significantly lower. The disadvantage is compensated by the presence of two alloys. As a result, the inner steel core prevents the aluminum shell from cooling quickly. There are different ways to join two metals. It is preferable if aluminum is poured over steel under pressure. This battery model will last longer. There is an option when metals are joined together by welding.

According to the technical type of design, radiators can be:

- Collapsible. This means that using a radiator wrench you can unscrew any number of sections and screw them to another radiator. This type is most often installed in private houses with an autonomous heating system, where there is no high water pressure.

- Non-separable. The radiator is monolithic, it cannot be untwisted, cut, or attached to another. Perfect for use in a city apartment, where there is always a high level of pressure.

Heating radiators aluminum section sizes

Today, every house and apartment has heating radiators. Cast iron radiators are widely used due to their efficiency, durability and high heat transfer coefficient. However, over time, they become clogged with rust and silt, which enters the heating system through the pipes. This drawback significantly reduces the efficiency of cast iron radiators. It is for this reason that aluminum heating radiators came to replace cast iron ones.

Aluminum heating radiators section sizes must be selected based on the following factors:

- Room area;

- Estimated power of the section;

- Heat transfer coefficient;

- Availability of free space for installation.

What is an aluminum radiator section?

The section (heating radiator) is a double-tubular aluminum structure, which is finned using convection and radiation methods to improve thermal transfer. The section is the smallest structural element of a heating radiator.

Available sizes of aluminum radiator sections:

- Section width - 80 mm;

- Section height - 350, 500, 600, 700 mm;

- Section depth – 80, 95 mm;

The working pressure of aluminum sections can reach 16 bar.

In order to correctly select the size of aluminum sections, it is necessary to calculate the radiator power. As a rule, this value is indicated by the manufacturer on each of the available models of aluminum radiators. There is also a simple and effective formula for calculating the required number of radiator sections:

S – area of the heated room (room);

P – power of the aluminum radiator section;

K – number of sections;

100 – value 100 watts per 1 sq.m. with a standard ceiling height in the room of 2.7 meters.

When calculating and choosing the size of an aluminum radiator section, it is necessary to take into account that the power reserve must be at least 20%.

Today, aluminum sections of different sizes are available from the following famous manufacturers:

Aluminum heating radiators – impeccable quality, high efficiency and versatility.

A very important topic. Especially today, when there are many types of radiators, and you have to make the choice yourself, since it is simply dangerous to absolutely entrust this choice to someone else. Wouldn't it burst with boiling water somewhere in the middle of winter! So light and elegant that out of habit they seem unreliable. It's beautiful though. So I study everything that is on the Internet. You did a good job of calculating the number of sections and heat transfer. Healthy. When replacing radiators, I ordered ball valves to be installed on all pipes. So that if something happens, immediately turn off the hot water. So I was on the safe side.

Heating devices of single-pipe systems

An important feature of the horizontal “Leningrad” is the gradual decrease in temperature in the main line due to the admixture of coolant cooled by the batteries. If 1 ring line serves more than 5 devices, the difference at the beginning and end of the distribution pipe can reach 15 °C. The result is that the latest radiators emit less heat.

Single-pipe closed circuit - all heaters are connected to 1 pipe

To ensure that long-distance batteries transfer the required amount of energy to the room, make the following adjustments when calculating heating power:

- Select the first 4 radiators according to the instructions above.

- Increase the power of the 5th device by 10%.

- Add another 10 percent to the calculated heat transfer of each subsequent battery.

Which company should I buy bimetallic heating radiators?

Sira Group

A brand from sunny Italy, which many experts in this industry attribute to the ancestor of bimetallic equipment. Having begun its victorious march across the planet at the beginning of the second half of the last century, the company by this time has many production sites, a significant part of which are located outside the country. The brand has earned such success among consumers by offering high-tech equipment with elegant external forms and effective heat dissipation. Focusing on people's needs is not the only advantage of the company. Today, the brand’s efforts are aimed at producing resource-saving equipment, coupled with a claim to protect and restore the environment.

Another Italian brand founded by the Fardelli brothers in 1971. In the first stages of its development, the company produced exclusively aluminum radiators. This fact can be explained simply - at that time in Italy, energy resources were very expensive, and with equal consumption, aluminum radiators provide 4 times more heat than cast iron or steel batteries. However, having entered the Russian market in 1994, the company had to master the production of bimetallic radiators. The fact is that the domestic heating system differs in some way from the Italian one. For example, the pressure of the working environment in our pipes is much higher than in European countries. The equipment of this company complies with domestic GOST standards. In addition, the company provides an unprecedented warranty period of 25 years!

Royal Thermo

A brand that owes its origin to the merger of the English corporation “Industrial Investment Fund Ltd” with several construction companies from Italy. Having carried out a couple of successful transactions in the northern regions of Italy, the British believed in the rapid development of the real estate market and began to invest in the production of radiators for water heating. Until 1998, all brand products were aimed at satisfying the needs of the domestic market. However, at the turn of the millennium, the need arose to develop the markets of Eastern Europe and in particular Russia. Today, heating equipment adapted for difficult natural conditions is successfully sold in the post-Soviet space. Evaluating the brand's products, experts claim that the company confidently occupies a leading position in this industry in terms of price and quality ratio.

Also an Italian brand founded by Silvestro Niboli in 1970 in the province of Brescia. Naturally, the history of the brand is directly related to its creator, who almost 50 years ago left a small production of chandelier elements with the firm intention of developing and producing injection-molded radiators under his own brand. Today it is a dynamically developing company, whose products are well known to many consumers around the world. High-quality equipment and the constant production of new products, coupled with a realistic assessment of the market and its development course, make the company competitive.

A domestic brand that began its activities in 2002. The design development of bimetallic radiators of this company was carried out together with specialists from Italy. Production equipment - lines for machining, high-pressure casting and so on also come from Italy. A distinctive feature of radiators of this brand is their high heat transfer, which allows them to be installed even in large rooms. In general, the company’s products are an ideal combination of European quality with the vast experience of Russians in using heating equipment in climatic conditions close to extreme!

Calculation of the number of radiator sections

The thermal power of the radiator section depends on its overall dimensions. With a distance between the vertical axes of 350 mm, the parameter fluctuates in the range of 0.12-0.14 kW, with a distance of 500 mm - in the range of 0.16-0.19 kW. According to the requirements of SNiP for the middle strip per 1 sq. meters of area requires a thermal power of at least 0.1 kW.

Taking into account this requirement, a formula is used to calculate the number of sections:

where S is the area of the heated room, Q is the thermal power of the 1st section and N is the required number of sections.

For example, in a room with an area of 15 m2 it is planned to install radiators with sections of thermal power of 140 W. Substituting the values into the formula, we get:

N=15 m 2 *100/140 W=10.71.

Rounding is done upward. Considering the standard shapes, it is necessary to install a bimetallic 12-section radiator.

Important: when calculating bimetallic radiators, factors affecting indoor heat loss are taken into account. The obtained result is increased by 10% in cases where the apartment is located on the first or last floor, in corner rooms, in rooms with large windows, with small wall thickness (no more than 250 mm)

A more accurate calculation is obtained by determining the number of sections not per room area, but its volume. According to SNiP requirements, heating one cubic meter of room requires a thermal power of 41 W. Taking these standards into account, we get:

where V is the volume of the heated room, Q is the thermal power of the 1st section, N is the required number of sections.

For example, the calculation is for a room with the same area of 15 m2 and a ceiling height of 2.4 meters. Substituting the values into the formula, we get:

N=36 m 3 *41/140 W=10.54.

The increase is again carried out upward. A radiator with 12 sections is required.

The choice of the width of a bimetallic radiator for a private house differs from that for an apartment. The calculation takes into account the thermal conductivity coefficients of each material used in the construction of the roof, walls and floor.

When choosing sizes, you should take into account the requirements of SNiP for battery installation:

- the distance from the top edge to the window sill must be at least 10 cm;

- the distance from the bottom edge to the floor should be 8-12 cm.

For high-quality heating of the room, it is necessary to pay attention to the choice of sizes of bimetallic radiators. The dimensions of the batteries from each manufacturer have slight differences, which is taken into account when purchasing

Correct calculation will avoid mistakes.

Find out what the correct dimensions of bimetallic heating radiators should be from the video:

Technical and operational characteristics

All basic parameters of the radiator are indicated in the passport of the heating device.

In order not to make a mistake with your choice, you need to understand the meaning of the following characteristics:

- heat transfer;

- operating pressure and temperature;

- center distance;

- dimensions;

- capacity, section weight.

Thermal power. The parameter indicates the amount of heat transferred from the battery to the atmosphere of the room at a given coolant temperature (+70°C). The indicator is measured in W.

The average heat transfer value of a composite radiator is 140-190 W. The difference in values is explained by the dimensions of the section and the design features of devices from different manufacturers.

Based on the thermal power of one section, the required battery performance for the entire room is calculated.

Work environment indicators. The maximum coolant pressure depends on the thickness of the steel core. The choice of strength is at the discretion of the manufacturer. The parameter value ranges from 15 to 35 bar and is determined based on the operating conditions of the battery.

An important characteristic is the limiting temperature of the coolant. All high-grade bimetals can withstand +90°C. Some manufacturers claim higher thermal resistance.

The maximum temperature stated in the equipment data sheet for different trade positions: Global Style – 110°C, Tenrad – 120°C, Altermo – 130°C, Grandini – 120°C

Radiator dimensions. Dimensional characteristics include the following parameters:

- Center distance is the “distance” between the axes of horizontal collectors. The standard size is 20-80 cm. Vertically oriented models with increased interaxial distance are used if the room layout is not suitable for installing horizontal radiators.

- Geometric parameters determine the height, width, and depth of the section. The total height of the radiator often exceeds the interaxial range by 6-8 cm. The traditional width of the fins of bimetallic models is 80 mm.

The depth of the section is 75-100 mm. Some manufacturers, in addition to external panels, add parallel fins to the design to increase heating efficiency due to convection flows.

Overall dimensions: a – section height, b – distance between horizontal axes, c – battery depth, d – width of one section. The most popular products with a core height of 35 cm, 50 cm

Volume and mass. In bimetallic modifications, the coolant circulates through a core of round cross-section, in contrast to aluminum counterparts with a heat conductor of oval cross-section. The capacity of one bimetal section is less than the volume of an aluminum section with the same standard dimensions.

For example, in convectors with an interaxial range of 500 mm, the coolant filling is about 0.2-0.38 l, with a core height of 350 mm - 0.15-0.25 l.

The weight of a standard bimetallic battery with dimensions of 580/80/80 mm (height/width/depth, respectively) and an axial distance of 50 cm is 1.8-2 kg. Less mass is one of the signs of a semi-bimetal.

Dimensions of cast iron radiators

Standard Soviet batteries of this type had a height of 580 mm, a rib width of 94 mm and a thickness of 140 mm. Many owners of houses and apartments still consider such models to be the most reliable. Therefore, cast iron radiators are still in demand today. Manufacturers, of course, noticed this and began to supply the market with retro-style cast iron radiators, which have a very attractive design. If you wish, you can, of course, buy such batteries for your home. Their sizes may vary. There are low, standard and high models of this type on the market. The approximate sizes of cast iron heating radiators of different types can be seen in the table below.

Dimensions of cast iron batteries

Very often, stylish cast iron retro radiators have small legs. In this case, the height is calculated, of course, taking them into account.

Bimetallic radiators, which are better?

Bimetallic radiators on the Russian market are fully certified, but they differ not only in the company and country of manufacture; there are small but very important nuances that are worth paying attention to when purchasing. Price is one of the most important aspects that consumers pay attention to

But before judging the quality of a product by its price, you should understand what makes up the cost of a radiator

Price is one of the most important aspects that consumers pay attention to. But before judging the quality of a product by its price, you should understand what makes up the cost of a radiator

The most inexpensive bimetal radiators are presented by manufacturers from China and Russia. The price of one section does not exceed four hundred rubles. The low cost is due to the simplified design and material savings in the production of the product. The working pressure of such radiators is slightly lower than analogues produced in other countries, and the appearance is not perfect.

If we compare bimetallic radiators in the price category from 400 to 600 rubles for each section, we will meet two manufacturers from Italy (Global, Sira) and another brand from Russia - RIFAR. Radiators from these companies look more aesthetically pleasing and attractive when coated in snow-white or cream shades. Some models are equipped with an air vent or thermostat. There are different installation methods and some production nuances (center-to-center distance, configuration, etc.), which do not significantly affect the performance (power) and reliability of radiators. But they all managed to prove themselves on the positive side among satisfied consumers.

The special RIFAR MONOLIT series includes models of radiators specially designed for operation at operating pressures of up to one hundred atmospheres. If you need to choose a radiator with a rounded shape rather than a straight one, you should evaluate the quality and design of the RIFAR FLEX series. And if your choice fell on radiators with a copper core, which has increased resistance to corrosion, then models of such heating devices are presented by the company PILIGRIM.

- Choosing which batteries are best to install in the apartment

- Installing heating batteries with your own hands

- Calculation of the number of sections of heating radiators

- Heating system - Leningradka installation, installation

Manufacturers

When purchasing any product, it is very important to know where it was made and which company produced it. After all, a branded product is always better than an ordinary one. This also applies to bimetallic devices.

Today there are many different devices on the Russian market. Among them, the following types are considered the most recognized and popular.

Italian radiators

Italian engineers came up with the design of a bimetallic radiator. Today you can purchase several models on the construction market:

- "Radena"

- "Global Style".

The appearance of such Italian devices differs from their analogues in their attractiveness and originality. The radiators are compact, have a high-quality finish, and an interesting design. They are designed for long service life. One section can be purchased within 1500 rubles.

Russian devices

The most popular brand remains “Rifar”. The quality of these devices is not lower than Italian models, but their cost is almost 3 times less. One section can be purchased for around 500 rubles.

South Korea

Bimetallic radiators are produced by. The devices have a copper core. Each section is sold on the market for 400 rubles.

Polish models

He is engaged in production. As in Korean radiators, the core is made of copper tubes. The company provides a 25-year warranty on its products, subject to proper use.