When arranging the heating system of a private house, various auxiliary mechanisms and components are used. One of them is a three-way valve. Its task is to redistribute the flow of hot water in the heating system to prevent water hammer or damage to important equipment. The operating principle of a three-way valve and its purpose are of interest to many homeowners.

A three-way valve is one of the auxiliary mechanisms for the heating system in the house

Installation and operation rules

Three-way dividing valves with an electric drive are installed in pipelines and radiators using American union nuts with seals.

Thermal valves (no matter with or without electric drive) are very easy to install:

- Mounted into the hole in the plug of the upper radiator hole.

- The bypass is connected to one outlet pipe, and the coolant supply is connected to the other.

The connection of a three-way mixing valve with an electric drive to the heated floor system is made in the manifold cabinet. The supply of hot coolant from the boiler is connected to one inlet pipe, and the cool return flow is connected to the other. Warm water (45 °C) is supplied to the outlet pipe and then to the pump using an electric drive for the heated floor pipeline.

In the piping scheme of a solid fuel boiler, three-way separating valves with an electric drive are also required. When the boiler is turned on, warm water from the supply pipeline is directed through the bypass into the boiler - this protects the boiler chamber from condensation.

As the water warms up to 50-60 °C, the valve gradually adds cold water from the return line to the water entering the boiler. After the system has completely warmed up, the valve switches to supplying return water to the boiler (at a temperature not lower than 50 °C). When the return water cools more strongly, the valve is turned on again by the electric drive and mixes hot water into the return.

Frequent errors and problems during installation

The most common installation mistake is connecting pipelines to the wrong connections. For example:

- Connecting a bypass to the inlet pipe when connecting the thermal valve to the battery.

- The valve location is not in accordance with the arrows indicating water flow.

Typically, such connection errors occur when the type or shape of the electric valve is incorrectly selected.

Expert advice

Electrically driven thermal valves should not be installed on cast iron radiators - they have a very high thermal inertia, and practically adjusting such radiators is pointless. In case of overheating, it is easier to screw on a regular valve at the coolant inlet to the radiator.

Installing thermal valves with a single-pipe heating system and in multi-storey buildings is quite ineffective (we don’t heat until it gets hot, and if it happens, it’s easier to temporarily cover the radiator with a blanket or cardboard).

But connecting underfloor heating pipes without a three-way valve can lead to very unpleasant consequences - overheating of the system and floor structures (in some cases, even cracking of the screed).

Even more unpleasant consequences are the absence of an electric valve in the piping system of a solid fuel boiler. The ingress of cold water from the return into the combustion chamber of a solid fuel boiler will lead to condensation on the heat exchanger and the walls of the boiler and, as a result, will quickly disable the boiler.

Rules for installing fittings

Typically, the manufacturer indicates the movement of water flow with arrows on the body of a three-way valve. Using these guidelines, you can determine the type of valve. Connection to the system occurs as indicated by the arrows. The installation location should be convenient for subsequent adjustments or replacement in case of malfunction. Both return and supply are suitable for this. But read the instructions carefully, since not all valves can be installed for supply.

Since most of the valves inside are made of ceramic, they do not handle dirty water well. Therefore, it is better to install a filter in front of the valve. If this is not done, the device may become clogged. In some cases, it is enough to clean it, but sometimes even this does not save. Therefore, you should not skimp on filters.

The electric drive should not be located at the bottom, and mechanical thermostatic mixers are also not recommended to be installed this way, only vertically. But I can say from my own experience that in some cases this is possible. And reviews from some owners confirm this.

Features of selection and installation

A three-way valve for heating systems must match the diameter of the heating pipes. Typically this parameter varies from 20 to 40 mm. If a suitable size is not found, then it is worth purchasing additional adapters

It is also important to consider the pipe capacity. If the fittings are purchased for arranging a heated floor system, you can connect a servo drive

The arrows on the housing will help you carry out the installation correctly; they indicate the direction of flow.

When welding, it is important to avoid heating the element. It is necessary to select a location in such a way that the tap can be easily accessed in the future.

When it works with coolant containing impurities, it is important to additionally install filters.

The three way motorized valve can be positioned vertically or horizontally, it doesn't matter

It is important to observe only the direction of the flows. When installing a welded structure, it is necessary to prevent waste from getting on the internal surfaces

This will prevent the mechanism from jamming, as well as the accumulation of scale and impurities.

Useful tips

Before starting the heating system, you must make sure that the three-way valve and other components are in full working order, do not need repair or replacement, and also meet operational requirements. It is not recommended to install a tee on a pipeline with a pipe diameter of 40 millimeters or more. When operating in a hot environment, the valve must be opened with extreme caution, otherwise there is a risk of hydraulic valve failure.

The best material for a three-way valve is brass.

Experts recommend placing control devices or a turning handle with a rod so that they are freely accessible. When choosing a suitable faucet model, it is advisable to give preference to products made of brass. They are characterized by a long service life and resistance to all kinds of influences.

As for the control method, the best option would be a product with pneumatic control. Before making a choice and buying a tee, it is better to consult with a specialist, talk about the possible pros and cons of the available models, and also read reviews about them on thematic forums.

Features of a three-way heating valve

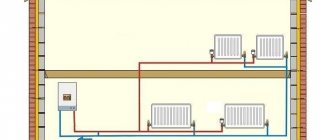

The problem is solved in two ways. The first is the quantitative regulation of the coolant. Part of the flow is directed in addition to the radiator using a bypass - a bypass pipe.

The bypass regulates the pressure in the heating network so as not to disrupt the operation of the circulation pump. If we shut off the radiators in one of the rooms, the pressure in the heating network increases, so the water flow is not blocked, but directed in addition to the radiator.

The second way to solve the heating problem is high-quality regulation with coolant recirculation. Cooled water from the return pipeline is mixed with the flow entering the battery. A three-way valve is used to manipulate the coolant.

Working principle and use

Depending on the installation orientation, the crane can perform different tasks:

- mix two streams into one;

- redistribute one flow into two pipelines.

The control system fittings have three pipes for connection to the coolant flows and a tap that regulates the water supply in two of the three pipes. The task is not to block the flow, but to redistribute it. Depending on the position, the valve completely shuts off one of the flows or partially shuts off two of them, regulating the outlet temperature by mixing in a colder flow.

How many positions does the mixing device have in the heating circuit:

- completely open - the coolant temperature corresponds to the temperature level at the boiler outlet;

- completely closed - a flow of return network water is supplied through the tap;

- intermediate position - the return is mixed with the direct in different proportions.

The three-way mixing valve is the connection point between the bypass and the control valves and allows you to easily and smoothly control the temperature in a single room.

This control method is widely used in heat exchange points of entire microdistricts. High-quality regulation leads to fuel savings.

Disadvantages of a quality regulatory system:

- difficulty in distributing the same amount of coolant across different branches of the heating network;

- reduced temperature at the inlet to the extreme heaters.

“Witches’ rings” in urban heating networks are an example of erroneous regulation of coolant supply to an object. Entire microdistricts are covered by the circulation of reverse network water, passing in a circle, bypassing the heat source.

When the coolant flows are mixed, the return temperature at the outlet of the heating unit increases. The amount of coolant and speed remain the same, but the fuel supply to the boiler is reduced, since less heat is required to heat the warmer water. This is one of the ways to save fuel at power plants.

Three-way valve device

Faucets are made of brass, stainless steel and cast iron.

Cast iron is used in heating systems with pipes with a diameter of more than 40 millimeters, which is rarely used in private homes. Brass taps are the most popular. They are durable, small-sized and light weight.

The mixer resembles a tee with a thickening at the junction of the pipes. According to their design, they are either rod or ball.

In a ball valve, there is a cylinder or ball inside, bounded by Teflon walls. The ball rotates around a central axis and has a hole in it. When the ball is rotated, the hole partially or completely opens. When fully opened, one of the incoming flows closes; if the ball hole partially opens into two pipes, it becomes possible to adjust the temperature when mixing flows.

The advantage of a ball valve is precise installation, but over time, the smooth surface of the ball facing the flow becomes covered with salt deposits. When the ball moves, the soft Teflon partitions wear out, which leads to a violation of the seal.

By its design, a rod valve is a device consisting of a saddle with two passages; a rod with valves moves in the center of the saddle, which can completely block one of the flows or, in the middle position, open both. The disadvantage of the design is the high hydraulic resistance, which is created by the narrowed saddle of the crane. If valves are selected incorrectly, hydraulic resistance increases, which leads to overload of the circulation pump and excessive energy consumption.

https://youtube.com/watch?v=2Y2N2p-8M0s

general information

It is no secret that the problem of uneven heat distribution in a room often causes a lot of trouble for owners. To get rid of this unpleasant phenomenon and create a comfortable temperature regime, you need to introduce a special device into the heating system - a thermal power regulator or a three-way valve.

The mechanism ensures recirculation of the coolant fluid by mixing a certain amount of cooled treatment with the main current. Currently, tees are installed in hot water supply systems, heating circuits and plumbing systems.

In most cases, three-way valves are installed in heating systems with many components and circuits, which is necessary to stabilize the temperature in all radiators. The use of the device allows you to control the flow of coolant, distributing it to different parts of the room (for example, in the kitchen, garage and living rooms). Among the main advantages of the invention are:

- compact and ergonomic dimensions;

- multifunctionality;

- ease of installation, operation and maintenance;

- high tightness;

- long service life;

- ease of switching between operating modes.

In addition to the advantages, tees also have disadvantages. These include the likelihood of valve jamming if operating rules are not followed and rapid wear of inexpensive products.

This video will tell you how to install a three-way valve correctly:

Adjusting the flow of working fluid. What to look for when purchasing

Manual adjustment is made using a conventional ball valve. Visually it is very similar to a simple valve, but has an additional output. Fittings of this kind are used for forced manual control.

As for automatic adjustment, a special three-way valve is used here, equipped with an electromechanical device to change the position of the rod. It should be connected to a thermostat in order to be able to regulate the temperature in the room.

Remember that when purchasing a valve, it is imperative to take into account the technical parameters of the device, which include the following

- Diameter of connection to the heating main. Often this indicator varies from 2 to 4 centimeters, although much depends on the characteristics of the system itself. If a device of a suitable diameter cannot be found, you will have to use special adapters.

- The possibility of installing a servo drive on a three-way valve, the operating principle is discussed at the beginning of the article. Thanks to this, the device will be able to work automatically. This point is very important if the device is selected for use in water-type “warm floors”.

- Finally, there is the pipeline capacity. This concept refers to the volume of liquid that can pass through it in a certain time.

Operating principle and design of a three-way valve for heating systems

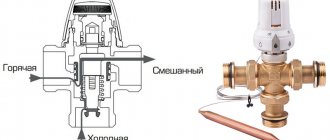

The design of a three-way valve is based on a conventional T-shaped tee. Two inlet pipes (in the diagram on the right and above) serve to supply cold and hot water. The outlet pipe (in the diagram on the left) removes the mixed flow. In the central chamber, the regulating sector rotates on an axis, partially blocking the incoming pipes. The figure shows how a sector three-way valve works

Figure 2. Operating principle of a sector valve

The overlap can be from 0 to 100%. The peculiarity of the design is that the more the lumen opens for one of the incoming pipes, the smaller the lumen becomes for the other. If the sector is in the middle position, 50% of each flow is passed through. By shifting the sector, for example, to the upper pipe, you can get the cold/hot proportions:

And so on until cold water is completely shut off (0/100%), in which case only hot water will flow into the outlet pipe

The valve can be controlled manually or using a bimetallic thermostatic device.

Figure 3. Diagram of operation of a thermostatically controlled valve.

This function can be performed using two two-way valves and a conventional tee used together. This is exactly what happens in two-valve mixers. To ensure constant pressure and accurately control the proportion of mixing of hot and cold flow, it is necessary to ensure that two taps open in antiphase (one opens, the other closes proportionally), for example, by placing them on a single axis.

Three-way valves are divided into two large groups. They can be:

- Separating. They serve to proportionally divide the incoming flow into two outgoing ones.

- Mixing. Designed to mix two incoming streams into one summing

Figure 4. Diagram of operation of a mixing and separating three-way valve

From the diagram it can be seen that the design of the mixing and separating valve is almost identical. They differ only in the directions of the flows. If installed correctly, the mixing valve will also work as a separating valve. You just need to configure the control system correctly. In case of manual control there will be no problems. It will be more difficult, but also possible, to configure electronic control. But the thermostatic control module, if connected via a separation circuit, will distribute flows depending on the temperature of the incoming flow. This will have to be taken into account when designing the heating system.

How many positions a sector valve with an electric drive has is shown in Fig. 5

Figure 5. Options for using an electric crane

In addition to sector three-way valves, saddle valves are also produced. Their operating principle is the same, but there are design differences.

Figure 6. Saddle or ball type valve

The mixing seat valve has a spherical working body moving on a rod; it locks the seats in turn, through which mixed flows pass into the chamber and then into the outlet pipe. The separating valve is equipped with two working bodies, mounted on a single rod and blocking the outlet flows. The more one is blocked, the more the other is open. Seat valves cannot be interchanged.

In addition, three-way devices are divided according to the control method:

Electrical. The sector is rotated using an electric motor with a gearbox. Such devices are connected to a computerized control system that reads temperature sensors and controls the flow in accordance with the built-in algorithm.

Figure 7. Electric crane

Manual. They are used in simple circuits with a constant proportion of distribution or mixing of flows. The angle of rotation of the sector is set manually by turning the flywheel.

Figure 8. Manual control

Thermostatic. Control is carried out by an autonomous thermostat. It is set to a certain temperature when setting up the system, and then it independently maintains it by passing part of the incoming flow from the radiator through the bypass pipe.

Figure 9. Esbe three-way valve with thermostatic control

If necessary, you can change the set temperature by turning the handwheel. It is often installed at the inlet of heating radiators to adjust the comfortable temperature in each room.

How to choose

The choice of a three-way valve is made based on the parameters of the existing heating system, the sizes and types of pipeline connecting devices, as well as other criteria:

Mismatch of any elements will either make it completely impossible to install a three-way valve, or will require the use of various adapters, for example, to attach a union type to a flange

Standard connection dimensions are in the range of 20–40 mm, but for high-pressure systems designed to serve large buildings with a large number of consumer devices, three-way valves with flanged connections are used. It is important to ensure that the diameters of the pipes and the valve match, otherwise the pressure in the system will be changed, which will entail a change in all design parameters. For large and extensive systems, such a change can cause failures or malfunctions, a drop in coolant temperature and other problems.

It is also necessary to purchase taps designed for the pressure existing in the existing system. When purchasing, you need to have an accurate idea of whether you need a servo drive, a pneumatic regulator, or whether the mode will be set manually. This is important, since replacing a three-way valve during operation is a difficult task, requiring disconnection from the coolant supply. In winter, this event can cause pipelines to defrost and fail. It is recommended to purchase three-way valves in brass or copper bodies. In practice, they have shown their superiority over steel and cast iron devices in terms of durability and reliability. It is best to choose products from well-known companies. The cost of such cranes is higher than that of less famous or Chinese models, but the quality and compliance of the operating parameters with the declared passport values will be guaranteed. Three-way valves are not purchased every day, so you can pay more once.

Collector connection diagram

The order of work is as follows:

- The collector box is mounted in a place that is convenient for access and at the same time so that it does not interfere. Pipes supplying heated water and return are connected to the cabinet. But before this, shut-off valves should be installed on the collector.

- In order to control the temperature and pressure in the system, a thermometer and a pressure gauge are placed in close proximity to the valves.

- To connect pipes connected to the manifold, compression fittings are used using a threaded connection.

- If it is necessary to combine pipes with different diameters, adapters or universal fittings are used, taking into account the connection diagram for the heated floor.

The simplest scheme for connecting a heated floor is as follows: one of the collectors connects the pipes supplying water, and the second - the return flow of the already cooled coolant (pro

Types of three-way valves

Since distribution valves for various purposes are now on sale, it is necessary to understand the difference between them and know the design features of these devices. In this case, it will be possible to make the right choice of a three-way valve. Below we will look at how the products of different models differ.

By purpose and principle of operation

Externally, different types of taps are no different, since they have 3 pipes, but their operating principle is exactly the opposite:

- Mixing tap (adjusting). Mixes two coolant flows. The inlet is carried out through two pipes, and the outlet through one. Inside the device there is a rod with a valve.

- Distribution valve (shut-off valve). It does not mix, but divides one stream into 2 parts. Valves are installed in the pipes. When one valve opens the passage for coolant, the second closes its line. The coolant enters the faucet through one pipe and exits through two. Such devices are often used for piping water heaters, in systems with installed boilers, to distribute heat to several rooms.

Manual ball three way valve

Housing material

- Brass. This is the most popular metal alloy, which is reliable and practical.

- Steel. Can be found much less frequently. It is characterized by increased strength, but less durability than brass.

- Cast iron. Not used in everyday life. It is used for installation of industrial heating systems in which pipes have a diameter of more than 40 mm.

According to control principle

A three-way faucet for home heating may differ in the control method:

1. Manual control. Products of this type have rotary knobs that control the flow of coolant. Turning the knob changes the proportion of water supplied from different lines. The disadvantage of such mechanisms is uneven and long heating of distant radiators. Such fittings are characterized by a simple design and low cost.

2. Automatic control. Automatically controlled faucets make it possible to heat rooms to the desired temperature without human intervention. Moreover, heating becomes more efficient, radiators heat up evenly, and there is no need to constantly monitor the operation of the heating circuit. The distribution valve can be controlled by a servo drive, as well as by a hydrodynamic or pneumatic thermostat. Below we will look at the features of each of these devices.

Three way valve with electric drive

A servo drive, which is an electric motor, is used as a control element. A command is sent from the electronic control unit to the servo drive, according to which the motor changes the position of the ball or rod inside the device. The control unit determines the temperature at the outlet of the valve or calculates the optimal setting based on the return temperatures and water coming from the boiler.

Three way valve with servo drive

Of course, it makes no sense to install a three-way valve for an electric heating system without a control unit.

Distribution valve with thermostat

Such a device is a valve with a thermal head in which gas or a special liquid is placed. These components respond to changes in ambient temperatures. As a result of temperature fluctuations, the volume of liquid or gas changes, which leads to automatic operation of the valve.

When installing the device, careful adjustment is required. Temperature limits are determined and associated with the extreme positions of the valve. This determines the operating range within which a three-way heating valve with a thermostat will change the temperature of the coolant. For this purpose, the pressure in the thermal valve is manually adjusted.

Three-way valve for heating system with thermostat

The coolant circulates through the device until its temperature changes to the set value. As soon as the temperature goes beyond these limits, the proportion of mixing cold and hot water in the tap will change.

The advantage of a faucet with a thermostat is that it does not require a control unit to operate. Such devices operate autonomously and also have an acceptable cost.

Simplified mixing elements with temperature lock

An autonomous three-way valve of a simplified type can be installed in simple heating systems of country houses, where heat is obtained from a TT boiler. To function, it does not require a thermal head with a temperature sensor, and there is no rod there.

The thermostatic element, which is installed inside the housing, is adjusted to a certain temperature of the coolant at the outlet, for example. 50 or 60 °C (must be marked on the body).

The mixing valve of this sample always maintains the set temperature of the coolant at the outlet; this setting does not change. This gives rise to positive and negative aspects when using such fittings:

- advantage - cheaper, unlike a unit with a thermal head. The difference is about 30%;

- disadvantage - there is no possibility of adjusting the heating of the exiting coolant. If the factory settings are set to 55°C, then it will constantly supply water at this temperature ±2°C;

- Before purchasing a valve of a simplified design, carefully study the documentation for the solid fuel boiler; it usually indicates the minimum return temperature.

A thermostatic three-way valve is a rather useful thing in the heating system of a private home, which makes it possible to efficiently use the heated liquid, and thereby save fuel. Moreover, this part allows you to increase the service life of solid fuel boilers, and also plays the role of a safety element. On the other hand, you should not sculpt the valve just anywhere; it is always better to consult with a specialist who is well versed in this.

Typically, warm water floors are installed in private households equipped with heating boilers. In this case, the heating scheme with heated floors involves connecting pipes with coolant through a manifold for heated floors with your own hands. First you need to lay the pipeline system and install the manifold cabinet (you can see how it looks in the photo).

Types by control method

Types of control depend on operating conditions and purpose. Fixing heat main sensors transmit commands to controllers, who coordinate the actions of energy suppliers.

There are different types of drives:

- with thermostat;

- electric drive;

- pneumatic;

- hydraulic.

A manually adjusted drive is much less common.

With manual control

Manual valve

The rod is driven by a rotary handle or valve. For convenience, a control panel is installed with marks on it. Risks correspond to certain thermal hydraulic regimes.

- The positive points include:

- low cost of manual drive;

- direct control of regime indicators;

- the ability to instantly change the order of work.

With thermostat

Valve with thermal head allows you to regulate coolant flows

A three-way heating valve is equipped with a thermostat in which liquid or gas is present. The internal environment reacts to all changes in the temperature of the flows. Heating to the specified parameters activates the thermal valve piston system and the flow of hot flow is blocked.

Three-way units with a thermostat can be mechanical or electronic. Mechanical ones operate autonomously, while electronic ones require connection to electricity or battery power. The disadvantage of the second type is compensated by absolute automation. Electronic regulation allows you to set changes in the heating order by day of the week or time of day.

Electrically driven

An electromagnet (solenoid) is installed or a combination servo drive is used, mounted on an electric motor with a transmission mechanism. The drive is coordinated by temperature or pressure meters, which are placed in the piping circuit. The unit is immediately equipped with a servo drive or supplied without it, which makes it possible to optimally select the device for actuation.

Technical characteristics of current, voltage, power, and overload capacity are taken into account

Choose an economical and reliable one, without high operating costs, pay attention to the surrounding operating conditions and safety requirements

Hydraulic

The three-way heating valve with thermostat is equipped with a thermostat installed inside the housing. The device operates according to the outlet water temperature parameters, which are set at the factory. The hydraulic drive includes a housing with a plate-shaped diaphragm.

The positive aspects of use include the low price. The negative side is the need to select a hydraulic drive according to the temperature of the fluid in the heating line. The second disadvantage is the impossibility of changing the heating mode set at the factory.

Pneumatic

The pneumatic actuator automates the operation of the distribution valve and is used for remote control. The drives are a cylinder with a piston that moves under the influence of compressed air.

Advantages of using pneumatic drives:

- fast control when environmental conditions change;

- simplicity of design and interchangeability;

- the change in force is achieved by simply limiting the air pressure in the drive.

Tap selection

The correct choice of a three-way valve depends on its technical parameters, as well as the features of its installation and use.

First of all, you should consider what diameter of the product is needed to connect to the pipeline. Typically it is 2-4 cm depending on the heating system. If it is impossible to select a device of the required diameter, adapters are used.

It is equally important to know the volume of working medium that each pipeline can pass through itself over a certain time period. Possibility of installing a drive with automated control

This property is necessary when choosing a device for use in a water-type “warm floor” system

Possibility of installing a drive with automated control. This property is necessary when choosing a device for use in a water-type “warm floor” system.

It is worth paying attention to the base from which the device is made. Brass taps are considered the best because they are less susceptible to corrosion.

Regardless of what type of product you choose, it is worth checking the operation of the shutter mechanism, as well as the surface of the tap for damage and traces of rust.

Advantages

The modern world is developing at a rapid pace. Modernization affects many aspects of public life. The changes also affected the design of pipeline fittings. Now we have half-turn three-way ball valves that easily distribute the flow of substances. Previously, valves were used instead. This caused a lot of inconvenience.

- Regular technical checks were needed.

- These devices were very large and heavy. This, of course, made the operation process much more complicated.

Their successors have a number of undeniable advantages. Among them:

- tightness at connection;

- simplicity and ease of operation;

- Possibility of use in polluted and uncomfortable environments;

- no need for constant inspections and maintenance;

- smooth turn;

- synchronization with various liquids (nitrogen, carbon dioxide, oils);

- compact in size and weight;

- durability, strength, resistance to various influences;

- Possibility of operation in cold climates;

- simplicity of design;

- significant savings on heating fees (they have the ability to regulate the temperature).

A three-way ball valve is a very useful and convenient device. Although during the operation of such products, some minor shortcomings were identified. For example, they cannot be used in environments where temperatures are above 200 degrees Celsius

But if we compare this point with the above advantages, then it loses significant importance, and there is no doubt about the effectiveness of the described device

How does a three-way valve work?

Externally, it looks like a bronze or brass tee with an adjusting washer on the top, and the design of the three-way valve depends on the model.

Option 1. In a cast body with three nozzles there are three chambers, the passages between them are blocked by disc elements mounted on the rod. The rod comes out of the body at the top. The principle of operation is as follows: pressing the rod smoothly opens the passage for the coolant flow on one side, while simultaneously closing the passage for the coolant on the other side. As a result, in the central zone the coolant is mixed until the desired temperature is obtained and enters the circuit.

Option 2. The switching element inside the tee is a ball, part of which is figuratively selected. The drive rotates the rod with the ball attached to it, as a result of which the coolant flows are redistributed.

Option 3. The principle of operation is the same as that of the design with a ball, but instead of a ball, a sector is fixed to the rod - its working part is capable of completely blocking one coolant flow, or partially blocking two flows.

3-way valve device

Thermal mixing valve drives

To control the coolant flows passing through the three-way valve, an external drive is required. The functionality and ease of use of the device depends on its type.

- Three-way thermostatic mixing valve. The thermostatic actuator is designed to include a fluid medium that is highly sensitive to temperature changes. It is she who, expanding, presses on the rod. Such a drive is installed on small household devices; it can be replaced with a drive of another type.

- Three-way mixing valve with thermal head. The thermal head is equipped with an element that is sensitive to the air temperature in the room. To adjust the temperature of the coolant, such a device is additionally equipped with a temperature sensor on the capillary tube, which is placed in the pipeline. In this case, the temperature regime of the circuit is more accurately regulated.

- Thermal mixing valve

- Three-way valve with electric drive. The electric drive acting on the rod is controlled by a controller, which receives information from sensors about changes in coolant temperature. This is the most accurate and convenient option.

- Three-way valve with servo drive. The electric drive directly controls the rod, without a controller, in accordance with signals from sensors. Servo drives are usually equipped with sector and ball mixing devices.