The reliability and performance of a heating system depends on the efficient operation of all parts included in it.

These include : a boiler for heating the coolant, radiators connected to it and to each other in a certain way, an expansion tank, a circulation pump, shut-off and control valves, and a pipeline of the required diameter.

Creating highly efficient heating system is possible thanks to special knowledge and experience in this field of activity. An important role in the working process of heating a room is played by the return pipeline.

What pressure should be in the heating system on the supply and return?

The operating pressure in the heating circuit of the top and bottom floors should not differ by more than 10%, and the pressure test pressure by 20%. Most often, in an average urban multi-storey building, the working pressure on the coolant supply pipe is 6 a - 4 ÷ 4.5 atmospheres.

Interesting materials:

What car color is the least easily soiled? Which color is closest to white? What color goes best with blue? What color goes best with gold? What color attracts men the most? Which color attracts the most attention? What color will be in fashion in 2022? What color to print? What façade color goes with a brown roof? What lipstick color suits brown eyes?

Types of heating schemes

For multi-storey buildings, a single-pipe direct distribution system is often used. It does not have a clear division of pipes into the liquid supply to the radiators and the return, so the complete circuit is conventionally divided into two equal parts. The riser coming out of the boiler is called the supply, and the pipes coming out of the last radiator are called the return. Advantages of this scheme:

- saving time and material costs;

- convenience and simplicity of installation work;

- aesthetic appearance;

- the absence of a return riser and a sequential arrangement of radiators (coolant is supplied to the 1st, then the 2nd, 3rd and so on ).

For a single-pipe system, vertical wiring with a vertical circuit and heat supply from above is common.

With a two-pipe wiring system, it is meant to install two closed, parallel-connected circuits, one of them provides the function of supplying coolant to the heating device (radiator), the second - the function of its outlet (return).

Radiators are connected in several ways:

- Lower (or saddle, crescent-shaped). Provides for connection of supply and return to the lower connecting holes of the radiator. A Mayevsky tap and a plug are installed on the upper holes. Used for systems in which pipes are hidden under the floor or baseboard. Suitable for multi-section radiators; with a small number of sections, heat loss reaches up to 15%.

- The lateral method is popular. The pipes are connected to the radiator on one side: coolant supply through the top, return through the bottom. Not suitable for devices with a large number of sections.

Photo 2. Two-pipe heating circuit with a side connection type. The supply and return temperatures are indicated.

- The diagonal (or lateral cross ) method involves supplying hot water from above, connecting the return line from below and on the other side. Suitable for radiators with at least 14 sections.

- The third option for organizing a heating scheme is a hybrid method, based on the simultaneous use of one-pipe and two-pipe systems. For example, a collector circuit involves supplying coolant through a single riser; further on-site wiring is carried out according to an individual plan.

How it works and how to improve productivity

A single circuit does not ensure uniform heating of heating devices; heat transfer decreases with distance from the boiler (the last radiators receive coolant cooler than the first ones). The disadvantage of such a system is the high coolant pressure.

Reference. The performance of a single-pipe system is increased by the presence of a circular pump or bypasses formed on each floor.

Advantages of a two-pipe heating option:

- heating a sufficient number of devices equally, regardless of their distance to the heat source;

- adjusting the temperature regime or carrying out repairs on a separate device does not affect the operation of others.

Flaws:

- complexity of the wiring diagram;

- complexity of installation and connection.

The optimal choice for private construction is the most productive two-pipe system, which is also often chosen for heating luxury housing.

It is advisable to install a two-pipe system with the installation of a circulation pump, which allows the use of pipes of smaller diameter.

After it, in order to protect the recirculation circuit from squeezing, a check valve is installed.

When installing a system without a circular pump, the rule is observed : supply is possible if there is a slope from or to the boiler. A coolant with a higher temperature enters the radiator through the inlet (slope from the boiler to the heating device) and warms it up, and then exits through the return (slope from the radiator to the boiler), but at a lower temperature. Experienced craftsmen often resort to replacing the recirculation pump ring with a system of 3 or 4-way mixers.

Important! With natural circulation, the entire pipeline from the riser to the radiators should not be long.

Peculiarities

Long-term operation of boiler equipment is possible with a properly designed pipe distribution system, which ensures a certain temperature difference between the pipes that discharge and supply the coolant.

Why doesn't the return work work?

There are many problems associated with return flow in a heating system.

Squeezes feed

The water temperature in the return pipeline is determined by the design of the heating system and corresponds to the value in the temperature chart approved by the service organization.

Often apartment residents are faced with a problem when the return flow squeezes the supply.

A common reason is the transition of hot coolant from the supply line to the return circuit through various parts (for example, jumpers) of the hot water supply pipeline or ventilation. With an automatic control device, as a rule, it is enough to configure it correctly.

The coolant does not drain well

If the circulation of fluid in the heating circuit is disrupted, the water in the return pipes does not drain well. Initially, check that the power of the circulation pump meets the requirements. The reason may be hidden in a banal pipeline leak . The situation with poor circulation is typical for apartment buildings located on the final section of a heating main with insufficient pressure drop .

The return is cold, the pipes are clogged

Low return temperature is a serious problem that prevents indoor comfort. Causes of cold return:

- incorrect heating wiring;

- air bubble in the system or riser;

- insufficient water flow through the network;

- low temperature in underwater pipes;

- increased volumes of heat loss ;

- inefficiency of pumping equipment , result: poor circulation and insufficient temperature difference between heat supply and return;

- low pressure;

- clogged pipes and radiators.

The use of Mayevsky cranes makes it possible to eliminate air pockets that impede the movement of the coolant.

Photo 4. Mayevsky tap installed on a heating radiator. Using it you can bleed excess air from the system.

It is important to bleed air correctly:

- shut-off valves to stop the heat supply;

- open the Mayevsky tap, bleed the coolant with air;

- restore the movement of heat by opening the lock.

The narrow passage of the control valve often explains the low return temperature, this is a reason to replace it with a new one.

Periodically check the pipeline for clogging, which interferes with the movement of the coolant. Dirt and deposits are removed . If pipe patency cannot be restored, the section is replaced with a new pipeline.

Attention! The exact cause determined after checking the entire heating system.

This article lists the main malfunctions that can happen to the heating system of a private home, as well as ways to eliminate them. Troubleshooting heating systems can be divided into two types. Do-it-yourself heating system repairs can be done in the heating system wiring: radiators and fittings. All problems that arise in the boiler room and equipment require special knowledge and experience, so heating system repairs related to equipment to specialists.

How to make radiators hot - looking for solutions

If you find that the return is too cold, you should take a number of steps to find the causes and troubleshoot problems. First of all, you need to check that the connection is correct. If the connection is not made correctly, the down pipe will be hot when it should be slightly warm. The pipes should be connected according to the diagram.

Sometimes it may be necessary to dismantle the control valve to increase the cross-section

To avoid air pockets that impede the flow of coolant, it is necessary to provide for the installation of a Mayevsky valve or bleeder for air removal. Before bleeding the air, you need to turn off the supply, open the tap and let out the air. Then the tap is turned off and the heating valves open.

Often the cause of cold return is the control valve: the cross-section is narrowed. In this case, the tap must be dismantled and the cross-section increased using a special tool. But it is better to buy a new faucet and replace it.

The reason may be clogged pipes. You need to check them for passability, remove dirt and deposits, and clean them well. If passability cannot be restored, the clogged areas should be replaced with new ones.

If the coolant flow rate is insufficient, you need to check whether there is a circulation pump and whether it meets the power requirements. If it is missing, it is advisable to install it, and if there is a lack of power, replace or upgrade it.

Knowing the reasons why heating may not work efficiently, you can independently identify and eliminate malfunctions. Comfort in the house during the cold season depends on the quality of heating. If you carry out the installation and inspection of the heating system yourself, you can save on hiring third-party labor.

Operating principle of a steam boiler

First of all, you need to understand what is called a steam boiler. A steam boiler is a device that generates steam. There are two types of steam produced - saturated and superheated. The saturated temperature is 100 degrees and the pressure is 100 kPa. Superheated steam heats up to 500 degrees, and the pressure can exceed 26 MPa. Saturated steam is used in household units, and superheated steam, due to its characteristics, is applicable only at industrial-scale facilities.

The raw material for creating steam is water, which is processed in a boiler running on any type of fuel. During operation, the generated steam is converted into a coolant that delivers thermal energy to the area where it is used.

Regardless of the design features of a particular device, the general principle of operation of a steam boiler always remains the same:

- First, the water goes through a purification stage and is sent to a reservoir (usually located at the top of the device) using an electric pump;

- The water accumulated in the reservoir flows into pipes leading to the collector located below;

- From the collector, water is directed upward, entering the heating zone;

- In the pipe, water is converted into steam, which escapes upward due to the difference in pressure between the liquid and gas;

- At the top of the structure there is a separator that allows you to separate steam from water and drain excess water into the tank;

- The steam is directed into the pipeline and sent to consumers;

- In steam generators, the heating stage is carried out again to achieve the required steam state.

To understand well how a steam boiler works, you also need to consider the features of its design, which will be discussed further.

Advantages

- Cost-effective;

- Attractive cost of the equipment itself;

- High performance indicators;

- Excellent heat saving;

- Versatility. Different types of steam boilers can use different types of fuel;

- High efficiency;

- For heating, pipes with a small diameter are used, which has a positive effect on the compactness of the circuit;

- Can be installed for any home, the circuit will remain safe. The main thing is to follow the rules of installation and operation;

- Consumed fuel does not require constant monitoring;

- Low inertia parameters, which ensures faster heating of rooms.

How to deal with problems

If the boiler goes out and does not light up again, check the quality of ventilation in the room. This is a common cause of problems for atmospheric models “Proterm”, “Navien”, “Ariston”, “Bosch” with an open combustion chamber, because they take combustion air from the room.

What to do:

- Organize high-quality ventilation in the room;

- Install ventilation valves on sealed window packages;

- Open the window in the boiler room for air flow.

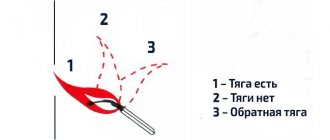

Check the presence of draft in the boiler chamber. To do this, light a match and bring it to the control window or chimney outlet. If there is draft, the flame will deviate to the side. If not present, it will burn evenly. In the latter case, a chimney inspection is required.

Problems with the chimney part

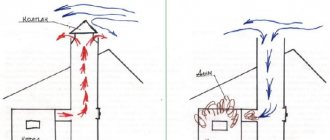

This is excess, deficiency or backdraft. All this leads to the fading of the wick and automatic shutdown of the equipment.

Backdraft or blowing out occurs due to weather conditions: strong winds, pressure changes lead to the burner extinguishing. During installation, take into account the requirements for the height of the chimney:

- The height of the pipe on a flat roof is at least 50 cm;

- With a distance from the roof ridge of 1.5 meters - from 50 cm above the ridge;

- At a distance of 1.5–3 meters - level with the ridge.

Compliance with these parameters will help to avoid blowing and backdraft.

Excess air flow occurs with a powerful kitchen hood or ventilation. The solution is to turn off the hood while the boiler is operating.

Lack or absence of traction provokes:

- Blockages. Occurs in stationary chimneys. Clear the mine of leaves, debris, and construction debris. Fixed and coaxial pipes can become covered with ice in winter. Along with combustion products, hot steam escapes into the street, condensation forms, which freezes on surfaces. Insulate the chimney.

- Damage, burnout of the pipe. Only replacing the chimney will help.

Line pressure drop

Does the dual-circuit device “AOGV”, “Beretta” or “Vailant” turn off and not turn on? This is possible when the fuel supply is unstable. For the same reason, the burner does not light the first time. First of all, check:

- Pipes and joints for gas leaks. To do this, lubricate them with soap foam. If bubbles appear, there is a leak. Then turn off the valves, open the window and call the gas workers.

- Counter. If there is a breakdown, the meter readings do not change; noise and crackling are heard. You can’t fix the problem yourself—you need a specialist.

If everything is fine, wait until the gas supply is restored.

Why is the riser hot and the batteries cold?

Sometimes, with a hot supply, the return of the heating battery still remains cold. There are several main reasons for this:

- installation was performed incorrectly;

- the system or one of the risers of a separate radiator is airborne;

- insufficient fluid flow;

- the cross-section of the pipe through which the coolant is supplied has decreased;

- The heating circuit is dirty.

Cold return is a serious problem that must be eliminated. It entails many unpleasant consequences: the temperature in the room does not reach the desired level, the efficiency of radiators decreases, and there is no way to correct the situation with additional devices. As a result, the heating system does not work as it should.

The main trouble with cold return is the large temperature difference that occurs between the supply and return temperatures. In this case, condensation appears on the walls of the boiler, reacting with carbon dioxide, which is released during fuel combustion. As a result, acid is formed, which corrodes the walls of the boiler and shortens its service life.