If a country house is actively used not only during the summer season, but also during the cold season, the creation of a high-quality heating system in it is an urgent need.

Different coolants can be used in heat supply lines: air heated to 60°C, water steam at 130°C and water at a temperature of 95°C. Water heating is most often used.

One of the main advantages of this coolant is the ability to install various water heating systems depending on the design features of the house, personal preferences and other factors.

In the article, we described a detailed classification of water heat supply schemes, outlined the features of each option, and also provided recommendations for choosing the main components of the system. The information presented will help you design the heating of a private home.

Requirements for the operation of the heating system

With all the variety of water heating systems, there are a number of general requirements for their operation.

They have to:

- uniformly warm up all the air in the rooms;

- be repairable;

- do not create difficulties during operation;

- be linked to ventilation systems;

- be regulated.

The operating principle of the heating system itself is also common: water is heated, after which it circulates through the pipeline and releases the resulting heat, warming the rooms.

The coolant in winter can be a non-freezing liquid - antifreeze. So that the ethylene glycol contained in its composition does not cause corrosion of pipelines

Water heating systems

Despite all the external differences and different connection schemes, the basic operating principle of water heating systems is the same. The coolant heated in the boiler is transported through a pipeline to the heating devices.

As the water cools, it transfers heat to the environment and then returns to the place where it will be heated. This cycle repeats itself over and over again.

Natural and forced circulation

The following types of heating systems are used in private homes:

- with natural circulation;

- with forced circulation.

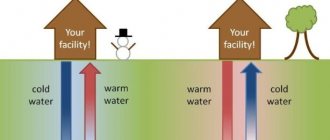

Natural circulation . Its performance is based on the difference in density between hot and cold. The upper positions of such a system are occupied by warm water, and the lower positions by cold water. When warm water cools down, it moves down, and when it warms up, it moves up.

The second factor that ensures the natural circulation of water masses is the slope at which the pipes are installed.

This is how the sources of circulation pressure are graphically represented. Firstly, its appearance is due to different water temperatures, and secondly, the inclined position of the pipes (+)

The advantage of the natural circulation scheme is its complete independence from the power supply.

It has many more disadvantages:

- small radius of action , not exceeding 30 m in the horizontal dimension;

- warm-up duration - a long period of reaching operating temperatures at all points of the system when starting after a long break;

- risk of work stoppage due to ice formation in the open expansion tank.

The diameter of the pipeline must be large enough due to the low circulation pressure in the circuit. This factor also influences the choice of batteries, because modern radiators have a too narrow cross-section, which creates additional resistance that counteracts circulation by gravity.

In order to further stimulate the movement of the coolant, the pipeline is constructed with a slope so that there is an average of 3 mm per 1 linear meter. Correct installation of pipes at the right angle is not an easy task, but without solving it, the system will function much slower and more efficiently.

Due to the fact that the coolant sequentially moves through the devices to those closest to the battery supply line, it arrives at a higher temperature (+)

The coolant flows to the distant radiators of gravity systems when it has already cooled down significantly. To maintain the heating temperature, cast iron radiators should be used. To balance the temperature difference, the furthest batteries must have more sections than those closest to the boiler.

Forced circulation is provided by a pump. The circuit may contain one or several pumps. Using several pumps is preferable: an emergency shutdown of one of them will not damage the entire heating system.

The coolant moves cyclically along a closed circuit, which includes an expansion tank, which eliminates the evaporation of water.

A distinctive feature of a water heating system with forced circulation of coolant is the presence in the circuit of a pump, which promotes the movement of water

Advantages of a forced circulation system:

- for heating installation you will need more pipes, but of a smaller diameter;

- you can use different types of radiators and heat pipes with small diameters;

- the temperature of heating devices is easier to regulate;

- the range of action has been significantly expanded due to artificial stimulation of coolant movement;

- the possibility of using heating units with increased coolant characteristics.

The disadvantage of forced systems is their dependence on energy supply. In order to avoid incidents with complete heating inactivity, it is recommended to stock up on a diesel or gasoline generator.

In addition, the disadvantages include:

- the need to accurately calculate the diameter of the pipeline, because too narrow channels will sharply increase the hydraulic resistance, and when circulating through excessively wide pipes, the coolant will “noise”;

- the considerable cost of construction due to the almost double length of the pipeline, the inclusion of one or two circulation pumps in the circuit, and, if necessary, a booster pump;

- mandatory use of expensive regulators of coolant flow, its temperature and pressure in the system.

The correct choice of the type of circulation depends on the individual characteristics and location of the building in which the water heating will be installed. However, recently they have begun to resort to schemes with natural movement less and less, using them mainly in buildings for temporary residence.

Most often, private houses are equipped with systems with artificially forced coolant movement due to significantly greater capabilities.

Combined circulation systems

The combined system can operate in both natural and forced modes. This means that when installing it, it is necessary, as in the case of using natural circulation, to provide for a pipe slope of 3-5 mm per linear meter, as well as installing a pump, as for forced circulation.

Typically, such a heating scheme includes a solid fuel boiler.

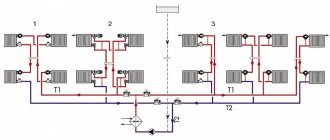

The circuit includes: 1- electric boiler, 2- solid fuel boiler, 3- pump. This is a diagram of a combined heating system, in which, in addition to the pump, there is an inclined pipeline system, and the electric boiler is duplicated with a solid fuel one, so that the system can operate without electricity (+)

The point of using a combined system is that it will continue to operate even in the event of a power outage. But a sudden cessation of heating in winter threatens not only a decrease in the temperature in the room.

Elements of the heating system may simply fail because water, expanding when freezing, will break their tightness.

Methods for installing water heating systems

Let's consider two main installation schemes for heating systems.

Single pipe heating system

The design of the pipeline in the single-pipe version is characterized by a direct sequence of supplying coolant to the radiators. The coolant fills and warms up the first battery, then the next, and so on.

Two pipes are connected from one pipe to each radiator: the first is needed to supply coolant, and the second is to drain partially cooled water.

A single-pipe heating system is characterized by a sequential connection of all radiators, in which the coolant, having passed through the first heating device, enters the next one.

The peculiarity of this scheme is the relatively low heating of the last battery compared to the first, since the water “reaches” it, having already given up part of its heat.

Another disadvantage of the single-pipe heating option is that it is impossible to stop the supply of coolant to one specific radiator in case it breaks down. You'll have to shut down the entire system.

Two-pipe system and its varieties

In a two-pipe heating scheme, as is already clear from the name, not one, but two pipes are involved. In this case, each of the batteries is connected by one pipe to the main line through which the coolant is supplied, and by the second to the return pipe. It turns out that separate pipes are provided for hot and cooled coolant.

This system involves two pipes: one carries hot water, entering the radiators through pipes, and the second carries coolant (+) from the batteries.

Thanks to this heating design, the water in all radiators has almost the same temperature. The operation of such a system is easier to control, adjust and automate.

The two-pipe system, in turn, is divided into two types:

- with the upper gasket of the supply pipe, i.e. with top wiring;

- with the bottom gasket of the supply pipeline, i.e. with bottom wiring.

Systems with overhead wiring are built mainly in multi-storey buildings with an attic space. Schemes with bottom routing are a priority in private low-rise construction, because they make it possible to hide the laying of the pipeline to the maximum and eliminate or reduce the number of risers.

A two-pipe heating system for a private house is often made according to a collector circuit, although the latter can also be single-pipe. The radial arrangement of pipeline sections allows to significantly reduce the cost of heating the coolant (+)

A comparative description of one-pipe and two-pipe heating systems is given in the video material, which is located at the bottom of our article.

Connecting radiators

The choice of method for connecting them depends on their total number, installation method, length of pipelines, etc. The most common methods are:

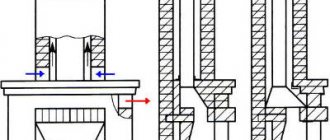

• diagonal

(cross) method: the straight pipe is connected to the side of the battery at the top, and the return pipe is connected to its opposite side at the bottom; this method allows the heat carrier to be distributed across all sections as evenly as possible with minimal heat loss; used with a significant number of sections;

• one-sided:

also used with a large number of sections, the hot water pipe (straight pipe) and the return are connected on one side, allowing for sufficient uniform heating of the radiator;

• saddle:

if the pipes go under the floor, it is most convenient to attach the pipes to the lower pipes of the battery; due to the minimal number of visible pipelines, it looks attractive in appearance, but the radiators heat unevenly;

• lower:

the method is similar to the previous one, the only difference is that the direct pipe and the return pipe are located almost at the same point.

Methods for connecting radiators

To protect against the penetration of cold and create a thermal curtain, the batteries are located under the windows. In this case, the distance to the floor should be 10 cm, from the wall - 3-5 cm.

Open and closed heating systems

In addition to the types of water heating systems we have already discussed, there is a division into open and closed structures.

An open heating system consists of a boiler (any type except an electric one is used), pipelines, heating radiators and an expansion tank, into which excess water flows as it expands during the heating process.

The tank is not sealed, water from the system can evaporate, so its level must be monitored and topped up if necessary.

In order for an open heating system with overhead wiring and natural coolant circulation to work more efficiently in winter, it is recommended to insulate the supply riser. This measure will prevent the coolant from cooling and, as a result, slowing down its movement (+)

The pump is not used in an open heating system. The heating boiler is located at its lowest point, and the expansion tank is located at its highest point.

The closed design is airtight . It includes all the same elements as the open one. But since the movement of coolant in it is forced, the mandatory list of elements is supplemented by a circulation pump.

The expansion tank, which is part of a closed structure, consists of two rolled parts, separated by a diaphragm. When an excess of expanded liquid occurs in the system, it enters one of the chambers of the tank, pushing the diaphragm into the second chamber filled with nitrogen or air.

As the coolant expands, the pressure in the system increases, and the part of the tank filled with water tends to displace and compress the gas mixture. When the pressure limit in the tank is exceeded, a safety valve is activated, releasing excess coolant.

A closed heating system is characterized by forced movement of coolant and the presence of a closed expansion tank with a membrane; this system is more complex than an open one

Each heating system has its own advantages and disadvantages. They differ in a number of characteristics and are suitable for various objects. If you need to heat a small private house or cottage, use a simple and reliable open design.

A closed heating system, which is more complex to install and operate, is more often used in large cottages and multi-storey buildings.

Heating system elements

Since we are going to install water heating in the house with our own hands, we need to have an idea of the components of the proposed design.

Determining the right boiler

The boiler is the heart of the heating system. It is very important to choose it correctly, since the reliability of heat supply largely depends on it.

Heating boilers can be used either singly or in pairs, for example, in addition to an electric boiler, a solid fuel boiler can be included in the circuit in case of a power outage

Depending on the fuel used in the boiler, the following types of these devices are distinguished:

- Gas . This boiler is most popular among consumers. It is easy to install and works without unnecessary noise. Gas is relatively inexpensive and produces a lot of heat when burned. But to use it, you need to obtain permission, order the installation of a supply line and organize exhaust ventilation in the boiler room.

- Electrical . These boilers are the safest. Their installation location does not require any additional equipment. Their operation does not produce open flames or combustion products that could cause poisoning. But the efficiency of this device is relatively low, electricity is expensive, and the energy-intensive boiler requires a reliable power grid.

- Liquid fuel . Unlike gas boilers, these boilers are equipped with a special type of burner. This equipment requires a special boiler room. Liquid fuel quickly pollutes the boiler.

- Solid fuel . These devices burn coal briquettes and other types of solid fuel. If you are ready to prepare firewood or coal for the entire cold season, then you can use this option.

Combination boilers are considered the most reliable, in which different types of fuel can be used. There is only one drawback to such equipment - such boilers are expensive.

What are heating radiators?

In order not to be disappointed with the results of the work performed, you need to take a responsible approach to the choice of radiators. In this case, you should focus not so much on aesthetic qualities, but on the technical characteristics of the batteries. And the technical properties largely depend on the material used to make these products.

Modern cast iron radiators can look very attractive, especially if the interior of the room as a whole is designed in the same style.

Radiators are:

- Steel . These inexpensive products are too susceptible to corrosion. If the water is drained from the system in the summer when heating is not used, the service life of steel radiators can be significantly reduced.

- Aluminum . These attractive looking radiators heat up fairly quickly. Only significant pressure drops have a negative effect on them. In private homes this danger does not threaten them.

- Bimetallic . Such batteries are resistant to corrosion from aluminum, and high heat dissipation from steel.

- Cast iron . These products are expensive, but they will last a very long time. They take a long time to heat up, but they also take a long time to cool down. The significant weight of cast iron products is not a hindrance during their operation, but can slow down the installation process.

There are new models of radiators that have a protective coating applied to the inner surface. These batteries are a little more expensive, but the money spent on them is more than worth it.

Image gallery

Photo from

Cast iron radiators for heating systems

Aluminum devices for heating systems

Bimetallic devices

Budget steel version of devices

How not to make a mistake with pipes

Installing a heating system will require a lot of pipes.

Which one should you prefer:

- Metal . The service life of such pipes is not very long. Over time, metal products can rust. They are mounted using threaded connections.

- Polymer . This is an inexpensive but fairly reliable material that is resistant to corrosion. Even a non-professional can install these pipes. A pipeline made of polymer pipes will last a very long time.

- Metal-plastic . These pipes contain aluminum and plastic. The pipeline from them is assembled using threaded or press connections. As a byproduct of the high coefficient of thermal expansion of these pipes, they can crack if the water temperature changes suddenly.

If the home owners have no budget restrictions, it makes sense to install heating systems using copper pipes. This is a very expensive material, but the costs are worth it. Such pipes are reliable and durable.

They tolerate increases in temperature and pressure well. For their installation, soldering is used - silver-containing high-temperature solder.

Everything we told you above concerned the radiator water supply. But water can also be used as a coolant in other heating systems.

When installing a water heating system, you may need quite a lot of pipes, so you need to calculate the feasibility of purchasing expensive products and focus on your real capabilities

Read more about the characteristics and selection of heating pipes in this article.

Features of the use of polypropylene pipes

Implementing a heating scheme in a private house made of polypropylene has many advantages.

Polypropylene pipes are cheaper and lighter than metal pipes, they do not rust. Plastic pipes do not need painting, they look good and do not deteriorate the interior of the room. The procedure for creating a heating system from polypropylene pipes is reminiscent of assembling it from a construction set. Pipes are quickly and efficiently connected using a welding unit. The following equipment, tools and materials are used for installation of polypropylene pipes:

- polyfusion welding machine;

- special pipe scissors;

- roulette;

- perforator;

- polypropylene pipes (calculated diameter);

- couplings;

- fitting;

- squares;

- valves;

- fasteners.

Note: the amount of necessary materials, tools and components is determined before installation, after drawing the heating circuit diagram. Couplings, ball valves and fittings are purchased depending on the type of boiler, the selected design and the size of the polypropylene pipe.

Water system "Warm floor"

“Warm floor” can either successfully complement radiator water heating or become the only source of heating for rooms if we are talking about a low-rise building. A huge advantage of the “Warm House” is that this system provides conditions that fully meet the sanitary and hygienic standards of the premises.

The air is heated unevenly along the height of the room: in the upper part of the rooms it is colder, and in the lower part it is warmer.

Warm floors are a wonderful invention that allows you to warm up a room in height in full compliance with the sanitary and hygienic standards required for it (+)

The system temperature is only 55°C, which meets design standards. The installation of heated floors is carried out over the entire area of each room. This is quite a complex job that can only be done efficiently at the stage of building a house. Operating the system also poses a number of difficulties.

Distinctive characteristics

If we compare with air and electric heating, then water heating has firmly taken a leading position due to many factors. First of all, this is an affordable price for materials, work and operation of the system, including payment for spent energy resources, which other types of home heating cannot boast of.

Here we can note the high heat transfer of heating elements, which contributes to uniform heating of rooms and the establishment of a comfortable climate. It is also important that the coolant can be heated using any type of fuel, which is impossible with electric heating.

All work on installing a water system can be easily done with your own hands and this is also a huge plus. With air routes, things are more complicated and, most likely, you will have to turn to specialists for help.

Baseboard heating system

If installing a “Warm House” is difficult, and radiators spoil the interior of the room, you can use a baseboard heating system.

With this type of heating, the pipes are installed behind the baseboard, that is, slightly above the floor level. In this case, the room, as in the case of “Warm Floor,” warms up in the correct sequence.

Thanks to baseboard heating, there is no need to rack your brains over how to fit pipelines, manifolds and radiators into the interior of a country house so that they are not conspicuous (+)

At the same time, the floor is heated, which creates favorable conditions at any time of the year. Heating under the baseboard is becoming more and more popular and is gradually becoming fashionable.

What are combi boilers

Since electric heating is expensive, you can use an alternative solution and choose a boiler that can operate on two types of fuel. For example, you can purchase electrical equipment that can also perform the functions of a gas water heater. Or you can choose a solid fuel boiler that can also work with electricity for some time.

As long as there are no interruptions in the gas supply, such a boiler will work properly according to the generally accepted scheme, but as soon as any problems arise, it will be possible to switch to another type of fuel and thereby provide stable heating to the house.

A combination boiler is more expensive than a regular boiler, but such expenses will be completely justified: your home is guaranteed not to be left without heat, and even if one system fails, the second will immediately be able to support it. The temperature level will remain at the same values, and it will be comfortable to be in the room.

It is quite difficult to independently design and implement an individual heating system, but it is still possible. Your home will receive reliable heating, which will not depend on the presence or absence of gas pipes.

You need to enable JavaScript or update your player!

Conclusions and useful video on the topic

Comparison of two-pipe and one-pipe heating systems:

The house you plan to live in all year round needs heating during the cold season. To make your living conditions comfortable, you need to choose a water heating system that is most suitable for your individual conditions.

We hope that the information contained in this article will help you make the right choice. After all, high-quality heating is not only comfort and coziness. This is also a prerequisite for maintaining your health.

Do you have anything to add or have questions about water heating systems? You can leave comments on the publication and participate in discussions. The contact form is located in the lower block.