In the process of heating a house or apartment, the coolant is pushed by the engine along the circuit. If it is not balanced, it will heat the rooms unevenly. For example, when the house has radiators and heated floors, one of the systems may warm up more than the other. To prevent this from happening, when installing a heating system, it is necessary that the heating system be balanced correctly.

Heating system diagram Source aw-therm.com.ua

The concept of balancing

For a heating system to operate as efficiently as possible, it is important that it releases heat in such a way that it warms all rooms evenly. This will not only provide warmth and comfort in the house, but will also help reduce heating costs.

Heating systems can be divided into two types:

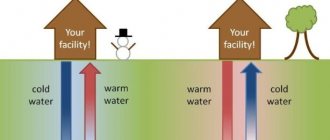

- Single-pipe or double-pipe. In them, the heated coolant moves through pipes from the heating boiler, giving off some of the heat to each radiator. Then the liquid that has lost heat enters the boiler again. After this, the cycle described here is repeated again.

- System with manifold connection. It has a distribution device, from which pipes go separately to each radiator. The adjustment occurs for each of them independently.

The last category includes heating systems that use not only radiators, but also heated floors.

The general principle of balancing is similar in different cases. Each radiator has an inlet valve. If they are all fully deployed, then the greatest heat loss in the first category of systems will occur in the first device. Further, increasingly cooled water will flow. To prevent this from happening, a valve is tightened in the initial batteries. Thus, the heat consumption will decrease and it will be enough for other heating devices.

Two-pipe system with heated floors Source eurosantehnik.ru

This procedure must be done in several steps to achieve the desired result. Between attempts, the batteries are given time to warm up properly.

For heating systems, regulation occurs by regulating the volume of incoming heated liquid. There should be so much of it that it is enough to heat each room.

The floors are adjusted in the same way, increasing or decreasing the heat supply. If the floors use heating based on the use of electrical energy, adjustment is made according to different rules, simply changing the settings.

Flow regulators, bypass valves, control valves, and pressure regulators are used to carry out adjustments. The layout of their installation depends on the specific type of heating system.

Thermostats occupy a special place. They have the most complete functionality. The device contains an electronic temperature sensor. The work takes place under the control of an electronic circuit. There is a simple and intuitive control panel.

The use of such electronic devices allows adjustments to be made at minimal cost. If necessary, it is possible to program the heating operation. For example, it is possible to reduce the heating temperature if the family is absent from the house for several days.

Water heated floors Source teplyiypol.ru

Pipes for connecting radiators and heated floors

For homeowners without installation experience, we recommend the following options:

- If you want to save on materials, take reinforced polypropylene pipes (PP-R) with fittings. In addition, buy an inexpensive Chinese soldering iron - it will definitely be enough to assemble 1 system.

- Without special tools, you can install heating pipes from metal-plastic pipes on compression fittings, tightened with open-end wrenches. The disadvantage is the high cost of parts.

- The best solution is to assemble the system from cross-linked polyethylene or metal-plastic with press fittings. You will have to rent special pliers.

The structure of a polypropylene pipe - to prevent thermal elongation, aluminum reinforcement is laid between the layers of plastic.

Polypropylene pipelines are welded according to technology, the main thing is to accurately maintain the heating time. It is strictly not recommended to wall PP-R joints in floors and walls to avoid the consequences of leakage.

On the left in the photo are pipes made of metal-plastic, on the right - cross-linked polyethylene

Adjustment methods

When balancing the heating system in a private home, you can use temperature readings or coolant flow data as a basis. Each of them has its pros and cons.

First way

The installation implies that all necessary calculations for coolant flow have been previously carried out for the project. It is necessary not only to have control valves, but also measuring devices. Here it is possible to control the volume of coolant pumped through the system and make the necessary settings if necessary.

The advantage of using this method is the high quality of heat control in various rooms. The disadvantage of this approach is the relatively high cost of installing such a system.

Heat distribution in a room Source thebridgestudio.ru

Second way

It is suitable in situations where no preliminary calculations were made when installing the heating system. Then the heating system is adjusted as follows. In such cases, thermometer readings are used for adjustment. At the same time, they try to make the heat consumption approximately equal for each radiator. If the battery is installed in a large room, then it is adjusted so that the heating is proportionally higher.

The simplicity of the procedure is the main advantage of the process. The disadvantages include: insufficiently precise adjustment of heat consumption, the duration of the balancing procedure.

System with collector distribution Source gidrotermika.ru

In what situations is balancing necessary?

In practice, this procedure must be performed in any case. When designing it, a certain level of heat use is planned for each radiator and heated floor. The calculation is performed based on the minimum permissible temperature in this area.

It is important that its distribution in the operating system corresponds to the planned values. After the system has been installed, all valves are first opened fully. Then measurements are taken and balancing is carried out.

A homeowner may need to perform balancing in the following cases:

- One or more radiators are noisier than usual - you can hear the sound of flowing water from them.

- If you touch the radiators in the house, you can easily notice that some radiators get much hotter than others. Moreover, among them there are both hot and barely warm.

- If the house has warm floors, you need to pay attention to the degree of heating of various areas. If you can find clear differences, it makes sense to think about balancing.

- If the apartment owner himself did the heating wiring, he must check how the heat is distributed and make appropriate adjustments.

Successful hydraulic balancing is only permissible if the heating devices and fittings have been selected correctly and there are no air pockets in the system. Otherwise, you must first correctly install the heating system and only then engage in more precise balancing.

How heating works in a private house Source kit-santech.ru

It is necessary to remember that you should not interfere with the operation of the heating system again if it is operating in normal mode. This applies to the following situations.

- When the equipment works flawlessly. Making adjustments is not only pointless, but also dangerous. As a result of the actions of an inexperienced person, the work may deteriorate.

- If technical problems are identified, then balancing the heat dissipation is pointless. First you need to repair the system and only then should you fine-tune the work. This, for example, applies to the following situations: coolant leakage due to a leak in the equipment, air locks, clogged one or more control valves, damage to the expansion tank membrane. Perhaps after finishing work, the heat distribution will become normal.

You should avoid making your own connections to the heating system of an apartment building. They can disrupt heating not only for the owner, but also in other apartments. The only exception to this rule is when individual thermal input is made to each apartment. In a private house there are no such restrictions.

Do not use ball valves to partially restrict the coolant flow. It must be used only in extreme positions, otherwise it quickly becomes faulty due to the influence of the coolant on the surface of the inner ball.

Heating system elements Source septik-pro.com

Where to put

It is recommended to install a circulation pump after the boiler, before the first branch, but on the supply or return pipeline it doesn’t matter. Modern units are made from materials that can withstand temperatures up to 100-115°C. There are few heating systems that work with a hotter coolant, so considerations of a more “comfortable” temperature are untenable, but if you feel safer, put it in the return line.

Can be installed in the return or direct pipeline after/before the boiler up to the first branch

There is no difference in hydraulics - the boiler, and the rest of the system; it makes absolutely no difference whether there is a pump in the supply or return branch. What matters is the correct installation, in terms of strapping, and the correct orientation of the rotor in space

Nothing else matters

There is one important point regarding the installation location. If the heating system has two separate branches - on the right and left wings of the house or on the first and second floor - it makes sense to install a separate unit on each, and not one common one - directly after the boiler. Moreover, the same rule remains on these branches: immediately after the boiler, before the first branch in this heating circuit. This will make it possible to set the required thermal conditions in each part of the house independently of the other, and also in two-story houses to save on heating. How? Due to the fact that the second floor is usually much warmer than the first floor and much less heat is required there. If there are two pumps in the branch that goes up, the speed of movement of the coolant is set much lower, and this allows you to burn less fuel, without compromising the comfort of living.

There are two types of heating systems - forced and natural circulation. Systems with forced circulation cannot work without a pump; systems with natural circulation work, but in this mode they have lower heat transfer. However, less heat is still much better than no heat at all, so in areas where electricity is often cut off, the system is designed as hydraulic (with natural circulation), and then a pump is installed into it. This gives high heating efficiency and reliability. It is clear that the installation of a circulation pump in these systems is different.

All heating systems with heated floors are forced - without a pump, the coolant will not pass through such large circuits

Forced circulation

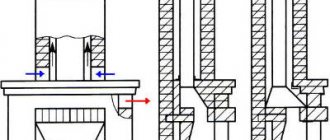

Since a forced circulation heating system without a pump is inoperative, it is installed directly into the gap in the supply or return pipe (of your choice).

Most problems with the circulation pump arise due to the presence of mechanical impurities (sand, other abrasive particles) in the coolant. They can jam the impeller and stop the motor. Therefore, a mesh dirt filter must be placed in front of the unit.

Installing a circulation pump in a forced circulation system

It is also advisable to install ball valves on both sides. They will make it possible to replace or repair the device without draining the coolant from the system. Turn off the taps and remove the unit. Only that part of the water that was directly in this piece of the system is drained.

Natural circulation

The piping of the circulation pump in gravity systems has one significant difference - a bypass is required. This is a jumper that makes the system operational when the pump is not working. One ball shut-off valve is installed on the bypass, which is closed the entire time the pumping is running. In this mode, the system operates as forced.

Installation diagram of a circulation pump in a system with natural circulation

When the electricity goes out or the unit fails, the valve on the jumper is opened, the valve leading to the pump is closed, and the system operates as a gravity system.

Installation features

There is one important point, without which the installation of the circulation pump will require rework: it is necessary to rotate the rotor so that it is directed horizontally. The second point is the direction of flow. There is an arrow on the body indicating which direction the coolant should flow. This is how you turn the unit so that the direction of movement of the coolant is “in the direction of the arrow”.

The pump itself can be installed both horizontally and vertically, just when selecting a model, make sure that it can work in both positions. And one more thing: with a vertical arrangement, the power (pressure created) drops by about 30%. This must be taken into account when choosing a model.

Preparation for the procedure

Before you start balancing, prepare everything you need for it. To get started, you will need the following:

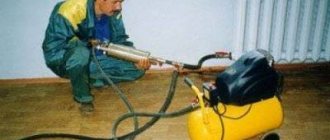

- A special contact thermometer with which you can accurately determine the degree of heating at various points.

- In order to adjust the balancing valve, you will need a hex wrench.

- If it has been preserved, it is advisable to take a heating wiring diagram. It may not exist if the equipment was installed a long time ago or was done without a diagram prepared in advance.

- You will need paper, pencil and marker.

Instead of a contact thermometer, you can use other models. Professional specialists often use a specialized thermal imager for this purpose. You can also use a remote pyrometer.

If there is no wiring diagram, then you need to sketch out a plan for the location of its elements yourself. First of all, the sequence of connecting the radiators and their distance from the boiler room are noted. Balancing a two-pipe heating system is similar to what is done for a single-pipe one.

When heating balancing begins, the mud trap at the inlet of the heating boiler is cleaned. Then it is necessary to warm up the heating boiler. This must be done up to maximum operating temperature. It doesn’t matter whether the weather outside is cool or hot.

How to heat a private house Source septik-pro.com

Scheme for a private house and components

The installation of double-circuit heating requires the presence of a number of required elements:

- heating boiler (there are no restrictions on the type of fuel);

- expansion tank;

- filter;

- radiators;

- pipes and connecting adapters for branching (fittings);

- thermostatic valves for radiators;

- safety valves;

- temperature manometer;

- automatic air vent valves;

- taps and control valves designed to disconnect radiators from the heating main and drain water from them;

- heating balancing device.

If it is necessary to arrange forced circulation, you will also need a circulation pump.

How the balancing procedure is performed

It is important to note that when carrying out it, it is necessary to take into account what kind of heating system is used - it can be single-pipe, two-pipe, with a collector or using heated floors.

Two-pipe heating system

To balance a two-pipe system, you must perform the following steps:

- When the coolant is well heated, all existing valves must be fully opened.

- At the outlet of the heating boiler, the liquid temperature should be maximum. To do this, a contact thermometer is applied to the pipe that leads from the boiler to the first radiator.

- Next, move on to the nearest radiator. It is necessary to measure the temperature of the coolant at the inlet and outlet. If the equipment is working properly, this difference should not exceed 10 degrees. In the case when the specified requirement is met, it is considered that this radiator does not require adjustment.

- A similar procedure is carried out in relation to each radiator installed in the house. At each step, the obtained data must be recorded.

- It is necessary to compare the temperature at the input valves of the first and last radiators. If it is less than 2 degrees, you need to tighten the input valves of the first two batteries by 0.5 or 1 turn. After this, the measurements must be repeated. The temperature difference is expected to increase slightly.

- If the value under consideration is in the range of 3-7 degrees, the inlet control valves of the first two radiators are tightened by 50%-70%, the next two by 30%-40%, and the rest are left unchanged.

- Before taking the temperature again, you need to wait 20-30 minutes. This is required so that the heating equipment warms up in accordance with the new settings. You need to make sure that the difference does not exceed 2 degrees at the inlet taps of the first and last radiator. If the heating main is of considerable length, the difference is allowed to be 3 degrees.

- These procedures must be repeated, tightening the input valves until the goal is achieved. These steps may need to be repeated several more times.

When hydraulic balancing is performed, it is necessary to control the temperature difference between the inlet and outlet valves. If it is more than 10 degrees. The inlet valve will need to be unscrewed slightly. It must be taken into account that precise adjustment occurs individually for each heating system.

Balancing valve for radiator Source termopaneli59.ru

Single pipe heating system

When adjusting a one-pipe system, they usually try to tighten only the valve on the first radiator. Usually after this it is possible to immediately achieve the desired indicators.

Manifold system

This section discusses balancing a system in which pipes are connected to a single node. Such balancing can also be carried out for heating systems that additionally use heated floors. These methods are also used to regulate the operation of heated floors. In this situation, there are two configuration methods.

Balancing valve for radiator Source termopaneli59.ru

Features of heating systems

Balancing hydraulic heating systems depends on the design of the system. There are circumstances that make the procedure easier:

- When a private house uses a boiler powerful enough to heat the entire home.

- Three-way valves are installed in the batteries.

- It is possible to carry out forced pumping of the coolant.

- If heating is not very important in certain rooms (such as a basement, garage or similar), then you need to take care of high-quality thermal insulation of pipes. This will reduce wasteful heat consumption.

- When adjusting the heating system, it is desirable that the heating system is turned on. This will allow you not only to carry out balancing, but also to evaluate the result based on your feelings. It is important not only to evenly distribute the heating between the batteries, but also to optimally determine the intensity of their work.

- To ensure efficient system operation, excessive heat loss must be prevented. In this case, it is necessary, for example, to take into account the operation of the ventilation system and the use of air conditioners.

- When making adjustments, it is recommended to pay attention to which room in the house is the coldest. It is recommended to open the valves as much as possible, and adjust the rest taking into account the fact that maximum heat consumption is expected in this room.

- When adjusting, for example, a two-pipe heating system, it is important not only to evaluate the temperature of the coolant, but also to hang thermometers in the rooms to evaluate the result of this work. It is important to consider that the comfortable temperature for different family members can differ significantly. Therefore, before you start balancing, you need to plan. What air temperature in the rooms should be obtained after the settings are completed.

- It is necessary not only to maintain a balance between the batteries, but also to correctly regulate the operation of the heating boiler. It should not work in vain, creating unnecessary additional heating in the house.

Using a steel radiator for heating Source utepleniedoma.com

conclusions

The considered methods do not provide a complete guarantee of balancing, since they are based on general recommendations. However, as we all know, each system is individual, although it is equipped based on generally accepted rules. It all depends on the basic settings. If everything was done wisely from the very beginning, then maintenance will not cause difficulties. As practice shows, quick balancing , so be patient and consistent. And don't forget about specialized designs designed to speed up adjustments.

What are the differences between different types of heating systems?

In one-pipe and two-pipe systems, each radiator is connected to two pipes. In a two-pipe system, the waste coolant is directly supplied to the boiler for heating. In a single-pipe system, the incoming pipe is connected to the outgoing pipe right next to the battery. As a result, warm and cold water is mixed.

Balancing valve for heating system Source iobogrev.ru

When using a collector connection, the pipes from each battery are connected separately to a common stand. Sometimes built-in measuring instruments are used to determine the supplied volume of coolant. This device is also used in cases where water heated floors are used.

The efficiency of operation depends on the material from which the radiators are made. If it is made using aluminum, steel or copper, it will quickly heat up and lose body. Cast iron batteries slowly gain temperature and retain it longer. If the owner plans to install a new model, then this must be done before the start of the heating season.

Heating of a private house Source innstroy.ru

In an apartment building, the possibilities for hydraulic balancing of the heating system are very limited. If vertical water supply is used in separate risers, then adjustment becomes impossible. In a private house the situation is completely different. Not only adjustments are available here, but also redevelopment of the heating system.

Signs of a critical coolant shortage

Not all owners of private houses monitor the technical condition of their water heating; it works - and that’s okay. When a hidden leak occurs, the system continues to function for some time until the amount of coolant drops to a critical level. This moment is monitored by the following criteria:

- In an open system, the expansion tank is first emptied, then the main riser rising from the boiler is filled with air. Result: cold batteries when the supply pipeline overheats; turning on the maximum speed of the circulation pump does not help.

- The lack of water during gravity distribution manifests itself in a similar way; in addition, the gurgling of water in the riser can be heard.

- On a gas heater (open circuit), frequent starts/turns of the burner are observed - clocking, the TT boiler overheats and boils.

- The lack of coolant in a closed (pressure) circuit is reflected on the pressure gauge - the pressure gradually decreases. Wall-mounted models of gas boilers automatically stop when they fall below a threshold of 0.8 Bar.

- Floor-standing, non-volatile units and solid fuel boilers continue to regularly heat the remaining water in a closed system until the volume vacated by the coolant is filled with air. The circulation will stop, overheating will occur, and the safety valve will operate.

We will not explain why the system needs to be recharged - this is an obvious measure to maintain the functionality of the heating. All that remains is to choose a method for replenishing the heating network.