A pressure tester is a special-purpose pump that is used to test the tightness and reliability of engineering systems and communications for domestic and industrial purposes. Pressure testing using equipment is performed by injecting pressure into the pipelines. After connecting the pressure tester, the working pressure norm can be exceeded by two to three times the permissible values.

The pumps can be used to accurately and quickly test the tightness of networks and tanks. The pressure tester is suitable for diagnosing heating and plumbing communications, devices for circulating compressed air, used in oil, steam, refrigeration plants, boiler houses, and in the construction of pressure tanks.

Popular models of manual pressure testing pumps

Models of manual crimping machines from domestic and foreign manufacturers are widely represented on the Russian market, all of them are distinguished by their simplicity of design and relatively low cost.

A wide range of pressure testing pumps is produced by the famous German company Rothenberger, which has more than 1,200 employees and 12 factories in the USA and leading European countries.

Rothenberger RP 50 (100 cu) – a manual hydraulic pressure tester designed for checking the tightness of pipes, components and mechanisms in water supply, plumbing and heating lines. The water tank is made of galvanized sheet steel, the device has a pressure gauge in a metal case with three measurement scales and a built-in filter to protect against contamination. The pressure hose of the device is made of durable fabric braiding, the design includes double valves, the device is designed to work with water and oil.

Technical parameters of Rothenberger RP 50

- tank volume: 12 l.;

- maximum pressure: 50 bar;

- liquid supply: 45 ml. per beat;

- outlet diameter: 1/2 inch;

- weight: 8 kg.

Rice. 6 German compressor for crimping pipelines Rothenberger RP 50

Voll V-Test 50 (115 cu) - a pressure tester from a Belarusian manufacturer, has a durable steel tank, painted with powder paint and a two-valve pump assembly made of corrosion-resistant brass. A pressure gauge with three scales is responsible for the accuracy of measurements, the connected hose is made of rubber on a fabric basis, the unit works with water and oil.

- tank volume: 10 l.;

- maximum pressure: 50 bar;

- delivery: 45 ml. per beat;

- outlet diameter: 1/2 inch;

- weight: 8 kg.

Rice. 7 Mechanical pressure test pump Voll V-Test 50

Saturn NIR-60 (110 cu) - manual test pump (NIR) from a domestic manufacturer, the device is designed for hydraulic testing of various tanks and pipelines, the working fluid is oil and water.

Technical parameters of Saturn NIR-60

- operating fluid temperature: 5 – 80 C.;

- tank volume: 12 l.;

- maximum pressure: 60 bar;

- delivery: 40 ml. per beat;

- Outlet diameter: 1/2 inch.

Rice. 8 Hand pump for pressure testing of heating systems Saturn NIR-60

Pump classification

Based on operational characteristics, all models of crimping machines are divided into the following categories.

Pneumatic. They are in the electric class, but their cost is significant, although the pressure created is no greater than that of electric ones. An electric pressure testing pump does not require any effort on the part of the owner, but its weight and dimensions will complicate transportation. The discharge pressure is at the medium level.

Mechanical pressure testing pump up to 1300 atm. is a complex mechanism. Its capabilities are enormous, but given the cost, it can only be used on a cosmic scale to test the networks of megacities.

If you are interested in all of the above, then it is not too late to consider the detailed characteristics. Perhaps they will change your choice.

What is pressure testing of heating and water supply systems?

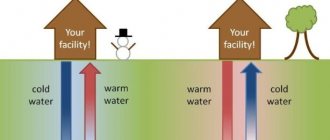

Heating and water supply are two systems consisting of a large number of varied equipment. As you know, the performance of any multicomponent system is determined by the weakest element - if it fails, it stops completely or partially. To identify all weak points, pressure testing of heating and water supply is carried out. In simple terms, the pressure deliberately rises much higher than the working one, pumping liquid. This is done using special equipment; the pressure is controlled using a pressure gauge. The second name for crimping is hydraulic testing. It's probably clear why.

Heating pressure testing is carried out after any repair or before the heating season

When a heating system is pressure tested, the pressure is increased by 25-80% depending on the type of pipes, radiators, and other equipment. It is clear that such a test reveals all the weak points - everything that does not have a safety margin breaks, leaks appear in worn pipes and unreliable connections. Having eliminated all identified problems, we ensure the functionality of our heating or water supply for some time.

If we are talking about centralized heating, then pressure testing is usually carried out immediately after the end of the season. In this case, there is a decent period of time for repairs. But this is not the only case when such events are held. Pressure testing still takes place after repairs or replacement of any element. In principle, this is understandable - we need to check how reliable the new equipment and connections are. For example, you soldered heating from polypropylene pipes. We need to check how high quality the connections are. This can be done using crimping.

If we talk about autonomous systems in private houses or apartments, then a new or repaired water supply is usually checked simply by turning on the water, although even here a strength test would not hurt. But it is advisable to test the heating “to its fullest”, both before commissioning and after repairs. Keep in mind that those pipelines that are hidden in walls, floors or suspended ceilings must be tested before they are closed. Otherwise, if during testing it turns out that there are leaks there, you will have to disassemble/break everything and fix the problems. Few people will be happy about this.

Electric pump

The electric type pump operates using a motor from a 220 W network. It is mainly used to test the tightness of both heating systems and water pressure systems. Pumps of this class are mainly used by professionals for constant loads. However, this option has many advantages. It is not only simple to repair, but also easy to control, because it is done using one button.

The high level of performance achieved using an electric drive is capable of delivering maximum pressure in a short time. The pump, hidden in a highly durable casing, can serve for a very long time. The bypass type valve allows you to regulate the pressure with light pressure.

The electric pump also has an overheating protection system. If the temperature rises, it reduces the pressure automatically, which helps to quickly cool the device. Small dimensions make the electric pump mobile.

But it’s worth saying a few words about the disadvantages. The high market price does not allow everyone to purchase such a device, and if you also take into account its weight and complete dependence on the network, then this is not only an expensive, but also a very inconvenient option.

How to make the right choice

When choosing, you need to take into account the capacity of the heating system.

When choosing a pump, you need to take into account the total capacity of the system that is undergoing the procedure and the frequency of pressure testing. There are models of various brands on the market, which must be chosen depending on their type. Manual models have a simplified design, do not cause complications and are inexpensive. But to create the required level of pressure when working with them, you need to spend more time, unlike electrically driven pumps. The devices vary in terms of operating time and are capable of producing results with varying accuracy, which is influenced by the power of a particular model.

If a low-power pump is used during the procedure, testing will take longer because such devices fill with water slowly. You need to select a pressure tester taking into account the dimensions of the pipeline system that is being tested. If we are talking about a private home, you can purchase a special supercharger that passes 2-3 liters of liquid per minute. For multi-storey buildings and heating mains, circulation pumps are used to ensure continuous movement of fluid within the system.

Manufacturers

Today there are many different models of crimping machines on the market, the difference between which is both in the principle of operation and in the characteristics. So, for example, crimping machines from MSKompany are compact mechanical. The SH-25 type modification is capable of creating a pressure of 25 bar when paired with antifreeze and oil.

If your soul is more in the electric model, then SHE equipment would be a good option. Its best budget model, SHE-60A, allows you not only to perform pressure testing , but also to fill the heating system. The equipment, made in a compact case, is equipped with comfortable handles, which makes transportation easy.

As backup options, you can consider companies such as: Saturn, ENA, Newton.

Are there differences between pumps for filling systems and pressing them?

The two types of crimpers do not have any significant differences. Often one device is used for two purposes at once: crimping and injection.

Today's crimpers and pumps differ in the type of drive mechanism: electrical and mechanical.

If we consider the principle of operation, they are as follows:

Membrane.

Piston.

Vane-rotor.

Pressure testing technology in an apartment building

The crimping procedure is carried out according to a single algorithm; the procedure has some peculiarities in different cases.

Special services are required to carry out hydraulic tests before and after the heating season.

This event is also carried out after repair or when commissioning equipment.

The outcome of the event is documented and a corresponding act is drawn up.

Before crimping the following is carried out:

- inspection of the supply unit, pipeline and other parts of the system.

- checking the condition of the thermal insulation of the main line.

When used for more than 5 years, it is recommended to flush the system before hydraulic testing. For this purpose, a special solution is poured into the pipes freed from coolant.

Having completed these activities, they proceed to crimping. The actions are in the following order.

- Water is poured into the newly installed or flushed system.

- Using special injection equipment, increased pressure is created, which is controlled by a pressure gauge.

- If the pressure level remains unchanged for 15-30 minutes, then this indicates the tightness of the system and the reliability of the equipment included in it.

- If a decrease in pressure is observed, the reason for this is determined.

- Having found out the place where the leak occurs, it is eliminated or the faulty element is replaced and the procedure is repeated.

- The test is considered successful if the pressure drops no more than 0.1 atm over 30 minutes.

Features of equipment operation

Practice has shown that the use of devices of this class allows one to avoid many possible problems during the further operation of equipment that is part of utility networks for various purposes. Experienced craftsmen recommend performing crimp testing in the following cases:

- If corrosion damage to the pipeline is detected, deformation in the areas between the fastening points.

- Before the start of a new operating season.

- When putting pipelines, heating networks, tanks into operation.

- After completing a set of repair measures, replace individual components of the system.

Please note that the current operating rules for utility networks and construction standards regulate the need and frequency of pressure testing for various cases. In addition to the operating instructions for the equipment, before operating the pressure test pump, it is worth studying these regulatory documents.

Who carries out the pressure testing

Responsibility for monitoring the performance of the heating system and carrying out preventive measures lies with the organization that operates it. Utility services deal with these issues in residential buildings, and in other enterprises and institutions - the corresponding technical services.

Certified specialists with the necessary qualifications are allowed to carry out pressure testing work.

This work in private houses with autonomous heating is carried out by employees of service organizations or independently, as is installation.

Regardless of who will carry out the pressure testing activities, one should adhere to the requirements and rules of the regulatory documents governing this type of work.

Carrying out the procedure at the preliminary stage

Video: hydraulic testing of water supply and heating

Building codes govern the order in which inspections are carried out.

- First, the water supply is filled with liquid. And leave it in this state for two hours.

- They proceed to create increased pressure for two hours. It happens very slowly. At this stage, it is already possible to identify a number of leaks.

- The pressure is reduced until they reach the calculated values. Then they move on to examining the general condition of the route.

- This pressure is maintained for thirty minutes or more. Without such a step, the deformed shape of the pipes simply cannot be stabilized.

- The next stage is turning off the taps at the entrances. The water is slowly drained using a pressure test pump.

- The route is checked for serious problems, as well as the density and strength of all sections.

Carrying out preparatory work before crimping

Each heating system maintains a working pressure that ensures movement along the coolant circuit necessary to heat the pipes and radiators, which, in turn, heat the air in the room surrounding them. The force of the working pressure must be sufficient to raise the coolant to the required height (more details: “Working pressure in the heating system - standards and tests”). This leads to the conclusion that taller buildings require a higher system pressure.

Before performing pressure testing of the heating system, it should be noted that when pressure testing with air, or pneumatic pressure testing, the operating pressure should exceed the norm by 40-50%. The increase in pressure in the system is associated with the ongoing hydraulic processes on the way of the coolant to the building from the main line.

The procedure for pressure testing a heating system begins with preparatory work, which includes the following steps:

- Checking shut-off valves (for example, valves) in each section of the system

- Checking the tightness, which can be ensured by sealing the required areas with oil seals

- Inspection and, if necessary, repair of elements intended for pipeline insulation

- Disconnecting the building in which the circuit is being pressure tested using a plug from the general heating system

Next, the drain valve, located on the “return”, is prepared for further filling of the pipes with tap water. When filling the heating system with water, it is necessary to close the valves and taps and leave the vents open.

How to perform pressure testing of a collector heating system, detailed video:

Advantages and disadvantages of a crimper

Further comparison of the two versions of crimping machines allows us to identify the advantages of manual models:

- Small dimensions and weight, the equipment can be easily transported by passenger transport and moved to any premises on site.

- A simple mechanical circuit that ensures reliability and increased service life.

- The maintainability of manual versions of crimpers, the low price of components, due to which the devices can be restored to functionality at home.

- Possibility of use at sites without power supply and during emergency shutdowns from the main or autonomous network.

Also worthy of attention is the possibility of safe operation by personnel who have little knowledge of how to use a manual pressure test pump. Detailed instructions will be enough to explain all the features of using the equipment.

At the same time, one should not underestimate the objective disadvantages. Among them, we note the need to make significant efforts to pump the pump, the increased duration of the work period, the need to constantly monitor the pressure of the working fluid due to the lack of automatic control systems. Here you have to choose - savings or comfortable working conditions.

Pump installation and use

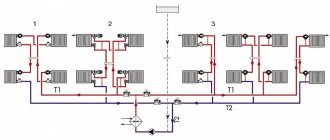

Scheme of crimping a heating system

Crimping devices and hydraulic presses of various calibers are used to test heating and water supply systems, as well as plumbing installations. With their help, they check the integrity of individual sections and identify various faults. First of all, testing with the help of a pressure tester is carried out during the commissioning of the system. During installation of elements made of polypropylene, polyethylene or metal-plastic, gaps may form at the fastening points. In the future, any of these places can cause a leak during operation.

Using a pump, you can quickly identify areas with a high risk of leakage. A pressure is created inside the system at a level much higher than the maximum operating pressure. If the pipes are able to withstand it for several hours, this indicates that they will operate normally for a long time. The pump also helps evaluate the quality of the repair work performed. All pipeline elements, for example, risers, must be checked before starting, forcing them to work under high pressure conditions. Before work, it is necessary to prepare the system; if it is autonomous, you will need to turn off the heat generator.

In a non-autonomous system, the area to be checked is closed using cranes

It is important to ensure that the coolant is drained. After the system circuit is filled with water heated to a temperature of no more than 45 degrees, during the filling process the air will gradually begin to escape

At the next stage, connect the compressor for pressure testing, bring the pressure to the operating level and inspect the area for damage. Then the pressure is gradually increased and left at the desired level for 10-15 minutes. The pressure level is adjusted using a pressure gauge. All places are inspected for leaks, radiators, fittings and pipe walls are checked, the serviceability of all taps and valves is checked.

Preventive pressure testing of systems allows you to prevent possible leaks and accidents, identify and eliminate damage in the early stages. A hydraulic manual or electric press for crimping pipelines additionally helps to determine the degree of wear of pipes and the expected timing of their replacement.

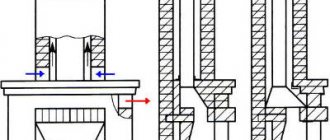

Operating principle of a manual hydraulic press

In order to carry out an event such as a hydraulic test of a pipeline, it is first necessary to fill the closed area with liquid. Once the fluid reaches the maximum circuit, the operator should begin monitoring pressure readings.

The pump is connected to an already assembled and ready-to-use system

As a rule, a pressure test lasts several hours. From the beginning to the end of the process, it is necessary to ensure the normal functioning of the manual hydraulic press. After the required time period has passed, the pressure in the system under test is measured again. The final measurement is compared with the initial data and on the basis of this the integrity of the system is determined.

Note! The range of crimping machines is incredibly wide. The choice of a specific model depends on what kind of network will be tested. For each communication, you need to select a device with a suitable pressure range.

If, after testing, the preliminary pressure measurement does not agree with the final pressure measurement, then in this case you can retest or immediately begin repairing the communication.

Necessary tool

To create the required conditions during pressure testing, you need equipment that allows you to achieve the required pressure level. A pump is most often used. It, together with the check valve, is connected using a high-pressure hose to the system through a pipe. The main characteristics when choosing a device are the level of performance and the pressure it can create

If the device is powered by electricity, then pay attention to the operating voltage (220 V or 380 V)

When carrying out work with a small volume of the circuit, it is advisable to use a manual crimping machine equipped with a hydraulic cylinder. Greater efficiency and ease of use can be achieved by using an electrically driven piston device. The electric type of crimping machine will create the required pressure in a short time without applying any muscular effort. These devices, in addition to the pressure gauge, have monitoring and control equipment.

In private houses where there is low pressure in the system, fill it with water and then record the pressure readings on the pressure gauge.

How to choose a manual crimping machine?

The main factor influencing the choice of manual pumping equipment is the expected resource, or the number of checks that are performed during the operation of the unit. Manually operated devices are worth purchasing if they are not expected to be used systematically and regularly, especially in industrial networks with large volumes of test fluids.

This type of device is in demand in the construction, installation, and repair sectors, and is successfully used in the home and in everyday life to check the tightness of water supply installations, mini-boiler rooms, and heating equipment.