Advice for owners of long-burning solid fuel boilers

In order for equipment to serve for a long time and with maximum efficiency, it must be chosen correctly.

The recommendations below are for those who are just planning to buy a system. A water heating boiler with two circuits is 1/4 more powerful than its single-circuit counterpart. Therefore, the power of the first must be at least 15 kW, while for the second 12 kW is sufficient. The larger the heated area, the more powerful the equipment should be.

For a good supply of hot water, the second chamber and heat exchanger of the boiler must be made of steel or copper. The cast iron firebox has a long service life.

- The dual-circuit heating system is capable of producing about 8 liters of water per minute. If this quantity is not enough for domestic needs, it is recommended to purchase a boiler with a boiler.

- Maintenance of the unit is quite simple - you just need to clean the ash pan and load fuel from time to time. Long-burning boilers can last 5-7 days on one stack.

Maintenance and safety recommendations

Before the first start-up, the owner needs to carefully inspect the pipes for leaks and the boiler itself - it should not let smoke into the room. The same applies to the chimney system. Once a year, the chimney, piping and radiators require cleaning.

For preventative maintenance, the system must be drained. To do this, an additional pipe is attached to the return circuit using a tee, at the end of which a plug is installed.

Security measures:

- The combustion chamber door must not be left open while the boiler is operating.

- It is prohibited to ignite fuel using gasoline.

- To avoid fire, do not place things on the boiler to dry.

- To load fuel, you should use special gloves.

- It is forbidden to entrust loading of the combustion chamber to children.

- You cannot store fuel in close proximity to the boiler; there must be at least a meter of distance between them.

- Overheating of the equipment is very dangerous, so you should not overload the firebox.

Modern variations of long-burning solid fuel systems with a water circuit ideally cope with the function of heat and water supply in a private home, as well as in large production, replacing gas.

Solid fuel boilers with a water circuit for heating a private house

Manufacturers recognized as the best

The difficult choice is indicated by the sufficient number of assortments on offer. Many countries produce such products of appropriate quality.

The price of a wood-burning boiler ranges from eight thousand one hundred rubles and varies depending on which country a particular unit was produced in.

If we look at the rating, then:

- The leaders are German-made boilers with full automation and great savings in fuel consumption;

- Boilers from Austria are identical in many respects, including a security system with many levels;

- Czech boilers, where certain brands are extremely popular, due to the ability to work not only on wood;

- Latvian boilers, assessed by Russians in terms of quality and thermal efficiency, which allow them to function for two days from one installation;

- After additional modifications, Russian boilers now have all the necessary indicators, so their popularity has increased greatly in recent years.

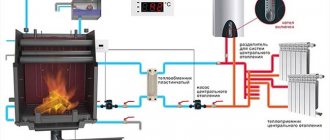

Combining a boiler with a heating water system

A system of pipes and radiators connected to the water circuit allows the heat to be evenly distributed over the entire area of the building. The simplest type of heat exchanger can be a water reservoir, when a heat source is located directly below it. But such heating is ineffective, since the liquid will be heated only from below.

The so-called “water jacket” will be much more effective in terms of transferring thermal energy. A more complex type of water circuit consists of double top and walls along the entire contour of the boiler, inside which the coolant circulates. Due to constant circulation, the water does not stagnate, and the thickness of 3-5 cm between the walls allows the liquid to warm up as quickly as possible.

Another equally effective type of water circuit is welded from thick steel pipes, bent in waves along the walls and top of the combustion chamber like a “coil”. The coolant moves slowly through pipes with a diameter of 5-6 cm, providing excellent heat transfer

In addition, this type of circuit has an important advantage - improved maintainability

Control and monitoring unit

The boilers are equipped with special systems to regulate the water temperature in the water circuit. The simplest system is based on the operation of a thermostat - when the required temperature is reached, the blower damper is closed and thus the air flow is reduced. As soon as the water cools down, the system will work in reverse.

More advanced control systems work with the inclusion of precise temperature sensors and forced electrified air supply. When installing forced ventilation, air is supplied from above, due to which the fuel is burned almost completely. Boiler equipment of this type needs to be connected to the electrical network, but in the absence of electricity it is not able to work.

Equipping a circulation pump can save the system from completely defrosting. A boiler left unattended in winter, having used up all the fuel, will not be able to maintain the temperature level of the water in the system for a long time, as a result of which it will freeze over time. In this kind of critical situation, the control system will turn on the circulation pump, which will lead to the circulation of the coolant - in mild frosts, running water will not freeze.

Rating of the TOP 5 best solid fuel boilers with a water circuit

The Russian market for domestic boilers is saturated with solid fuel boilers of both domestic and Western production. Serious competition in the market forces manufacturers to make innovative changes in design and reduce consumer prices. According to buyers, the following brands have the greatest advantages.

Lemax Forward-20

Single-circuit solid fuel unit with an innovative top-type fuel loading. It has an increased heating rate and high accumulation qualities, due to which it maintains the temperature of the coolant for a long time, even after the fuel has burned out.

Its modern design allows it to fit into any interior and connect to various heating systems. It is capable of efficiently heating a house from 150 to 200 m2.

Operating parameters:

- production - Russia;

- thermal power - 20 kW;

- steel heat exchanger;

- non-volatile;

- manufacturing option for the combustion chamber is open;

- temperature control - mechanics;

- location - floor type;

- Efficiency - 76%;

- fuel - wood/coal;

- water heating temperature - 95 C;

- warranty - 3 years;

- price - 21,700 rub.

ZOTA Carbon 20

Solid fuel model with top loading of fuel for heating a residential building from 180 to 200 m2. Does not require connection to an electrical outlet. It has a capacious combustion chamber and an autonomous loading system.

Has one of the highest efficiency for similar boilers. They are used with additional capacity, as boilers for warm water floors.

Operating parameters:

- production - Russia;

- thermal power - 20 kW;

- steel heat exchanger;

- non-volatile;

- manufacturing option for the combustion chamber is open;

- temperature control - mechanics;

- location - floor type;

- Efficiency - 80%;

- fuel - coal;

- water heating temperature - 95 C;

- warranty - 1 year;

- price — 46579 rub.

Protherm Beaver 30 DLO

Water-water solid fuel high-performance boiler. The design provides powerful heat removal due to the installation of a durable 5-section cast iron two-pass heat exchanger. Capable of efficiently heating a residential building with an area of 250 m2.

Operating parameters:

- production - Slovakia;

- thermal power - 24 kW;

- non-volatile;

- cast iron heat exchanger, 5 sections;

- manufacturing option for the combustion chamber is open;

- temperature control - mechanics;

- location - floor type;

- Efficiency - 76%;

- fuel - coal/wood;

- water heating temperature - 95 C;

- warranty - 2 years;

- price — 75490 rub.

Wirbel EKO-TK 20

A solid fuel hot water boiler heats rooms well with an area of up to 200 m2. It has the ability to function in both open and closed heat supply circuits.

Equipped with reliable protection against boiler overheating. When the coolant reaches T +95 C, the unit automatically turns off.

Operating parameters:

- production - Russia/Austria;

- thermal power - 20 kW;

- energy dependent;

- steel heat exchanger;

- manufacturing option for the combustion chamber is open;

- temperature control - mechanics;

- location - floor type;

- Efficiency - 78%;

- fuel - coal/wood;

- water heating temperature - 95 C;

- warranty - 3 years;

- price - 55230 rub.

Kentatsu ELEGANT-04

The floor-standing solid fuel water heating boiler works with any heating system, both with and without a circulation pump. Does not require connection to an electrical network.

It is capable of heating an object with an area of up to 270 m2, and can also be used as an autonomous source for an indirect hot water heating boiler.

Operating parameters:

- production - Slovakia;

- thermal power - 27 kW;

- non-volatile;

- steel heat exchanger;

- manufacturing option for the combustion chamber is open;

- temperature control - mechanics;

- location - floor type;

- Efficiency - 78%;

- fuel - coal/wood;

- water heating temperature - 90 C;

- warranty - 2 years;

- price - 38,000 rub.

Installation features

To heat a small home, it is advisable to install it directly in the house itself. Also, the boiler room can be equipped as a separate building or inside other outbuildings.

In this case, the heating pipe is always laid underground, always below the freezing level of the soil, and thermal insulation is ensured. In the boiler room, the air temperature should be at 10 degrees, and special care should be taken to ensure high-quality ventilation equipment.

The floor covering at the installation site must be non-flammable, level and hard. To increase the strength of the floor, the boiler is installed on a thin concrete screed. A sheet of metal with an area of at least 1 square meter must be placed in front of the heating unit. m.

During installation, you should strictly adhere to all recommendations given in the operating instructions for boiler equipment regarding the main parameters of chimneys: cross-section and height. The joints between the chimney and the chimney must be filled with heat-resistant sealant or coated with a clay solution.

Design Features

Boiler equipment of this type, in fact, is a slightly modified version of standard boilers - the design additionally includes a water circuit.

The design includes:

- firebox;

- grate;

- ash chamber;

- water circuit.

If single-circuit models are intended only for heating rooms, then double-circuit models are used both for heating the building and for supplying it with hot water.

Fuel loading can be done manually or automatically. The second option involves having a reservoir in the boiler into which fuel is added every 3-7 days. But models are more expensive than those with manual fuel supply, and therefore less common.

In addition, only fuel that has undergone special preparation is suitable for supply - coal up to 2.5 cm or the so-called “eco-peas”. Some models are equipped with built-in electric heaters that start up when the fuel supply is cut off, thus ensuring their continuous operation.

Design

Solid fuel boilers have a simple operating principle. The combustion chamber is placed in a steel casing; fuel is loaded through the door on the front side of the boiler and ignited.

During fuel combustion, hot flue gases wash a heat exchanger, made in the form of pipes or a water jacket, and transfer heat to the water of the heating circuit. When heated, the water begins to move naturally along the circuit due to the temperature difference at the inlet and outlet of the boiler.

Cooled boiler gases are carried away into the atmosphere through the chimney, also due to the temperature difference at the inlet and outlet of the boiler. Under the firebox there is an ash pan, which is designed to collect unburned parts of the fuel.

The ash chamber door acts as a damper to regulate the air supply to the combustion zone to ensure complete combustion.

Integrating the stove into a water heating system

It is possible to integrate a furnace with a water circuit into an existing water-type heating system. If the house has, for example, a gas boiler, then you can connect a stove to it, which will replace the heating boiler.

Modern heating devices, as a rule, do not have tanks for heating water. However, they have a heat exchanger that is used for the same purpose.

Today, the market offers a large range of stoves with a built-in heat exchanger, which are capable of not only heating the room, but also providing the entire house with hot water.

Modern models of stoves involve the use of not only ordinary firewood as fuel, but also pellets - wood granules made in industrial conditions.

Types of equipment

Heated floor equipment must be energy efficient, easy to operate and maintain. Models are distinguished by the type of fuel on which the boiler operates. Let's look at 4 popular types of units.

Gas

Modern equipment operates on both main and liquefied (cylinder) gas. The body of the equipment is made of cast iron or steel. The first varieties are very large, heavy and expensive. The cost is paid off by simple repairs and durability. The second types are light in weight, affordable and do not take up much space during installation.

The maximum efficiency of standard gas boilers begins at a temperature in the range of 70-90 C. The underfloor heating system operates within the range of 55-60 C. If the equipment is set to 55 C, the performance drops. In the “low” mode, the efficiency of the equipment is reduced to 85-80%.

Circuit layout options

There are two such options:

- Flow-through.

- Cumulative.

Heating using the flow-through method requires that the water heating circuit coil be built into the jacket. This heat exchanger heats up thanks to the energy of the heating circuit. The coolant, moving along the coil, reaches a temperature of +45 ℃. The productivity of this equipment is 8 l/min.

With storage heating, the system is equipped with a boiler - a special tank for heating water. The boiler is built into the main heat exchanger or chimney. Water is heated by hot air. As hot water is consumed from the tap, cold water is supplied to the tank from the plumbing system. The maximum heating is +90 ℃.

To increase the productivity of the equipment, it is equipped with a circulation pump, which almost doubles the efficiency. However, this technology requires a source of electricity, which in turn affects financial costs.

If there are power outages in the house, the system should be supplemented with a switch that will switch the water pumping to natural circulation.

So how do you choose a boiler for heating a private house?

To make it easier to navigate when choosing, let's systematize the information. Let's look at the most typical requirements that influence the choice of boiler type:

- The most economical heating. The cheapest heating options are wood/coal and gas. Next come pellets, liquid fuel and electricity. In general this is true, but the situation greatly depends on the region. In some places electricity will be cheaper, in others liquid fuel will be cheaper. In general, you have to count.

- Degree of autonomy. The most automated are gas, electric and pellet units. They can be left at work unattended. Liquid fuel ones require a little attention. The least automated are solid fuel ones.

To keep your home warm, you need to choose the right boiler for heating your private home. - Difficulty connecting. The most difficult thing is with the registration and connection of gas. There may be problems with allocating power for electric heating - not all substations have a reserve. With the rest, everything is simple: the main thing is to follow the recommendations for safe installation.

If you take into account the availability and affordability of fuel, making your choice is not difficult.

Characteristics of the heating boiler

A heating boiler with a water circuit is designed for heating residential buildings, as well as a wide variety of industrial premises. Such boilers are made exclusively from high-quality steel, which is coated with powder paint. The only fuel used is firewood. (See also: Stove with water heating boiler)

Such boilers are very profitable and convenient, first of all, because they are usually combined and have three power levels, which help to use the thermal energy they consume very economically and rationally. In addition, if necessary, a brick oven with a water boiler can be equipped with an automatic control panel, which will help control the air temperature in the room and the temperature of the water when it leaves the boiler.

On some boiler models, there are no cast iron burners on the top panel, which allows you to greatly increase the volume of water space and thereby make it possible to increase the power of the boiler itself.

Main types of solid fuel boilers

- the fuel that is used;

- number of circuits;

- device design and fuel loading option;

- Device efficiency;

- sizes.

The main unifying point is that a solid fuel boiler with a water circuit can only be installed on the floor. Various materials can be used as fuel - firewood, coal, coke and special fuel briquettes.

The peculiarity of double-circuit boilers is that they not only heat rooms, but also make it possible to obtain hot water in any quantity. In order to choose the right solid fuel boiler, you should first consult with a specialist who will help you choose the right model. This determines how well the room will be heated.

Automation and Security

Solid fuel water-water boilers are equipped with a control and automatic safety unit. Of course, the peculiarities of the solid fuel combustion process do not allow the boiler to provide a level of automation similar to gas or electric boilers; however, installing a thermostat in the heating circuit allows you to control the temperature in the room.

The automation system works on the principle of regulating the air supply through a fan or by opening the damper, which is performed by the actuator, receiving a signal from the temperature sensor and from the electronic unit.

The second level of automation can be implemented by changing the coolant circulation speed set by a centrifugal pump, which is connected to an electronic control unit.

This starts or stops the circulation of water through the pipes, for which the system must have a circulation pump connected to the control electronics:

And the third, higher-quality level of automation of solid fuel boilers is achieved by regulating the fuel supply to the firebox and can only be implemented in pellet boilers.

The difference between single- and double-circuit boilers

Double-circuit boilers, which are called pyrolysis boilers, differ from single-circuit boilers by the presence of an additional firebox, due to which the burnt gases do not immediately fly out into the chimney, but are saturated with air and continue to burn in the second chamber. This factor is responsible for such a high efficiency. The body of solid fuel heating equipment with a water circuit can be made of steel or cast iron.

A single-circuit boiler only provides water heating for radiators. Its design is as follows:

- firebox - a chamber in which fuel combustion occurs;

- ash pan - a box for waste generated as a result of combustion;

- chimney - a system for removing burnt gases;

- jacket - a water heat exchanger placed directly in the firebox.

The principle of operation of the equipment is as follows: firewood or coal is placed in the firebox. When burned, they release heat. Thanks to the jacket, heat is accumulated and transferred to the coolant (water), which distributes it throughout the system.

When water is heated, it expands, a quality that causes it to circulate naturally. Warm liquid goes into the radiators, and the cooled liquid returns to the boiler for heating. The advantage of a boiler with two circuits is an additional coil, which is connected to the water supply system and heats water for domestic needs.

Wood boiler design

Such boilers have in their design:

- Fireboxes, in one of which the wood is burned, and in the second the actual afterburning process takes place, for which a fireclay brick lining is provided. Thus, the temperature in it remains unchanged for a long time, reaching up to eight hundred degrees.

- Automation, which allows them to function as an autonomous station, regulating both air flow and temperature. If the boiler is of a simple design, then this function is performed by a coil, allowing the coolant to circulate unhindered;

- Taps through which radiators for heating are connected;

- A broken-type chimney capable of accumulating heat from gases;

- Many models are equipped with a loading chamber.

Autonomously, such a device can function from eight to twelve hours. Some manufacturers produce units that continue to operate for several days from one refill.

Features of pyrolysis boilers

As mentioned above, pyrolysis boilers have two combustion chambers. In the first, the fuel burns directly, and in the other, the gases generated by this fuel burn. If you put damp firewood in the firebox, which is quite possible in winter, they begin to emit steam.

The second chamber eliminates the negative impact on the combustion process. Hot gas enters it and neutralizes moisture. On its way, the gas is saturated with air, which promotes further combustion. To separate the chambers, a grate is used, on which firewood lies. For the pyrolysis system to operate, forced air supply is required, which is provided by a smoke exhauster.

How the pyrolysis system works:

- The fuel is placed on the grate.

- They light the boiler.

- Close the firebox damper.

- They start the smoke exhauster.

- Combustion creates a high temperature in the chamber, resulting in the formation of volatile combustion products in the form of nitrogen and hydrogen.

- These formations enter the second chamber and mix with the air flow.

- Complete combustion occurs, and the released heat is returned to the first chamber.

This process provides a very high temperature, due to which the waste of burnt wood is decomposed, and the fuel is used to the maximum. The heat released by the burnt waste is used twice.

Along with numerous advantages, pyrolysis boilers also have disadvantages:

- High price.

- Dependence on electricity.

- The power declared by the manufacturer does not always correspond to reality.

- If you use the equipment half-heartedly, there is a high probability of clogging the flue with tar.