A combination heating boiler is a new equipment that uses both gas and electricity to heat rooms. This technology will provide the house with heat in the event of a lack of electricity or gas supply interruption. To use an electric gas boiler as efficiently as possible, you need to install a combined heating system in your house. It is designed at the very beginning of the construction of the structure. The coolant in this design is water. Correct installation and adjustment increases the service life of the boiler.

Characteristics

Gas-electric boilers are cheaper due to the absence of two different fireboxes.

Gas-electric heating devices regulate the operating mode (on, off) automatically. In this way, the required temperature is maintained in the room, and resources are used as economically as possible.

Combined heating devices have the following characteristics:

- Small sizes. The design of such units includes oversized combustion chambers for burning gas and heat exchangers with a built-in heating element.

- Low level of electrical energy consumption. The boiler mainly operates on gas, and the electric heater starts up if necessary for prompt heating of water, as well as in the absence of a gas mixture supply.

- Reasonable price. It is formed due to the absence of a separate chamber (combustion chamber), since the heater is built into the heat exchanger. In equipment where there is no secondary circuit, an option is planned for the possible connection of a water heater.

- Heating elements with low power. Most models on sale only support the specified temperature value. Water heating heating elements begin to work when the electric operating mode is started.

Gas is considered an economical type of fuel, which cannot be said about electricity. In this regard, for heating houses in areas with a poorly developed gas supply, it is better to find a boiler option that runs on a different type of fuel.

An electric gas boiler costs on average 70-80% higher than a pure gas boiler. But since the installation of such a unit is cost-effective, its cost is fully recouped within 3-4 years.

Basic operating principle

Everyone knows how boilers work. Their goal is to bring water that circulates through the system and heats the home to the desired temperature. The main difference between such devices is the type of energy carrier.

Most often boilers are:

- electric:

- solid fuel;

- gas;

- liquid fuel.

In this case, there may or may not be a water circuit.

Features of operation of universal boilers

If conventional heating systems can only operate on one type of fuel, then universal boilers operate on any fuel, and most often on two simultaneously. That is why you can hear that such units are also called multi-fuel.

Nowadays, installing such a device for a private home is the best solution. Due to interruptions in fuel supplies and jumps in their cost, you may find yourself in a hopeless situation. However, anyone who has installed a universal boiler model can easily use any fuel, just by changing some settings.

Advantages and disadvantages

A gas-electric boiler requires a three-phase network.

Electric-gas heating boilers, like other devices, have their pros and cons.

The important advantages of units for 2 types of fuel are:

- high efficiency (reaches 97%);

- compact dimensions;

- simple maintenance and repair of equipment;

- significant savings in resources required;

- easy controls;

- no waste from fuel combustion.

A gas-electric boiler also has disadvantages:

- high price compared to devices for 1 type of fuel;

- a three-phase network is required.

After a few years, the cost of an economical boiler pays for itself, since funds are saved to pay for the use of resources. The versatility of the unit greatly simplifies everyday problems.

An electric gas boiler has an important distinguishing feature: the presence of several outputs, allowing the device to be used as a multi-circuit one. Such a boiler heats radiators, heats the sauna room, heats the pool and water for household needs. The “warm floor” design can also be heated by such a unit. Summer residents use one outlet to heat greenhouses.

Pros and cons of a combined heating system

Considering combined gas and electric heating boilers, their characteristics and capabilities, one cannot help but note some advantages of using the equipment:

- Equipment efficiency reaches 95%;

- Due to its small size, installation of the device is easier;

- minimum degree of contamination by emissions into the atmosphere;

- due to the possibility of combining types of heating, the consumption of both is reduced;

- boiler equipment can automatically switch between two types of heating, successfully combining different types;

- double-circuit boiler equipment. Has the ability to combine room heating and water heating;

- Over time, the cost of the equipment pays off.

Minuses:

- When connecting this type of boiler equipment with your own hands, you must coordinate your actions with the relevant authorities. Since the connection method is a three-phase network;

- cannot be used in apartments. Only on private property;

- if we compare gas heating, then this type of equipment costs 65% more;

- Constant supervision is required - tech. service and prof. work.

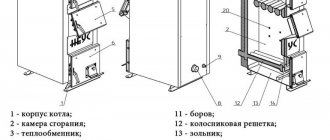

Combined heating boilers (gas, electricity)

Types of boilers by number of circuits

Single-circuit devices are heating units designed only for heating network water. Double-circuit devices also additionally provide hot water supply. They are a good option for installation in country houses. At the same time, two important tasks are solved: high-quality operation of the heating system and the constant availability of hot water are guaranteed.

Single-circuit

The boiler is single-circuit; a boiler is used for hot water supply.

The power of such devices is quite sufficient for heating premises. But such a unit cannot provide hot water on a regular basis. For these purposes, you should additionally connect a capacitive water heater.

Dual-circuit

If staying without hot water is impossible, you need to immediately purchase a double-circuit gas-electric boiler. Unlike a single-circuit one, its design contains an additional heat exchanger that solves the problem of heating water. If power allows, you can increase the number of water points. To minimize the loss of water temperature, they should be located close to each other (boiler and tapping points).

All disadvantages of gas-electric units are determined by technical characteristics and depend on the manufacturer. When choosing a heating device, it is recommended to consult a specialist.

Minimum required power

For an average house in the climatic zone of the Moscow region, with 2 bricks and a ceiling height of 2.7 m, the minimum required power is calculated using a simple formula: 1 kW for every 10 m2. We also recommend setting aside a power reserve of 20-30%.

For example, for the average house described above with an area of 100 m2, the minimum required power of heating equipment is 100/10 * 1.3 (30% reserve) = 13 kW. Boilers of this power are not found on the market, so we round up to the nearest higher value - 14 or 15 kW.

When choosing a double-circuit boiler, it is recommended to add another 10-15% to the result, since when heating hot water, the heating circuit is not heated.

How to accurately calculate the required boiler power Individual calculation, formula and correction factors

Nuances of choosing an electric gas boiler

The circulation pump will not work if there is no electricity.

The design provides 2 chambers: for burning gas and for a heating element powered by electricity. Modes change automatically. In some boilers it is possible to set a cyclic operating mode. This is useful at low temperatures, which can last for a long time. When a sufficient temperature is reached, the unit switches from gas to electricity. The combined use of both types of fuel makes it possible to save expensive resources and make heating independent.

If the electric gas boiler does not have a tank for heating water, a boiler will be required. An electric pump is used to improve water circulation. The latter does not provide the ability for the gas part of the unit to function in the absence of electricity. This detail limits the use of such a device in multi-story buildings.

Useful features of universal boilers

Heating systems for private homes are now so advanced that we can only rejoice at some of the features.

Maintaining heat with electric heating elements

If the boiler heats your home only using solid or liquid fuel, it usually requires a lot of it. But if, at the moment of the most intense heating, electric heating elements are connected to operation, then fuel costs are significantly reduced.

It is noteworthy that during the operation of the boiler, in the event of a sudden stop in the fuel supply, the electric heating elements turn on automatically, preventing your house from cooling down. It turns out that if the boiler goes out or the fuel runs out, the boiler will not turn off, but simply switch to another mode.

This feature is very relevant where there are frequent interruptions in energy supply.

Selection of economical raw materials

Due to constant price jumps, sometimes you want to protect yourself. If today gas is one of the cheapest types of fuel, it cannot be said that this will be the case tomorrow.

Thanks to universal boiler models, the consumer can easily control their heating costs, and if the price of one type of fuel rises, they can easily replace it with a more acceptable one.

Installation and operation rules

Before connecting, you need to check the draft in the chimney.

The combined heating system is installed by specialists from the gas service or a special organization according to a pre-approved plan.

Stages of work:

- Installation of supports that will provide the required level for the heating unit. As a rule, they are present in the latter's kit.

- Connecting the boiler to the gas supply.

- Electrical connection.

- Installation of special filters for water and gas.

- Leak testing and cleaning of the heating system.

- Connecting the boiler to the pipeline.

- Setting up the chimney.

- Test run of the heating system, troubleshooting problems.

- Final adjustment of the heating system.

Installation of a gas-electric boiler is permitted in a room where, in accordance with the rules and regulations, supply and exhaust ventilation is equipped.

Basic operating rules:

- During operation of the combined unit, acceptable traction is required. In this regard, the chimney must have a sufficient cross-section.

- The chimney used must be insulated to prevent the parts in contact with it from catching fire.

- During regular operation of the boiler, the ash pan should be periodically cleaned. The frequency of such procedures depends on the degree of gas combustion and the intensity of operation of the unit.

- There should be a steel sheet in front of the combustion chamber, which will provide the flooring with protection from sparks.

Electric gas heating boilers are considered the most technologically advanced and advanced.

Which is better: a factory or homemade model?

Some craftsmen, seeing the popularity and prevalence of universal models, decided to independently assemble the one they needed based on a solid fuel boiler. They purchase different types of burners and independently connect the boilers to the gas mains. Is this kind of work acceptable?

There is no need to do any re-equipment yourself. Why? There are two reasons for this:

- safety;

- uneconomical.

Usually, before the boiler reaches the store, it is tested in the factory. It is not possible to do this at home. Consequently, the home owner cannot be completely confident in the reliability of his equipment. Such boilers can pose a serious danger.

By purchasing a boiler from a specialized store, you can be sure that your home will be safe and the heating system will last for many years!

Popular manufacturers

Gas-electric boilers produced in Sweden, brand STS.

On the Russian market, combined heating devices are represented by products of domestic and foreign manufacturers. The most popular are:

- Navien (Korea). Gas-electric boilers from a Korean manufacturer are fully adapted to Russian conditions. They are not damaged by frequent power surges and do not respond to a drop in gas pressure. The use of such devices makes it possible to save money due to low gas consumption. High-quality protection guarantees complete safety during operation. The operating modes of heating units are determined by independent settings. They can be controlled using the remote control.

- Hercules (Russia). A gas-electricity boiler can heat a room up to 300 m2. The wide Hercules model range includes devices with different configurations depending on the functions. The presence of two circuits provides space heating and a constant supply of hot water without additional burners. In such devices, the DHW circuit has a protective coating, which extends the service life of the unit.

- CTC (Sweden). The manufacturer produces heating units with a power of 45 kW and the ability to heat up to 500 m². Their distinctive feature is that they are equipped with heating elements with a power of 15.75 kW. Internal automation allows you to maintain a constant water temperature. Programming devices can be included in the design of boilers, which allows operation to be adjusted in accordance with outdoor temperature conditions.

When choosing, it is first recommended to base your choice on the area of the room, its insulating properties, and the availability of the required amount of money.

An electric gas boiler for heating a private house has a complex design. With its help, it is possible to heat a country house economically and efficiently in autonomous mode. It is expensive, but the purchase and installation costs pay off quickly.

Rating of combined boilers

A large number of different models sometimes causes difficulty in choosing even for specialists, not to mention ordinary buyers, so we publish the top 5 models. For clarity, let's summarize the data in a table.

Table 1. The best models of 2018-2019

| Model | Fuel types | Description | power, kWt | Efficiency,% | Weight, kg |

| ZOTA MIX-20 | Coal, firewood, gas, diesel fuel electricity | A model from a Russian manufacturer that consumes basic types of fuel without problems. Withstands short-term pressure increases up to 4 atm (working 3 atm). The material of the heating elements is a seamless stainless steel tube. Their operation is controlled by an external control panel. The device is also equipped with a draft regulator and a thermomanometer, which increases the efficiency of the combustion process. To protect against heat loss, the water jacket is insulated. Wear resistance of the outer casing is achieved thanks to powder paint coating. | 3-9 | 80 | 140 |

| KARAKAN 16TPEV 3 | Firewood, gas, electricity | The dual-circuit model of the Russian manufacturer is especially popular among rural residents, because It is equipped with a wide hob on which you can cook food for yourself and your livestock. The unit can easily heat an area of up to 160 sq.m., this applies not only to residential, but also to industrial premises, incl. greenhouse or garage. The depth of the steel firebox is 0.56 m. The “water jacket” prevents the metal from overheating or burning out, which makes the device’s service life long. | 9 | 75 | 120 |

| Teplodar Cupper PRO 22 | Firewood, coal, gas, pellets | The domestic model can easily heat rooms up to 220 sq.m. When using firewood or coal, the unit acquires the features of a long-burning boiler, since on one tab the operating period is 8 and 10 hours, respectively. Another plus is the spacious firebox, which can accommodate firewood up to 600 mm long. | 6 | 80 | 115 |

| Kiturami KRM 30R | Firewood, briquettes, coal, diesel. | The double-circuit boiler from South Korea is equipped with several combustion chambers and electronic control. Capable of heating a room up to 350 sq.m. The heat exchangers are made of alloy steel, so you should not increase the pressure too much. | 35 | 85-92 | 170 |

| Protherm Bison 40 NL | Gas, diesel, fuel oil | The double-circuit model from Slovakia is capable of heating areas up to 400 sq.m. The control is carried out using a microprocessor, and the electronic display clearly shows the operating parameters of the boiler at any given time. | 38 | 89 | 148 |

Appearance of the Protherm Bizon 40 NL boiler

Design and cost

A combined gas boiler involves using gas as the main fuel source. This means that the structure can be either stationary or wall-mounted.

But it is worth considering that if the secondary heat source is solid fuel, the design can only be stationary.

- In fact, the design is as simple as possible; a regular boiler is used, to which an additional one with another burner is mounted. Also, outputs to the main system are additionally installed, through which the connection to the home system will occur.

- Thus, using a stationary design as a basis, it is possible to combine several boilers for different types of fuel, connecting them into a single system with the ability to automatically switch from one type of fuel to another.

The price of combi boilers for homes varies greatly. The main factor is the types of fuel that will be used. Everything here is individual, you need to calculate in advance which types of fuel will be more profitable in certain conditions, and based on this, make a choice in favor of one type or another.

Also, the cost is affected by the design and power, which is obvious.

What are the installation requirements?

Connecting electric gas boilers must comply with certain standards and regulations, and you must also follow the attached instructions from the manufacturer. Depending on the design, installation can be floor or wall.

In any case, regardless of the device, the following requirements must be observed during installation work:

- according to fire safety conditions, the walls and floor of the room intended for the installation of a gas-electric heating boiler must be insulated, for example, with a sheet of metal;

- when working, you must be guided by the connection diagram issued by the gas service employees;

- when using several sources of thermal energy connected in parallel, free access to each must be ensured;

- the system must be connected to a protected electrical network (grounded and isolated);

- when installing a chimney, it is mandatory to maintain the distance from the walls; all requirements can be found in the technical data sheet;

- the circulation pump is selected taking into account the length of the utility network and the diameter of the pipes;

- Only threaded types of connections are allowed to be used;

- dual-circuit designs involve the use of filters for water purification for each circuit.

If you follow the rules for connecting electric gas boilers, there will be no problems with performance, efficiency, fire safety, uninterrupted operation, and high efficiency is also guaranteed.

Description and capabilities of double-circuit boilers

For houses and cottages located in the countryside, the ideal option would be double-circuit gas-electric boilers due to the following advantages:

- Less gas consumption;

- the cost of a double-circuit heat generator is higher than a single-circuit one, but lower when compared with the cost of equipment with a single circuit and an integrated boiler;

- simultaneous heating of hot water and coolant occurs;

- Less space is required for installation due to its compact size, which allows installation in the kitchen or in the furnace room, but subject to compliance with all norms and requirements.

But there are also disadvantages here:

- the consumption of gas, electricity and water must be balanced;

- if the flow of hot water decreases with unregulated gas, the temperature increases;

- It will be necessary to reconfigure the equipment if the pressure in the water supply network changes;

- periodic maintenance is necessary, since with hard water carbonate deposits quickly form on heat exchangers, which generally leads to decreased performance or breakdown;

- When you turn on the tap, cold water will flow for about 30 seconds.

Advice! It is worth understanding that all the disadvantages of double-circuit gas-electric boilers depend on the technical characteristics and manufacturer. When purchasing heating equipment, it is better to use the services of a specialist.

The best known manufacturers and models: characteristics and prices

Teplodar Kupper OK 15

One of the best and most famous combined gas-electric boilers for heating a private home. The model is known for its simplicity and reliability at a low price. It is also distinguished by its successful inclined design of the firebox and its ease of cleaning. The power of the heating element block is 6 kW. The owners also note the stylish modern design and excellent build quality for a domestic manufacturer.

Despite the fact that the model is quite successful and in demand, there are also many disadvantages: a small loading hole and the firebox itself (wood up to 35 cm), a steel heat exchanger that is susceptible to corrosion, relatively low efficiency, and high soot formation.

Cost: 19,900-21,200 rubles.

Karakan 20 TEGV

Very compact domestic double-circuit combi boiler. In addition to its dimensions, it is distinguished by a simple and reliable design, omnivorous (you can use any fuel of any quality), and at the same time it has a large loading hole and the firebox itself. The heating element is pre-installed by the factory, but the gas burner, as in any other case, must be purchased separately.

The disadvantages are the same - a steel heat exchanger, efficiency is only 75%, and the maximum permissible operating pressure is 1 bar, which means it cannot be installed in a closed-type heating system, where the operating pressure is usually 1.5-2 bar. There have been no service complaints over more than 5 years of operation.

Cost: 22,500-25,000 rubles.

STS V25 FG

An expensive, high-tech, double-circuit multi-fuel heating boiler from a Swedish manufacturer. Works on almost all available types of fuel: natural and liquefied gas, electricity, diesel, fuel oil, firewood, coal, coke, anthracite, peat, pellets. The body itself is steel, but the firebox is cast iron: heavy and fragile, but extremely durable due to its resistance to corrosion (service life of 30 years). The power of the heating element is 6 kW.

The boiler is supplied from the factory with a remote electrical box with a power of 2×6 kW. When using a battery, you can achieve the highest combustion temperature, maximum efficiency, minimum amount of soot, flue gas purity and efficiency of more than 90%. There is also a built-in boiler for preparing hot water with a volume of 115 liters.

The disadvantages are the huge weight of 385 kg and dimensions (height more than 1.5 m).

Cost: 330,000-500,000 rubles.