Today, there are many options for arranging individual heating for a private home. And if some homeowners prefer gas or solid fuel boiler models, others believe that nothing better than electric heating systems has yet been invented. In addition, in the context of constantly rising prices for energy resources, any prudent owner begins to think about ways to reduce utility costs and choose a truly effective and cost-effective heat source. Fortunately, modern manufacturers provide everyone with this opportunity.

As an alternative to today's popular heating systems, ion, or, as they are also called, electrode boilers have long attracted the attention of potential buyers. Thanks to the unique method of heating the coolant in the system, they have a number of advantages compared to traditional heating equipment.

What to follow

When asked how to choose a heating boiler, they often answer that the main criterion is the availability of a particular fuel. In this context, we will highlight several types of boilers.

Gas boilers

Gas boilers are the most common types of heating equipment. This is due to the fact that fuel for such boilers is not very expensive and is available to a wide range of consumers. What types of gas heating boilers are there? They differ from each other depending on what type of burner is atmospheric or inflatable. In the first case, the exhaust gas goes through the chimney, and in the second, all combustion products escape through a special pipe using a fan. Of course, the second version will be a little more expensive, but it will not require smoke removal.

Wall-mounted gas boiler

As for the method of placing boilers, the choice of heating boiler involves the presence of floor and wall models. Which heating boiler is better in this case - there is no answer. After all, everything will depend on what goals you are pursuing. If, in addition to heating, you need to supply hot water, then you can install modern wall-mounted heating boilers. This way you won’t need to install a boiler to heat the water, and this will save money. Also, in the case of wall-mounted models, combustion products can be discharged directly onto the street. And the small size of such devices will allow them to fit perfectly into the interior.

The disadvantage of wall-mounted models is their dependence on electrical energy.

Electric boilers

Next, we will consider electric heating boilers. If there is no mains gas in your area, an electric boiler can save you. These types of heating boilers are small in size, so they can be used in small houses, as well as in cottages with an area of 100 sq.m. All combustion products will be harmless from an environmental point of view. And installation of such a boiler does not require special skills. It is worth noting that electric boilers are not very common. After all, fuel is expensive, and its prices are rising and rising. If you are asking which heating boilers are better in terms of economy, then this is not an option in this case. Very often, electric boilers serve as backup heating devices.

Solid fuel boilers

Now it’s time to consider what solid fuel heating boilers are available. Such boilers are considered the most ancient; such a system has been used for heating premises for a long time. And the reason for this is simple - fuel for such devices is available, its quality can be firewood, coke, peat, coal, etc. The only drawback is that such boilers are not able to operate in autonomous mode.

Gas generating solid fuel boiler

A modification of such boilers is gas generator devices. This boiler differs in that it is possible to control the combustion process, and the productivity is regulated within the range of 30-100 percent. When you are thinking about how to choose a heating boiler, you should know that the fuel that such boilers use is wood, and their humidity should not be less than 30%. Gas fired boilers depend on the supply of electrical energy. But they also have advantages over solid fuel ones. They have high efficiency, which is two times higher than solid fuel devices. And from the point of view of environmental pollution, they are environmentally friendly, since combustion products will not enter the chimney, but will serve to generate gas.

The rating of heating boilers shows that single-circuit gas generator boilers cannot be used for heating water. And if we consider automation, it is great. You can often find programmers on such devices - they regulate the temperature of the coolant and give signals if there is an emergency.

Gas generator boilers in a private home are an expensive pleasure. After all, the cost of a heating boiler is high.

Liquid fuel boilers

Now let's look at liquid fuel boilers. Such devices use diesel fuel as a working resource. To operate such boilers, you will need additional components - fuel containers and a room specifically for the boiler. If you are thinking about which boiler to choose for heating, then we note that liquid fuel boilers have a very expensive burner, which can sometimes cost as much as a gas boiler with an atmospheric burner. But such a device has different power levels, which is why it is profitable to use it from an economic point of view.

In addition to diesel fuel, liquid fuel boilers can also use gas. For this purpose, replaceable burners or special burners are used that can operate on two types of fuel.

Liquid fuel boiler

Prevention

Compliance with operating rules, along with the implementation of timely preventive measures, largely affects the service life of the boiler. Some manufacturers include an annual service inspection of heating equipment in its cost. If this option is not provided, it is better to carry out preventative maintenance of the boiler in the summer.

Before the start of the new heating season, all unstable functioning elements should be replaced, malfunctions should be eliminated and the system should be checked for operability in advance.

Preventive measures can also include cosmetic repairs of the heating boiler. For example, cleaning air ducts and checking the reliability of connections will help to avoid major problems during operation. Timely, regular implementation of preventive measures along with high-quality installation and proper operation will allow heating equipment to operate trouble-free for decades.

Electric ion boilers

Such boilers operate on the principle of heating water (coolant) using the ionization method. This process occurs as follows:

When the boiler is turned on, water molecules are separated into positive and negative ions, which oscillate between two electrodes (anode and cathode). During this process, thermal energy is generated. It is immediately transferred to the coolant, which distributes it throughout the heating system.

Such units are used as an autonomous heating system. They differ from boilers with heating elements in their small size, as well as in the electrode block, which has high performance and efficiency. Table salt is additionally added to the water, which acts as a coolant. This is necessary to increase the electrical resistance of water. To avoid metal corrosion or scale formation, antifreeze designed specifically for ion boilers is poured into the system instead of water.

Electrode boilers were initially used only for military purposes to heat submarines or warships. After which, slightly changing the design, the developers began to produce boilers for domestic or industrial use.

For example, a Galan brand boiler is produced in accordance with all established standards of military equipment, since manufacturers specialize in the manufacture of devices for submarines and ships.

Simple DIY ion boiler

Having become familiar with the features and principle by which ion heating boilers operate, it is time to ask the question: how to assemble such equipment with your own hands? First you need to prepare the tools and materials:

- Steel pipe with a diameter of 5-10 cm

- Ground and neutral terminals

- Electrodes

- Wires

- Metal tee and coupling

- Persistence and desire

Before you start putting everything together, there are three very important safety rules to remember:

- Only the phase is supplied to the electrode

- Only the neutral wire is supplied to the housing

- Reliable grounding must be provided

To assemble an ion electrode boiler, just follow the following instructions:

- First, a pipe 25-30 cm long is prepared, which will act as a body

- Surfaces must be smooth and free of corrosion, nicks at the ends must be cleaned

- On the one hand, electrodes are installed using a tee

- A tee is also necessary to organize the outlet and inlet of the coolant

- On the second side they make a connection to the heating main

- Install an insulating gasket between the electrode and the tee (heat-resistant plastic is suitable)

- To achieve a tight seal, the threaded connections must be precisely adjusted to each other.

- To secure the zero terminal and grounding, 1-2 bolts are welded to the body

Having put everything together, you can embed the boiler into the heating system. Such homemade equipment is unlikely to be able to heat a private home, but for small utility areas or a garage it will be an ideal solution. You can cover the installation with a decorative casing, while trying not to restrict free access to it.

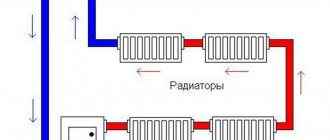

Connection diagram for the Coterm DACHNIK M-5 boiler

Connection diagram of the KOTERM M-5 “DACHNIK” electric boiler to the radiator heating system of a private house.

1 – Coterm Summer Resident boiler 2 – Control panel + thermostat 3 – Circulation pump 4 – Expansion tank + safety group 5 – Shut-off valves 6 – Radiator 7 – Drain valve 8 – Pipe 20 mm (outer diameter) 9 – Pipe 25 mm (outer diameter )

History and principle of operation of the ion (electrode) boiler

This type of heating boiler was created in the middle of the last century by enterprises of the defense complex for the needs of the USSR submarine fleet, in particular for heating the compartments of submarines with diesel engines. The electrode boiler fully complied with the conditions of the order of the submariners - it had extremely small dimensions for conventional heating boilers, did not require exhaust, did not create noise during operation, and effectively heated the coolant, for which ordinary sea water was most suitable.

By the 90s, orders for the defense industry had sharply decreased in volume, and at the same time, the military fleet’s needs for ion boilers were reduced to zero. The first “civilian” version of the electrode boiler was created by engineers A.P. Ilyin and D.N. Kunkov, who received the corresponding patent for their invention in 1995.

The operating principle of an ion boiler is based on the direct interaction of the coolant occupying the space between the anode and the cathode with an electric current. The passage of electric current through the coolant causes a chaotic movement of positive and negative ions: the first move towards the negatively charged electrode; the second - to the positively charged. The constant movement of ions in a medium that resists this movement causes rapid heating of the coolant, which is especially facilitated by the change in roles of the electrodes - every second their polarity changes 50 times, i.e. Each of the electrodes will be the anode 25 times and the cathode 25 times within one second, since they are connected to an alternating current source with a frequency of 50 Hz. It should be noted that it is precisely such a frequent change of charge at the electrodes that does not allow water to decompose into oxygen and hydrogen - electrolysis requires a constant electric current. As the temperature in the boiler increases, the pressure increases, causing coolant to circulate through the heating circuit.

Thus, the electrodes installed in the container of the ion boiler do not directly participate in heating the water and do not heat up themselves - positively and negatively charged ions, split from water molecules under the influence of electric current, are responsible for increasing the water temperature.

An important condition for the effective operation of an ion boiler is the presence of an ohmic resistance of water at a level of no more than 3000 Ohms at 15°C, for which this coolant must contain a certain amount of salts - initially, electrode boilers were created for sea water. That is, if you pour distilled water into the heating system and try to heat it using an ion boiler, there will be no heating, since such water is completely free of salts, which means there will be no electrical circuit between the electrodes.

Types of malfunctions of electric heating boilers

Problems in the electric boiler circuit

Since various metals and salts are almost always dissolved in the coolant, sooner or later under the influence of temperature they will precipitate and accumulate inside pipes and radiators.

This leads to a decrease in clearance, poor thermal conductivity, corrosion and other consequences that reduce the efficiency of the heating system. In order for the batteries to always be warm, it is necessary to periodically - once every 1-2 years - flush the circuit. Since scale mainly forms in electric boilers, the easiest way to remove it is with a solution of citric acid. To do this, you need to replace the coolant with it and let the system run for several hours, then drain and rinse in the same way with ordinary water. These actions are sufficient to protect the metal and provide good heating.

The second problem associated with the circuit is airing. Air is produced due to cracks, poorly tightened taps, boiling over or cavitation. When there is too much of it, the boiler begins to heat the coolant worse and worse, and the wear of parts increases. You can check the pressure in pipes either with a pressure gauge built into the equipment or with remote instruments.

Most modern systems have special valves that allow excess air to be released. If there are none, then they can be installed separately. Having released the gas, you need to add coolant to the norm.

Noise during operation of the electric boiler

Most often, the first sign of an impending breakdown is the non-standard sounds that the electric boiler makes. By the type of noise that comes from the circuit and the boiler itself, you can understand what exactly is going wrong:

- Knocks - mainly occur due to the accumulation of scale and its separation from the walls. It can also occur when dirt filters are clogged.

- The pipes are humming - the lumen of the pipes is narrowed, there is insufficient coolant. It is quite possible that there is a leak somewhere.

- Hissing is a decrease in the volume of coolant due to its boiling. Too hot water leads to just such sounds.

First of all, when noise appears, it is necessary to check the circuit for leaks. The cause of overheating and airing is most often a lack of water, which is why the heat from the heating element or electrodes goes not into the water, but into the metal. This effect reduces the service life of key boiler parts and leads to breakdown. The coolant “leaves” from the circuit most quickly during leaks.

If there are no cracks or chips, then it is worthwhile to diagnose the temperature sensor and pressure sensor. This is done using the control unit by checking the data on the display: if they show non-standard numbers, you need to ring the sensors with a tester. If there is a break in the internal network, the contacts must be soldered back. If the sensor is faulty, replace it entirely.

Temperature drop in an electric boiler

If the temperature in the boiler decreases gradually, this indicates that the heat exchanger is clogged. It is in this part that heating occurs, which is why scale forms most of all here. Cleaning the heat exchanger at home can be done in three ways:

- Mechanical cleaning of the heat exchanger. You need to remove the front panel and remove the heat exchanger (depending on the design, you may need to dismantle the entire system). Next, unscrew the 4 bolts on its cover and clean the metal plates with a special brush, then rinse them thoroughly with water or a chemical solution. After this, you can assemble the heat exchanger and start the boiler.

- Chemical cleaning of the heat exchanger. An alternative method is to dissolve scale with citric acid. Repeating steps from step 1, you need to remove the heat exchanger and place it in a container with a solution for several hours. In this case, you can either disassemble the part itself or place it in liquid as a whole. Then the heat exchanger needs to be washed with water and returned to its place.

- Cleaning the heat exchanger with a booster. The easiest way to clean it is to connect a booster to the circuit - a device for pumping liquid under pressure in both directions. In this case, the heat exchanger itself does not need to be removed. The booster is filled with the same solution and begins to drive liquid through the heat exchanger. Literally after a couple of hours, the purifier is replaced with water, washed, and the boiler can be connected back. The main advantage of this method is the parallel cleaning of the coil (with a certain connection) and other pipes.

If after carrying out these procedures the problem is not resolved, then the cause may be a weak power supply. You can check it on the display of the boiler itself. This often happens if the electric boiler is not connected directly through the panel, but using a power cable and socket. In this case, it is worth making a direct connection of the equipment to the current source and replacing the aluminum cables with copper ones. Current stability can also be ensured by an additional generator or UPS.

Electric boiler does not turn on

The boiler may not start for many reasons, but most often the problem lies in the electrics. This or that element blocks the system and prevents it from working. This could be a thermal relay or a pressure sensor, which themselves “tell” the system about malfunctions. Therefore, you can check this version using the error indicators on the control panel.

If you cannot find out the specific location of the breakdown, then you need to ring the contacts of each unit. Contacts often break, therefore, having found a fault, you should solder them or replace the part.

The circulation pump is also often a source of trouble. If for some reason it does not work, then the boiler will not turn on. The impeller in it may stop rotating due to airing, blockage, wheel locking or damage. To check the pump, you need to unscrew the bolt on the cover, drain the water, inspect the parts, troubleshoot problems, turn the crankshaft with a screwdriver and put everything back together.

Electric boiler does not turn off

Electric boilers have sensors that monitor the temperature of the coolant and various parts. In case of overheating, the automation should stop the operation of the equipment. If the water becomes too hot, and the boiler continues to heat, then a malfunction of the thermostat or fuses is obvious.

To check the electrics, you need to remove the cover of the control unit and inspect the parts. It’s also worth sniffing: burnt wiring has a characteristic pungent odor, and it can indicate the location of the damage. The sensor contacts should be tested with a tester, and burnt fuses should be replaced.

Also, the reason may lie in the failure of the pressure sensor. If there is little coolant in the circuit, the system should turn off, but if there is an electrical problem, this may not happen. You need to check the pressure using a pressure gauge, check the sensor for functionality and, if necessary, replace it or solder it.

Damage to the heating element of the electric boiler

The heating elements themselves - heating elements, induction coils and electrodes - suffer the most in heating equipment. Constant heating in combination with harmful elements contained in the coolant often lead to breakdowns.

Removing these parts is simple: you need to get to the heat exchanger, unscrew the fastenings of the heating element, disconnect the wires, having previously photographed the circuit or remembering it, and remove the heating element. Usually physical damage makes this spare part completely unusable, so it is better to replace it with a new one. If the outer casing is not damaged, then the problem may lie in damaged wires and terminals.

Ion boiler "Beryl" with a seven-stage block

More expensive models, with automatic control and regulation of power at each specific moment in time, are equipped with a special seven-voltage unit (pictured) and a PID system - electronic temperature control. It is believed that the PID controller, which consists of an amplifier, integrator and differentiator, most quickly and accurately estimates the heating level taking into account the immediate future and generates control signals that allow saving up to 20% of energy.

Line of boilers EOU (Energy Saving Heating Installation)

This is also a Russian-made product. Simple in design, relatively inexpensive, but quite easy to use, the boilers cover a power range from 2 to 120 kW. They can be produced for single- and three-phase current networks, differing in size.

Device and technical characteristics

This method of instantly heating the coolant is not some kind of modern development; it has existed for several decades, so today models are produced by several companies. The designs are basically similar and differ only in minor details.

This is usually a vertically mounted cylinder, with a wide lower part where the electrical switching unit is located. The design contains two pipes for supply and return coolant.

Electrodes are installed inside the device. When working in a 220 V line, there is one electrode in the center, and in a 360 V line, there are three insulated electrodes made of specialized alloys, secured with protected polyamide nuts.

In addition, the design contains:

- control unit;

- control unit controller;

- low quality voltage protection;

- power and ground terminals;

- rubber gaskets for insulation

- insulating.

Average characteristics of a domestic ion boiler:

- diameter of the electrode boiler – up to 300-350 mm;

- length – approximately 600 mm;

- weight of one installation is from 10 to 12 kg;

- thermal power from 2.0 to 55.0 kW.

An indispensable component of an ion boiler unit is a special coolant, which must necessarily meet the conditions specified in the technical instructions of the manufacturer.

Which coolant is suitable for an ion boiler

An ion electric boiler is very demanding on the quality of the coolant. Distilled water and antifreeze liquid are not suitable for it. As a coolant, you need to use ordinary tap water that has undergone special preparation. The heater's data sheet indicates how much salt should be contained in the coolant.

To “set up” the coolant for ion heating boilers, according to reviews, you need to spend a lot of time. For example, if the water resistance is insufficient, then it needs to be salted. Regular table salt is suitable. You only need to sprinkle a little bit of it, literally on the tip of a teaspoon. Then the salted liquid is passed through the system and the resistance is measured. If it has reached the required level specified in the passport, then you can leave everything as is. If necessary, add more salt to the coolant or dilute it with distilled water.

Who should do the repairs?

Foreign-made domestic electric boilers are quite represented on the Russian market. Service companies to support them are established in the branches of leading distributors of manufacturing companies or on the basis of installation companies and dealer companies.

Before concluding a contract for warranty service, the owner of the equipment will need to check that the service company has a list of necessary documentation certifying its right to carry out design and adjustment work, as well as warranty service of the heating boiler:

- licenses for design, installation and commissioning work on gas equipment;

- certificate from the manufacturer with permission to perform assembly, adjustment and maintenance services by trained personnel;

- protocol for certification of workers according to safety regulations.

The work of the service company should, on the one hand, be based on the requirements of boiler equipment manufacturers, described in operating manuals, certificates and other technical documentation, and on the other, on the state provisions of SNiP, GOSTs and fire safety standards.

In most cases, the warranty period begins from the moment of completion of commissioning procedures performed under a contract, which describes the general requirements and range of work performed.

The warranty service agreement also establishes the price, procedure, composition and time of routine maintenance, as well as the powers and responsibilities of the parties.

"Galan" Vulcan 36

was one of the first to begin developing such a family of heating devices, using developments in the military space industry and patented engineering solutions. For a quarter of a century, even the first line of devices has not failed and continues to function.

"Galan" Vulcan 36

Model power 36 kW, suitable only for three-phase network. The maximum current for three phases is 27.3 A. The control is mechanical; the boiler is installed only on the floor.

This model “Vulcan” 36 has many advantages, let’s highlight the main ones:

- ease of maintenance and operation.

- safety and reliability - if an electric short circuit occurs, the current supply wires overheat, the set temperature is exceeded, or a coolant leak occurs, the boiler turns off.

- the coolant volume is 600 liters, the volume of the heated room is 1700 cubic meters.

- affordable cost - the average price is 11,000 rubles.

Features of ion boilers

There has long been an opinion among property owners that heating using electric energy is a rather risky undertaking that can result in exorbitant operating costs. To be fair, it is worth noting that this opinion applies to electric boilers with an integrated heating element. The appearance of ion boilers on the market has made it possible to dispel the myth about the high cost of electric heating at home. The unique design of the electrode heating boiler guarantees rational and economical consumption of resources.

In addition to the obvious advantage of efficiency, the electrode heating boiler also has a number of other positive qualities, including:

- long service life;

- overheat protection;

- compact body;

- simple installation;

- the ability to select operating modes for the most economical consumption of energy resources;

- high fire and explosion safety;

- working with available fuel;

- versatility;

- protection of the circuit from freezing (for ion boilers it is typical to use a non-freezing coolant);

- environmental friendliness;

- high class of electrical safety, etc.

Main types of electric boilers

Heating units are divided into several types based on the method of heating the coolant:

- Heating elements - heat transfer is due to the operation of special heating elements - heating elements.

- Electrode - based on the principle of heating water when exposed to electric current.

- Induction - the conversion of electrical energy into heat occurs due to the phenomenon of electromagnetic induction.

Installation features

To install an energy-saving boiler, it is necessary to install a safety valve, pressure gauge and automatic air vent. The horizontal position of the equipment is unacceptable; install it only vertically, without displacement.

The insertion into the thermal circuit is made so that the zero terminal is at the bottom. Wires connected to the boiler must have a cross-section of at least 4 mm². Connect only through machines, in accordance with all rules of the PUE.

For installation in a new main, only a used boiler is treated with inhibitors. Follow the recommendations for using cleaning products. Ignoring this point will lead to difficulties when setting the ohmic indicators of the liquid in the system.

For heating, the choice of radiators is important. Cast iron samples are not acceptable as they are prone to increased scale formation and other contaminants. It is better to select small radiator batteries, made of lightweight materials (aluminum), so that 1 kW of energy is consumed per 8 liters.

Parallel connection - power amplification

When choosing batteries, it is preferable to choose primary-type aluminum structures, since they contain significantly fewer impurities - this will reduce the overall resistance.

DACHANT M-1 for houses up to 80 M2

Energy-saving ion-type electric boiler for heating private houses, cottages, and domestic premises with an area of up to 80 m2.

Advantages of the electric boiler "DACHNIK" M-1

- large heating area (up to 80 m2) with low energy consumption;

- works from a regular 220 V network;

- 3 power modes 1.5 - 2 - 3.5 kW;

- fast heating of the coolant (1 l / 30 sec);

- compact dimensions (130x250 mm, 3 kg);

- ease of installation;

- maintenance no more than once every 3 years;

- The price of the boiler includes a control unit;

- super economical (99% efficiency).

ELECTRIC BOILER (3.5 KW) replaces 4 OIL RADIATORS (6 KW)*.

Technical characteristics of the electric boiler "DACHNIK" M-1

| № | Indicators | Unit change | M-1 |

| 1 | Maximum volume of heated room | m³ | 224 |

| 2 | Adjustable power | kW | 1,5/2/3,5 |

| 3 | Voltage | IN | 220 |

| 4 | Maximum current | A | 16 |

| 5 | Coolant volume in the heating system | l | up to 35 |

| 6 | Efficiency factor (efficiency) | % | up to 98 |

| 7 | Liquid heating temperature recommended/possibly achieved * | gr. WITH | up to 55/80 |

| 8 | Size | mm | 130x250 |

| 9 | Weight | kg | 3 |

| 10 | Diameter of inlet/outlet holes | mm | 25,4 |

| 11 | Average daily consumption | kW/h | 2,0* |

| 12 | Recommended diameter of heating system pipes | mm | no more than 25.4 |

| 13 | Recommended power cable size | mm2 | not less than 2.5 |

| 14 | Coolant (antifreeze) in the heating system | COTERM ECO |

* - this indicator may differ from that shown in the table. Depends on the thermal insulation and volume of the heated room.

Installation of the Coterm M-1 “Dachnik” boiler in the heating system

Guide for informational purposes

Before installing an electric boiler, it is necessary to flush the heating system with clean tap water to remove possible installation debris.

Connection diagram of the “DACHNIK” boiler to the radiator heating system

We recommend this scheme as the most efficient and energy-saving for heating private houses.

- Boiler Summer resident.

- Control panel + thermostat.

- Circulation pump.

- Expansion tank + safety group.

- Shut-off valves.

- Radiator.

- Drain tap.

- Pipe 20 mm (outer diameter).

- Pipe 25 mm (outer diameter).

The boiler kit includes

- Boiler.

- Power mode control panel.

- User manual.

The thermostat for controlling the heating temperature (up to 60 degrees Celsius with the ability to program the boiler for every day) is sold separately.

Installation

The boiler must be installed vertically, with the yellow lid down (to prevent air from accumulating inside the boiler), as low as possible in relation to the heating system, in a place out of reach of children. There must be free space above the boiler for maintenance work. The connection of the boiler fittings with the heating system pipelines must be made with couplings of the same diameter (25.4 mm) as on the boiler.

It is prohibited to install taps, shut-off or control valves in the area from the boiler outlet to the expansion tank (without an additionally installed pressure relief valve, safety group). There is no need to install a coarse filter on the system, because if it is contaminated, the circulation of the coolant is reduced, which will lead to uneven heating of the coolant.

Not recommended

Installing the boiler in a system with large-volume radiator batteries with a total system capacity of more than 50 liters, large-section pipes (32 mm or more), with aluminum radiators (over time, aluminum oxide is released which negatively affects the stable operation of the boiler).

We recommend

Use ordinary bimetallic radiators, plastic pipes reinforced with fiberglass, with a diameter corresponding to the connection diagram, fill the system only with standard Coterm Eco antifreeze.

Power connection

To connect an electric boiler from the power supply input, a cable with a cross-section of at least 2.5 mm2 is required, connected through a separate input circuit breaker with a rating of 25 A (the use of an RCD is not permitted). Check the correct marking of the supply cables and follow it when connecting the boiler L – phase, brown (black, white); N – zero, blue; PE – grounding, yellow-green).

Protective grounding with a resistance of no more than 4 Ohms from a copper wire with a cross-section of 4-6 mm2 must be performed. All exposed metal parts of the heating system must be grounded. For the convenience of correct connection, there are color marking stickers with the name on the supply wires and automation. The boiler must be connected in compliance with all PUE and fire safety rules.

The boiler temperature regulator (thermostat) must be configured to operate according to the coolant temperature sensor!

Connection

- Phase wire of the network - connects to a free connector on the “vago terminal” (sticker “Phase”).

- Network neutral wire - connects to a free connector on the “vago terminal” (sticker “Zero”).

- Grounding wire – located on the boiler body, must be grounded.

Turning on the boiler and selecting the operating mode

The electric boiler has 3 heating modes:

- Economical.

- Average.

- Forced.

The choice of mode depends on the indoor temperature.

Forced mode (3.5 kW) is necessary for quickly heating the coolant at low indoor air temperatures. Do not forget that a comfortable indoor temperature in winter is achieved after prolonged operation of the heating system. Set the required temperature on the thermostat and wait for the boiler to turn on/off automatically.

Medium mode (2.3 kW) or economy mode (1.3 kW) can be turned on after the room has reached the required internal temperature; using these modes will allow you to significantly save energy consumption.

About all the advantages of the boiler in detail

Super savings

The main advantage of electric boilers of the “Dachnik” series is their super efficiency, which distinguishes them from the products of their closest competitors. Innovative patented technology for heating liquids makes it possible to achieve high efficiency of up to 99% (1 liter of water in 30 seconds), making it possible to heat large private houses up to 80 square meters. meters (224 cubic meters), from a regular 220 volt network, while consuming significantly less electricity (3.5 kW/hour or less, depending on the selected operating mode). Competitive manufacturers of electric boilers only state the fact that to heat rooms of a similar area, an electric boiler with a capacity of more than 8 kW (1 kW per 10 sq.m.) is required, while forgetting to take into account that for residents of country cottages and houses, in most cases 5 kW is allocated . per home, and the payment for the allocation of additional power turns out to be very high, or increasing the power is not possible at all. Also, the use of high-power heating devices with 220-volt home networks causes overload of the networks and shutdown of the input circuit breaker, interruption in the operation of electrical appliances, overheating of power cables, and the occurrence of a fire hazard. We offer an electric boiler with unique properties that are superior to similar products from other manufacturers and are similar in economic and performance indicators to the use of gas equipment.

Ideal solution for those who do not have gas supply

At the moment, the most relatively inexpensive way to heat homes is to use gas. However, if you look at it, this method also has its disadvantages:

- high cost of gas equipment;

- high cost of connecting to the gas main;

- mandatory approval of installation and connection is required;

- fire hazard.

In addition, gas is becoming more expensive every year and, according to some experts, prices for gas and electricity may become equal as early as 2020. These factors make the installation of gas equipment unprofitable.

Three boiler operating modes provide additional savings

1.3 KW (Economic mode), 2.2 KW (Medium mode), 3.5 KW (Strong mode) and the use of automation will save your budget much more compared to conventional heating element boilers and oil radiators. (For example, one ordinary oil-fired electric radiator consumes an average of 2 kW of electrical power, while the possible heating area is disproportionately smaller).

Compact and easy to use and install

Thanks to its small dimensions, only 130 x 250 mm, there is no need for a separate technical room. For example: can be installed under a sink or stairs. Installing the boiler requires minimal labor (See installation instructions).

Inexpensive

Due to its unique structure and the use of polymer materials, the boiler has a relatively low cost compared to similar boilers on the market.

Durable boiler operation and minimum maintenance

Preventative maintenance of the boiler and replacement of the coolant in the heating system must be carried out no more than every 3 years of operation. Before the start of the season, if necessary (in case of leaks), it is necessary to fill the system with coolant.

Coolant

Prevents defrosting of the heating system - all seasonal, environmentally friendly coolant COTERM ECO contains special components that protect your heating system from corrosion and freezing in winter, and will also ensure long and stable operation of the electric boiler.

Remote control of boiler heating

If you have installed the boiler under a sink, stairs, in a basement or technical room, there is no need to access the boiler to control the heating temperature; this can be done remotely. The thermostat can be installed in a place convenient for you (for example: in the bathroom, living room, kitchen, etc.). The thermostat has an internal memory function for the set temperature, which allows the device to turn on independently from the set value, without outsiders turning on the device again, in cases of a short-term power outage. This function can save your home and heating system from defrosting during your absence.

Using a boiler with a heated water floor system

It will allow you to be independent from the use of a centralized heating system, use heated floors in the off-season, and also set a floor heating temperature that is comfortable for you.

Silent and safe

KOTERM boilers operate silently, are fire and electrical safe when properly installed and operated, and are certified for use.

Selection of heating devices for systems with electrode boilers

For efficient operation of heating systems with ion boiler units, aluminum or bimetallic heating devices (heating radiators) should be installed. When choosing the former, you should take into account the fact that secondary aluminum, from which cheap radiators are made, contains a large amount of impurities and increases the ohmic resistance of the working coolant. In this case, you should not skimp on radiators, as this will lead to system instability and increased energy costs.

Aluminum radiators coated inside with a polymer composition are usually installed in open systems. The presence of dissolved oxygen in the coolant contributes to the rapid corrosion of the surface of heating devices. For closed systems there is no such need, and the use of radiators with increased protection will only unreasonably increase the cost of the heating system.

Manufacturers of boiler equipment do not recommend the use of heating appliances made of cast iron –

their high contamination significantly affects the ohmic resistance of water. Also, cast iron radiators have a large internal volume, which will require the installation of a higher power electrode boiler and increased power consumption. The exception is cast iron appliances manufactured according to European norms and standards. To increase reliability, a dirt filter and a filter for rough mechanical cleaning of the coolant are installed before entering the boiler unit.

For optimal operation of the boiler unit and to eliminate unreasonable power consumption, it is necessary to accurately calculate the volume of the heating system, most of which consists of heating radiators. The ideal ratio for ion boilers is 8 liters of system volume per 1 kW of equipment thermal power. Exceeding this indicator will lead to high energy costs and uneconomical operation of the units, while the service life of the boiler electrodes will be reduced.

Design features

In order to understand what we are talking about, let us recall the student and/or military background of many of those who are now reading this article. We are talking about a method of boiling water, for which some used a boiler, while others used a simple homemade design. These are two blades, fixed at a short distance from each other and connected by a 220V power cord. When this “boiler” was placed in water, heating occurred literally within 2-3 seconds and violent boiling began. This is precisely the principle on which an anode heating boiler works.

Please note that conducting experiments with heating water is dangerous to life and health. On the one hand, a short circuit may occur, on the other hand, a person runs the risk of electrical injury (electric shock).

The convenience of using such devices lies in the fact that parallel installation of electrode heating boilers into an already existing heating system, which works, for example, with a gas boiler, is allowed. The coolant in both cases remains the same. But manufacturing companies produce not quite standard heaters, in which water is simultaneously used as both a coolant and a heating element.

The main elements of the module are:

- steel tube;

- inlet/outlet pipes;

- terminal for connecting wiring;

- heating electrodes;

- high quality insulation.

Cathode heating boilers have a powerful steel body on the outside. The walls are made of sheet metal up to 4 mm thick. Several electrodes up to 20 mm are located inside the household structure. They are made of a refractory alloy that has a long service life.

Modern electrode ion boilers do not have an intermediary material between the anode and cathode. Heating from both terminals occurs directly from the coolant itself, water. Accordingly, there is practically nothing to “burn out” inside the cavity. The scale that appears on the tubes in electric electrode boilers after long-term operation is cleaned off with ordinary sandpaper.

What is the difference between electrode and heating element boilers?

The individual characteristics endowed with electrode heating boilers allow them to be distinguished from heating elements:

- in heating elements, at the initial stage of start-up, the working tubes are heated, and electrode boilers, made by hand or purchased in a specialized store, begin to heat the water immediately after start, which reduces inertia;

- ion heating boilers have positive reviews, as they are 20-0% more economical than devices with heating elements;

- thanks to alternating current with a frequency of 50 Hz, the electrodes move between the terminals and create a chaotic movement that promotes heating; this feature reduces the starting current for the electrode heating boiler, reducing the load on the electrical network

The difference between electrode boilers and heating elements

- A do-it-yourself electrode boiler made or produced at a factory has smaller overall parameters than other household analogues.

Such features ensure significant distribution of this heating system.

What are the advantages of using

Homeowners do not have to completely give up gas if the premises already have wiring from radiators and mains installed. Often such ion heating boilers play a duplicate role in finished systems. Although, if the cost of gas rises faster, then they can be used as the main source of heating.

Their positive properties include:

- high degree of reliability;

- temperature is controlled automatically;

- real efficiency reaches 99%;

- installation of additional equipment may not be carried out;

- startup and operation in systems designed to operate on gas;

- increased efficiency.

An electric electrode boiler operates exclusively on alternating current. Switching to constant voltage is not allowed.

Thanks to the built-in automation, the set optimal temperature is maintained for the specified time. You can increase energy efficiency by programming the system to lower the temperature on weekdays when no one is home, and raise it in the evening and on weekends.

Thermostat block

According to reviews, electrode boilers have a good emergency shutdown system. If a possible coolant leak is detected, the device will automatically turn off. Also, short circuits do not occur in these heating devices.

The coolant for such equipment can be purchased directly from the manufacturer, who will provide the appropriate quality composition.

Coolant-electrolyte

What are the disadvantages of using

In addition to the advantages, each system has its disadvantages. Ion electrode boilers have the following disadvantages:

- increased requirements for electrolytic water quality;

- it is necessary to carry out mandatory grounding of the device in order to reduce possible risks of working with an electrical device;

- it is advisable to maintain the water temperature in the system no higher than 70-750C in order to reduce energy consumption;

- the cathode and anode need periodic descaling to ensure greater efficiency for the ionization process;

- the system requires mandatory coolant circulation, so a water pump must be installed in it.

Voltage drops are not dangerous for the boiler itself, but they are necessary for the accompanying automation. A UPS or, at a minimum, a surge protector will help you avoid damage from an unstable network.

Rules for safe operation

The optimal water temperature for operation is 50-75ºС. This information is indicated in the device passport. In closed and open systems, expansion tanks must be used.

The outlet from the boiler to the expansion tank in an open system should not have any shut-off valves.

Do-it-yourself installation of an electrode boiler into the system must be accompanied by the installation of an automatic air valve, a pressure gauge for measuring the operating pressure and an explosion safety valve at the highest point of the system.

It is possible to install it in the heating circuit as an additional heating source, but in this case it is necessary to bring the quality and type of coolant into proper condition.

Not all radiators can work with ion boilers, and the quality of the coolant is suitable for some. With very big reservations, cast iron radiators can be used.

Read with this article: Types of heating radiators and their performance characteristics

When installing, one and a half meters of supply pipes to the boiler must be made of non-galvanized metal. After this section, the use of metal-plastic is allowed.

Grounding according to PUE standards is mandatory. The cable should have a cross-section of 4-6 mm. Its minimum electrical resistance must be no higher than 4 Ohms.

If possible, the entire system of pipelines and consumers should be flushed with clean water before installation. It is allowed to use special chemicals to help clean the lines.

After the coolant has been used up, it must be properly disposed of. It is not allowed to discharge it into sewers, water bodies or into the ground.

When making calculations, they are guided by the following parameter: 8 liters of coolant must correspond to 1 kW. To operate in the 10 l per 1 kW mode, the device will be turned on almost constantly, which may negatively affect its performance properties.

Let's make a brief overview of the most popular models of electrode heating boilers, which have already been rated by consumers and identified their strengths and weaknesses. When choosing such equipment, the brand name itself means little. Only in operation can you understand how well the boiler copes with the task, how often it breaks down, and what problems there are in operation. The purpose of this rating is to name the best Russian and European brands.

These boilers have been certified by the Customs Union

The table shows technical data and the average price level for boilers operating on a 220 volt network, as the most popular in domestic conditions:

| Technical data | Unit | Single-phase modifications | |||||||||

| 1/2 | 1/3 | 1/4 | 1/5 | 1/6 | 1/7 | 1/8 | 1/9 | 1/10 | 1/12 | ||

| Operating voltage | Volt | ~220 | ~220 | ~220 | ~220 | ~220 | ~220 | ~220 | ~220 | ~220 | ~220 |

| Power consumption | kW | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 12 |

| Heated room volume | m³ | 120 | 180 | 240 | 300 | 360 | 420 | 480 | 540 | 600 | 750 |

| Heated area | m² | 40 | 60 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 250 |

| Electricity consumption per day | kW | 2-16 | 3-24 | 4-32 | 5-40 | 6-48 | 7-56 | 8-64 | 9-72 | 10-80 | 12-96 |

| Raising water in a water system (without pump) | m | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 13 |

| Weight, no more | kg | 3 | |||||||||

| Price of the device, without control panel | rub. | 4200 | 4300 | 4400 | 4500 | 4600 | 4700 | 4800 | 4900 | 5000 | 5100 |

| Price of a set of components for the control panel | rub. | 1410 | 1990 | 1990 | 1850 | 1850 | 1850 | 2540 | 2540 | 2540 | 2540 |

Despite the unpretentious design of EOU boilers, the manufacturer gives them a factory warranty of at least 10 years, and the total service life is estimated at 30 years.

Imported electrode boilers

In addition to Russian-made boilers, models produced in some neighboring countries are in demand.

Ukrainian-designed and produced Forsazh boilers are interesting in that they are equipped with a special casing - a casing, which increases the operational safety of the installation and still makes its appearance more attractive.

Review of popular models

Today, boilers produced by Galan CJSC, EOU, Koterm, STAFOR EKO LLC, etc. are in good demand on the heating equipment market.

The “Ochag” series of the “Galan” brand, represented by the “Ochag2”, “Ochag 3” and “Ochag 5” models, is intended for domestic use and differs in the size and power of the units produced. The “Dachnik” series of ion boilers of the “Coterm” brand is also quite popular. Coterm M1 Summer Resident can be used to heat rooms up to 200 cubic meters. Having 3 power modes (1.2 / 1.7 / 3.5 kW), it has quite economical energy consumption - about 1.5 kW/hour.

It must be said that ion boilers, subject to the operating conditions recommended by the manufacturer, are designed for an impressive service life - up to 10 years. It is recommended to replace electrodes every 2-4 years.

In terms of cost, such units are often much cheaper than other heating boilers, which is an additional advantage in their favor. The price of ion boilers starts from 3000-4000 rubles. for the simplest models. Of course, equipment with advanced functionality will cost much more - from 10,000... 12,000 rubles. and more.

Installation and operation

When installing an electrode boiler, the main condition is the presence of working automatic air vents, a pressure gauge and a safety valve. The shut-off valves should be located near the expansion tank.

When installing, make sure that the tank is in a vertical position. In this case, the first 1.2 m of pipe must be made of metal, but the rest can be made of any material.

It is best not to install climate control and thermoregulation system sensors yourself, but to entrust this work to specialists.

Features of installation of ion boilers

A prerequisite for installing ion heating boilers is the presence of a safety valve, pressure gauge and automatic air vent. The equipment must be placed in a vertical position (horizontal or at an angle are not allowed). At the same time, about 1.5 m of supply pipes are not galvanized steel.

The zero terminal is usually located at the bottom of the boiler. A grounding wire with a resistance of up to 4 ohms and a cross-section of over 4 mm is connected to it. You should not rely solely on RAM - it cannot help with current leakage. The resistance must also comply with the rules of the PUE.

If the heating system is completely new, there is no need to prepare the pipes - they must be clean inside. When the boiler crashes into an already operating main, it is necessary to flush it with inhibitors. The markets offer a wide range of products for removing deposits, salts and scale. However, each manufacturer of electrode boilers indicates those that it considers best for its equipment. Their opinion should be followed. By neglecting flushing, it will not be possible to establish the exact ohmic resistance.

It is very important to select heating radiators for the ion boiler. Models with a large internal volume are not suitable, since 1 kW of power will require more than 10 liters of coolant

The boiler will constantly work, wasting some of the electricity in vain. The ideal ratio of boiler power to the total volume of the heating system is 8 liters per 1 kW.

If we talk about materials, it is better to install modern aluminum and bimetallic radiators with minimal inertia. When choosing aluminum models, preference is given to primary type material (not remelted). Compared to the secondary one, it contains fewer impurities, reducing the ohmic resistance.

Cast iron radiators are the least compatible with an ion boiler, since they are the most susceptible to contamination. If it is not possible to replace them, experts recommend observing several important conditions:

- The documents must indicate compliance with the European standard

- Installation of coarse filters and sludge traps is required

- Once again, the total volume of coolant is produced and equipment suitable in terms of power is selected

Difficulties in operation

Branded coolant from the manufacturer Galan. At the time of writing, the cost of such a canister is about 2,200 rubles.

- Proper operation in accordance with the requirements implies the use of high-quality coolant with a balanced chemical composition and all the qualities of the electrolyte. Manufacturers recommend using liquids specially prepared for these purposes that have good ionization, sufficient heat capacity and anti-corrosion properties. It is possible to pour ordinary tap water into the heating system, but this usually leads to a decrease in efficiency and rapid corrosion of all metal lines of the heating system. In addition, over time, any coolant loses its properties and requires replacement after 3-4 years, which also causes additional hassle and expense.

- As we have already mentioned, the effect of electric current on ferrous metals and stainless steel significantly accelerates the corrosion process, which reduces the life of the heating system. Therefore, in conjunction with electrode boilers, it is generally not recommended to install steel or cast iron radiators - only aluminum or bimetallic ones. Otherwise, the lifespan of radiators is literally reduced several times.

- The phases of the electrical network are connected to the electrodes, and zero is connected to the body of the electric boiler, so reliable universal grounding is required and it is not recommended to limit yourself to installing an RCD. If the grounding is poor, dangerous potentials may appear on pipes and batteries. In addition, it is necessary to ensure the quality of the wiring in the house, since high-power equipment creates a serious load on the electrical network and causes voltage fluctuations. However, this is not a feature of ion electric boilers, but in general of any electrical equipment with a power of 4-6 kW.

Connection diagram of the electric boiler to the heating system and network for 220 and 380 V

Modern electric boilers are very popular because they are very easy to install and configure. They do not require the construction of a smoke exhaust system or exhaust ventilation, or the presence of a separate room to house the boiler.

Typical modifications of electric boilers already contain all the necessary components and functional units: network pump, expansion tank, thermostat, safety group.

Correct installation affects the complexity of the connection. Photo source: termo-volga.ru

Therefore, connecting an electric boiler is very simple, since you will need to connect a minimum number of in-house utility networks and you will not have to select an expansion tank.

Types of boilers by heater type

Today there are many modifications of units that differ in the connection diagram of the electric boiler, and are classified according to:

- configurations;

- characteristics of thermal conditions;

- design solutions;

- type of heating;

- manufacturing plants;

- cost.

All electric boilers designed for water heat supply, according to the method of heating the coolant, are divided into 3 main categories:

- Heating elements that use tubular electric heating elements.

- Electrode or ionic/electrolysis, operating using the ability of water to heat up when passing alternating current through an electrode.

- Induction, using the properties of ferromagnets to heat up under the influence of induction current.

Boiler selection

The choice of boiler unit for heat supply is made according to thermal power, electrical network parameters and the principle of the heating element. The price of the heating set depends on the last parameter. Such electric units have increased functionality - all models are equipped with block automation with a temperature controller.

Modern modifications of electric boilers are implemented with various peripheral devices - weather-sensitive sensors, room thermostats and GSM modules for adjusting the indoor temperature at a distance from a mobile phone via the Internet.

The level of assembly of block units is very high, which allows you to install such heating with your own hands. The only exception is the installation and adjustment of power supply lines to the unit, which must be performed by certified specialists.

For example, for a house with a total area of 150 m2, the boiler power will be required: 150x1.2x0.1= 18 kW.

How to connect an electric boiler to a heating system

There are several standard piping schemes, one of which must be selected before connecting the electric boiler to the heating system:

- installation of the unit with piping of the electric pump and expansion tank;

- installation of an electric boiler in a parallel operation scheme with a solid fuel or gas boiler unit;

- connection with a hot water storage tank or an external electric water heater;

- connection of a double-circuit modification of an electric boiler to heating networks and hot water supply;

- connection to an indirect heating boiler.

Typically, modern electric boilers are equipped with all the necessary auxiliary equipment. The safety group protects the unit from high pressure and releases air from a closed water circuit using a membrane expansion tank.

Connection diagram for a double-circuit electric boiler

A safety group is installed on a straight section of the supply pipeline, and after it - a ball valve that cuts off the coolant supply. The circulation pump and dirt filter are installed on the return pipeline.

If it is necessary to connect the boiler to an open heating system with natural circulation, then the heating pipes will need to be placed with a slope of 3 mm by 1 pm.

Electric boiler circuits for preparing hot water supply are used in two versions:

- double-circuit design of the boiler, which has two built-in heaters for the heating circuit and DHW;

- single-circuit boiler with external indirect heating water heater.

In the first option, connecting the electric boiler to the heating system is carried out according to the standard scheme. There are practically no difficulties here, the main thing is to correctly install the shut-off valves.

Single-circuit diagram. Photo source: twlwthrt.appspot.com

Connection to an indirect heating water heater is made using three-way shut-off valves. Based on a signal from a thermostat integrated into the battery tank, the valve switches the movement of heating water to heat up the DHW circuit or heating system.

DHW loading is a priority: until the water in the tank warms up to a certain temperature, the heating network will not receive thermal energy.

How to connect the boiler to the electrical network

Before connecting the boiler equipment to the electrical network, it is necessary to carry out a thorough check of its technical condition.

If problem areas are detected, it will be necessary to carry out repair work; if it is not possible to increase the power supply of the existing line, the reconstruction of the in-house electrical networks is carried out with the involvement of certified specialists.

Schemes for connecting an electric boiler to the network

Copper electrical wiring is used for connection; the cross-section of the wires is calculated in accordance with the data provided by the manufacturer in the instructions for the boiler equipment.

Connection to an external cable is made using specialized terminals located at the bottom of the boiler. Typically, a grounding terminal with a copper bolt is also located in this location.

When installing an electric boiler, it is essential to implement a grounding system. In this case, it is necessary to ensure that the contact between the device body and the copper bolt is strong.

A control device for adjusting the temperature schedule must be connected to the circuit. In order to protect electrical equipment from voltage surges, it is necessary to install an RCD.

Connection diagram for a single-phase boiler at 220

The 220 V power supply line of the boiler unit is protected by a differential circuit breaker made of one module, a protection unit made of an RCD with a circuit breaker.

Grounding must be connected to the boiler body. The heating element in such an electric boiler is designed exclusively for 220V, therefore, a phase is connected to one of its ends, and zero to the other.

To connect the unit to the 220 power supply network, it is necessary to lay a three-core cable and select the required cross-section and automatic protection ratings for it to ensure reliable power supply to the boiler. When choosing, proceed from the thermal power of the electric boiler.

Connection diagram for a three-phase electric boiler to the power grid 380

Electric boilers, which are most often used for heating homes, do not have very high power - up to 15.0 kW, since energy regulations no longer allow them. Such installations can be equipped with heating elements manufactured for 220 V.

They are connected to the 380 V network by a “star” with a common “0”. For example, three heating elements of 6 kW each create a total load of 18 kW. With this connection, the operation of any heating element is allowed, regardless of the adjacent one, that is, a choice of power of 6, 12 and 18 kW is allowed. If the heating elements are supplied at 380 V, then they are connected between the phases in a “triangle”.

The RCD compares the strength of the current flowing through it in phases. These data in a properly functioning system will be approximately the same. But when damage occurs or a person touches the current-carrying surface, a current leakage will occur from a certain phase and a current differential will arise between the wires. In the event of such a disruption in the network, the relay will turn off the network in a very short time.

The circuit breaker operates when the specified current strength in the circuit increases. For example, in case of a short phase-to-phase circuit. In this option, the RCD will not work, since the current strengths in the phases will become the same. But limit current protection will turn off the circuit and prevent fire of electrical appliances and wires.

To summarize, it can be noted that the installation of modern electric boilers for heating individual houses is not difficult, since they are equipped with a full set of auxiliary boiler equipment.

The owner will need to carefully follow all the recommendations of the manufacturer and invite an electrician if reconstruction of the home electrical network is required.

Source: https://kotle.ru/elektrokotly/podklyuchenie-elektrokotla

Electrode heating boilers and the Russian market

Despite their shortcomings, ion heating boilers still remain in demand in Russian markets. And this is not strange, since this way you can save a lot on heating. Today, both foreign and domestic companies are engaged in their production (which is very pleasing). In order for you to get an idea of a particular brand, a short overview of the most common manufacturing companies will be provided.

Electrode heating boilers can be of different shapes

Ion boilers "Galan"

Galan is a Moscow company that began its work back in the 90s, gradually gaining leading positions both in Russia and in other countries. The main elements of production are three main models:

- "Galan-Ochag";

- "Galan-Geyser";

- "Galan-Vulcan".

“Galan-Ochag” is their smallest creation (weight does not exceed 500 grams). But such miniature size does not at all affect the performance. For example, one such boiler can easily heat a room of 200 square meters. m. Their average cost varies between 4,000 rubles.

Galan-Geyser boilers are mainly used for heating residential premises. Their rated power of 15 kW is enough to heat a room of 450 square meters. m. Naturally, their cost will be slightly higher compared to the previous model. This is about 7,000 rubles.

Now let's talk about the most powerful model - "Galan-Vulcan". Their power (depending on modification) can reach 50 kW. Such boilers are already used for heating large premises (warehouses, supermarkets, etc.). High power and should not be cheap, as in our case - from 10,000 rubles.

Electrode heating boilers "Beryl"

An exclusively Russian creation is “Beryl”, produced in two variations (depending on the power and power supply). Those people who encounter the products of this company for the first time will not be able to help but notice one characteristic feature - the location of the power supply. In this case, it is located right at the top. This difference makes installation and maintenance much easier.

The cost of single-phase boilers (220 V) with the ability to heat rooms up to 150 sq. m. - from 120 to 140 euros.

The cost of three-phase boilers (380 V) with the ability to heat a room up to 400 sq. m. - from 280 to 380 euros.

So, having understood the design, operating principle and advantages, all that remains is to make a decision in favor of one manufacturer or another.

The best manufacturers

Due to their advantages, ion boilers remain very popular sources of heat supply on the Russian market.

They are produced by a number of domestic factories, and there are also models from Western manufacturers.

General overview of the most popular brands:

- "Galan", a boiler unit from a Moscow company. The company produces several basic models on a 220 V network: "Ochag", "Turbo" and "Geyser", and on a 380 V network - "Vulcan". For the devices you will need to buy a main control unit "Navigator", a circuit breaker "ABB", a thermostat "BeeRT", which controls the performance of the circulation electric pump.

- Electrode ion boilers Beryl, a Russian manufacturer, are available in 2 standard sizes for a 220/380 V network and, accordingly, with a power of 9/33 kW. It has a top-mounted power supply unit, which simplifies installation and maintenance. It is necessary to additionally purchase a “Euro” CSU unit, which allows for stepwise control of the coolant heating power every 200 W.

- Electrode boilers of the EOU brand of a domestic manufacturer, with a power range from 2 to 120 kW, in a 220/380 V network.

- "Forsazh" of the Ukrainian manufacturer are equipped with a special protective casing that increases safe operation and has a designer appearance. It is presented in 5 modifications for a 220 V network, with a power from 3.0 to 20 kW, which are equipped with an ECRT control unit.

- STAFOR, a Latvian manufacturer, complies with EU requirements. The design has a number of innovative solutions, including the use of a “Faraday cage” with distribution of safety and working zero. Together with it, it is possible to buy a branded coolant and a specialized additive STATERM POWER, which allows timely adjustments to the chemical composition of the electrolyte to regulate the efficiency of the boiler.

Model range of electrode boilers "Galan"

Today the company produces three main models, each of which has several gradations in terms of heating power level.

The smallest ones are “Galan-Ochag”. Weighing only 500 g, these “babies” are capable of efficiently heating quite large volumes - up to 200 m³, delivering power up to 5 kW. The cost of such boilers is from 3300 to 4000 rubles. A more modern model - "Galan-Ochag-Turbo" can be slightly more expensive - up to 6,000 rubles.

In private residential construction, the most popular are single-phase and three-phase electrode boilers "Galan-Geyser". They have two heating power thresholds - 9 and 15 kW, and this should be enough for a completely respectable country cottage with a total volume of sealed rooms of up to 450 m³. The average cost of such boilers is 6 to 7 thousand, and “Geyser-Turbo” is about 8 thousand rubles.

The most powerful are the electrode colas in the Galan-Vulcan line. They are all designed to operate in a three-phase network, have a power of 25 and 50 kW, and are intended for heating fairly large structures. The price for them is over 10 thousand rubles.

| Basic parameters of electric heating boilers | VULCANO 50 | VULCANO 25 | GEYSER 15 | GEYSER 9 | HEATH 6 | HEATH 5 | HEATH 3 |

| Consumption voltage, V | 380 | 380 | 380 | 220/380 | 220 | 220 | 220 |

| Heated room, m³ | up to 1600 | up to 850 | up to 550 | up to 340 | up to 250 up to 200 | up to 120 | |

| Coolant volume, liter | 300-500 | 150- 300 | 100- 200 | 50-100 | 35-70 | 30-60 | 25-50 |

| Current consumption, max, A | 2×37,9 | 37.5 | 22.7 | 13,7/40 | 27.3 | 22.7 | 13.7 |

| Peak power consumption in kW, at water temperature 90ºС | 50 | 25 | 15 | 9 | 6 | 5 | 3 |

| Power consumption in kW, on average for the heating season (6 months - 4320 hours) from October 15 to April 15. | up to 36000 kW | up to 18000 kW | up to 12000 kW | up to 8000 kW | up to 6000 kW | up to 5000 kW | up to 3000 kW |

| Recommended outlet temperature, °C | 60 | 60 | 60 | 60 | 60 | 60 | 60 |

| Coupling diameter for connecting the boiler to the heating system | 32 | 32 | 32 | 32 | 25 | 25 | 25 |

| weight. kg | 11.5 | 42130 | 42130 | 42130 | 0.5 | 0.5 | 0.5 |

| diameter, mm | 130 | 130 | 130 | 130 | 35 | 35 | 35 |

| length, mm | 570 | 460 | 410 | 360 | 335 | 320 | 275 |

If the basic models of Galan boilers themselves remain practically unchanged, then the control automation is constantly being improved. Thus, for modern household-grade boilers, it is recommended to purchase Galan-Navigator control units in various designs (price - from 6 thousand).

Advantages of an ion boiler

How to install an ion boiler

Most often, a gas or solid fuel boiler is used to heat a private home. If none of the options suits you, choose ion heating boilers. The technical characteristics of this type of boiler will pleasantly surprise you, because this device works thanks to a special method of heating water in the heating system.

Technical characteristics of the ion boiler

During operation, water ions move in chaos between the anode and cathode located inside the boiler. The current generated between them helps accelerate the ions and thus heats the coolant. Cathodes and anodes are made from a special durable material that does not rust.

The housing is made hermetically sealed to avoid a breakthrough if the system is connected incorrectly. The complete set of the heating device consists of a heating element, a relay protecting the boiler and a special thermostat that allows you to regulate the temperature.

An ion boiler allows you to install several closed heating systems in one room. This heating device is compact and can be mounted in any more suitable place. The efficiency of such a boiler is almost 100 percent.

Installing a cathode and anode in the system allows energy losses to be reduced to zero. 20 square meters per hour consumes about one kilowatt. During boiler operation, the water in the system heats up much faster compared to other types of boilers. The low start-up inertia allows the coolant in the radiators to be heated to the required level in a short period of time. In addition, the boiler has increased protection against power surges. If there is no coolant in the heating system, the boiler does not fail.

Installation of an ion heating boiler

Before purchasing a boiler, you need to calculate the heated area in the room. For example, you can take an area of 48 square meters with ceilings of 2.6 meters and high-quality thermal insulation.

The area, that is, 48, is multiplied by the height from floor to ceiling, that is, by 2.6. From this it is calculated that to warm up one meter it will be 0.025 kilowatts. A boiler with a power of 3 kilowatts is enough to heat the entire room.

- To shut off the coolant in case of system failure or replacement of the coolant, a ball valve is installed.

- To ensure uniform circulation and distribution of water across the batteries, a circulating pump is installed.

- The filter cleans the incoming coolant into the boiler from scale and rust.

- A drain valve is mounted on the return pipe at the bottom to remove water from the system.

- An expansion tank is required to collect excess water that is generated when it is heated in the system.

- The automatic module for turning on the boiler starts the boiler with the specified parameters.

- After this, the air intake is installed.

For an ion boiler to operate in the correct mode, water must have a certain density. When replacing any boiler with an ion one, you first need to drain the old water from the system and fill it with new one. In addition, an inhibitor is added to it. Distilled water is taken for the heating system.

To connect the boiler to the heating system, steel pipes without galvanization are used. After 120 centimeters from the boiler, the pipeline can be made of a different material.

An ion boiler allows you to quickly and efficiently heat a room, so read the technical specifications carefully. You can install the ion boiler yourself if you carry out the calculations correctly and follow the step-by-step instructions.

Main characteristics

The main technical characteristics of the ion heating boiler can be found below:

- • The minimum power of the equipment cannot be lower than 2 kW (it is enough to heat rooms up to 80 cubic meters), the maximum reaches 50 kW (suitable for heating large industrial premises up to 1600 cubic meters);

- • The power of units with one phase varies from 2 to 6 kW, with three - from 9 to 50 kW;

- • Energy consumption reaches its nominal level at 75⁰ temperature inside the boiler. At temperatures exceeding the specified one, energy consumption increases and does not correspond to what is stated in the data sheet.

- • The dimensions of a standard domestic boiler are usually no more than 320 mm in diameter, 600 mm in length and 12 kg in weight.

Advantages and disadvantages

There is a lot of conflicting information in the technical literature about the operation of ion boilers. However, the achieved technological parameters of the operation of such a heating system indicate its significant advantages compared to similar heating devices operating on electricity:

- The highest efficiency level is 90-98%, higher than that of conventional heating elements structures.

- High speed of ion heating boilers reaching operating power.

- Small dimensions and weight, which simplifies the piping of the ion boiler.

- There is no need to install a smoke ventilation system. heated room.

- There is no overheating or coolant leakage.

- Voltage drops in the network slightly reduce the power of ion heating boilers, but do not stop the process of heating the coolant.

- Can be placed in a heating circuit with a traditional boiler running on any fuel as an additional source of heating at night or during peak load hours.

- Cascade installation of several ion units with stepwise adjustment of heating power is allowed.

- With proper disposal of waste coolant, ion boilers absolutely do not pose a threat to the environment.

- They have a low cost compared to traditional units.