When operating a gas boiler, you can often encounter the problem of its excessive heating. We will look into why the gas boiler is hot in this article. If you find that the body of the device has become warm or hot, it means that a malfunction has occurred. It needs to be eliminated as quickly as possible. First, you should immediately check the functionality of the burner. Probably its settings have gone wrong. As a result, a powerful flame appears, from which the heat exchanger, as well as the upper part of the boiler, overheats. In this case, it is necessary to reduce the flame power.

In addition to this reason, heating may appear when you independently reset the settings of gas boilers. The units are manufactured in accordance with the burner power. Exceeding the recommended power leads to malfunctions of the boiler unit. In this case, you should immediately seek the help of a specialist.

Attention! Converting boilers yourself is illegal and can lead to fires or explosions!!!

How does the heating system work?

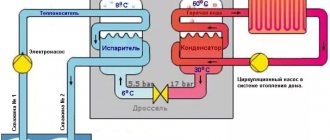

The functioning of the heating system in a private house is ensured by the fact that water/antifreeze is heated in the boiler to the set temperature. Through heating pipes, the liquid is directed to the radiators, from which the room is heated. After this, the already cooled liquid comes back, where it is again automatically heated.

Heating system diagram

An open heating system with natural circulation has a number of features

- There is a lot of dissolved air in the system, which can lead to corrosion of internal metal elements in the system.

- Great inertia of the system. After turning on the heating, the house heats up slowly. The system must be warmed up gradually, otherwise the water will simply boil in the boiler, while it will still be cold in the radiators.

- The house warms up evenly

- Large temperature difference between supply and return

- Fuel consumption is higher (low efficiency) than in a closed system with a circulation pump

- Independence from electricity

- The system is simple, there is practically nothing to break in it. Fairly simple installation.

- Aesthetically not very good, because... large diameter pipes are used, and sometimes pipes of increased diameter are used as radiators

- The system is quite cumbersome

- Antifreeze cannot be used in the system.

- The water from the system gradually evaporates, so it must be added periodically. It is advisable to install automatic topping up.

- The boiler must be installed at the lowest point of the system. The best place is in the basement, or in some kind of recess.

- The expansion tank is installed at the highest point of the system. If you install it in the attic, it must be insulated.

- Quiet operation due to the absence of a circulation pump

But nevertheless, this system has been successfully used and is used when installing heating in small private houses with a height of 1 or 2 floors.

Let us describe the entire system in order:

Types of heating systems

There are two main types of heating systems:

- Single-pipe. The simplest and most economical system. It is made in the form of a ring into which heating radiators are built. The coolant circulates in a circle. The hottest fluid goes to the closest radiator. It supplies the radiator with heat, while cooling only a couple of degrees. The fifth or sixth radiator receives significantly cooled liquid.

In order for the batteries to retain heat, they need to be equipped with additional sections. Then you will not notice the loss of heat in your living space. There is another option - to increase the temperature of the coolant in the boiler. However, this will lead to high costs.

a circulation pump helps solve the problem . It increases the speed of coolant movement and, naturally, reduces heat consumption. Heating will also occur much faster. The downside to this solution is higher electricity bills.

- Double-pipe, many times superior in energy performance. It involves branching the coolant into two outlets, as a result of which heat losses are halved. They have a common return circuit. However, to build such a system you will need twice as many pipes, shut-off valves, and sensors. Most often, such a heating system is used in gasified premises.

Pipe layout diagram

Tee and manifold pipe layouts

Having determined the number of plumbing fixtures that will be connected to utilities, a choice is made of the location where it will be located.

It is necessary, first of all, to determine where which plumbing fixtures will be installed.

To do this, you need to mark all the places where plumbing items will be located and circle the kennels on the floor, and then remove the equipment from the bathroom. Now you need to draw a diagram of the room on a piece of paper and put on it a diagram of how the pipeline will run.

To do this, it is advisable to use principles such as:

- Undesirability of crossing pipes;

- It is recommended to lay the water supply very close to the sewer. This is necessary so that they can be easily closed with a box in the future;

- When the plumbing is installed, there should be easy access to the place where the pipes will be connected to flexible hoses. In this case, most of the system should be hidden behind a special box.

There is no need to complicate the pipe layout; it is advisable to make everything as simple as possible:

- all main communications must be laid below, directly above the floor;

- It is imperative that water outlets be made through tees, which will be directed perpendicularly upward relative to the main pipes;

- It is recommended to make sewer outlets without a vertical part, using them only as tees to which flexible hoses will be connected directly.

Why is the gas boiler hot: reasons

Heating of gas boilers is a common occurrence. Since the maximum heating temperature of the case depends on the characteristics of the model used. Therefore, heating the housing is a loss of energy that could be used to heat the room. Many models of boiler units are designed for minimal heat loss. The body of such boilers is equipped with a special removable circuit, which reduces the heating of the body.

If the degree of heating of the housing walls is too high, cracked or reddened, then there is a serious malfunction.

Common causes of boiler heating

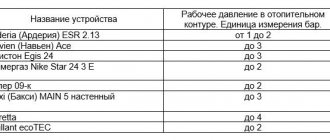

The most common reasons for heating boilers are:

- There is no heat carrier in the heat exchanger. When the heat exchanger is empty, energy does not enter the heating circuit, resulting in the boiler walls heating up. As a result, the boiler may explode;

- Incorrect traction setting. Excessively powerful thrust ensures rapid combustion of fuel and produces a large amount of energy, but it is not absorbed by the coolant. In this case, it is necessary to reduce the draft at the inlet and outlet of the boiler by adjusting the damper and gate;

It must be taken into account that permanent heating of the boiler walls leads to steel deformation. Faulty equipment will lead to failure of the entire heating system.

- Incorrect installation of the boiler and the entire system;

- Lack of circulation, or low circulation. The problem is typical for an open type system with an expansion tank;

- Very high power of the device compared to radiators;

- Lack of water in the main.

Poor circulation

If the circulation is too slow, the coolant will not be able to fully provide heat. The water will simply boil. The problem is typical for systems in which liquid circulates naturally. The diameter of the pipes in them is selected incorrectly, and the slope is set incorrectly. In systems with forced circulation, this problem is extremely rare. This is due to insufficient pump power.

Not enough coolant

When there is not enough fluid in the heating system, this can also cause it to boil. A similar situation arises when air jams form. If the unit is equipped with an expansion tank, you can simply add the required amount of water. In other situations, it will be necessary to bleed the air if the system does not provide automatic deflation.

To increase circulation significantly, you will need to completely reinstall the heating system. You may need to install a circulation pump. Thanks to these solutions, if the angle of inclination of the pipes is incorrect, water will circulate as it should.

Boiler power is higher than heat output

The liquid in the heating equipment can also boil in the case when the boiler itself significantly exceeds the heat transfer power of the radiators.

This problem occurs when there is a problem with the air supply (draft) control system, through which it is possible to reduce the thermal output of the boiler. In this case, an automatic traction control system is installed. If installation of the system is not possible, it will be necessary to replace the boiler or increase the power of the radiators due to their number.

The ideal solution would be to install an indirect water heater (boiler) heating system. It consumes part of the heat to heat water and acts as a heat accumulator.

Gas and electric heating boilers – which one to choose?

Pellets and wood briquettes

The Scandinavians were the first to come up with the idea of turning sawdust into fuel. Later, other European countries followed suit. In our country, pellets have long been produced only for the European market, so still only a few homeowners know what they are.

Pellets are divided into classes, and their price depends on this. For example, for wood pellets of the first class (with minimal bark and moisture content) you will have to pay 110 euros per ton, for the second class - 100, for the third, lowest - 85-90. The lower the class, the more ash is formed after combustion, the greater the volume of fuel required for the season. To heat an average-sized house, about 3-4 tons of pellets are purchased per year. The main problem is to find a dry and ventilated room to store them.

Burning such expensive fuel in an ordinary solid fuel boiler is not profitable. Pellets (granules) are intended for combustion in special heat generators with a pellet burner - fuel combustion occurs under forced air pressure. Such boilers are an order of magnitude more expensive than any solid fuel boilers, but the difference in price is justified. These boilers are automated: they can control several pump groups, be equipped with weather-dependent sensors, room programmers, some models even have auto-ignition and automatic fuel supply from a special bunker. With a pellet boiler, you need to go into the “stoker” once or twice a week - replenish the bunker, clean the ash pan.

Wood briquettes

can be burned in an ordinary solid fuel boiler. The main component for their production is the same sawdust. They burn well and leave little ash behind. Manufacturers claim that one cube of wood briquette can replace up to 3-5 cubes of firewood! After such statements, it is logical to assume that prices will be higher. For example, a ton of Pini Kay briquettes costs an average of 250 rubles per ton, RUF - 200 rubles per ton.

Why does a gas boiler boil?

When the boiler operates correctly, the coolant in it is heated to the temperature specified by the user. Then it is distributed independently or forcibly (using a pump) throughout the heating system. Thanks to this process, our apartments always have warm radiators. The liquid moves through the radiators and back, forming a vicious circle.

What to do if the boiler boils?

To restore the normal functioning of the gas boiler, you need to eliminate the cause of the breakdown. If there is a built-in self-diagnosis system, the display will show an error code depending on the manufacturer of the unit:

- E01 "Navien";

- E02 Baxi;

- A03 "Koreastar";

- 01 Ariston;

- F20 "Proterm";

- 16 Rinnai, etc.

If there is no self-diagnosis system, or it malfunctions, then it is not difficult to detect a breakdown by external signs. The main thing is to understand why the gas boiler is hot.

Troubleshooting solid fuel models

Solid fuel boilers may have the same causes of smoke associated with the chimney as gas appliances described above. When burning, it is necessary to use well-dried raw materials. It should be stored in well-suited places with low humidity. Do not use synthetic materials as fuel.

Wood-burning boilers such as Buderus Logano SW, Stropuva S and Zhitomir D should be heated only with dry wood. To be able to use different types of fuel, you need to purchase combined devices such as KST or Dymok. You can experiment with the degree of opening of the gate in air-heating models, such as. If smoke appears, make the chimney opening larger.

Ensure air flow into the boiler room. For safety reasons, the window must be open constantly while the boiler is operating during the heating season. The device operating on solid fuel must be cleaned regularly. This is especially true if it is coal or diesel, running on exhaust, since these types of fuel clog the burner especially quickly.

What is the expansion tank for?

The expansion tank is usually installed in the attic. Most often, this room is not heated. Based on this, there is a need to insulate the walls of the expansion tank. Otherwise, in the cold season, the water in it will completely freeze. The tank compensates for changes in water temperature. In addition, water may boil in the boiler, especially if the boiler is heated too intensely. Due to the formed bubbles, the volume increases. This is what the additional volume in the expansion tank is for.

Expansion tank

It is recommended to pay attention to the release of excess water from the tank when it overflows. You will have to consider the presence of drainage into a sewer or septic tank.

Why do heating boilers explode?

If used incorrectly or malfunctions, the boiler explodes quite easily. You should find out why the gas boiler is hot. Most often, not constantly running boilers, but those that start from time to time fall into this category. Particularly dangerous are areas that may become covered with ice. These are, most often, expansion tanks, circulation pipes and unheated rooms. The main reason for boiler explosions is freezing of the heating system. The water in the pipes stops circulating, but the fuel burns as before.

Review of domestic gas heating boilers from leading manufacturers

Water is boiling inside the battery sections or pipes. At the same time, the vapor pressure inside the system increases at a catastrophically fast pace. When the critical point of pressure increase is reached, an explosion occurs. Metal is not able to withstand such pressure from the inside. Broken windows are not the worst outcome of such an explosion. They may not withstand the structure of the room. But the worst thing is the infliction of enormous harm to human health or even death of those who were in the immediate vicinity of the explosion as a result of the collapse of the boiler room structures.

Basic safety precautions when turning on a gas boiler

Before putting the boiler into operation, you must make sure that the locks are open on both pipelines. The first of them supplies coolant to the boiler, and the second removes coolant from it. The shut-off devices located on the heating system also need to be opened. The lower compartment of the chimney will need to be cleaned of accumulated condensate. This is important to do in order to avoid carbon monoxide poisoning.

It is advisable to check the condition of the chimney regularly. Before starting the boiler, it is necessary to open the system make-up line and the control line for filling the expansion tank. The fact that the system is ready for operation and is not frozen will be indicated by the water flowing from the control line.

Boiler explosion

On January 4, 2016, an explosion occurred in a domestic boiler located in an apartment in Lyakhovichi. The residents were not injured. The enclosing structures of the boiler room in which the boiler was installed were destroyed. The cause of the explosion is the lack of water circulation in the heating system. Most likely as a result of the formation of an ice plug in the outlet pipeline. Factors that led to the explosion:

- unsystematic boiler firing mode,

- improper operation of the boiler,

- failure to comply with safety precautions when using the device.

On January 8, 2022, in Lyuban (Minsk region), a household solid fuel boiler exploded in the boiler room of a residential building. The consequences of the explosion were the collapse of a brick wall, damage to the roof, and the destruction of the boiler itself and the boiler room. Fortunately, no people were injured.

Why does a gas boiler click: 5 main reasons and ways to eliminate them

Sad statistics

You should always find out why the gas boiler is hot. In addition, over the past eight years, about 70 emergency situations have occurred due to incorrect operation of heating boilers. The boilers that have exploded over the past few years were constructed independently. Craftsmen, being incompetent, made the units themselves. Accordingly, this creates a colossal risk that problems with the operation of the boiler and its overheating may begin. As a result, the operation of such a model leads to the fact that the water overheats, the walls of the boiler cannot withstand the pressure, and, alas, an explosion cannot be avoided. Even safety valves are not installed on homemade devices.

Every year, Gospromnadzor warns citizens not to use homemade units and not to trust the installation of certified boilers to people who do not have the appropriate qualifications. Once you save money, you risk all your property, housing, health and even life. In doing so, you put strangers at risk. To avoid freezing of the boiler pipelines and heating system, it is necessary to responsibly follow the safety rules when operating gas boilers.

Employees or specialists of the competent services must train the owner in the rules of safe operation of the boiler and heating system and put a note about this in the device passport.

It's warm, it's cold

It happens that periodically the air conditioner does not heat or even turns on when it is cold. This is normal if the appliance has a defrost mode. The fact is that when working for heating, the temperature of freon in the condenser of the outdoor unit drops sharply. Frost and ice may form on it.

Icing of the condenser radiator can cause problems. Therefore, the air conditioner periodically warms it up so that the frozen moisture evaporates. You only need to sound the alarm if your air conditioner does not have a defrost mode. In this case, there is a problem with the temperature sensor or electronics.

The condenser of the outdoor unit of the air conditioner, which worked for heat, was frozen with snow.