Today, the issue of energy efficiency has become an issue. Therefore, everywhere, and ventilation systems are no exception, energy-saving installations and machines are used. A careful attitude towards energy forces consumers to increasingly turn to heat recovery systems.

Depending on specific conditions, an installation with a built-in recuperator can save up to 90% of energy needs compared to an installation without it. This is theoretical data. In practice, our research has shown that the most efficient rotary heat exchanger saves a maximum of 75%, but this, you see, is also a rather impressive figure. The ventilation with recovery itself and the principle of operation were previously mentioned in the article at the link. We will not repeat ourselves and will consider the recuperator itself.

What are recuperators?

"Recuperatio" is a word meaning "getting back" something. In our case it is air. The task of recuperators is to return part of the heat to the room by transferring it from the outgoing heated flow to the cold incoming one. This equipment is part of the supply and exhaust system; it helps to minimize losses for “street heating”.

There are two large classes of recuperators - rotary and plate. They have their advantages, but they also have some disadvantages. The feasibility of using a particular unit is largely determined by the characteristics of the room, but plate models are more popular. It is better to dwell on them in more detail.

A plate device is a cassette (block, heat exchanger) in which there are many thin partitions - smooth or corrugated sheets, they are made of various materials. Warm air moving through the plate exchanger gives off heat to it. Due to it, cold masses coming from the street are heated. The result is partial heating of the air, which means saving energy from the heaters.

Device cassettes are made from aluminum foil, galvanized steel, plastic or paper that has undergone special treatment. The gaps between the plates are 2-4 mm. Recuperators differ not only in the materials of the heat exchanger partitions. Models have different directions of air flow:

- in the more common type of equipment - cross-flow - the outgoing and incoming flows are perpendicular to each other, the efficiency reaches 65%;

- in counterflow recuperators - in opposite directions, since non-contacting flows must ensure ideal heat exchange.

Thanks to this principle of operation, plate units make it possible to guarantee constant heating of the cold air entering the room. Heat losses trying to “warm the street,” on the contrary, are minimized.

Another difference between recuperators and conventional (natural) ventilation systems is their ability to eliminate unpleasant odors. Some models - membrane ones - have another additional advantage: they successfully combat high humidity in the room.

Main technical parameters

Knowing the required performance of the ventilation system and the heat exchange efficiency of the recuperator, it is easy to calculate savings on air heating for a room under specific climatic conditions. By comparing the potential benefits with the costs of purchasing and maintaining the system, you can reasonably make a choice in favor of a recuperator or a standard air heater.

Equipment manufacturers often offer a model line in which ventilation units with similar functionality differ in air exchange volume. For residential premises, this parameter must be calculated according to Table 9.1. SP 54.13330.2016

Efficiency

The efficiency of a recuperator is understood as the efficiency of heat transfer, which is calculated using the following formula:

K = (Тп – Тн) / (Тв – Тн)

Wherein:

- Тп – temperature of the air entering the room;

- Tn – outside air temperature;

- TV – room air temperature.

The maximum efficiency value at a standard air flow rate and a certain temperature regime is indicated in the technical documentation of the device. Its actual figure will be slightly less.

In the case of self-manufacturing of a plate or tubular recuperator, in order to achieve maximum heat transfer efficiency, you must adhere to the following rules:

- The best heat transfer is provided by counter-flow devices, then cross-flow devices, and the least by unidirectional movement of both flows.

- The intensity of heat transfer depends on the material and thickness of the walls separating the flows, as well as on the duration of the air inside the device.

Knowing the efficiency of the recuperator, you can calculate its energy efficiency at different temperatures of external and internal air:

E (W) = 0.36 x P x K x (Tv - Tn)

where P (m3/hour) – air flow.

Calculation of the efficiency of the recuperator in monetary terms and comparison with the costs of its acquisition and installation for a two-story cottage with a total area of 270 m2 shows the feasibility of installing such a system

The cost of recuperators with high efficiency is quite high; they have a complex design and significant dimensions. Sometimes you can get around these problems by installing several simpler devices so that the incoming air passes through them sequentially.

Ventilation system performance

The volume of air passed through is determined by static pressure, which depends on the power of the fan and the main components that create aerodynamic resistance. As a rule, its exact calculation is impossible due to the complexity of the mathematical model, therefore experimental studies are carried out for standard monoblock structures, and components are selected for individual devices.

The fan power must be selected taking into account the throughput of installed heat exchangers of any type, which is indicated in the technical documentation as the recommended flow rate or volume of air passed by the device per unit of time. As a rule, the permissible air speed inside the device does not exceed 2 m/s.

Otherwise, at high speeds, a sharp increase in aerodynamic resistance occurs in the narrow elements of the recuperator. This leads to unnecessary energy costs, ineffective heating of the outside air and reduced fan life.

The graph of pressure loss versus air flow rate for several models of high-performance recuperators shows a nonlinear increase in resistance, so it is necessary to adhere to the requirements for the recommended air exchange volume specified in the technical documentation of the device

Changing the direction of air flow creates additional aerodynamic drag. Therefore, when modeling the geometry of an indoor air duct, it is desirable to minimize the number of pipe turns by 90 degrees. Air diffusers also increase resistance, so it is advisable not to use elements with complex patterns.

Dirty filters and grilles create significant interference with flow, so they must be periodically cleaned or replaced. One effective way to assess clogging is to install sensors that monitor the pressure drop in areas before and after the filter.

Air recovery principle

To understand the advantages and benefits of using recuperative heat exchangers, you first need to understand the very essence of their work. Literally translated from Latin, recovery is called “return of used, spent.”

It is the energy return effect that is used in climate control devices of this design. Air flows passing through the unit exchange thermal energy with each other, allowing the air conditioner to subsequently maintain a comfortable temperature, using less energy. On particularly cold days, this allows you to significantly save on heating the room.

Example: the air temperature outside has reached minus 20°C. For residents to feel comfortable, the air conditioner must create a room temperature of at least + 25 C. The temperature difference is easy to calculate - 45 degrees Celsius. Of course, some part of the air will heat up due to the heat capacity of the walls, furniture, and heat exchange between the incoming and outgoing flows. But the air conditioner will still require a significant amount of energy to maintain comfort.

Plate and any other recuperator of the chosen design allows you to move the point of contact of cold and warm air outside the room. The device conducts active heat exchange between them, allowing the incoming flow of fresh air to reach a more comfortable temperature value than the original one.

In winter, warm exhaust air partially warms the incoming cold flows, and in summer it slightly cools them. This helps not only to reduce energy costs from using an air conditioner, but also to increase the stability of maintaining the selected climatic conditions.

What is ventilation with recovery?

Ventilation in premises can be natural, the operating principle of which is based on natural phenomena (spontaneous type) or on air exchange provided by specially made openings in the building (organized ventilation). However, in this case, despite the minimal material costs, dependence on the season, climate, as well as the lack of the ability to purify the air, do not allow us to fully satisfy people’s needs.

Supply and exhaust ventilation, air exchange

Artificial ventilation makes it possible to provide more comfortable conditions for those in the premises, but its installation requires certain financial investments. It is also quite energy-consuming. To compensate for the pros and cons of both types of ventilation systems, their combination is most often used.

Organization of air exchange

Any artificial ventilation system, according to its purpose, is divided into supply or exhaust. In the first case, the equipment must provide forced air supply into the room. In this case, the exhaust air masses are removed outside naturally.

air ducts through which air moves;

fans responsible for its influx;

sound absorbers;

filters;

air heaters that provide air at a certain temperature, which is especially important in the cold season.

Supply and exhaust ventilation

In addition to the above, the system can be equipped with additional modules to ensure a comfortable microclimate.

The exhaust system, operating simultaneously with natural ventilation, is designed to remove waste air masses. The main component of such equipment is exhaust fans.

The optimal option for a ventilation device is supply and exhaust equipment, the installation of which helps create the conditions necessary for people in the premises. This scheme is especially useful in buildings whose finishing materials do not have vapor permeability, which is not uncommon today.

Supply and exhaust equipment

Ventilation with supply and exhaust devices

Ventilation system

There is one significant drawback in the operation of supply and exhaust ventilation - heated air is exhausted outside, and air masses at ambient temperature enter. A large amount of electricity is consumed for heating (this is especially noticeable during the cold period). To reduce unnecessary costs, recuperators are used.

Recovery (in relation to ventilation) is the return of part of the thermal energy of the exhaust air in a room for use in the technological process. It can be used in centralized and local systems.

Ventilation diagram

The recovery process is carried out in special heat exchangers (recuperators), to which supply and exhaust channels are connected. The air masses removed from the room, passing through the recuperator, give up some of the heat to the air coming from the street, but do not mix with it. Such a scheme can significantly reduce the cost of heating the supply air flow.

Recuperators can be installed in various areas of the building: ceilings, walls, floors or on the roof. They can also be installed outside the building. The equipment is either a monoblock or separate modules.

Daikin HRV plus (VKM)

When designing a ventilation system, many factors are taken into account:

- dimensions and number of premises;

- purpose of the building;

- air flow.

The efficiency of the installed system depends on this and the type of recuperator chosen. The efficiency when using thermal energy recovery can vary between 30...90%. But even the installation of equipment characterized by minimal efficiency brings tangible benefits.

How does the circulation of air masses work when installing supply and exhaust ventilation with a recuperator:

- with the help of air intakes, air is taken from the room and disposed of outside through air ducts;

- before leaving the building, the air flow passes through a recuperator (heat exchanger), leaving part of the thermal energy there;

- Cold air coming from outside is directed through the same recuperator, which is heated by heat and supplied to the room.

Recuperator

Recuperators are part of the forced ventilation system

A plate air recuperator, like any other device of this type, is only part of a forced ventilation system. You should not expect a more or less noticeable improvement in the microclimate in the house when using only a recuperator. Combining it with a natural supply and exhaust air exchange system, it is quite difficult to achieve any noticeable effect. For effective heat exchange between streams, they must constantly move through the device.

For the same reason, installing a recuperation system is not always considered effective and economically justified in a home. Before choosing or making a recuperator with your own hands, it is recommended to calculate:

- Energy consumption before upgrading ventilation.

- Approximate lifespan of the system after upgrade.

- The cost of purchasing and installing the necessary units.

- The cost of annual system maintenance.

Cases where the above-mentioned costs are unable to completely cover the cost of using the ventilation system “as is” are not as rare as it might seem. Especially when it comes to factory devices. Homemade recuperators often help to slightly reduce coolant consumption, and their cost is low.

Installation of a recovery system is necessary only when it really seems quite effective based on calculations. In all other cases, modern air conditioners do an excellent job of maintaining the given climatic conditions.

How to calculate the efficiency of a rotary recuperator?

Calculation of the overall efficiency of a rotary recuperator (or, more simply, its productivity) and its payback period can be done manually. The calculation should be carried out according to the following scheme:

- required amount of heat (parameter Q): Q = C (parameter of specific heat capacity of air) * M (parameter of the mass of heated air) * dT (parameter of temperature difference);

- consumption of electrical energy by the heater (parameter Ek): Ek = Q/heater efficiency;

- year-round costs for electrical energy (parameter E): E = Ek * 24 (days) * 30 (days of the month) * 7 (heating months);

- volume of potential savings in the amount of electrical energy (Rel parameter): Rel = E * efficiency at the cost of the recovery system, resulting in savings of Rel * cost of 1 kW/electric energy;

- payback period for the installation : T (cost parameter of the device) / E (saving parameter expressed in monetary terms).

As you can see, these calculations can be carried out independently, without resorting to consulting with specialized companies (which costs some money).

Sources:

- https://dom-i-remont.info/posts/ventiljacija/rotornyj-rekuperator-ustrojstvo-princzip-raboty-plyusy-i-minusy/

- https://ventilsystem.ru/klimaticheskaya-texnika/rekuperator/rotornyj-rekuperator.html

- https://oventilyacii.ru/ventilyaciya/ustrojstvo-rotornogo-rekuperatora.html

- https://stroy-podskazka.ru/rekuperator/o-rotornyh/

- https://climatdoma.net/ustroystva/ustanovki/rotorniy-rekuperator-vozduha.html

Types of recuperators

Recovery systems can be divided into several types.

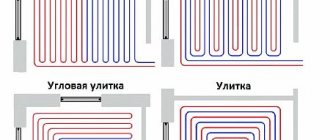

- Direct-flow, counter-flow, cross-flow recuperators differ in the way they move air flows.

- Depending on the design features, recuperators can be ribbed, tubular, plate or plate-fin.

- Based on the material of manufacture, heat exchangers can be metal, plastic, or membrane.

- According to the principle of operation, they distinguish: plate (cross-flow) recuperator - the most popular type of simple design, used in houses and apartments;

- rotary recuperator - operation requires a source of electricity that rotates the rotor element, are large in size and have high efficiency (up to 87%);

- roof-mounted recuperator – industrial level installation;

- coaxial recuperator - easy to implement even without experience;

- recirculation (liquid) recuperator - transfers heat to the air using water or antifreeze, has a complex design and efficiency comparable to the efficiency of a plate heat exchanger.

Disadvantages of a recuperator in a private house

If we talk about negative characteristics, here we need to highlight the following:

- The recuperator hangs on the wall, which means it takes up space. Any element has an internal structure, but the size will differ. But on a vertical structure the block will still be present.

- Noise level. If in a standard scheme it is possible to make a silent operation mode, then with recuperators this is more difficult to do.

- Indirect integration for smart home. This is absolutely impossible to do. The only exception is the use of modules.

- There is no possibility of organizing effective ventilation for huge rooms. The installation limit is 300 square meters. If the area exceeds, then it is better to turn to central systems that will work more efficiently.

- The cost of professional models is too high.

Elements of a plate recuperator

The main parts of the recovery system are the fan and the main unit (cassette) with plates. Other elements:

- The condensate removal system is a condensation bath. The device is necessary to remove moisture from the plates, since it will inevitably lead to liquid entering the air channel, in which ice may form. If there is a large accumulation of liquid, the operation of the supply and exhaust system is blocked by the water seal of the condensate collector.

- Bypass valve. Its task is to regulate the intensity of both air flows. Unlike a rotary heat exchanger, this unit and valve have absolutely no moving elements.

Now it is necessary to dwell on the materials used for the production of plate recuperator heat exchangers. There are no ideals: they all have strengths and weaknesses.

- Aluminum or galvanized steel. Models with these heat exchangers are invariably successful due to their reasonable price. If we talk about the disadvantages, the main one is low efficiency, because in winter such devices have to be constantly thawed.

- Plastic. He is completely unaware of the problems of the imperfect “union” of water and metal, so the efficiency of such recuperators is all right. But their infallibility is the reason for their much greater cost.

- Special paper. The efficiency of this equipment is quite high, however, there are fly in the ointment here too. This makes it impossible to use them in rooms where the humidity level is very high: in swimming pools, bathrooms, etc. Although double paper cassettes are more effective, they are just as afraid of moisture. Absorption of odors is another disadvantage of the material.

Brass and cast iron are also used in the production of units. However, most often the plates are made of a certain grade of stainless steel - AISI 316, with molybdenum and nickel added to its composition. These components significantly increase corrosion resistance in aggressive environments. To ensure greater efficiency of the devices, an additional heat exchanger is installed inside. This improvement allows increasing efficiency to 85%.

Where are rotary recuperators used?

The scope of application of rotary heat exchangers is quite extensive; they are mainly used for large industrial facilities, but they can also be used in private buildings (for the home, but very rarely).

They can also be used in both residential and non-residential premises. Areas of application:

- ventilation systems of large non-residential buildings - for example, in shopping centers (in the product storage department), in warehouses;

- ventilation systems of large residential buildings - for example, in educational institutions, in various government buildings, in catering establishments, in fitness centers.

Due to the fact that the design of the rotary heat exchanger allows partial mixing of air flows, despite the separate channels, it cannot be used in rooms requiring sterile air, such as operating rooms, intensive care units, laboratories where work is carried out with medicines, chemicals or jewelry products.

Principles of operation of the recuperator

The operating principle of the recuperator depends on its type. Obviously, all of the listed types of construction have their own operating characteristics. Let's list the most common ones here.

Plate recuperator

This type is a monolithic cassette made of metal sheets. Air passes through such a cassette through special channels stamped on the sheets or laid with a special intermediate seal. The flows in such a recuperator are not mixed. The heat exchange process is carried out due to the simultaneous heating of the plates by one flow and cooling by another. Plate heat exchangers have a number of advantages that make them the most common type of thermal barrier for homes.

The main features of the plate recuperator are:

- low price;

- elementary design;

- compactness;

- ease of maintenance;

- easy to clean (if the cassette is disassembled)

- availability of materials for manufacturing;

- lack of mechanisms.

Collapsible heat exchangers are able to provide the highest level of hygienic purity of incoming air during operation of the device without loss of efficiency.

When using these devices, you should always remember about dew points and the fact that condensation forms during the operation of such heat exchangers. At negative air flow temperatures, the plate recuperator unit may undergo a process such as frostbite and block access to air.

The most common type of recuperator, due to the simplicity of its design, is the cross-flow one. Its efficiency can be defined as “Medium Type”, some sources indicate that their efficiency is up to 60%.

Rotary recuperator

This type of heat exchanger has the shape of a short pipe, filled with corrugated steel plates along the body. The rotating mechanism is installed along the tidal axis. The rotor first passes the heated internal air, and then the cold incoming air. The plates are heated and cooled in turn, maintaining the internal air temperature. This type of recuperator is considered the most effective. However, the design feature does not allow it to be made compact; experts recognize the bulkiness of such a device as a disadvantage.

Heat exchanger with intermediate coolant

Such recuperators use liquid heat exchangers where an ethylene glycol solution (an effective coolant) circulates. In such waste heaters, the tidal and exhaust sections are separated and separated by a certain distance. This feature allows the use of such devices for environments where incoming and outgoing flows cannot be mixed. The coolant circulates either naturally or through a pump. To increase the efficiency of such a heat recovery device, fine adjustment of the coolant flow is necessary in accordance with the design.

Advantages and disadvantages

Modern recuperators operate efficiently and reliably. They perform their tasks much better than standard supply and exhaust ventilation. Both in winter and in summer, the indoor microclimate will be much closer to ideal. The same result can, of course, be achieved by improved batteries and air heaters - however, they waste too much energy. In reality, everything is not so simple.

For example, the advantages of recuperators are revealed to a sufficient extent only in large houses. Only there it is possible, without losing the height of the ceilings, to lay air ducts in all the required places. In any case, the serious disadvantage is the price. Of course, there are also relatively cheap recovery units. However, they cover a maximum of 1 or 2 rooms, and do not always work effectively enough.

Fans operate continuously inside the recuperator, which by definition emit a characteristic sound. Air flow also creates noise, both when moving through pipes and when entering the room at discharge points. The sound becomes stronger as it is used, because dust and other particles settle inside the recuperator. The filters of the device will have to be changed quite often, especially in kitchens. Grease and other contaminants can damage the device within a few years, and therefore the recuperator must be equipped with several filtration systems at once.

Establishing ventilation and air conditioning through a common system means that the entire building will live by the same rules. It is not possible to integrate temperature control units into most systems. This means that in some rooms specific people may feel cold, while in others it may be hot. Yes, there are recuperators that do not have this problem, however, they are significantly more expensive than mass-class products.

Advantages and disadvantages of different types of recuperators

The advantage of recuperators is obvious - they allow you to significantly save on heating the supply air in winter and cooling the supply air in the summer. Among the disadvantages of recuperators are the following:

- They create additional aerodynamic resistance in the network. Indeed, like any other element in the ventilation network, recuperators have some resistance, which should be taken into account when choosing a fan. However, this resistance is not high (usually no more than 100 Pa), and does not lead to a significant increase in fan power.

- Recuperators increase both the cost of the ventilation unit and the cost of its maintenance. Like any other solution aimed at increasing the energy efficiency of the system, recuperators cost some money and require regular maintenance. However, experience has repeatedly proven that the costs of heat recovery are much lower than the benefits obtained.

- Rotary, chamber and, to a much lesser extent, plate heat exchangers have one drawback, which can be critical at some facilities - leakage of air flows is possible in them. In this case, the danger is the flow of exhaust air into the supply air. Such leaks are undesirable in clean room ventilation systems and are not acceptable, for example, in infectious diseases departments of hospitals and operating rooms. The reason is the danger of viruses that have entered the hood from any room flowing into the supply air flow with subsequent spread throughout all rooms of the facility. As a result, recuperators with intermediate coolant or freon recuperators are used at such facilities.

- Recuperators increase the dimensions of the ventilation unit. This primarily applies to plate recuperators, since they are air-to-air heat exchangers and are quite large in size. In addition, this applies to recuperators with intermediate coolant due to the presence of two separate heat exchangers, two pipeline lines and piping units near each of the heat exchangers.

Design of a unit with a recuperator

The internal structure of supply and exhaust ventilation systems with an integrated recuperator is quite simple, so it is possible to independently purchase and install them element by element. If assembly or self-installation is difficult, you can purchase ready-made solutions in the form of standard monoblock or individual prefabricated structures to order.

A typical design of a supply and exhaust ventilation system with a recuperator located in a single housing can be supplemented with other components at the user’s discretion

Main elements and their parameters

The body with heat and noise insulation is usually made of sheet steel. In the case of wall installation, it must withstand the pressure that occurs when foaming the cracks around the unit, and also prevent vibration from the operation of fans.

In the case of distributed air intake and flow into various rooms, an air duct system is attached to the housing. It is equipped with valves and dampers to distribute flows.

If there are no air ducts, a grille or diffuser is installed on the supply opening on the side of the room to distribute the air flow. An external type air intake grille is installed on the inlet opening on the street side to prevent birds, large insects and debris from entering the ventilation system.

Air movement is provided by two fans of axial or centrifugal action. In the presence of a recuperator, natural air circulation in a sufficient volume is impossible due to the aerodynamic resistance created by this unit.

The presence of a recuperator involves the installation of fine filters at the inlet of both flows. This is necessary to reduce the intensity of clogging of thin heat exchanger channels with dust and grease deposits. Otherwise, for the system to function fully, it will be necessary to increase the frequency of preventive maintenance.

Fine filters must be changed or cleaned periodically. Otherwise, increased resistance to air flow will cause fan failure.

One or more recuperators occupy the main volume of the supply and exhaust device. They are mounted in the center of the structure.

In the case of severe frosts typical for the territory and insufficient efficiency of the recuperator to heat the outside air, you can additionally install a heater. Also, if necessary, a humidifier, ionizer and other devices are installed to create a favorable microclimate in the room.

Modern models include an electronic control unit. Complex modifications have functions for programming operating modes depending on the physical parameters of the air environment. External panels have an attractive appearance, thanks to which they can fit well into any interior.

Solving the problem of condensation

Cooling the air coming from the room creates the prerequisites for the release of moisture and the formation of condensation. In the case of a high flow rate, most of it does not have time to accumulate in the recuperator and goes outside. With slow air movement, a significant part of the water remains inside the device. Therefore, it is necessary to ensure that moisture is collected and removed outside the housing of the supply and exhaust system.

An elementary device for collecting and discharging condensate is a tray located under the heat exchanger with a slope towards the drain hole

Moisture is removed into a closed container. It is placed only indoors to avoid freezing of the outflow channels at sub-zero temperatures. There is no algorithm for reliable calculation of the volume of water received when using systems with a recuperator, so it is determined experimentally.

Reusing condensate for air humidification is undesirable, since water absorbs many pollutants such as human sweat, odors, etc.

You can significantly reduce the volume of condensate and avoid problems associated with its occurrence by organizing a separate exhaust system from the bathroom and kitchen. It is in these rooms that the air has the highest humidity. If there are several exhaust systems, the air exchange between the technical and residential areas must be limited by installing check valves.

If the exhaust air flow is cooled to negative temperatures inside the recuperator, condensate turns into ice, which causes a reduction in the open cross-section of the flow and, as a consequence, a decrease in volume or a complete cessation of ventilation.

For periodic or one-time defrosting of the recuperator, a bypass is installed - a bypass channel for the movement of supply air. When a flow bypasses the device, heat transfer stops, the heat exchanger heats up and the ice passes into a liquid state. The water flows into the condensate collection tank or evaporates outside.

The principle of the bypass device is simple, therefore, if there is a risk of ice formation, it is advisable to provide such a solution, since heating the recuperator by other means is complex and time-consuming

When the flow passes through the bypass, there is no heating of the supply air through the recuperator. Therefore, when this mode is activated, the heater must automatically turn on.

Self-production of a plate-type recuperator

Since the average cost of a plate heat exchanger is 300 USD. That is, it makes sense to make this easy-to-make air recuperator with your own hands.

In order to make a recuperator yourself, you will need:

- sheets of galvanized metal (4 sq. m.);

- technical cork 2 mm thick;

- silicone sealant with neutral reaction;

- tin box for the body or sheets of MDF, metal or plywood for its manufacture;

- glue;

- insulation 4 cm thick (mineral wool or polystyrene foam);

- corners for racks;

- plastic flanges;

- jigsaw or grinder.

Stages of work:

- We cut the material into small squares with a side size of 200 to 300 mm. The plates must be identical and perfectly flat; it would be better to cut the folded sheets with a grinder rather than use metal scissors. There should be about 70 such plates, which serve as blanks for the recuperator cassettes.

- In order to create a gap between the sheets, we use a technical plug. The point is to make a section at which the air flow speed will be 1 m/s. We glue the cut cork along two opposite edges of the square blanks, without touching the latter.

- After waiting for the glue to dry, we create a heat exchanger cassette by gluing the sheets so that each subsequent one is located at an angle of 90 degrees to the previous one. The cassette produces alternating channels perpendicular to each other. The last one will be the sheet on which we did not glue the cork.

- After connecting all the plates using a corner, we tighten the structure with a frame.

- We carefully seal all cracks with sealant.

- On the walls of the cassette we place fastenings for flanges having a diameter corresponding to the air duct pipes. It is advisable to place the cassette vertically, then condensation will collect at the very bottom. A drainage channel is prepared in the same place: a hole with a tube for draining liquid.

- In order for the cassette to be removed from the case, guides from the corner must be installed inside it.

- The housing with the cassette is placed in a box made of thick plywood or tin. An important point will be the use of thermal insulation materials (mineral wool or polystyrene foam), which are used to cover all sides of the box from the inside.

Note! The width of the recuperator body should correspond to the width of the cassette, the height and length should correspond to the diagonals of the square plates.

For more reliable operation of the recuperation system in conditions of negative supply air temperatures, when the heat exchanger plates can ice up, a bypass is added to the system, through which the supply air flow is directed, if necessary. At this time, only warm exhaust air will pass through the heat exchanger, and under its influence the frozen heat exchanger plates will thaw.

The efficiency of a homemade recuperator will be about 60–65%, which will ensure that an optimal indoor microclimate is maintained.

Popular models of rotary recuperators

Rotary heat exchangers can be used in any case to create an indoor microclimate; they are effective in garages, country houses, office premises and small warehouses; The most popular models include:

Rotary recuperator LESSAR (Sweden)

The rotary recuperator LESSAR (Sweden) is manufactured by Heatex and has the following characteristics:

- rated power – 39 W;

- air flow – 470 m3/h;

- class of filters used – F5;

- dimensions – 900x553x850 mm;

- weight – 79 kg.

The feasibility of purchasing a recuperator

This device is only part of the forced-exhaust ventilation system. It is impossible to achieve maximum efficiency of its operation using one recuperator and only natural ventilation. For heat transfer to be ideal, constant movement of both flows - incoming and outgoing - is necessary.

Before making the final choice in favor of purchasing or making it yourself, it is better to make some preliminary calculations. The list includes calculations:

- energy consumption before installing a new ventilation system;

- the cost of purchasing and installing all necessary elements;

- its approximate service life;

- annual maintenance costs.

Often, after calculations, it turns out that the costs do not cover the cost of using factory ventilation systems. If we talk about homemade recuperators, then in this case their low cost gives a chance to stay in the black - to slightly reduce coolant consumption. In other cases, an air conditioner is the equipment that will fully cope with its task - maintaining a favorable indoor microclimate.

Where to buy and how much do rotary heat exchangers cost?

Rotary heat exchangers can be purchased at specialized ventilation and climate control equipment stores. The easiest way is not to select the product yourself, but to order it from special companies that design and install ventilation systems.

They will select the most optimal option for you and then install the equipment. The average cost of a product at the beginning of 2022 is as follows (using the example of several models):

- RR 500x250 – 209,000 rubles;

- RR 1000x500 – 363,050 rubles;

- RR 800x500 – 361,000 rubles;

- RR 700x400 – 320,000 rubles;

- RR 600x300 – 253,000 rubles;

- RR 500x250 – 209,000 rubles;

- RR 400x200 – 208,000 rubles.

You can try to make a recuperator with your own hands, but this task is extremely difficult and achieving “store-bought characteristics” is almost impossible.

Model overview

Let's look at several popular models of recuperators.

"Vents PR 600x300"

The plate recuperator model is designed to remove used air from the room. The material of the internal equipment is aluminum, and the material of the body is galvanized steel. The device weighs 31 kg. For installation it is necessary to use a pipe with a diameter of 300 mm.

To connect the model to the air duct, you will need an elbow with a rectangular cross-section.

Thanks to the aluminum plate, there is highly efficient heat transfer. This recuperator provides for the collection of a small amount of condensate that forms on exhaust surfaces. The kit includes a condensate drain fitting, which is installed in the bottom panel.

"Vents PR 700x400"

The rectangular plate heat exchanger is made of galvanized steel with a connecting pipe . This model weighs 47.8 kg. It has a cross-shaped air passage and is designed to remove the latter from the room through the ventilation and air conditioning system. This device is connected to an air duct with a rectangular cross-section, with a parallel routing, and can also be connected with a perpendicular or diagonal routing at an angle of 45 degrees.

You can choose any of the options. In any case, it is necessary to purchase a knee for a given position . The heat exchange device consists of special thin aluminum plates that ensure active heat transfer. In summer, the heat exchanger can be replaced with a VL summer rate; it does not produce heat, but reduces pressure loss by 10%.

Vaillant recoVAIR VAR 60/1 D

The recuperator is designed for a decentralized system with supply and exhaust air exhaust in two directions. The model is wall mounted with a mounting hole diameter of 162 mm. The minimum productivity is 30 m3/hour, and the maximum is 60 m3/hour. There are three fan speeds. During operation, the device produces a noise level of 34 to 46 dB.

Equipped with a plate heat exchanger with an efficiency of 85%. The minimum temperature for the device to operate starts from -20 degrees.

For more convenient control there is a remote control, it is possible to control via the Internet. Power consumption is 9 W from a voltage of 220 V. Mounted on a wall with a minimum thickness of 30 cm. Weighs 3.4 kg.

Mitsubishi Electric VL-50ES2-E

The recuperator is designed for decentralized supply and exhaust ventilation. The device weighs 6.2 kg and has dimensions of 522x245x168 mm. This channel model is mounted on a wall with a mounting hole diameter of 120 mm. Performs the functions of a recuperator with a capacity of 15 to 54 m3/h. During operation, the noise level varies from 15 to 37 dB. The model is equipped with a plate heat exchanger with an efficiency of 86%. During operation, it consumes power of 19 W with a voltage of 220 V.

Daikin VAM 350 FC

The recuperator is designed for a centralized system with supply and exhaust ventilation. It has the following characteristics: weight – 33 kg, width – 828 mm, height – 310 mm, length – 816 mm.

It has a suspended mounting method with a mounting hole diameter of 150 mm.

Performs the function of a recuperator with a capacity of 210 to 350 m3/hour. It has three fan speeds with a maximum noise level of 32 dB. External static pressure – 103 Pa. The plate heat exchanger has an efficiency of 84%. The minimum temperature for operation of this device is -15 degrees. During operation, it consumes power of 71 kW from a voltage of 220 volts.

Cooper Hunter CH-HRV2K2

The recuperator is designed for a centralized system with supply and exhaust ventilation. It has a suspended mounting type with a mounting hole diameter of 145 mm. The minimum productivity is 150 m3/h, and the maximum is 200 m3/h. There are three fan speeds. During operation, the noise level is 27 dB. The device is equipped with a plate heat exchanger with an efficiency of 75%. The minimum operating temperature is -15 degrees. A control panel is provided. During recovery, it consumes 105 W of power. It weighs 23 kg and has dimensions of 580x264x666 mm.

Electrolux EPVS-450

The Electrolux EPVS-450 air handling unit is a compact device that includes fans that provide air flow from the street into the room and in the opposite direction.

Membrane-type design, the distinctive feature of which is the effective extraction of moisture from the air. The fan impellers are equipped with curved blades and are driven by asynchronous motors. The design of the device includes thermal contacts that ensure automatic restart of the equipment when the threshold temperature value is reached. The recuperator has two fan speeds and protection against freezing of the plates. Installation in round air ducts is recommended.

Model features:

- built-in automation system;

- Efficiency - 80-90%

- programming of work and self-diagnosis of errors.

At temperatures below -15°C, two operating modes are possible:

- auto defrost;

- connection of external heating.

Specifications:

- remote control;

- maximum power - 140 W;

- noise level - 36 dB;

- productivity - 440 m3/hour;

- dimensions - 275x815x860 mm;

- weight - 33 kg.

The manufacturer provides a 1-year warranty for its products. Average price 44,100 rub.

Recuperator Marley MEnV-180 Plus

A small-sized installation from a German manufacturer has many advantages:

- almost silent operation;

- ceramic honeycomb heat exchanger with many channels for air flows;

- purification of incoming air masses using filters of class G3 and G4;

- noise reduction system;

- remote control using a remote control;

- low power consumption: 3.5-11 kW.

The heat exchanger body can be adjusted depending on the thickness of the wall into which the device is installed. The casing of the device is insulated, and there is a power on and off button on the front decorative panel. When installing two devices, a synchronized ventilation mode is possible: one heat exchanger works for air flow into the room, the second for air outflow.

The recuperator design includes:

- filter that retains dust;

- sensors: temperature, carbon dioxide, humidity;

- electronic boards coated with a moisture-proofing agent;

- coarse filter.

Specifications:

- power - 3 kW;

- noise level - up to 22 kW;

- performance - 60 dB;

- cross section - 180 mm.

The average price is 29,300 rubles.

Exhaust unit Shuft RHPr 400×200

The Shuft RHPr 400×200 plate heat exchanger is designed for installation in residential, public and industrial premises. The body of the device is made of galvanized steel with a thickness of 0.7 mm. The heat exchanger cassette consists of aluminum plates 0.2 mm thick. Moisture extracted from the air accumulates in a removable tray.

The specificity of the use of the recuperator is that it cannot be installed in air transportation systems that contain aggressive gases, sticky dust (including flour), metal and other heavy particles. Only horizontal installation of the recuperator is permissible.

Specifications:

- Efficiency - 70%;

- dimensions - 222x474x474 mm;

- weight - 19 kg.

Average price RUB 24,822.

Features of different types of heat exchangers

The design of the recuperator determines the flow pattern of the coolant, the efficiency of the ventilation system, the energy consumption class and the cost of the equipment. Five types of heat exchangers are used: plate, rotary, heat pipes, chamber devices and models with an intermediate coolant.

Plate recuperator – simplicity of design

The basis of the heat exchanger is a sealed chamber with many parallel air ducts. The channels are separated by partitions - heat-conducting plates made of steel or aluminum.

Wave-shaped plates (60-70 pieces) are grouped in one block so that the formed channels are located crosswise to each other - the created turbulence improves heat transfer (+)

Gas flows move towards each other, intersect in the recuperator cassette, but do not mix. Heat exchange is carried out due to simultaneous cooling and heating of the plates from different sides.

Advantages of a cross heat exchanger:

The efficiency rate varies in the range of 40-70%.

The main disadvantage of the plate model is the settling of condensate in the exhaust duct and the formation of ice in winter. To defrost the unit, the incoming stream is redirected to bypass the heat exchanger, and the warm outgoing stream melts the ice on the plates.

In the “defrost” mode, energy savings do not occur; air heaters with a power of up to 5 kW are used to heat the incoming air. The average efficiency value drops by 20% (+)

There are two possible ways to solve the problem:

When choosing a cross heat exchanger, you should take into account the operational features of the plates.

Their characteristics depend on the material of manufacture:

The hygrocellulose recuperator is the most economical and optimal for ventilation of residential buildings.

Rotary recuperator – high system efficiency

The heat exchanger is presented in the form of a cylinder filled with layers of corrugated metal. As the drum unit rotates, warm or cold jets of air alternately enter each compartment.

Design of a rotary recuperator: rotation shaft and two air channels. One section of the rotor is heated by “working off”, the drum rotates and the heat is redirected to cold masses concentrated in the adjacent channel (+)

The efficiency of heat transfer is determined by the speed of rotation of the rotor; the operating efficiency can be adjusted.

Arguments for a rotary recuperator:

- heat recovery up to 65-90%;

- economical energy consumption;

- partial moisture replacement - you can do without a humidifier;

- payback period – up to 4 years.

Despite its high efficiency, the drum-type heat exchanger has not become a leader among similar installations.

Disadvantages of the ventilation system:

Due to their bulkiness, rotary units are used mainly in industrial enterprises.

To minimize the mixing of air flows, rotary heat exchangers are supplemented with intermediate sectors - here the microchannels are blown with fresh air, which flows back into the hood. The disadvantage of the circuit is a decrease in efficiency (+)

Coupled Heat Exchangers – Glycol Model

Due to its design features, a recovery unit with an intermediate coolant is often called coupled heat exchangers or a glacier unit. This is one of the most flexible heat recovery systems. One heat exchanger cuts into the supply duct, and the second into the exhaust duct.

The piping diagram contains: circulation pump, expansion tank, air valve, controller, temperature sensor, safety valve, pressure indicator (+)

Principle of operation. The glycol composition circulates between the heat exchangers. The temperature of the coolant increases due to the heated exhaust flow, and then the thermal energy is transferred to fresh air. The closed system eliminates the mixing of oncoming air masses.

Features of operation of heat exchangers with coolant:

- Efficiency – 45-55%;

- efficiency adjustment using a pump - the speed of antifreeze movement is selected;

- possibility of placing supply and exhaust air ducts remotely from each other (up to 800 m);

- the recuperator is installed vertically or horizontally;

- in severe frost, the surface of the exhaust heat exchanger freezes and ice appears; the use of antifreeze allows you to operate the recuperator without resorting to defrosting;

- payback period of the system – up to 2 years;

- a combination of 1 hood and several inflows or vice versa is permissible.

The volume of exhaust and intake air should be approximately equal. Such recuperators are usually used if the influent is toxic or heavily polluted, when mixing of streams is unacceptable.

Chamber unit – versatility of use

Structurally, the chamber heat exchanger is a closed box, divided inside by a moving damper. The opening partition determines the operation scheme of the recuperator.

The outflow passes along one channel, and the inflow enters the second chamber. In the heat exchanger, warm masses heat the walls of the first compartment. After a while, the damper moves and the air flow changes direction

As a result, the inflow moves along the warm walls of the first air duct, and the “exhaust” heats the surface of the second chamber. At a certain point, the septum comes back and the cycle repeats.

Advantages of a chamber heat exchange unit:

- Efficiency – 80-90%;

- in tandem with high-quality thermal insulation, heating costs are reduced to a minimum;

- ease of installation - specialist help will be needed when choosing the parameters of the ventilation unit;

- maintaining humidity levels;

- freezing of the system is excluded.

A chamber heat exchanger is an excellent option for regions where there is a significant imbalance between indoor and outdoor temperatures for a long period of the year.

The disadvantages of the heat recovery unit include:

- the need for regular maintenance of moving elements;

- counter air currents partially mix - odors and impurities can flow back into the building.

To reduce contamination, the system is equipped with a filter element. The air becomes cleaner, but the efficiency of the recuperator decreases.

Heat pipes – closed heat exchange system

The recuperator consists of many copper or aluminum tubes filled with an easily evaporating substance, such as freon. The operating principle of a tubular heat exchanger is based on physical processes - changes in the state of a substance when heated.

The heat pipe is placed vertically - the lower end of the heat exchanger is in the exhaust duct, and the top is in the supply air duct. The outgoing flows go around the end of the tube - the freon heats up, boils and evaporates (+)

The gas rises and releases thermal energy to the inflow, after which the freon condenses and flows down the recuperator. The thermal cycle repeats itself in a circle.

Technical and operational characteristics of the tubular heat exchanger:

- device efficiency – up to 65%;

- silent operation due to the absence of moving elements;

- simplicity of design and ease of maintenance;

- compactness - small dimensions and low weight;

- energy independence – the coolant circulates naturally;

A significant advantage is that the inflow and return air flows do not mix.

Weaknesses of heat pipes:

- a high level of efficiency is achieved within a narrow temperature range - with sudden overheating, all freon evaporates, and with insufficient heating, the intensity of vaporization slows down;

- low strength of tubes - change in shape or depressurization reduces the performance of the equipment.

Tubular heat exchangers are used in private construction, administrative and office buildings and small industrial areas.

How to increase efficiency

Careful assembly and attention to detail when creating a homemade heat exchanger will allow you to achieve good efficiency indicators. However, the assembled air recuperator with your own hands can be significantly improved and its efficiency increased

To do this, when calculating the design and its implementation, it is necessary to provide for the following nuances:

- Maximum sealing of the device;

- Use of high-quality heat-insulating materials;

- Increase the size of the recuperator and the area of the heat exchange surface. This will reduce the speed of air passing through the device, and accordingly allow it to warm up or cool down better;

- The use of corrugated plates or plates with stampings, which will significantly increase the heat transfer surface area while maintaining the total volume of the device;

- Increasing the exhaust volume compared to the inflow. Thus, a larger volume of outgoing air will better transfer heat to a smaller volume of incoming air.

A do-it-yourself air recuperator is a simple, affordable, cheap and effective way to save expensive thermal energy and effectively use irreplaceable natural resources.

How to make a tubular coaxial recuperator with your own hands

Apartment owners often choose a tubular coaxial heat exchanger for their own manufacture and installation, considering its design simpler. The technology for making a heat exchanger yourself is not too labor-intensive and requires basic skills in working with tools.

Tubular coaxial design - pros and cons

A tubular recuperator with coaxially arranged shells has the following advantages:

- increased efficiency to 65–70%;

- no moving parts;

- compact design;

- availability of materials for self-production;

- ease of manufacture;

- ease of installation;

- ability to work without additional electrical equipment.

The second recuperator, which is quite easy to make with your own hands, is tubular.

The coaxial recuperator also has disadvantages:

- impossibility of changing the humidity in the room;

- dependence of the device’s operating efficiency on the length of the coaxial pipes.

Necessary materials

To make a tubular recuperator yourself, you will need materials that can be purchased at any specialized store:

- plastic pipe with a diameter of 16 cm, used for sewage;

- adapters with a diameter of 16 cm to 10 cm, used as splitters;

- corrugated pipe with a diameter of 10 cm, made of aluminum;

- fan with a seat size corresponding to the pipe diameter.

When purchasing materials for making a recuperator, remember that the length of the channel determines the efficiency of the device. To increase the intensity of work, you can install a small fan that improves air circulation.

Manufacturing of a tubular recuperator

To make the device yourself, first develop a diagram of a tubular recuperator - this will help to avoid errors during assembly.

When manufacturing, take into account the movement of air flows

Carry out the work following the sequence of operations:

- Cut a plastic pipe blank of the required size, which is the heat exchanger body.

- Pack the aluminum corrugation inside the plastic pipe, ensuring its maximum stretch.

- Attach the adapters to the ends of the line by connecting the corrugated pipe to them.

- Ensure that the corrugated pipe is tightly attached to the adapter pipes.

- Connect the supply line to the free pipes of the transition element.

- Connect the coaxial heat exchanger to the fan. This improves the passage of air flow through the corrugation.

The proposed assembly scheme will ensure effective heat exchange between the walls of the corrugation and the outer pipe of the coaxial recuperator.

Types of structures

There are several main types of recuperator designs:

- Lamellar.

- Rotary.

- With coolant.

- Tubular.

Plate - consists of assembled sheets of aluminum, which has the best thermal conductivity at an affordable price of the material. Easy to implement, no moving parts, inexpensive. Efficiency – 40-70%.

The rotary one has a rotating shaft powered by electricity and two channels with countercurrents. The air heats up part of the rotor, it turns and transfers heat to the cold flow in another channel.

The efficiency of such devices is usually higher, but:

- energy dependence;

- big sizes;

- difficulty of playback;

- complexity of repair and maintenance;

- and also that the flows are slightly mixed...

...make the rotor not so popular among consumers.

Options with coolant and tubular are even more difficult to reproduce at home.

Design features and operating principle

The principle of operation of the recuperator is very simple: warm air removed from the room or building by exhaust ventilation passes through a heat exchanger. There it gives off its heat to the cold air flow coming from the street through the supply ventilation.

The flows do not mix, but only exchange thermal energy.

The design of the heat exchanger depends on the type of recuperator. Its general elements are as follows:

- frame;

- inlet pipe;

- exhaust pipe;

- fan;

- heat exchanger;

- filters;

- condensate drainage system.

Some recuperators have units for additional air heating and climate control.

The device allows you to reuse up to 70% of the heat lost with the air leaving the exhaust ventilation.

Determining system efficiency

In order to determine whether it is necessary to install a heat redirection system, efficiency studies are carried out. We will give an example of such a calculation using a relatively small private house. Features of the calculation include:

- According to calculations, approximately 35% of the heat is lost through the ventilation system. Let’s take 30% as the average value, since modern ventilation systems are more efficient in terms of energy savings.

- The average show power consumption is 500 watts. Note that this indicator was chosen taking into account the location of the house in Sevastopol. The average temperature in January is about 3.5 degrees Celsius. Energy consumption in colder climates will be significantly higher.

- If a plate-type recuperator design is installed, then the consumer power will be limited to 30 watts.

- The system efficiency indicator is at around 40%.

According to calculations based on the entered data, the payback period is approximately 114 years. Therefore, it does not make sense to purchase a plate heat exchanger for a private home.

DIY air recuperator for home

The plate model is the easiest to make, so let’s look at it in more detail.

Pros and cons of a plate recuperator

Pros of the plate model:

- good efficiency;

- simplicity of design;

- availability of materials;

- energy independence;

- There are no rubbing elements, which means it will last a long time.

There are also disadvantages that you need to be aware of right away.

The main problem is icing in severe frosts. This is due to the fact that indoor air is more saturated with moisture than outdoors. Under normal conditions, this moisture falls into condensation, but in cold weather it sets, forming a layer of ice.

Several solutions have been invented to combat freezing:

- Automatic diversion of flow bypassing the plates to allow warm air to warm up the icing (during this period the room is not heated).

- Heating the recuperator to a temperature that does not allow ice to linger (efficiency decreases by 20%).

- Cellulose cassettes that absorb moisture, returning it through the adjacent compartment to the apartment. Humidifier effect + no condensation.

- The easiest way to make a “ground heat exchanger” in your home is to bury the supply pipe below the freezing level of the soil. The length of the underground air duct is up to 50 m. The intake increases efficiency, heats the flow in winter and cools it in summer, and this is an excellent way to combat ice.

We can say that cellulose cassettes are the best solution, because with their use, the recuperator operates in any weather, electricity consumption does not increase, and there is no need to arrange a condensate collector and its disposal into the sewer.

Materials for production

What you need to prepare if you decide to assemble a plate recuperator yourself. Materials:

- Sheet metal (aluminum is best, but you can use roofing iron, textolite, getinax, or cellular polycarbonate). The thinner the metal, the better the heat transfer will be.

- Wooden slats for laying between the plates (technical cork or a simple cord are also suitable). Thickness 2 - 3 mm - the thinner the better. Width – approx. 10 mm.

- Sealant (non-acidic).

- Glue.

- Case material. It can be plywood, metal, MDF or a finished box.

- 4 flanges, the same section as the pipes.

- Mineral wool (4 cm thick).

- Corner.

- Hardware.

- Special fan or cooler.

The parts will be cut using a power tool.

The width of the housing will be equal to the diagonal of the future heat exchanger, and the height depends on how many plates you plan to collect and how thick they will be together with the slats.

We make a recuperator for the home - product drawings

Squares with a side of 20-30 cm are cut from metal. About 70 pieces need to be made. If you cut several pieces at once, it will be faster and smoother.

The slats are dried and cut to the size of a square side (20 or 30 cm). The blanks are glued to two sides of each square and left until the glue dries completely. There is no need to glue slats onto one square.

The upper parts of the slats are coated with glue, and a sandwich is assembled from all the squares

Important! Each subsequent square must be rotated at right angles to the previous one. The channels alternate, lying perpendicular to each other

Drawing of the heat exchanger of the recuperation unit

The top square is glued, without slats. Using the corners, the structure is pulled together and fixed.

All cracks are treated with a neutral sealant.

Fastenings for the flanges are made.

The heat exchanger is inserted into the housing. To do this, guides are made from angles on the walls of the building. The heat exchanger will need to be positioned so that its corners rest against the side walls (you will get a rhombus). Condensation will flow to the bottom

It is important here that there are two isolated spaces, and the air intersects only inside the plate structure

A small hole is made into which a hose is inserted to collect and drain moisture.

Four holes are cut in the body for the flanges.

Installation diagram of ventilation with recovery

It would be great if there was a place for attaching filters at the entrance.

The walls of the building are finished with mineral wool.

Now you can install the fan and install the unit into the ventilation system.

Mount ready-made devices directly on the wall or in a special niche. The noise level depends on the power of the fans and the material of the air ducts. But, as a rule, it does not exceed the noise from the computer.

Installation location and method

Recuperators come in floor and suspended ceiling installations. There is a third option - point wall recuperators, which are installed in every room adjacent to the street and do not require additional communications.

Ceiling installation options are interesting because they allow you to hide the technical equipment of your home in the cavity of suspended or suspended ceilings. Such devices are slightly more expensive due to compactness requirements, but at the same time, additional bypass channels are not required to connect them. An obvious disadvantage of this type of placement is increased noise caused by the short distance of the operating engines from the ventilation grilles.

Method of installing a recuperator in an apartment

Floor-mounted (and wall-mounted) heat exchangers are designed for installation in technical rooms. Their performance is not limited by size, but it is necessary to perform a high-quality piping system. As a rule, devices in this category are used in combination with air heating and air conditioning systems.

Rotary or plate unit?

Both heat recuperators - both plate and rotary - are in demand among buyers. They are the most popular and widespread. The reason for this love is the successful combination of a relatively low price and sufficient efficiency. To choose from two applicants, you need to get acquainted with another possible candidate for the “position of economist.”

Rotary design - a slowly rotating heat accumulator shaft. It is installed perpendicular to the flow of air - outgoing and incoming. When the heating is turned on, the removed flow gives off heat to the sector of the drum through which it passes. Rotating, the section with heat enters the inflowing cold masses, where it gives off heat and cools.

With the right choice of model, efficiency reaching 80% can be guaranteed. Using the installation, it is possible to transfer not only heat, but also moisture. Felt or plastic acts as a seal between the body and the frame. The rotor rotation speed can be changed using a frequency converter, so it is easy to vary the heat transfer efficiency.

Plate recuperators - elementary and inexpensive devices - are less efficient, their efficiency is lower, and their power, of course, is lower. Therefore, it is not advisable to buy them for large rooms. If they have high humidity, then this option is not the best solution. The rotor in this case is optimal. Its disadvantages are bulkiness and the presence of moving parts.

Plate units are used in private houses and apartments, small offices, public and administrative buildings, warehouses and small industrial areas. Where the footage is large and the air is far from ideal (humid or, conversely, very dry), “heavy artillery” is already required - rotary devices. They are more complex, and therefore expensive.