Korovin Sergey Dmitrievich

Master of Architecture, graduated from Samara State University of Architecture and Civil Engineering. 11 years of experience in design and construction.

A vapor barrier for the external walls of a wooden house is needed when insulating with mineral wool. This insulation is very susceptible to moisture. Due to its high hygroscopicity, it is able to accumulate water. At the same time, the heat-shielding properties of the material are significantly reduced. To prevent unpleasant consequences, it is necessary to protect the mineral wool from moisture on all sides.

Why do you need a vapor barrier?

To protect against water from the outside, wind and waterproofing is used. It prevents the insulation from weathering and exposure to precipitation. An air ventilated layer approximately 50 mm thick is also usually provided, which allows dangerous condensation to be removed from the surface of the insulation.

Purpose of wall vapor barrier

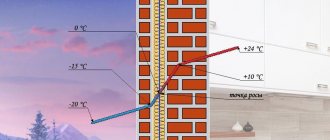

But when designing the walls of a house, it is necessary to take into account that moisture can also come from inside the building. This is especially true for a wooden structure or any other built from vapor-permeable materials (for example, frame). To protect against moisture from the inside, a vapor barrier is used. It is needed to prevent the movement of vapors inside the walls of the house and prevents the mineral wool from gaining moisture.

conclusions

We talked about the basic principles of installing vapor barrier films and membranes in insulated wooden floors. The main approach is to protect the insulation from steam and, if water vapor gets into the ceiling, to escape. Those. do not lock the thermal insulation into two layers of vapor barrier , and this mistake is often made. And do not wrap wooden beams with vapor barrier, unless it is a film specifically designed for this purpose. Another nuance - ensure the tightness of the vapor barrier . Overlaps, joints, and junctions with walls, skylights, stove and ventilation pipes must be sealed with materials recommended by film and membrane manufacturers.

We recommend the topic Waterproofing in a cold attic, which tells you whether it is necessary to install waterproofing under the roofing.

- What does improper vapor barrier lead to: real experience and repair methods

- The correct “pies” of a frame wall, which are recommended by FORUMHOUSE users.

- The most complete instructions on the RuNet for installing a roof window with the stages of installing a vapor barrier, a moisture-proof film and a gutter for condensate drainage.

Which material to choose

The construction market offers a wide variety of materials for installing a vapor barrier for a wooden or frame house. All of them are divided into two large groups:

A new material has also appeared, which is coating insulation. It is liquid rubber. The solution consists of polymers and is used in a liquid state. After application, the surface must be allowed to dry. The result of the work will be a film that is impermeable to vapor or liquid. But such vapor barrier is not applicable for the walls of a wooden or frame house. It will become a modern alternative to conventional materials when constructing a building made of brick and concrete.

For the case under consideration, traditional insulation with roll materials is needed. Before starting work, you need to find out how films differ from membranes, and what is better to make a vapor barrier when insulating with mineral wool.

Vapor barrier films

The use of materials of this type has become popular quite a long time ago. As the simplest option, builders use the usual polyethylene film. In this case, polyethylene can be smooth or perforated. Experts recommend using the first type for the vapor barrier. The thickness of the material must be at least 0.2 mm. For vapor barrier of house walls, it is recommended to choose two-layer films.

Polyethylene materials have a fairly large number of disadvantages. Disadvantages include:

- low tensile strength, the material is easy to damage during installation;

- low service life;

- preventing air movement (a greenhouse effect is created), it is necessary to pay increased attention to the ventilation of the building.

If holes or cracks appear in the film during installation, the protective ability will be significantly reduced. For this reason, it is necessary to carry out work carefully even with reinforced films. The advantage of polyethylene is its low cost and high availability (you can purchase it at almost any hardware store).

The second option for films is polypropylene. They are similar in appearance and properties to polyethylene, but do not have a number of disadvantages:

- increased strength;

- increased service life;

- resistance to overheating;

- reduced risk of cracks.

The vapor barrier membrane will not only protect the insulation from moisture, but will also allow the house to “breathe”

Many companies are involved in the production of vapor barrier membranes. They are often found in the product range of companies involved in the production of mineral wool or waterproofing protection. The material is a non-woven fabric and has the following positive characteristics:

- a reliable barrier to steam dangerous to the insulation;

- good air permeability, does not lead to a greenhouse effect in the building;

- safety for human health;

- environmental friendliness.

The disadvantages include the relatively high cost. When choosing which membrane you need, you should pay attention to its strength. There are types that do not have good resistance to tearing; they must be installed especially carefully.

When laying, it is important to strictly monitor which side of the material is facing the insulation. The manufacturer's recommendations must be strictly followed.

Peculiarities

When insulating a house, you should carefully follow the correct sequence of actions and use only the best materials

Unfortunately, often owners who undertake to insulate their home themselves forget about one very important aspect - the vapor barrier. They install only insulation and don’t even think about the fact that it comes into contact with too warm or too cold air inside the room, and that condensation in the form of water droplets will soon begin to form on it

And this not only does not contribute to insulation, but also spoils the material itself - it moisturizes it, and if the steam does not yet have time to evaporate, mold appears and the insulation structure deteriorates. Moreover, taking into account our climatic conditions, a similar situation occurs at least four times a year - when the seasons change and, accordingly, the temperatures in the room and outside “conflict”, and the insulation becomes the battlefield.

That is why an important stage of insulation is the installation of a “vapor barrier”. The vapor barrier becomes an impenetrable obstacle to steam, preventing it from turning into water, as it “closes” it inside the room and prevents it from coming into contact with excessively warm or excessively cold air.

Vapor barrier can be made using several materials. From this set, three main types should be distinguished.

- Film. A solid vapor barrier that does not allow water vapor to pass through. One of the main advantages is low price. As a rule, it is made from polyethylene or butylene, their derivatives. Vapor-condensate films are two-layer with a smooth inner and rough outer surface. Lingering on the outside, drops of condensate do not flow down, but evaporate over time. In the case of a solid vapor barrier, you also need to take care of the air gap in order to avoid the greenhouse effect, but more on that later.

- Diffusion membrane. The main difference from film is that the membrane allows some of the vapor to pass through itself - but only the optimal amount that does not linger inside and evaporates instantly. Therefore, the vapor permeability of membranes is usually considered limited. The diffusion membrane is made of polymer film and polypropylene and has two sides.

- Reflective or energy-saving film. The outer layer of this film is metalized, which allows it to withstand high temperatures. Therefore, it is most often used in baths or saunas, reflecting part of the infrared radiation.

As you know, materials such as mineral wool, expanded polystyrene, and ecowool are used to insulate houses in modern conditions. Vapor barrier is also needed in the case of mineral wool insulation.

In fact, vapor barrier is always needed, no matter how expensive or high-quality insulation material you use. Mineral wool or mineral wool is otherwise the cheapest material, but its level of thermal conductivity is low, which reduces the likelihood of heat loss in the room. Rodents, mold, and mildew do not like mineral wool; it has high sound insulation and is easy to install. But it still requires a vapor barrier.

The most commonly used is a vapor-permeable limited diffusion membrane. It is laid against the walls, after which you need to lay mineral wool, and in symbiosis they allow the walls of the house to “breathe”.

The question of vapor barrier also arises when insulating a house with ecowool. In general, ecowool is loose cellulose fibers that have the ability to absorb warm moisture and still remain dry. Fungus and mold do not grow on it, the air in it simply does not get wet (if the change in humidity does not exceed 25% percent). From all of the above it follows that in the case of ecowool, the vapor barrier need not be attached.

Another popular insulation material, polystyrene foam, actually has another more common name: polystyrene foam. It applies to both external and internal surfaces, and in the case of external insulation of loggias, balconies or attic floors, it does not require a vapor barrier - it itself copes well with this if the insulation technology is maintained. But if you are insulating interior spaces with polystyrene foam, vapor barrier and waterproofing are required to avoid the formation of fungus, mold and getting the walls wet.

What types of building membranes are there?

To begin with, let’s take a closer look at what vapor barriers are and depending on their purpose. Based on their purpose, membranes used in construction work can be of the following types:

- vapor-permeable membranes;

- membranes with vapor barrier properties.

To protect mineral wool from moisture penetration, a layer of vapor barrier material is laid inside it. When insulating a roof or a room under a roof, such a film must be installed. The vapor barrier layer should be located below, under the layer of mineral wool. If you are going to insulate the walls on the inside of the building, you also need to provide a barrier to water vapor. In this case, you cannot use material that has pores or perforations. For more information about insulating walls from the inside, see the material: How to insulate walls from the inside of an apartment or house and how to do it correctly.

The vapor permeability coefficient of this layer should be as low as possible. It is preferable to use, for example, a film made of polyethylene (possibly reinforced). An aluminum foil coating on such a film would also be useful. Do not forget - when using a vapor barrier, the humidity in the insulated room will increase many times over. Therefore, it is necessary to think over a good ventilation system.

There are special films on which an anti-condensation coating is applied. Moisture does not accumulate on them. They are usually laid under materials that are susceptible to rust. These are corrugated sheets, galvanized sheets, and metal tiles (without a protective coating on the inside). The film prevents wet fumes from reaching the metal. To do this, on its reverse there is a rough fabric layer that collects moisture. The film with anti-condensation coating should be laid with the fabric side down, at a distance of 2 to 6 centimeters from the mineral wool layer.

Film with anti-condensation coating.

Construction membranes that allow vapor to pass through are used to insulate walls from the outside, protecting them from gusts of wind. They are also used in pitched roofs and unsealed facades as additional protection against moisture. Vapor-permeable films are required to have microscopic pores and perforations. Moisture accumulating in the insulation must pass freely through them into the ventilation system. The more active water vapor leaves, the better. After all, then the insulation dries quickly, and the effect of its use is higher.

Vapor-permeable films can be of the following types:

- Pseudo-diffusion type membranes allow less than 300 grams of water vapor per square meter to pass through per day.

- Diffusion-type membranes have a vapor permeability coefficient from 300 to 1000 grams per square meter.

- For superdiffusion type membranes, this figure exceeds 1000 grams per square meter.

Since pseudo-diffusion membranes protect well from moisture, they are convenient to use under the roof as an outer layer. In this case, it is necessary to provide an air gap between the film and the insulation. But such membranes are not suitable for facade insulation - they allow steam to pass through too poorly. After all, when it’s dry outside, dust can get into the pores of the membrane from the ventilation. So the film stops “breathing”, and condensation as a result settles on the insulation.

How to install vapor barrier of diffusion or superdiffusion type? Much simpler, as experience shows. Such a membrane has fairly large pore openings, and it is not so easy to clog them. Therefore, when laying it, you do not need to worry about the air gap for ventilation on the bottom side. This makes the task easier - you don’t have to bother with installing the sheathing and counter slats.

There are not only ordinary diffusion films, but also three-dimensional ones. They are designed so that the ventilation layer is located inside the membrane. Thanks to this, condensation does not reach the metal roof. The principle of operation of such a film is the same as that of an anti-condensation film. The difference is that the volumetric membrane removes moisture from the heat insulator. After all, if the metal roof is inclined at a small angle (from 3 to 15 degrees), then the condensation formed on the lower side cannot flow down. It slowly but surely undermines the galvanized coating, gradually destroying it completely.

Volume diffuse membrane.

The third mistake is the refusal of moisture and windproof film in the ceiling of a cold attic

Having read the article to this point, you have already understood the basic principles of vapor barrier of wooden structures and floors. Let's move on to the nuances. Another “stumbling block” is the correct pie of a cold attic, for example, the second floor of a country house.

I'm finishing up the cold attic ceiling. The ceiling is insulated. I know that first they install a vapor barrier and only then, between the beams, do they lay mineral wool. How to cover the insulation on top? The manufacturer's booklet says that you need to install a waterproofing, vapor-permeable membrane. Why is she needed there? Maybe just lay out some cheap hydro or wind protection?

In my opinion, the insulation in a cold attic does not need to be covered with any films at all. Otherwise, you will damage it due to condensation. Let him lie there and lie there.

Let's answer Bolt41's question first.

The manufacturer correctly recommends covering the top of the insulation with a waterproofing material - a membrane that allows water vapor to pass through, but does not allow moisture to enter the insulation. Remember that membranes have their own characteristics. First of all, pay attention to vapor permeability. It varies up or down.

Then the next question. Membranes are usually mounted on pitched insulated roofs close to the insulation. Those. water flows down them and does not linger on the surface. And if you lay the membrane horizontally, will it not leak?

If you are concerned that a horizontally installed superdiffusion membrane will leak or leak water due to roof leaks, choose a material with higher water resistance. The simplest and cheapest vapor-permeable membranes have low water resistance. Therefore, they are laid obliquely, because standing water will sooner or later leak through them into the ceiling.

Now let's return to the words of alligator135, that the insulation on top does not need to be covered with films. Is this approach justified?

Stone wool is dusty. Therefore, the insulation must be covered with films on both sides. On the heat side, a vapor barrier, and on the cold side, a membrane with high vapor permeability. Over the years, the insulation becomes increasingly dusty. Think about your health! In addition, the wind that blows through the attic, which is necessary to ventilate the under-roof space, blows heat out of the mineral wool fibers. If the insulation is closed, then it, as a heat barrier, works more efficiently than one not covered with film.

As a result, I ended up with the following cold attic pie, from bottom to top:

Important! In a cold attic, cover the top of the insulation with a vapor-permeable moisture-proof membrane , which will additionally protect the insulation from wind and moisture, and you from inhaling particles of stone wool.

Video: Waterproofing or Vapor Barrier

The construction of a residential building or its renovation is a long-term work, the result of which must be quality. Vapor barrier is a film that, together with other structural objects, interacts to stop the formation of condensation. Usually people carry it out during major renovations. Hydro-vapor barrier helps to increase the service life because it prevents moisture from penetrating into the insulated layer.

In winter, vapor barrier is especially important, since the temperature indoors and outdoors is significantly different - this leads to the formation of steam in the house, which must leave the room without any obstacles. Basements, attics, first floors, and interfloor partitions most need vapor insulation.

The walls don’t really need it if they are insulated from the outside. A sign of this may be that the surface does not allow air to pass through:

- surface covered with non-porous coating;

- a thick, continuous layer of waterproofing is applied;

- wall made of bricks.

There are other situations where a vapor barrier is not necessary. From all this we can summarize that walls, floors and ceilings insulated with mineral wool do not necessarily need protection from condensation. Vapor barrier is necessary only in cases where there is constant contact of warm air flow with the surface in the room.

Hydro-vapor barrier is one of the most important factors when insulating a residential building with mineral wool. This fence will help you overcome the dampening of walls, floors or ceilings by condensation (the transition of a substance from a gaseous to a liquid state) when warm air comes into contact with the surface.

Rules for attaching a vapor barrier layer

The reliability of fastening depends on screws or nails. Regardless of the location of the room, hydro-vapor barrier is established by general principles.

For the integrity of the vapor barrier coating, it is important to apply the layer in a continuous layer to avoid any holes or cracks. It is advisable to fasten the sheet with a furniture stapler. With the help of this construction tool, the vapor barrier film is attached closely to the surface of the insulated walls and a certain ceiling.

The vapor barrier layer is laid by overlapping individual rolls or sheets (depending on the types of vapor barrier) by 10-12 centimeters. In places with door and window openings, the sheets must be glued; this can be done using adhesive tape specially designed for this situation. But there is no need to stretch the vapor barrier film, otherwise due to sudden changes in air temperature, it will not be able to maintain its integrity. It is attached with a margin of three centimeters.

Hydro-vapor barrier of a ceiling insulated with mineral wool or ecowool is also carried out with overlapping rolls or sheets. To protect the ceiling from steam and moisture, the interior and exterior of the room must be covered with waterproofing vapor barrier layers.

The outer part of the building should consist of three layers:

- paraisolating;

- thermal insulation;

- repeated vapor barrier.

Thanks to this, the service life is increased and the likelihood of condensation in your room is eliminated.

Floors made of reinforced concrete especially require protection from steam and moisture. Otherwise, sudden changes in air temperature will lead to the appearance of steam, which can cause fungus or mold to appear on the ceiling.

Mineral wool and its properties

The main indicator that shows the quality of insulation is the thermal conductivity coefficient of the material. Mineral wool is a fibrous insulating material. For such insulation materials, the thermal insulation qualities depend on the specific water content in the material (moisture content).

When any liquid gets in, mineral wool absorbs it, pushing out the air. As the amount of humidity increases, the thermal insulation properties of mineral wool decrease. The main disadvantage is that the liquid that gets inside is difficult to remove from the material. Mineral wool can absorb 2/3 of its entire weight in liquid, but its performance deteriorates.

Mineral wool

But despite the excessive accumulation of water, mineral wool has become widespread. In rooms where there is no constant contact with water, the use of this insulation is recommended.

Before insulating this material, it is important to cover the surface of these places with a special film that protects it from any moisture, but at the same time allows air flow to pass through:

- brick, frame walls;

- the outer side of the walls made of wood;

- floors;

- interfloor ceilings;

- the upper element of the building (roof).

Mineral wool can be made from various raw materials: glass, stone, or slag. Today, mineral wool is very popular in construction, in particular for room insulation. In particular, walls and ceilings are insulated with it. Mineral wool is also used for insulating furnaces and pipelines that have a high temperature, since this material is non-flammable. Additionally, mineral wool has soundproofing properties.

Mineral wool may contain potential dangers to the human body. But in fact, it contains fibers that are good for health. It is best to use it in a place that is regularly ventilated, or use ecowool. Ecowool consists of environmentally friendly materials.

What is mineral wool?

Rock melts (basalts, dolomites) are used as raw materials for production. Sometimes industrial slags are added. The molten mass is formed into fibers, which are then pressed into slabs or rolls.

The strength of the final products is determined by the degree of compression during pressing and the binders, which use phenol-formaldehyde or urea resins.

The greater the force applied at the molding stage and the higher the concentration of binders, the more dense and rigid the material is.

Density, depending on the release form, can fluctuate within a very significant range:

- Rolls – 20-50 kg/m3;

- Mats –50-80 kg/m3;

- Lightweight slabs – 80-120 kg/m3;

- Medium hardness slabs – 120-200 kg/m3;

- Rigid slabs – over 200 kg/m3.

Vapor barrier

The thermal insulation “pie” must allow air to pass through so that the room “breathes”. Therefore, the hot air flow escapes very slowly through the insulation fibers. With proper installation of insulation, this ability should increase from room to street.

There should be a ventilation gap of two centimeters under the decorative finishing of the walls and ceiling. Mineral wool is attached between the supports.

First, it is necessary to lay a wind and waterproofing barrier that will protect against precipitation and powerful gusty winds.

Partitions between rooms and interfloor ceilings need to be insulated using a different method, because air and moisture can impregnate mineral wool or ecowool from different sides, therefore, to preserve thermal and technical properties, a vapor barrier is required on both sides. In this case, residual moisture passes through the ventilation gap, which is located under the facade.

There are situations when hydro-vapor barrier when insulating with mineral wool or ecowool is not required at all.

For both waterproofing and vapor barrier, it is important to carry out a number of preparatory work:

- cleaning the coating from various dirt and dust;

- priming. This is necessary to seal surface cracks;

- drying the coating.

Vapor barrier of walls in the room

How should additional floor insulation work?

So, when and why do you need to insulate existing floor insulation? The main goal of additional insulation is to improve its performance, as well as to ensure that the existing heat is distributed across the floor more evenly and for a long time. In all cases, when floor insulation works without additional thermal insulation, over time the floor heating system begins to not work at full capacity and, as a result, fails in the future.

In order for a floor heating system to function correctly and serve for many years, it must be organized wisely. To install heated floors, you can only use insulation that has a low level of thermal conductivity. What problems can additional floor insulation solve?

Types of membranes for floor insulation:

Types of membranes for insulation

How to choose an insulating membrane

Special equipment is used to install underfloor heating

Types of vapor barrier

Vapor barrier is divided into two types:

- Rolled. Rolls are rolled out from the bottom of the item to the top. Next, they are secured with slats made of wood in a horizontal position. The gap for ventilation is located between the inner lining and the steam protective layer. This hole should be about five centimeters. After the procedure, check that everything is securely fastened.

- Leafy. To work with sheet material, you should first install a profile frame. Sheets must be mounted into this frame. Self-tapping screws or nails will help you secure the sheets. The joint areas must be covered with polyvinyl chloride (PVC film). The vapor barrier layer sheet is placed with the inner area towards the place that you want to insulate.

Installation of vapor barrier on the floor

Insulating the walls of a wooden house from the inside

Sometimes it happens that it is not possible to insulate a log or cobblestone house from the outside. For example, the building is already lined with bricks or some unheated structure is attached to it. In this case, insulating the walls of a wooden house from the inside is the only way out. This is usually done using mineral wool or expanded polystyrene.

Preparatory work for wall insulation

The walls of the house should first be thoroughly cleaned of dust. Next, the wood is treated with insect and rot repellent. You should also treat the surface with special compounds that increase the fire resistance of the material.

If we are talking about a log structure, you must also carefully caulk all the cracks. Usually jute fiber is used for this. For large cracks, take tow rolled into a roller.

Installation of mineral wool slabs

Insulating the walls of a wooden house from the inside can be done using mineral wool. This material has excellent heat-retaining properties and is easy to install. It will be necessary to install sheathing under the slabs. Bars 50*50mm are stuffed in a vertical position. The step between them depends on the width of the insulation. Usually it is about half a meter.

Advice: It is best to make the distance between the beams such that it is 2 cm greater than the width of the mineral wool layers. At the same time, they will fit into place more tightly, and the insulation itself will be more reliable.

Nailing can be done with regular nails. After the sheathing is installed, begin laying the slabs. At the same time, they carefully ensure that there are no gaps between them and the beams. Insulating the walls of a wooden house from the inside with your own hands will be quite effective only in this case. For greater reliability, the slabs should be secured with special dowels “fungi”.

Laying a vapor barrier layer

When carrying out measures to insulate walls, it is necessary to install a vapor barrier. High humidity will not only reduce the heat-shielding properties of mineral wool, but will also lead to wood rotting. As a vapor barrier, it is allowed to use either ordinary cheap polyethylene film or some of its modern foil analogues. The material is mounted directly on top of the cotton wool, secured to the bars with special staplers.

Important: The vapor barrier should be stretched with foil inside the room. In this case, it is necessary to maintain an overlap between the strips of at least 10cm

Additionally, the joint should be taped with aluminum or plumbing tape.

At the next stage, they begin installing the counter-lattice under the cladding. It can be assembled from 30*40mm beams. As a final finishing for a wooden house, of course, lining is best suited.

Use of expanded polystyrene

Insulating the walls of a wooden house from the inside with polystyrene foam is done in much the same way as with mineral wool. That is:

- Walls are pre-treated

- A timber sheathing is mounted on a chopped wall,

- Expanded polystyrene slabs are laid closely between the battens. Secure them with dowels,

- Next, stretch the vapor barrier and install the counter-lattice under the finishing sheathing.

On cobblestone walls, it is not necessary to install lathing under polystyrene foam. It can be glued to the surface with foam glue. In any case, all joints should be sealed with foam or taped.

If the walls of a wooden house have been insulated from the inside with polystyrene foam using lathing, the finishing sheathing is mounted on it. If the slabs were installed with glue, they should be reinforced with a special mesh. The top surface is subsequently plastered.

We think now you understand how to insulate the walls of a wooden house from the inside yourself. This procedure may take a little time, but technologically it is not particularly complicated.

Insulating the walls of a wooden house from the inside

Methods and recommendations for insulating the walls of a wooden house from the inside on your own.

wall pie

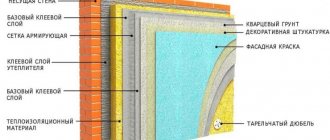

The “pie” of the wall consists of the following elements:

- Exterior finishing protects all subsequent layers from aggressive external influences, moisture and temperature fluctuations. It can be made of various materials. Siding, facade plaster, decorative stones, facing bricks - the choice depends only on your imagination;

- The waterproofing membrane is located under the exterior trim or wall sheathing. It creates conditions for a favorable microclimate in the room and ensures the safety of wooden frame elements from moisture. Waterproofing releases water vapor out, but does not let moisture in;

- Insulation is one of the most important components. It is placed between I-beams - in cells formed using horizontally located connecting links;

- The vapor barrier membrane prevents vapor from penetrating into the interior of the walls. Its installation is carried out on a wooden frame from the inside of the walls. Its installation is necessary in places where there is strong humidity (kitchen, bathroom, toilet). Wax paper often acts as a vapor barrier.

- Interior finishing is the final layer of the “pie.” The inner surface of the wall, if desired, can be covered with plasterboard, clapboard, etc.

Arrangement of the attic

The roof of the finished attic has the appearance of a layer cake. Exterior covering is a roofing material designed to protect a home from precipitation. From the point of view of thermal insulation, it does not provide any effect. The top waterproofing barrier is roofing material or a special film that is capable of retaining water, but is vapor permeable. It is laid in such a way that water flows through it to the outside. Next comes a layer of insulation, which forms a thermal insulation barrier.

The vapor barrier is designed to completely protect the installed insulation layer from moisture and steam. This polyethylene film is truly completely vapor and waterproof. Everything ends with a decorative coating to give aesthetic appeal and protection from mechanical damage.

The greatest difficulty in insulating an attic space is installing a waterproofing layer on insulation of a complex shape. The difficulty lies in bypassing all the load-bearing elements of the roof and organizing its exit under the roof to discharge water. It is very important here to maintain the integrity of the layer. The joints and fastening points must be taped, and secured between the rafters with staples or vertically nailed slats.

The insulation is placed tightly between the rafters and, together with the hydrobarrier, is secured with slats, which will later serve as a support for the finishing. It is recommended to insulate with mineral wool formed into sheets or slabs, since it is more resistant to caking and shedding during operation compared to rolled wool.

Final finishing

The material for the final finishing of the attic can be any sheet material that can protect the insulation from damage. Most often, plasterboard, chipboard or OSB boards, as well as wooden lining or plastic are used.

Installation is carried out on slats that secure the thermal insulation to the roof. You can assemble a separate metal frame from profiles, but this will require additional space in the attic and will once again compromise the tightness of the waterproofing.

Properly installed attic insulation will not only help conserve heat, but will also protect roofing and ceiling elements from premature aging.

Results

Today we figured out how to properly insulate an attic with mineral wool and came to the following conclusions. If the attic is unheated (cold), then the insulation is placed between the floor beams. If the attic is heated, then thermal insulation is placed between the roof rafters. There is a method of laying thermal insulation on the attic floor, then the wall itself is insulated and then a section of the first floor floor from the wall to the edge of the building. This approach will slightly reduce heating costs, since there is no need to heat extra square meters.

For work, it is better to use glass wool, since it does not break and, after compression, restores its previous shape. It is lightweight and does not overload the load-bearing floor beams and rafter system. If you use stone wool, then you need to take slabs with a soft end so that they can be inserted between the guides at random. A vapor barrier is laid between the heated room and the insulation. When laying thermal insulation on the roof, you also need waterproofing, which is placed on the outside. There must be a ventilated gap between the waterproofing and the finishing.

Preparatory work

Before installation, carry out the following steps:

- Now comes the time to seal cracks and gaps . They are sealed with sealants or jute fibers;

- Next, proceed to installation of the sheathing . bars measuring 50×50 mm or 50×100 mm are attached to the surface of the walls with self-tapping screws - they are selected according to the number of layers of insulation.

- The lathing is installed in the form of horizontally and vertically located guides with a distance between them almost equal to the width of the insulation - less by one cm, in order to more tightly join the material.

Choice of insulation

The methods of insulating the ceiling of the upper floor of the ceiling along beams in a private house are very diverse. When doing the work yourself, the insulation is placed between the joists and provides reliable thermal insulation and noise protection. There are many options for insulating a structure, the most common of which are:

- insulation with mineral wool;

- laying expanded polystyrene (foam plastic or penoplex) on wooden beams;

- filling with expanded clay;

- insulation with sawdust;

- filling the ceiling space with foam.

Each of these options has its own characteristics and advantages.

Mineral wool insulation

The material is available in two versions: plates and rolls. Insulating the attic floor with mineral wool has the following advantages:

Styrofoam

Foam plastic has become one of the most common materials for thermal insulation. It has earned its place in the top three thanks to its very attractive price. Using this insulation in an individual home provides the following advantages:

- high degree of protection;

- resistance to rotting and mold and mildew;

- low degree of water absorption;

- ease of installation and no need for complex tools and protective equipment;

- the light weight of the material prevents excessive load on the structure and allows for insulation from below.

Extruded polystyrene foam

More often this material is called a shorter word - penoplex.

Being the closest relative of foam plastic, penoplex is devoid of most of its disadvantages. In the process of improving performance characteristics, the cost has increased. The material is produced fireproof, it has sufficient strength for use as a base for flooring and is light in weight for use in ceiling construction. Do-it-yourself installation is quite simple. This issue is discussed in detail in the article. The text discusses options for using both penoplex and polystyrene foam for different types of floor construction.

For people who decide to build their own wooden house, the naturalness of the materials is usually important. Here penoplex, like foam plastic, loses to other types of insulation due to its artificial origin.

Expanded clay or sawdust

If you decide to use completely natural materials in your home, these two types of insulation will become indispensable helpers. They do not have high heat-protective characteristics, like previous types, but provide reliable protection from the cold with a sufficient layer thickness. Sawdust can be obtained almost free of charge; expanded clay is also an inexpensive material.

Insulation of the attic floor can be carried out by non-professionals and does not require special skills. The application is limited by the physical characteristics of these materials: they cannot be used for thermal protection from below.

Heat protection foam

Polyurethane foam insulation is a fairly new material in construction. When constructing a building yourself, this method can provide high speed work and reliable protection from the cold. You can read about insulating a building, including attic floors, with foam in the article.

This provides a large selection of materials for insulation and significant savings on construction.

A large percentage of heat losses occur precisely through the ceiling of the upper floor, which is why it is so important to choose the right insulation and follow the installation technology. Are you insulating your house for winter and don’t know how to insulate the attic floor using wooden load-bearing beams? Having gained experience in this matter, I will accurately convey the technical aspects of thermal insulation, and also describe step by step the procedure for carrying out the work

Are you insulating your house for winter and don’t know how to insulate the attic floor using wooden load-bearing beams? Having gained experience in this matter, I will accurately convey the technical aspects of thermal insulation, and also describe step by step the procedure for carrying out the work.