Home » Classification of gas boilers » External gas boilers - advantages and features

An outdoor gas boiler is designed for heating housing or government institutions: hospitals, schools, kindergartens, shopping centers. External top-burning boilers have insulated bodies and are installed outside the heated structure. Low-power outdoor devices have ratings from 40 to 100 kW. They are capable of heating an area of up to 1000 m². Gas boilers for cottages and residential buildings are chosen with precisely this power. To heat hospitals, offices and other large buildings, they use stronger units or create a complex of several boilers.

…

- 1 What are the differences between outdoor gas boilers?

- 2 How can you complete an outdoor gas boiler?

- 3 Advantages of an external heating boiler

- 4 How does a gas boiler work?

- 5 Chimney installation for gas boilers

- 6 Gas boilers KSUV

What is the difference between outdoor gas boilers?

Outdoor gas boilers are water-tube structures that heat water, which are located in insulated metal boxes. For ease of use, the front and back panels can be opened. The main advantage of such boilers is that they are located outdoors and not indoors. This significantly saves living space. pipes are led from the boiler into the building through the wall , after which it can be used. The outdoor boiler is controlled using a remote control installed in the house. The unit is connected to it using cable wires.

There are two types of outdoor boilers: single and double. The latter are distinguished by the presence of a double heat exchanger, two fireboxes, and also have two atmospheric gas burners. Single units have a power range from 40 to 500 kW, and twin units have a power range from 80 to 800 kW.

The best manufacturers and models: characteristics and prices

Next, we will consider several Chinese models that have proven themselves to be the best based on reviews from experts and ordinary users.

"Bulat" series W and R

These heating devices are ready-to-connect mini-boiler rooms located in a monoblock box. Gas boilers of the W series have an installed power from 24 to 105 kW, and are designed for heating small buildings, for example, a private residential building. Boiler units of the R series are made in the form of a built-in unit and are capable of delivering high power - from 100 to 150 kW. Both models are equipped with a GSM module, allowing the owner to monitor operating parameters remotely via a smartphone or computer. Cost 210-340 thousand rubles.

"Phoenix"

Boilers of the Phoenix series are designed for autonomous heat supply to residential, commercial and administrative buildings. Placed in a monoblock box, available in single or double versions. The power of various modifications ranges from 40 to 455 kW. Thanks to such a wide range, the PRCs of this series are perfect for heating buildings of various sizes in any climatic regions. The cost of heating units, depending on the power, ranges from 225 to 515 thousand rubles.

RS-H series

These hot water boilers are capable of developing power from 40 to 2,000 kW. All equipment is fully assembled and installed in a monoblock insulated box. Available in single and double versions. The most powerful models in this series are designed for heating rooms up to 12,000 m2. Price from 230 to 110 thousand rubles.

Advantages of an external heating boiler

Outdoor gas have a number of advantages compared to other units:

…

- have low levels of pollution and noise;

- have relatively small dimensions with fairly high power;

- do not require significant maintenance costs and are cheaper for their owners than centralized heating;

- save usable space inside the building;

- easy to maintain and easy to install;

- are safer than a boiler placed indoors; equipped with several automatic security systems;

- have a long service life - from 10 years;

- they can be equipped with additional functions.

Some consumers prefer a coal unit, but they do not know that gas boilers are more functional. They work perfectly on gas supplied from the network, as well as on liquefied fuel.

Typically, outdoor boilers are equipped with a circulation pump; you can also order a device with gas control units. This is relevant if operation on medium and high pressure gas is expected.

An outdoor boiler is mounted from steel profile sheets with a special insulation made of mineral wool.

An automated monitoring console allows you to monitor the operation of the boiler without leaving your home. If any breakdown occurs, the system turns off and automatically sends a signal to the remote control. If the power supply stops, the unit immediately stops working. When power is supplied again, the boiler automatically resumes operation.

Note! External boilers can be placed not only near the outer wall of the structure, but also at a distance of up to 50 m from it.

Using an automated control panel, the following functions can be performed:

…

- turning off the burner if the operating parameters deviate from the established ones;

- automatic ignition of the burner;

- shutting off the gas supply when a leak occurs;

- operation of light and sound alarms;

- maintaining water at the required level;

- operation of the security alarm.

Learn more about the gas boiler piping diagram. Find out how to install a wall-mounted gas boiler

Optimal operation of a gas boiler

Reviews of outdoor boilers: advantages and disadvantages

Against the background of the obvious positive qualities of outdoor gas boilers, due to the fact that they are still fairly new units in the heat supply and domestic hot water supply of private properties, there is little experience in long-term use. User reviews mostly focus on negativity when designing and connecting equipment. In technical terms, there is a debate about burners, open and closed fireboxes.

An open combustion chamber allows you to build an independent system from the power supply and the boilers are inexpensive, silent, and often do not need a chimney or it is simple. However, too much gas consumption by such a unit reduces interest.

A closed boiler firebox, on the contrary, can save up to 30% of gas, but the automation is tied to a reliable power supply and requires a complex chimney and air pressurization, which makes it noisy, complex and more expensive.

The post-warranty service of complex imported automation and electronics raises concerns.

| Advantages | Flaws |

| Placing it outside the house allows you to save living space, as well as money for installing a chimney and ventilation. There is only a control panel in the house. Saving space is especially important in commercial and industrial buildings. | The use of outdoor gas boilers is convenient and profitable only when using natural gas from the mains. It is unprofitable and unsafe to use bottled gas in China. |

| Due to the fact that the boiler is outdoors at a distance of up to 50 m, it is already safer than others. Safety is enhanced by shutting off gas and coolant if they leak. You can also install emergency warning and fire alarms. | Outdoor placement of complex equipment requires a tamper alarm system, as well as anti-vandal fencing, especially when located within 50 m. |

| Automation and modern technologies make it possible to burn fuel as efficiently as possible and minimize heat and hot water losses and increase efficiency to 95%. | Obtaining specifications, ordering a project, the high cost of installation work, and obtaining permission to connect will require the user to spend a lot of time and additional money. |

| The quality of components and new technologies for controlling burners and smoke removal result in low noise, low pollution and a long service life. | The cost of a set of equipment depends on the level of automation, the country of manufacture and will require much more serious investments than in the case of internal boilers. |

| Controlling a boiler with automation of any complexity is intuitive. | |

| Units with an open firebox can be completely autonomous from electrical networks; boilers with a closed burner can be autonomous if alternative sources of electricity are available. |

How does a gas boiler work?

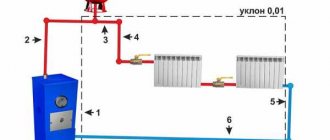

The gas outdoor boiler operates in automatic mode. The operating principle of the unit is that heat is supplied to the coolant through pipes and a heat exchanger. With the help of circulation elements, the coolant is supplied to the house. Automation ensures fairly smooth operation of the equipment. Below is a video describing the operating procedure and features of outdoor gas boilers.

For the boiler to work efficiently, it is important to have a coordinated operation of the heating system in the house with the power volume of the heating device. The latter is equipped with an open firebox and an atmospheric gas burner. The heat exchanger is a coil of contoured pipes to ensure high heat transfer.

The unit must be connected to a three-way automatic valve, which prevents the formation of condensation and tarry sediment in the firebox.

Note! Heating systems with forced circulation of coolant must necessarily have circulation pumps of the required power.

The boiler is started in the following steps:

- the system is filled with coolant;

- the gas supply is opened on the gas pipeline using a special tap;

- start the boiler according to the instructions;

- when the coolant heats up to 60C, the network pump turns on.

The operation of outdoor heating devices is similar to gas wall-mounted boiler. However, external structures are more economical and reliable.

external heating boiler is installed on a free-standing foundation or on the roof.

To prevent the boiler from being covered with snow, it is placed 5-10 cm above the average level of snow cover. Note! In some boiler models, heating with an electric heater is provided to maintain continuous operation of the burner in winter.

Prices: summary comparison table

Next, consider a comparative table of the cost of some external gas boilers of various modifications.

| Model | power, kWt | Price, thousand rubles |

| Phoenix-40 | 40 | 225 |

| Phoenix-60 | 60 | 235 |

| Phoenix-100 | 100 | 250 |

| Phoenix-200 | 200 | 365 |

| Phoenix-300 | 300 | 425 |

| Phoenix-400 | 400 | 490 |

| Phoenix-500 | 500 | 515 |

| RS-H-40 | 40 | 230 |

| RS-H-150 | 150 | 350 |

| RS-H-300 | 300 | 695 |

| RS-H-600 | 600 | 905 |

| RS-H-1000 | 1000 | 1100 |

Chimney installation for gas boilers

If you want to retrofit an outdoor gas boiler with a chimney, when installing it you should take into account the regulatory documents SNiP 2.04.05-91 and DBN V.2.5-20-2001:

- the diameter of the chimney cannot be smaller than the pipe on the boiler; more is possible, but less is not;

- the structure must go vertically upward; in extreme cases, a deviation of 30°C is allowed;

- the chimney must be made of gas-tight materials;

- the joints are carefully sealed;

- when installing a smoke removal structure, it is necessary to provide a condensate collector in its lower part;

- the height of the chimney must be sufficient to provide good draft to prevent smoke in the residential area;

- A special umbrella should be installed at the top of the pipe to prevent debris and moisture from getting inside.

The listed requirements must be observed without fail; they are the basis for the safe operation of a chimney for a gas boiler .

The choice of type of smoke exhaust design depends on the type of combustion chamber. It can be open or closed. In the second case, a coaxial pipe is installed, in the first - a regular one. The coaxial design looks like two pipes that are inserted into one another. It is bought ready-made and is easy to assemble. One pipe removes combustion products, and the other provides air flow to maintain combustion.

Chimneys for gas boilers are made from different materials:

- Brick is becoming increasingly rare. A smooth pipe of the required diameter made of stainless steel or asbestos is inserted into the brick structure.

- Stainless steel – single wall pipes and sandwich. The requirements for the material are quite high, as it must withstand long-term contact with caustic substances. Sandwich chimneys have insulation linings and are more reliable than single-wall chimneys, as they are made of two layers of metal.

- Ceramic structures have many advantages: they are reliable, durable, and withstand contact with caustic substances well. However, they have two significant disadvantages: they are expensive and heavy, so they will require a solid foundation.

- An asbestos-cement pipe is the cheapest option for a gas boiler chimney for a private home. However, it has problems with sealing and aligning seams due to its specific rough surface.

Details about Chimneys for wall-mounted and floor-mounted gas boilers https://oteple.com/dymoxody-dlya-nastennyx-napolnyx-gazovyx-kotlov/ Natural and forced draft

Find out the characteristics of Buderus gas boilers:

Nuances of installing China

Installation of outdoor gas boilers is carried out in accordance with existing regulatory documentation. But it talks either about boilers for internal use or about boiler rooms located in separate premises, so controversial issues may arise that are resolved by gas services, service companies, and Rostechnadzor.

The main thing is to be able to negotiate with representatives of all authorities and skillfully operate with the provisions of SNiP and GOST.

For those who want to study the regulatory framework, we suggest studying the following documents:

- SP 41-104-2000;

- SNiP 42-01-2002;

- SP 42-101-2003.

But the main document for installing and operating the equipment is the manufacturer's technical manual .

Conditions for installation of gas structures

PRC are completely ready-to-use structures that require connection and commissioning, so their installation requires only a flat base and permission for installation work.

For the most powerful boilers, a foundation is also required - this is stated in the technical data sheet of the unit. Concrete slabs or pouring are used as the foundation

Before installation, it is necessary to obtain specifications from the gas service, which, in turn, is guided by the requirements of the Technical Regulations. The rules for issuing special technical conditions are set out in Decree 1314 (2013) , which states that the basis for failure of the installation can only be the lack of technical ability to connect the boiler to the facility.

GOST R 54961-2012 indicates that approval of specifications is carried out after checking the compliance of the equipment power, as well as the connection point.

Chimney requirements

Outdoor structures, just like conventional gas boilers, are equipped with chimneys, which are subject to the following requirements:

- the diameter of the pipe must be equal to or greater than the boiler pipe;

- the material of manufacture is gas-tight;

- installation of a condensate collector is required;

- the direction of the structure is strictly vertical, in special cases – an inclination angle of up to 30°;

- joints must be sealed;

- The height of the chimney eliminates smoke from the living area and provides good draft - from 5 m or more.

The upper part of the chimney of external gas boilers, just like conventional ones, is closed with a deflector - a cap from debris, dirt and street dust.

Manufacturers recommend choosing straight pipes that have no more than 3 turns with a radius of curvature equal to or greater than the diameter of the pipe

Installation of factory-made pipes proceeds from the bottom up, starting from the boiler. The joints of tees, bends, and corner elements are additionally secured with clamps. If the pipe is attached to the wall, then brackets are installed at intervals of 2 m.

Detailed requirements for the selection and installation of Chinese chimneys are set out in DBN V.2.5-20-2001 and SNiP 2.04.05-91 .

Installation and connection rules

The placement and connection of equipment to the central gas supply system is carried out in accordance with the drawn up and agreed upon project. Boilers that are small in weight and volume do not require the construction of a foundation.

They are installed on a flat piece of ground so that the load is distributed evenly over the entire site. For large-scale devices, the foundation construction plan is also included in the overall project.

Depending on the manufacturer’s recommendations, the unit is placed next to the wall of the heated object, at a distance of up to 50 m, or on the roof.

If the gas boiler is located in an area open to unauthorized persons, it must be surrounded by a fence that prevents entry

According to the rules, it is necessary to ground the structure, since the boiler is connected to the power supply system. She is responsible for the operation of security alarms, pumps and other automatic equipment.

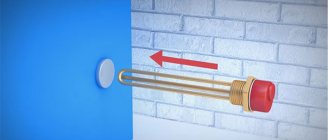

The unit is connected to the internal heating system by pipes for supplying coolant with a diameter of 50 mm. The pipeline passes through the wall in a sleeve that provides its protection. Entrance structures inside the building are equipped with shut-off valves.

First, the internal system is cleaned and pressurized, and based on the results - if there is no leak, rupture, or pressure drop in the network - a connection is made to the boiler. During the crimping process, the shut-off valves are closed. The heating system must be equipped with air vents at the top points and a drain valve at the bottom.

An expansion tank is installed inside the building, selected taking into account the volume and expansion coefficient of the liquid, pressure and other important parameters.

Start-up and operating requirements

Before putting the boiler into operation, first prepare the heating system: set the recommended pressure, open the shut-off valves on the pipes and in the thermal-mechanical compartment of the unit, fill the heating network with water, eliminate errors, and bleed air.

Then apply voltage to the boiler and check that the phases are connected correctly according to the diagram. At the same stage, the operation of automatic equipment - control and alarm panels - is diagnosed. Lastly, start the pump and check its operation.

The operation of the boiler must be monitored by the owner of the gas equipment. Inspections, adjustments, preventive measures, and repairs are carried out by a service organization

It is necessary to regularly monitor the cleanliness of filters. When dirty, turn off the taps, drain the water, remove the filters and wash the mesh.

If the boiler is turned off for the winter, the heating system and the unit itself are completely freed of water so that the coolant does not freeze in the pipes and rupture them.

Gas boilers KSUV

Outdoor boilers KSUV are especially popular among consumers, especially in those regions where power outages often occur. They operate without the use of electricity, so they are not afraid of sudden power outages. The autonomous system consists of an external KSUV boiler, which can have an atmospheric or blown burner and an automatic three-stage valve, which, if necessary, turns on the standby heating of the system. Such a gas boiler is capable of heating rooms up to 8000 m² and producing up to 100 tons of hot water. Using a blower burner can double the boiler power.

External gas boilers KSUV are often used for heating municipal buildings up to 6 floors high.

The modern market provides a huge selection of outdoor gas boilers for private homes, hospitals , schools, warehouses, offices and other institutions. They are individual mini boiler rooms that effectively heat the building, do not require special maintenance efforts and are cheaper than other heating systems. This is confirmed by numerous reviews from the owners of such units. It is only important to install it correctly and follow the operating rules specified in the instructions.

Types of outdoor wood boilers

Outdoor heating units are:

- solid fuel standard design;

- top combustion with a chamber in the form of a cylinder;

- pyrolysis with high-temperature splitting of firewood into highly flammable gases;

- long burning with a shaft to increase the volume of fuel storage;

- equipped with a screw feed of granulated or pressed raw materials.

Boiler design

Devices for heating rooms convert combustion energy into heat, while volatile substances are removed through the chimney. Structurally, the boiler is a wood-burning stove made of steel sheets.

To increase efficiency, the combustion chamber is covered with a double layer of metal plates. The sealed mediastinum, formed by the outer and inner iron casing, forms a water jacket, which is filled with coolant.

The boiler has fittings for connecting the supply and return pipelines.

The design consists of the following parts:

- housings made of steel sheets or cast iron elements;

- combustion chamber;

- grate;

- ash collection compartments;

- smoke exhaust duct;

- mediastinum filled with coolant (water jacket);

- an insulating layer to protect against atmospheric influences and prevent energy losses;

- devices for pumping air into the combustion chamber;

- circulation pump;

- control module.

Criterias of choice

When purchasing, you need to pay attention to the following factors:

- Availability of fuel on which the boiler operates.

- You should not purchase a unit with maximum power or more than necessary. A device operating in nominal mode uses fuel much more efficiently.

- The parameters of the boiler are closely related to the dimensions of the room where it will be installed. Insufficient air volume in the boiler room or weak air pressure has a significant impact on the performance of devices with forced injection.

- The efficiency of the device varies when operating on different types of fuel. When choosing a boiler, you need to pay attention to the efficiency of its operation on the fuel that will be used most often.

- Units with a cast iron heat exchanger are more reliable than steel ones.

- The weight and dimensions of the equipment affect the requirements for the boiler room. It is necessary to discuss in advance with specialists how the unit will be delivered to the installation site, whether the doorway is wide enough to accommodate it, and whether the base on which the device will stand is strong enough.

- Door height for loading fuel and cleaning the ash pan. It should be convenient to maintain the installation and fill it with firewood.

- Boiler cost. The price is determined based on the technical characteristics, and also depends on the reputation of the company and the time during which the equipment of this brand has been produced.

Properly organized heat supply significantly affects indoor comfort. Rational use of resources for high-quality heating of housing, industrial or commercial facilities largely depends on the boiler unit. For this reason, you need to approach the choice of heating installation responsibly.