A gas boiler is a complex thing, and therefore requires proper treatment. Indeed, in addition to its benefits, it can also cause very serious harm, since the incorrect use of a gas boiler is associated with great risks to human life.

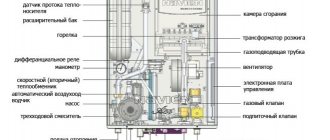

Gas boiler installation diagram.

That is why today we will provide instructions for operating a gas boiler.

There are many models of this unit, which are produced by different companies, but in general their operating requirements are the same.

What are they? The gas boiler user manual will be presented below. So, the basics of operating gas boilers.

Operating principle of the boiler

Gas heaters may differ in design and technical parameters, but the principle of creating heat in the house is the same - heating the coolant (water/antifreeze) with combustion gas (natural/liquefied). Supplying gaseous fuel to a residential area is not the easiest or safest thing, but consumers are attracted to gas, its comparative cheapness and versatility.

Blue fuel can be used not only for heating, but also for heating domestic water, using columns or dual-circuit heater models. Modern equipment is equipped with effective safety systems that prevent all possible emergency situations. Nevertheless, there are operating rules that must be followed and are a guarantee of safe operation.

Precautionary measures

Despite the desire of manufacturers to ensure the safety of gas appliances, they can still become a source of danger. The Ministry of Emergency Situations regularly reminds owners of any gas-powered equipment about the following precautions:

- You need to buy gas-powered appliances from organizations that have the appropriate sales license.

- Installation should only be carried out by specialists from the relevant services.

- The kit should include an instruction manual.

- It is prohibited to change the design of the device in any way.

- A technical inspection must be carried out annually.

- It is prohibited to reduce ventilation openings in windows and walls.

- If there are sealed windows, it is necessary to organize air flow.

- Materials that can quickly ignite should not be stored in the boiler room.

- It is prohibited to increase the coolant temperature above 90°C.

First start

Before starting the gas water heating boiler for the first time, it is necessary to check the correct installation and installation, in compliance with all instructions. The installed boiler must be inspected by a gas service inspector and sealed. After which you can begin preparing for the first launch. Before starting, the automation is configured with the required parameters set, following the operating instructions supplied with the boiler.

We recommend: Chimney damper: definition, types, pros and cons, installation methods

Filling the system with coolant

Step one is to fill the system with water or another coolant. The entire circulation circuit is checked for the presence or absence of “air” plugs in the system.

If present, air pockets must be vented by slowly releasing air through a special valve. Most often this is found on heating elements. Etching must be carried out with caution, with the readiness to close the valve in time.

Checking the supply lines

Step two is to check gas pipes, valves, and shut-off valves for leaks. The inspection is carried out by a gas service employee. But if you smell a specific gas smell, you can check it yourself before a specialist arrives and find the leak. For this, use a regular soap solution.

By applying it to welds, at the joints of pipes and shut-off valves, you can detect gas leaks.

Putting the boiler into operation

Step three is the direct start of the gas water heating boiler itself. Carry out strictly according to the attached instructions. If you can’t figure it out on your own, then it’s better to contact specialists who have access to this type of work.

Boiler shutdown

At the end of the heating season, if the boiler is not planned for use in the hot water supply system, then it must be turned off for a long period. To do this, follow a few simple steps:

- turn off the gas supply, make sure that the burner in the boiler goes out completely;

- turn off the power supply to automatic ignition and automation;

- shut off the water supply to heating and water supply.

No special additional actions are required. Do not drain the entire coolant circulation system to avoid corrosion.

Posting rules

- The area of the room in which the heater is installed is at least 7.5 m².

- Ceilings - from 2.2 m.

- There must be a window providing access to air from the street.

- The door should open in the direction of movement of the person leaving the room.

- It is prohibited to install switches in the boiler room. If they are already installed, you will have to take them outside the premises.

- It is necessary to equip supply and exhaust ventilation. For every m³ of fuel consumed - 15 m² of air.

- The distance from the heater to elements capable of burning is 25 cm or more. To non-combustible elements - 5 cm. From the chimney to combustible parts - 40 cm, to non-combustible parts - 15 cm.

- The device is mounted on a perfectly flat plane, without slopes.

New solution - heated floors

What is the reason for such popularity of heated floors? The fact is that installation and repair of such a heating system is quite simple, it will not take as much time as repairing DKVR boilers, which in itself makes the “underground” heating system a strong competitor in the housing and communal services market. (See also: How to choose a solid fuel heating boiler)

The device of Soviet radiator heating is so accessible that, if necessary, the home owner can independently inspect the integrity of the heating system, and, if necessary, add the necessary sections to any of the batteries. As a rule, batteries, as part of the radiator system, are placed directly under the window, thus “blocking” all the most likely sources of cold during the winter months.

What is the area of action of such a heater? In fact, it is quite low: only a few square meters, although the temperature created at the site where the heater is exposed can fluctuate up to 70°C, which triggers physical processes into action. According to the laws of physics, heated air rushes upward, rising slowly to the ceiling along the wall, to the location of the radiator. As the warm air cools, it moves towards the opposite wall, along which it slowly descends, and only then moves again in the warm radiator.

But if we look at this process from the other side, it turns out that the cold air, having given up all the heat to the walls and ceiling, moves again along the cold floor to the radiator. From this it follows that a person’s feet will constantly be cold: warm air does not flow to the feet. This theory caused a controversy among scientists, as a result of which heated floors now appeared.

Chimney requirements

- The chimney material is steel. It is recommended to use stainless steel.

- Cleaning hatches and condensate drainage are required. There should be a pocket at the bottom of the chimney where deposits accumulate.

- The chimney is equipped with external thermal insulation, which is protected from moisture (condensation, precipitation).

- The height of the chimney is from 5 m and at least 2 cm above the outlet pipe.

- The smoke exhaust is installed on the receiving plate of the vapor trap.

- The expansion tank is installed at the highest point of the system.

- A safety group and a thermometer are installed on the supply pipeline.

- It is not advisable to place the device in openings, niches and other hard-to-reach places.

Why is tuning a gas boiler important and what will it give?

The boiler itself is quite simple in design, but nevertheless, some of the electrical components are capable of operating only a certain number of on/off cycles.

If you set the power incorrectly, the boiler will constantly turn on at very short intervals, thereby shortening the life path that the manufacturer had already measured out for it with a not very generous hand. Planned obsolescence is what it is...

For example, I don’t yet have interior doors and an entrance door in my house—from a city apartment. I still hope to win the lottery and buy everything needed for relocation.

In the meantime, I’m relying on luck and for the second winter I’m heating the house in vain, the boiler turns on quite often, because without normal doors the heat, of course, slowly escapes.

As the slogan says.

The second key point for boilers with a hot water supply circuit is the smooth operation of the gas valve, which regulates the intensity of the burner flame.

Hence the comfort of bathing procedures. In order not to get cooked or freeze from a contrast shower, the boiler settings must be correct.

I literally and figuratively experienced first-hand what it’s like if the ignition is not adjusted smoothly. In the apartment where I am waiting for the housewarming, by coincidence, there is also a gas boiler.

Initially, the ignition flame was set according to the principle “as long as it burns,” so the water was thrown either hot or cold. Until a competent specialist corrected everything with the ignition settings.

These rings are used if the chimney length is about a meter or less. They say they also help save 4-5% of gas due to the fact that less heat escapes into the “pipe”.

Well, how about without the financial issue. We must not forget about saving gas. In addition to adjustments, you can use thermostats and a ring that limits heat loss through the exhaust pipe.

It is better, of course, to use them in tandem for more efficient gas consumption. Rumor has it, at least the local rygas workers told me this, that a sensor and chimney ring can save from 5 to 40% of your money.

How to use

In modern heater models, human participation is reduced to a minimum. Before the device is started, it is connected to:

- gas pipeline - gas service workers;

- heating pipes;

- water supply - representatives of organizations servicing heating systems.

The first start-up is also carried out by service workers. If the instructions are violated during connection and maintenance, the warranty will be void. The equipment must be used only for the purposes intended by the manufacturer.

During installation, maintenance and repair, original spare parts must be used. If a breakdown or incorrect operation is detected, the user must immediately turn off the gas valve and call the service or gas service. Carrying out repair work yourself is strictly prohibited.

When performing any work on or near an air duct or chimney, turning off the gas is mandatory. Having completed the work, they check the functionality of the chimney and air duct and only then proceed to start up the device.

Service life

The service life of gas equipment is determined in the technical passport of the boiler and ranges from 10 to 15 years. However, with regular maintenance and prevention, it can last much longer. The regulatory services may establish additional requirements for service life.

This may be due to the presence (or absence) of spare parts that are needed in the process of maintaining full operation of the boiler. If during the repair some part is required, and the manufacturer has stopped producing them, it may be necessary to replace the boiler as a whole with a more modern one and one equipped with spare parts.

How to turn off the boiler correctly

If the device will not be used for a long time, perform the following actions:

- Close the gas valve.

- If the equipment is volatile, you need to disconnect the automation and water pump from the power supply.

- Turn off the water supply and heating valves.

- If the temperature is expected to drop below zero, you will have to drain the water.

- Call a specialist to completely turn off the equipment.

The heater is also turned off for cleaning. Clean it with a damp cloth with mild detergent and soap. The use of aggressive substances is prohibited.

Features of power calculation

How to calculate the power of a heating boiler and choose heating equipment if you don’t know one more feature: the relationship between the power of the heating system and the volume of the firebox. In fact, everything is quite simple: according to the laws of physics, gas can burn completely or not. If the firebox is too large, then all the accumulated gas will be cooled by air, which means it will release less heat. If the firebox is too small, the gas will burn without residue due to a lack of oxygen.

If we collect all the above information in one sentence, then an effective heating boiler: a reliable, economical, high-quality, ideally selected heating system that can heat your home in record time to the optimal temperature. (See also: Using electric boilers)

Safety system

Gas-powered appliances require serious monitoring. It is provided either by a person or an automation system. The latter is capable of providing multi-stage protection that prevents dangerous situations and increases equipment safety. The main task of the protection system is to turn off the device in time by stopping the fuel supply.

Let's look at the stages of protection using the example of the Proterm Wolf KSO floor-standing boiler. These modern devices have multi-stage protection. One of the stages is an ionization sensor that controls the flame. If the fire goes out, a signal will be sent to the control unit, it will shut off the fuel supply and prevent an accident.

The combustion chamber has a temperature sensor that monitors the heating of the coolant and prevents the firebox from quickly burning out. “Wolves” are equipped with a KTD system - chimney draft control. It prevents the accumulation of carbon monoxide. If there is no draft, combustion products begin to accumulate in the chimney, and the thermostat heats up. When the temperature limit is reached, the thermostat contacts open and the flow of fuel stops.

Automatic protection

Modern heater models are equipped with electronic control and measuring instruments that generate signals for the control unit. Automation, receiving signals from sensors, coordinates the work of all nodes. Elements that prevent various types of malfunctions and problems are safety valves, expansion tanks, air valves, smoke detectors and other devices.

What to do if problems occur

Let's look at breakdown situations using the example of Italian Baxi boilers. Italian wall and floor heaters are an example of quality and efficiency. But even with proper use, malfunctions may arise that require prompt correction.

The following problems may appear in Baksi models:

- the burner does not light;

- during operation, popping noises are heard in the firebox;

- the boiler overheated;

- the device is very noisy;

- The sensor has failed.

The probable causes of breakdowns are associated both with violations of operating rules and with reasons beyond the control of the user:

- moisture has entered the device;

- low quality coolant;

- the pressure in the gas pipeline has decreased;

- voltage drop in the electrical network;

- errors were made during installation.

Violation of at least one rule or norm leads to breakdowns, incorrect operation and unnecessary costs.

CORRECT MAINTENANCE

- How to care for a gas boiler?

Any boiler needs to be serviced once a year . The best time is after the heating season. It is important to properly maintain new boilers during the first 5 years of operation. Otherwise, efficiency may decrease by 40%, and gas consumption will increase.

- How to maintain the manufacturer's warranty on the boiler?

Each manufacturer sets its own warranty rules (indicated in the data sheet). Most often, the condition is the purchase of equipment from an official dealer, and its installation, commissioning and further maintenance must be performed by certified specialists from a service organization. Also often one of the conditions for maintaining the warranty may be annual boiler maintenance.

- The boiler is connected to the electrical network. Is it sensitive to voltage changes?

All modern boilers are connected to the electrical network. Current is needed to ignite gas, operate the circulation pump, fan and automation. This equipment is sensitive to voltage fluctuations. It is recommended to purchase a stabilizer immediately with the boiler. If your lights often turn off, it is worth purchasing an uninterruptible power supply.

- Boilers can operate on liquefied gas

It’s not a well-known fact, but gas boilers can operate not only “from the pipe”, but also on liquefied gas from cylinders. To switch to another source, you need to purchase a set of injectors.

But heating or heating water in this way is extremely expensive. One 50-liter cylinder contains about 10 m3 of gas, while the cost of refilling is 600-800 UAH.

Frost protection

One of the important rules for operating heating systems is to ensure the minimum permissible coolant temperature. If water is poured into the system, freezing occurs at low temperatures, and pipes and radiators become unusable. In modern models, this problem is solved - the user is relieved of the need to monitor the coolant.

For example, the boilers of South Korean Navien [/anchor] provide reliable protection against freezing. Navien is cheaper than its European counterparts, but these boilers have all the necessary protection functions, which greatly simplifies their use.

When the coolant temperature drops below 10°C, the circulation pump starts automatically. If the coolant cools down to 6°C, the burner automatically turns on, warming the coolant to 21°C.

Firewood or coal - how to properly use a solid fuel boiler (instructions)

In general, solid fuel boilers are considered less dangerous than gas boilers. Fuel is added manually and thus the boiler operation is monitored more closely and frequently. For heating, wood, coal or special fuel briquettes can be used.

Sectional view of a solid fuel boiler

However, we should not forget that such boilers use flammable substances, which in any case are potential sources of open fire and carbon monoxide, poisonous gas. Therefore, when using them, certain safety measures must be observed so that the heat source does not turn into a source of fire.

As in the case of a gas boiler, the initial launch of a solid fuel heater must be authorized by the commissioning organization that is developing the heating project and has permits for this type of activity.

One of the options for connecting a solid fuel boiler

In preparation for launch, the following actions must be taken.

- installation of the boiler in a room specially designed for this purpose

- connection of water pipes, including pressure testing

- turning on the circulation pump that moves the coolant through the system

- installation of a chimney pipe, bringing it to the roof or securing it at the proper level along the wall of the building

For each item, it is necessary to comply with the technical conditions described in the boiler passport and regulated by fire safety regulations.

Water requirements

In such boilers, drinking water with a certain hardness coefficient can be used as a coolant. The furnace cavities are sensitive to scale formation and therefore the water should contain a small amount of salts in its composition - no more than 2 mg.eq/dm3. Water softeners may be added. Do not mix antifreeze containing ethylene glycol.

Note: Failure of the boiler due to scale formation on the walls of the heat exchanger is not considered a warranty case. Formation is 1 mm. water stone on the walls of the heat exchanger, reduces the efficiency of the boiler by 8–10% and leads to overheating of the equipment.

Requirements for the water pipe system

All pipes leaving the heat exchanger must be steel, connected by steel or cast iron pipes. Flexible connections are not permitted. The diameter of the pipes must correspond to the design displacement, the wall thickness must be within acceptable limits.

It must be remembered that the pressure in the system should be the minimum necessary for circulation. Exceeding the pressure value more than 0.120 MPa is considered unacceptable.

A necessary condition for operating a boiler in a closed heating system is the presence of a safety valve. The presence of a membrane-type expansion tank located on the return line of the water supply system significantly increases the heating efficiency (from 20% to 30%). In addition, the inclusion of an expansion tank in the connection diagram promotes uniform heating of the coolant in the system.

Installation of a domestic heating boiler

The distance from the walls must be at least 500 mm. The basis for installation should be a foundation made of non-combustible material. The optimal pedestal is made of concrete, cast using steel reinforcement, with a thickness of 150 mm. In this case, the gap between the bottom of the furnace to the foundation should not be less than 100 mm.

Fuel storage is unacceptable closer than 1 m from the walls of the boiler, and best of all - in a special adjacent room.

What are the requirements for chimney calculations?

The chimney pipe is designed in such a way that the draft it creates is sufficient to discharge exhaust gases into open space. This depends on the material from which it is made, the cross-sectional area and the roughness of the inner surface.

To avoid the formation of an abundant layer of condensate on the walls of the chimney, it is recommended to use pipes with sandwich-type thermal insulation, insulated with basalt mineral wool.

Depending on the power of the boiler, pipes with a cross-section of 150 mm or more are installed. up to 300 mm. Its height varies from 6 to 10 m.

If excessive draft occurs, a throttle valve is installed inside the chimney.

Video: ideal conditions for burning solid fuels

Ignition instructions

Heaters differ in the type of ignition, so when starting different modifications there are some nuances. Before turning on the device, you need to read the ignition instructions to ensure everything is done correctly. Let's look at ignition using the example of the Italian boiler "Ariston". Before turning it on, it is important to check the system for leaks. For this purpose, the thermostat is turned on to maximum so that the switching occurs automatically. Ariston ignition process:

- the device is connected to the power supply, and the heating regulator is set to the desired temperature value;

- When the pump is turned on, a slight noise is heard;

- when all air pockets in the pipes are eliminated, the noise will disappear;

- When the electric ignition is triggered, the boiler turns on automatically.

SAVING GAS

- Why the boiler burns a lot of gas: reasons, what to do

Households have different gas boilers, the gas consumption of which is different. Gas consumption is affected by the heated area, the initial and desired temperature in the room, the outside temperature, and the number of windows. But there are also technical factors that lead to overspending:

– Sediment in the heat exchanger . Water takes longer to heat up, and gas consumption increases.

– Incorrect installation or incorrect settings of the boiler (you need to contact the service).

– boiler operating mode If you set the temperature of the coolant in the pipes to a minimum (for example, 40 degrees instead of 60), then the air in the room will quickly cool down. Consequence: the boiler turns on more often and the consumption of the gas boiler increases.

– Poor insulation of walls and roofs. Apartments with walls facing a cold corridor lose a lot of heat. In new buildings, gas consumption will be higher if the neighboring apartments are not occupied - in fact, you will heat them too.

- The boiler is working properly, the house is insulated, but gas consumption is still high. What is the reason?

Over time, the pipes become clogged with scale (due to bad water) or rust. The passage of pipes can narrow by 70-80%, therefore, in order to warm the room, the boiler works longer and at shorter intervals, burning more gas.

To clean pipes , you should pressure wash them. But cleaning can be harmful if the water you pour in later is hard and brings in a new portion of salts. It is advisable to use filtered and softened water.

Instead of water, you can fill in household antifreeze for boilers (in this case, the system will also not freeze in severe frosts). However, it is quite expensive (from 20 UAH/l) and not all boilers are designed to work with it (you may lose the warranty). The chemical composition of the antifreeze is important: the fill is not what you need, and you can damage the boiler.

Self-diagnosis

The process of operating heaters is simplified if they have a self-diagnosis function. Almost all European manufacturers have equipped their products with it.

For example, German Bosch heaters, displaying error codes on the display, allow the user to quickly understand the cause of the problem and take measures to eliminate it. If code A7 appears on the screen, it is clear that the hot water temperature sensor is faulty.

If A8 is displayed, the connection to the BUS bus is broken. This function greatly simplifies the use of gas equipment, making it easier and more comfortable.

Dangerous situations

The greatest danger is a malfunction associated with the operation of the burners. If the flame goes out, gas may accumulate in the room, which will subsequently cause an explosion. Reasons for the fire going out:

- gas pressure has dropped below the permissible norm;

- no draft in the chimney;

- the supply voltage has disappeared;

- The pilot light went out.

In an emergency, it is necessary to immediately shut off the fuel supply to the burners - automatically or manually. Modern versions are equipped with automation devices necessary for prompt shutdown of equipment. The operation of such devices is not only convenient, but also safe.

How to prevent gas accumulation indoors

Modern safety standards provide for the installation of gas analyzers in boiler rooms; they are necessary for signaling when gas appears in the room. A special electronic valve reacts to their signals, automatically stopping the flow of fuel to the burners.

Setting up the ignition device in a cauldron

How to set up the ignition device of a gas boiler?

To set up the ignition device of a Baxi or other gas boiler, you will need a set of tools:

- Pliers.

- Screwdriver.

- Keys.

- Multimeter.

- Alcohol.

Procedure:

- Remove the terminals, short and tighten with pliers.

- Turn on the pilot burner.

- Find out the resistance using a multimeter.

- Not 1-2 Ohms? Get a new meter.

- Norm? Clean the sensor with cotton wool and alcohol.

- Put everything as it was. Check if the ignition device is working.

What other safety regulations are there?

- Do not disassemble or dismantle gas appliances yourself.

- Handle the power cord carefully.

- Do not place foreign objects on the device.

- Don't stand on the boiler. Do not stand on chairs, tables or other unstable objects to clean the wall-mounted boiler.

- Monitor the coolant and add it to the system on time.

- Be careful - in some modifications the use of antifreeze is prohibited.

- If you smell gas, immediately turn off the gas and open windows and doors. Leave the boiler room and call the gas service.

In order for the operation of a household gas boiler to be safe and uninterrupted, the user must read the instructions for it in advance. By choosing models equipped with automation, the consumer increases the comfort of use and safety. By following the rules for the use of gas appliances in everyday life, for their installation and maintenance, the number of emergency situations can be reduced to a minimum.

Models of gas installations and their technical characteristics

Gas heating boilers of various modifications and manufacturers are collected on the website santechbomba.ru. For example and reference, the technical characteristics of several models are presented:

Gas boiler Daewoo GasBoiler DGB-130 MSC

The reliable and durable Daewoo wall-mounted double-circuit gas boiler has a modern, ergonomic design. A boiler with a closed combustion chamber has a convenient control panel with a display that displays digital values, set modes, and a simple interface. The heat exchanger for the heating circuit is made of copper. The boiler power is 15 kW, the efficiency is more than 90%, it is designed to heat a room up to 150 sq. m., good hot water performance. Compact dimensions and light weight make the model convenient for any room; the boiler does not take up space.

Gas boiler Baxi ECO 5 Compact 1.14 F

An Italian single-circuit gas boiler is ideal for an apartment with autonomous heating. The installation is wall-mounted, with a closed combustion chamber. The heat exchanger is made of copper, its service life is much longer than that of its aluminum counterpart. The boiler efficiency is almost 93%, the power is 14 kW, this model can heat up to 140 square meters of living space. The unit has an attractive design, an easy-to-use control panel with an LCD screen and weather-compensating automation. The model is equipped with built-in protections, smooth electronic ignition and the ability to connect to solar collectors.

Gas boiler Mimax KSG-20

The Russian-made floor-standing boiler is distinguished by its reliability and excellent performance characteristics. Mimax double-circuit boiler with an open combustion chamber. The high power of the installation - 20 kW and efficiency - 92% allows you to heat up to 200 sq.m of living space. High productivity of hot water. The weight of the unit is 62 kg, control occurs by increasing/decreasing power. The model has a 15-year warranty.

Gas boilers differ in power characteristics and performance; models have various built-in functions and protections. Gas boilers are selected based on the technical characteristics of a house or apartment, taking into account the capabilities and preferences of the consumer. A gas boiler must have a power reserve of at least 10%.

When choosing a gas installation for heating your home, you should not neglect safety. It is necessary to monitor the technical condition of the equipment, check the tightness of connections in circuits, chimney and gas supply systems. Compliance with simple requirements and proper operation will protect the house from emergency situations.

01.02.2022

Return to list