The boiler starts up independently after a long period of inactivity outside the heating season, the burner is turned off automatically or goes out during wind (if there is no automatic start), also after any repair work. The initial commissioning of a new gas boiler should be carried out exclusively by a specialist who will put the appropriate mark in the boiler unit’s passport. Without it, the boiler warranty is void.

However, even starting a previously configured boiler is not such a short process; according to the operating rules for hot water boilers, it requires a more thorough approach: proper filling of the system, bleeding of air, pressure testing and monitoring of indicators. All this is done to avoid problems and emergency situations during the heating season.

Gas boilers Koreastar Ace

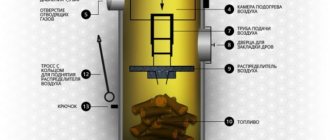

Korea Star in section.

The Ace series are double-circuit wall-mounted gas boilers, which are represented by two positions Atmo and Turbo. Externally, they are no different; the difference lies in the design of the combustion chamber. The Korea Star Atmo gas boiler is equipped with an open (atmospheric) combustion chamber, and the Turbo model is equipped with a closed (sealed) combustion chamber. In the first case, air to maintain the flame is supplied from the room, and in the second - from the street. Based on the characteristics of the combustion chamber, a chimney is selected. For atmospheric, a standard sandwich pipe insulated with mineral wool is suitable. A coaxial chimney is required for a sealed chamber.

The characteristics of the Korea Star Atmo and Turbo gas boilers are largely the same. Both boilers have the same power gradation from 10 to 32 kW. A pressure gauge and a manual control unit are installed on the front part of the housing. There is a built-in German Wilo pump with three speeds, and an anti-blocking system is also provided.

The heaters can be connected to a room thermostat and a remote control.

The casing can be painted white or silver. The heat exchanger is made of copper. There is a built-in bypass. Two-level protection against overheating of heat exchangers and an uninterruptible power supply are installed.

At the same time, the Turbo model has its advantages:

- possibility of working on natural and liquefied gas;

- three-way valve anti-blocking system;

- heat exchanger of the “pipe-in-pipe” type, which is treated with anti-corrosion from the inside;

- electronic flame modulation.

There are also some differences in the power of the DHW circuit. Thus, in all Koreastar Ace Turbo models from 10 to 20 kW, the heat exchanger power for hot water supply is 20 kW, and for Atmo series units this value is already 24 kW. The manufacturer provides a 2-year warranty.

Installation

Before installing the device, you should make sure that it runs on natural gas. If you plan to use liquefied gas, you need to readjust the heater - this should be done by a specialist. A power supply with parameters of 220 V/50 Hz must be supplied to the installation site of volatile models. Deviation of parameters from the norm leads to decreased performance and reduced service life.

It is prohibited to connect other electrical appliances to the boiler power source. It is also prohibited to use extension cords and adapters when connecting. Violation of safety standards may result in a fire.

Gas boilers Koreastar Premium

This series provides a similar protection system as in Koreastar Ace heaters. In this case, the control is already carried out by an electronic unit; on the front part there is a liquid crystal display and a pressure gauge. The line is represented by four positions:

Atmo are heaters with an open combustion chamber. In principle, they differ from the Koreastar Ace Atmo series only in the presence of an LCD display. Boilers with a sealed combustion chamber are available in power from 10 to 40 kW with a copper heat exchanger for heating and a steel one for hot water supply. The Turbo model has a Wilo pump, while the Turbo-K and Turbo-C have a Koreastar pump. In addition, the Turbo series is available in two colors (white and silver), while Turbo-K and Turbo-S are only available in white.

The method for insulating a chimney pipe with your own hands is simple. For work you need glass wool and foil.

We talked about how to properly insulate ventilation in this article.

The Turbo-K and Turbo-C models differ from each other only in that the former has a fan installed to remove high-power gases. Such units are designed specifically for apartments. The manufacturer provides a 3-year warranty on all Korea Star Premium boilers.

Solutions to Question 1

The boiler has a self-diagnosis system and fault signals appear on the display. Errors marked with the symbol A cause the boiler to block. In this case, the user must manually reset the boiler by pressing the RESET button. Errors marked with the symbol F cause a temporary shutdown of the boiler with automatic activation after the value that caused the error returns to normal values.

Accordingly, errors A01.

Corestar boiler error codes - troubleshooting instructions

Did the Corestar boiler show errors on the display? This means that the self-diagnosis system “detected” a malfunction. All modern heating equipment is equipped with automation - sensors that monitor the operation of each unit. Sometimes the user does not even need to contact the service center. It is enough to determine the meaning of the code and find the problem.

Gas boilers Koreastar Buran

There is only one unit in this series. The Korea Star Buran gas boiler is installed on the floor, it is single-circuit, does not depend on electricity and can work with open and closed heating circuits. Such units are called AOGV and are the simplest heaters. At the same time, they are very reliable and have earned a good reputation.

Floor models have a 5 year warranty.

Characteristics of Korea Star Buran:

- open combustion chamber;

- mechanical automation made in Italy (SIT);

- 15 power options from 7.5 to 100 kW.

The Buran model differs from the Koreastar Senator series in the heat exchanger material, which is made of steel. While in the Senator boiler the heat exchanger is made of high-quality cast iron. Buran can only run on natural gas. The gas pressure must be no less than 6 mbar, and the coolant pressure must be no more than 0.4 mbar.

Maximum temperature 90 degrees. When igniting, due to the fact that the coolant temperature is below 30 degrees, condensation may occur. This leads to corrosion, so the temperature of the water in the circuit should not be allowed to drop so low. Before the heating season, the device must be checked for serviceability, and if necessary, clean the heat exchanger and chimney.

- Content:

- Features and technical data of boilers

- Specifics of application and operation

- Tips and tricks for choosing

Despite its name, the Koreastar gas boiler has nothing to do with Korea. It is developed and assembled at the Wilo plant. Moreover, this is practically the only model among all European equipment that was manufactured specifically for Russia, taking into account the peculiarities of operation in domestic conditions.

The consumer is offered two basic wall-mounted Koreastar models - classic and bithermic type.

Premises requirements

The room in which gas equipment is to be installed should be equipped with fresh ventilation.

Moreover, door and window openings cannot be classified as such if they do not have devices that ensure constant air flow - fans, holes in the door leaf, etc. When the heater is put into operation, it is prohibited to carry out construction work in the room that could change the ventilation design, thereby affecting the volume of incoming oxygen. In the boiler room it is prohibited:

- Store flammable substances and materials.

- Store chemically active substances - chlorine, ammonia, acids, etc.

- Place heating devices and air conditioners near the boiler.

- Install equipment near stairs, in wall openings, near windows and emergency exits.

Features and technical data of boilers

What features do Corestar boilers have?

- Wall-mounted gas boiler Koreastar Premium - the classic design of heating equipment includes: two heat exchangers, a circulation pump, a closed combustion chamber, a safety group, and an automatic bypass valve. Mounted double-circuit gas heating boilers Koreastar Premium stably withstand voltage drops in the range of 15% of the nominal. DHW capacity 13.6 l/min. The maximum output is sufficient to heat 240 m².

The Koreastar ACE boiler has a double-circuit copper heat exchanger, made of the “pipe-in-pipe” type and has an anti-corrosion, heat-resistant coating. The design includes: a closed combustion chamber with a modulation-type pressurized burner. The Koreastar ACE 2-circuit wall-mounted gas heating boiler has a built-in anti-freeze function, an anti-blocking system for the pump and gas valve, and an automatic bypass circuit that protects the combustion chamber from water hammer. Maximum performance reaches 32 kW.

The flame does not ignite (general faults)

Pipe burnout

To organize the safe operation of the chimney, a steel pipe is used. However, it can overheat when interacting with combustion products and burn out. To avoid this problem, it is recommended to use a sandwich pipe, which will protect against overheated gases.

Chimney problems

There may be several problems associated with the chimney design. So, fallen leaves, snow can get into it, and the mouth can freeze over (in this case, the frequency of occurrence depends on the deflector, umbrella or other end). This requires cleaning the chimney or reshaping its fungus to allow smoke to escape unhindered. Below in the picture are options for “fungi” deflectors.

In addition, if the chimney is poorly insulated, the gases in it can form an air lock, since the cooled, cold gas is more dense and does not allow hotter gases to escape freely.

If the chimney is not insulated, strong condensation may settle inside it and freeze up during the cold season. Insulating the chimney will help solve the problem.

If foreign objects (house, tree) interfere with the mouth of the chimney, you will need to increase its height, cut off interfering branches, or otherwise remove the obstacle to the exit of smoke.

Weak supply ventilation

Organizing normal supply ventilation is very important for the proper operation of gas equipment. Thus, combustion requires oxygen, and combustion of 1 m3 of gas uses 10 m3 of air. If this air is not enough, then backdraft may form in the chimney, and ventilation will not be enough. The exhaust hood in the kitchen also contributes to weak supply ventilation if the boiler is installed in this room. Also, due to plastic windows there may not be enough air. The problem needs to be solved by proper installation of gas equipment and proper ventilation.

Specifics of application and operation

Judging by consumer reviews, Corestar boilers are productive and reliable equipment, which has its own certain disadvantages, which are inherent in all equipment with closed combustion chambers.

The model range of gas wall-mounted boilers from Koreastar has the following characteristics:

- High noise during operation is a consequence of the operation of the burner fans. Air intake and combustion products removal are carried out using a coaxial chimney, in a forced manner. All forced-air burners are noisy, so stations must be installed away from residential premises.

- DHW heating - hot water heating is carried out independently of the heating system. The presence of a three-way solenoid valve significantly increases the heating rate. A uniform supply of hot water is ensured, regardless of the pressure in the water supply system.

- Safety group - when the coolant cools down to a temperature of +5°C, the boiler automatically starts, preventing the heating system from defrosting.

- Connection to power supply - although the manufacturer indicates the ability of the equipment to operate despite voltage fluctuations in the network up to 15% of the rated power, practice shows that this is not always the case. The controller board can fail due to any surge in electrical current. Protection can be provided by the installation and installation of a UPS.

Possible startup problems

- The gas boiler slams when the main burner starts.

The most common problem, the cause of which is most often clogging of the igniter (dust, combustion products, etc.). It is recommended to call a specialist to clean it.

The reason may also be that the pilot flame is too low: below the main burner. When using electrode ignition, the electrode may be clogged or faulty. In rare cases, the cause may be excess gas pressure in the line. It is important to understand that slight, barely audible pops are characteristic of most models of gas boilers that do not have a sound insulation layer.

- Only the wick is lit and cannot light the main burner.

The reason may be the same clogging of the igniter or its incorrect installation, when the flame simply does not reach the main burner. Clean the pilot nozzle (it is advisable to entrust this to a specialist) and check the operation: its flame should reach the main burner and simultaneously “wash” the thermocouple. Sometimes the reason lies in a malfunction of the thermocouple, which does not open the gas supply.

Gas boilersInstructionsBoilers

Probable errors and causes of occurrence

This article contains all possible malfunctions and options for eliminating them, as well as error codes for Korea Star boilers. All information is read in the following order: code - name - possible malfunction. If you have any additional questions, please leave them in the comments to this article.

If you are not 100% sure what exactly the problem is and that you can solve it, immediately contact the service center to diagnose and fix the problem.

You can find out the price and buy heating equipment and related products from us. Write, call and come to one of the stores in your city. Delivery throughout the Russian Federation and CIS countries.

The design of Koreastar wall-mounted boilers includes the following components: circulation pump, primary and secondary heat exchangers, closed combustion chamber, automatic bypass valve, safety group. These elements can easily withstand voltage fluctuations of 20 percent and have a throughput capacity of approximately 13.8 liters / minute (hot water supply). Such devices can heat rooms of about 240 square meters. meters.

The equipment of some models includes 2-circuit copper heat exchangers, which are made using the pipe-in-pipe method. They have an anti-corrosion coating and are therefore resistant to heat. The units are equipped with special functions that protect them from freezing, as well as a pressurized gas burner with modulation. The anti-blocking modes of the gas valve and circulation pump protect the combustion chamber from hydraulic shock. Their maximum power is 35 kW.

Korea Star gas boilers are characterized by increased noise due to the use of a modulating supercharged burner. DHW supply is carried out independently of the heating system. An electromagnetic 3-way valve is installed in the hydraulic part of the unit, due to which the heating rate is maximized. Hot water is prepared regardless of the pressure of the heating system. If the temperature of the heating system drops by 5 degrees, the device turns on automatically, preventing the system from defrosting.

The unit is equipped with a self-diagnosis system, which notifies about malfunctions with symbols on the display. Errors marked with code A cause the unit to lock. In this case, you must manually reboot the device by pressing the Reset button. Errors marked with code F cause a temporary shutdown of the device with automatic restart after the parameter that caused the malfunction reaches the required values.

Error code A01 - No flame signal

Probable reasons: Gas is not supplied to the burner. The ionization ignition electrode is malfunctioning or not working properly. Gas valve malfunction. The electronic control board has malfunctioned.

- The shut-off valve is closed. It is necessary to open all shut-off devices installed on the gas pipe.

- During the first start-up, make sure that the air is bled from the pipeline. Check the gas inlet pressure before the gas valve. The nominal pressure value is 20 mbar (2 kPa).

- Check that the minimum and maximum gas pressures are within the recommended values.

- Adjust the Koreastar boiler for gas pressure.

- Check the ignition/ionization electrode for contamination.

- Make sure that there is a nominal gap of 3 ± 0.5 mm between the burner and the ignition / ionization electrode.

- Check the electrode cable for fur. damage.

- The gas valve needs to be replaced. Check the quality of grounding. There should be no potential on the unit body.

- Restart the device. If the error appears again, replace the electronic control board.

Error code A02 - False flame signal

Probable causes: Problem with the ionization ignition electrode. Faulty electronic control board.

- Check the ignition/ionization electrode wire for fur. damage and breakage.

- The ignition/ionization electrode touches the burner. Check the distance between the ignition/ionization electrode and the burner. Standard value 3.5±0.5 mm. Replace the control board.

Power setting

After starting the device, you need to press and hold for 5 seconds. buttons to adjust the temperature to enter the setting mode. Adjust the gas pressure by decreasing and increasing the pressure using the DHW adjustment buttons. While the setup is in progress, a number will appear on the screen. This board designation is the minimum power value in percent: 44–54. When the pressure gauge shows the required pressure value, press the RESET button, the parameters will be saved.

When setting the operating power, set the gas pressure using the buttons that regulate the heating agent temperature. The power percentage will appear on the screen: 0–99. Having set the required value, press RESET, save the parameters, exit the settings mode.

Inclusion rules

Connecting an open or closed type gas boiler is not as simple as it might seem, since this is not only a high-tech device, but also a dangerous one. There are too many connection options and circuits. The installation method and the order of connecting the highways are all individual. For this reason, it is recommended that the connection process, start-up and commissioning of gas equipment be carried out by an authorized service center.

In addition, if you connect a double-circuit or single-circuit gas boiler of an open or closed type yourself, this will void the performance warranty. However, situations are different. You should proceed as indicated in the instructions.

The algorithm for how to light a gas boiler will depend on the method of installation of the boiler. So, you can connect a wall-hung gas boiler correctly by proceeding as follows:

- Connect the device to the electrical network;

- Unscrew the gas valve and press the start button (the type with the name of this button is indicated in the operating instructions);

- Select the operating temperature using the plus and minus buttons.

Burners running on electricity are connected automatically after they have been switched to the hot water heating mode. The piezo type of ignition occurs by short adjusting the flame and pressing a special key.

Note! Switching on is blocked when air accumulates. It is enough to press the restart button and the boiler will be able to start working.

As for how to turn on a floor-mounted double-circuit or single-circuit open or closed boiler, this can only be done after the boiler room has been completely ventilated. The rest of the connection process is simple. First, you need to set the temperature selector to off mode, open the gas supply valve, and set the selector to piezo ignition. Then hold down the key for 5 seconds, press the piezo button and adjust the temperature.

Important! To prevent rupture of pipes and freezing of the system, you need to set the minimum indicator values before starting the boiler.

Circulation pump

This part requires special attention when starting the boiler. It is not uncommon for air to be found in it, and the pump blades slow down. An error icon will appear on the display. Before starting the boiler, it is important to carefully rotate the shaft yourself.

This can be done by removing the front panel, after which you need to unscrew the main bolt. After this, the shaft must be turned. An arrow will indicate the correct direction.

Circulation pump

At the top of the pump there is an air exhaust system. The small handle lifts up and the air comes out.

Floor-mounted boilers have more power than wall-mounted boilers. If you need to heat a large space, the best option would be the floor option.