Home » Classification of gas boilers » Operating principles » Features of ignition of different models of gas boilers

After purchasing and installing a new gas unit, inexperienced users may have a question about how to light a gas boiler. Please note that the first start-up should only be carried out by a gas service specialist. He can also give some recommendations on how to turn on and subsequently operate the unit.

…

- 1 Preliminary work

- 2 The process of igniting a gas boiler

- 3 Features of ignition of different models of gas boilers

- 4 Problems when igniting a gas boiler

Preliminary work

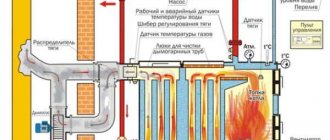

Before lighting a gas boiler, you need to check it for leaks - perform a pressure test. This can be done in two ways: by filling the system with water or using an air compressor. The process consists of the following steps:

- open the tap, which is responsible for filling the system with coolant;

- slowly fill the radiators with water until the pressure in the system reaches 2 atmospheres;

- close the tap and wait about an hour;

- if the pressure remains at the same level, then everything is normal; if the reading on the pressure gauge has decreased, there is a leak - you need to find it and fix it.

Checking the air heating system is advisable if you do not intend to use it in the near future.

This will eliminate the need to drain water from the system. If, after pressure testing, you plan to put the gas boiler into operation, it is better to immediately fill the radiators with coolant. Note! Checking the tightness of the heating system can only be carried out if the room temperature is above zero.

Before lighting an old gas boiler that has not been used for a long time, you should thoroughly rinse its heat exchangers, clean the burner device, and also wipe the body.

The heating system is flushed using pressurized water. It is advisable to rinse not only the old, but also the new heating system, since during the installation process debris often gets inside the radiators.

…

Find out here how to reduce gas consumption in a gas boiler?

Why doesn't the gas boiler light up?

Gas boiler does not reach temperature - causes and methods of eliminating them

Video on the topic

As a rule, we entrust the first start-up of a gas boiler and the work of setting up and adjusting it to specialists from service centers. Why? Yes, because without their mark in the equipment passport, the manufacturer’s warranty is simply not valid, and in the event of an early breakdown, we will simply be denied warranty repairs.

Whether this is actually the case is, of course, debatable. Specialists from the service center will find a million reasons to refuse you free equipment repair. And even if you get such generosity from them, your repair will last more than one week - either there are no spare parts, or the queue has not yet arrived, or it is wrong. This is a verified fact and it is very difficult to refute it. If you want a quick “warranty repair”, pay both for spare parts and for the work of the technician.

By the way, in order to put the boiler under warranty service, you also need to pay money. So what is this guarantee? Pay for the warranty, then pay for parts and repairs. So where is the free warranty service? That is why, since you already have to pay for everything, I suggest you independently start up the gas boiler for the first time and set up the heating system. Moreover, it is not difficult.

Filling the heating system with water

We look under the bottom of the boiler - where all the pipelines are connected, and look for something like a small valve there. For each model of gas boiler, it can have a different shape: one manufacturer makes it in the form of a valve that is familiar to us, another - in the form of a rotating plastic pin. In general, their form does not change the essence - as a last resort, open the instructions and look at its location.

We open this tap, not completely (so that air does not hang anywhere in the pipes, it is better to fill the system slowly) and direct our gaze to the pressure indicator - the pressure gauge. As a rule, most boilers of this type have an operating pressure from 1 to 3 Atm - read the instructions for more details. We wait until the pressure gauge needle reaches 2.5 Atm and close the valve.

Now the boiler will have to be left alone for a while - air must be removed from each installed battery or convector.

For these purposes, each heating device must be equipped with a Mayevsky tap. We open it and wait for the air to drain and water to run out. The water started flowing and Mayevsky’s tap was turned off. This procedure must be done with each battery. Did you do it?

Now we return to the boiler and look at the pressure gauge again - the pressure in the system should drop. We adjust it, add water if necessary - the optimal pressure at which the boiler operates normally is 1.5-2 Atm. If you pump more, then during operation at a high coolant temperature the excess pressure will be released. This is due to the fact that when a liquid is heated, its pressure increases.

First start of a gas boiler

Having completed all these simple preparations, you can begin to directly start the boiler. Open the gas valve and plug in the boiler. All sorts of symbols and numbers appear on the screen, but for a full launch you still need to perform some actions.

First, press the power button and set the temperature control knobs to the operating position. After these steps, the boiler will begin to make futile attempts to turn on - this is normal and there is no need to be alarmed. The most important thing is that the circulation pump is turned on, inside of which for some reason there is always air that prevents the boiler from fully turning on. It is its removal that needs to be done as quickly as possible.

We remove the front cover of the boiler - in almost all cases it is secured with two or four screws. We fold back the dashboard, behind which the circulation pump is hidden.

In the center of the pump there is a wide screw with a slot for a screwdriver. This is the one you need to unscrew a little, and when water runs out from under it without air bubbles, tighten it again. Only now will full circulation of the liquid in the heating system begin, and the boiler will start working.

At first it will gurgle and make some strange sounds, but this is only for the better. Just know that all these sounds indicate that the remaining air in the system is being forced into the expansion tank, where the automatic air valve releases it to the outside. Five minutes will pass and the system will return to normal - the pressure will stabilize, and the gurgling sounds will subside. And after another five minutes you will already be enjoying warmer radiators and an unlimited amount of hot water in the tap.

That, in principle, is all you need to know in order to start up a gas boiler for the first time. The boiler is working, the batteries are getting warmer, and I think you can figure out how to regulate the temperature of the batteries and hot water in the tap yourself - read the instructions, everything is clearly described there regarding the control of your specific boiler model.

Did you find this article helpful? Subscribe to site updates to receive the latest articles about renovation and interior design before anyone else!

Yes, yes, this is exactly what you thought... A wonderful series of computer (and later not only...) books, Simple and understandable, which was very useful to many.

Your new home has taken good care of you all winter. Saved from bad weather, protected from precipitation, wind, cold... But the sun warmed up, and the winter snowdrifts had long since disappeared. May. It's time to turn off the heating in the house. But as? Here in the boiler room there is so much stuff that can be opened, closed, switched, turned off... It’s almost like an airline pilot :-) What to do? Should we quickly look for the phone numbers of “those guys” who installed the boiler and call them for help? Oh no. This is not our choice. If part of your life is your own home, and if your home is not part of a cottage community, you will have to be an electrician and a plumber and many many others... Well, if you are not a “pro,” then at least be a “teapot”, but one that you can manage yourself with your own home. So let's get back to our problem. Summer is knocking on the door. It's hot outside. It is necessary to turn off the heating in a private house. But as? First of all, we determine what kind of boiler we have in our house. This can be done, for example, by simply looking at the documents that exist for this boiler. If the boiler is double-circuit, then everything will be quite simple - you just need to switch it to the “summer” position. What exactly needs to be pressed and turned for this - read the instructions for your boiler - everything is written there simply and clearly. (For reference. A double-circuit boiler works something like this - the coolant circulates in a circle through the pipes and radiators and “looks” at the temperature of the coolant - if it becomes less than what the owner (or the temperature sensor) set, it ignites the gas and heats it. If the owner of a double-circuit boiler turned on hot water - the boiler “stops” caring about the temperature of the coolant in your heating system and devotes all its efforts to only one task - heating cold water in order to make it hot and give it to the owner. Well, that is, if we take it to the extreme - if It’s frosty outside, and the owner of a double-circuit boiler is actively draining hot water from the tap hour after hour - he risks freezing the whole family. Priority of hot water supply - this is the clever name for this behavior of a double-circuit boiler.) It’s a completely different matter for those owners who have a single-circuit boiler. I’ll tell you a terrible secret - a single-circuit boiler has only one circuit :-) Inside a single-circuit boiler there is simply no separate circuit that would be occupied only with heating and which could simply be turned off for the summer. But how is it possible that a single-circuit boiler, having inside itself only one coolant circulation circuit, still manages (and is much more effective than a double-circuit boiler, with its misanthropic “priority of hot water supply”) to drive hot coolant both through the radiator system and through the hot water supply system ? It's simple. Yes, inside a single-circuit boiler there is one single circuit, but outside the boiler, with a system of external pipes, valves, circulation pumps, etc., from this single circuit you can create as many different circuits as you like. Well, that's just it. Imagine: here the coolant, heated by the flame of the boiler, runs through the pipes - along the only circle that a single-circuit boiler has. The hot one ran up the pipes, ran around all the heating radiators, gave all its heat to the house, the cold one ran back into its single-circuit boiler, warmed up, ran up again... He was bored. He runs and runs in the same circle... How to “pinch off” a piece of this flow circulating through the heating system, in order to not only heat the house but also heat the water, with this “pinch off flow”? Yes, it’s clear how. Very simple. We cut the tee into the heating circuit. That's it, now the coolant, having reached the tee, will split into two directions - one flow, as before, will run through the heating radiators - giving off its heat to the house, and the second flow will run into the hot water supply system. Ugh. Well, we finally got to the hot water supply system of a single-circuit boiler. But in fact, there is almost nothing to tell about it... A hefty barrel into which cold water flows through pipes, and inside this barrel there is a “spiral-coil” pipe through which runs the part of the hot coolant flow that we have “pinched off”. That's all. The hot coolant, running again and again inside a barrel of water, each time gives up and gives up its heat to this water - trying to heat the water to the temperature of the coolant. This “magic barrel” in the hot water supply system is called an indirect heating boiler (or, more simply, “water-water boiler”). And that’s all, the heating system, the hot water supply system... The boiler, the pipes, the radiators, and now there’s this “water-to-water” boiler. The whole system, or what? Well, almost... Here, at home with you and me, how can I say this..., well, “they are not small.” It’s usually hard for the coolant to rush around these endless and, as a rule, long circles - until you run from the boiler room to the farthest room... and you still have to run back to the boiler to “warm up”... but you don’t have the strength... Here. To help the coolant move, electric circulation pumps are installed into the pipes. I turned on such a pump and it “like a taxi” moves the coolant through the pipe. Such a circulation pump is located in the same heating circuit (where, until the tee was cut in, the coolant was running alone) and such a circulation pump is located in the pipe of that “pinched off” flow that runs in the boiler. In addition, in these heating and hot water supply systems there are “safety groups”, expansion tanks, many many (often depends on the flight of fancy of those guys who installed these systems in the house :-) taps, and something else that is not mentioned this topic... So true. So far everything is elementary simple. A single-circuit boiler works and heats the house and heats the water and, most importantly, now we already know how it does it. Having thought a little, we understand that there is no way to turn off the boiler itself for the summer - it is necessary to heat the coolant in the “pinched off” flow, otherwise the water in the boiler cannot be heated. This means that in order to turn off only the circulation of coolant through the pipes and radiators of the heating system for the summer, you just need to turn off their valve - so look for and turn off such a valve on the main thick pipe going up from the boiler - look somewhere above the “pinch off into the boiler” "tee), while the valve that you will find standing immediately after the "pinch off tee, but not on the main thick pipe going up, but on its side branch (this valve determines how much or little to "pinch off" into the boiler) - on the contrary, We need to open it completely for the summer. All. Now the circulation through your heating circuit is turned off and the house is no longer heated. The circulation along the hot water supply circuit is completely open, which means there is hot water in the house in the summer. Once you have determined where and what kind of valve you have installed and once you have switched from winter to summer, don’t be lazy, write it down in detail in your own “house book” - believe me, you will use it more than once..

There are some important nuances of the operation of a single-circuit boiler on a usually “short” hot water supply circuit, but I’ll talk about this in my next post.

In the last article we talked about it, but besides this, an important point is its launch. In order to perform the first start-up of the boiler, it is not necessary to invite specialists from the service center. Judge for yourself, this condition under which a brand new boiler is put under “free” warranty service is not worth a penny - anyway, in the future, if a breakdown occurs, you will have to pay for both spare parts and the work of the technician.

So what kind of free warranty repair can we talk about? Moreover, for the first start of the boiler

They will also charge you a fee, a considerable one at that, motivating it for commissioning work. Don't want to waste money? Then read on and learn how to start the boiler yourself and debug the heating system, especially since it’s not difficult.

The initial stage, which involves the first start-up of the boiler, is filling it with water. I think you can definitely cope with this task without outside help. We look under the boiler, where all the communication pipes are connected, and look for something resembling a faucet there - it can be made in the form of a lamb we are familiar with, or it can be a flag or simply a rotating pin. In any case, it is difficult not to recognize it, but if something happens, its location can be determined by looking at the instructions for the boiler equipment.

Found it? We slowly open it, fill the system with water and wait for the pressure indicator on the boiler to reach 3.0 atm, and while the system is filling up, we go and check all the pipes and batteries for leaks. And along the way, we immediately eliminate them - tighten the nuts and close the open Mayevsky taps.

After the pressure in the system has reached 3 atm, we turn off the make-up tap, go through all the batteries one by one and use the Mayevsky tap to bleed the air from them. We return to the boiler again and add water to the system until the pressure indicator on the boiler shows 2-2.5 atm.

Well, the system is dialed up, you can directly start the gas or electric boiler, in principle, there is no difference in the process of starting them. To do this, you will have to disassemble the boiler a little - don’t be afraid, we won’t go anywhere where something can be broken. Our task is to get to the circulation pump - it is it, or rather the air accumulated in it, that is the reason for the boiler equipment not turning on when first started.

The location of this pump is easy to see - it is a cylinder, located with its end facing us, in the center of which there is a wide screw with a slot for a screwdriver. This is exactly the screw we need.

Found this stumbling block? Then you can turn on the boiler and set the necessary levers to the operating position - from this moment the first start of the boiler

. Immediately after the boiler receives its energy supply, the circulation pump will turn on and the electronics will make futile attempts to turn on the rest of the equipment. It is at this moment that there is no need to rush; slowly unscrew the central screw of the circulation pump and release the air from it.

As soon as water flows from under the screw, quickly close it and calmly watch the noisy operation of the boiler. Now the electronic gas supply valve will open, the electronic ignition will work and the boiler will start. It will gurgle, grunt, and make some strange sounds, but this is normal - the boiler is simply expelling air that is stuck in some places from the heating system. The design of the boiler equipment includes a so-called expansion tank, which is equipped with an automatic air release valve - it is through this that the remaining air is removed.

After a few minutes, when the operation of the boiler has stabilized and the gurgling sounds have subsided, we check the pressure in the system and, if necessary, bring its value to 2-2.5 atm by opening the water supply tap to the system. At first, while the heating operation is just getting better, the system can be refilled with water several times - you will have to periodically check the pressure gauge readings and, if necessary, replenish the volume of water in the system.

Well, we figured out how to start the heating boiler, the equipment is working normally, the batteries are starting to get warm - it’s time to start debugging the operation of the entire system.

The process of igniting a gas boiler

When the preparatory activities are completed, they proceed to starting the gas unit. Manipulations for igniting a gas boiler depend on what type of ignition is installed on it: piezo or automatic.

Most modern gas boilers, for example, such as Beretta, Ferroli, Bosch, are equipped with automatic ignition and can be easily ignited by pressing one “Start” button. Before doing this, do not forget to turn on the unit to the electrical network and open the gas valve. Temperature adjustment is usually done using the “+” and “-” buttons. The unit does not always turn on instantly; sometimes you need to wait a few seconds for it to light up.

Piezo ignition is a little more difficult to implement: you will need to press the flame regulator and hold it for a while, and then activate the piezo button. Many domestically produced units are ignited in this way: ZhMZ, Lemax, AOGV, etc.

…

If a gas boiler is controlled using a remote control, then it always has a “Start” button, when pressed, the unit will ignite.

Note! Do not light a gas boiler if you smell gas in the room.

Service

Buderus boilers are serviced by specialists from service organizations.

It must be done annually; the necessary procedures include cleaning the heat exchanger, removing soot from the chimney, inspecting and adjusting the contacts of the control board.

It is not recommended to perform independent maintenance of the boiler; you can only clean the body of dust or soot that appears on it during operation.

IMPORTANT! Carrying out any work on your own is regarded as termination of the warranty agreement by the owner, therefore, for repairs or maintenance, you must use the services of technicians from the warranty workshop.

Features of ignition of different models of gas boilers

Different models have their own ignition features. For example, before lighting a gas boiler Aton or Danko, you should set the regulator to the icon with an asterisk and hold it there for 5-10 seconds. After this, you need to press the button next to it.

How to light a gas boiler AOGV? When the boiler is turned off, the control knob is in the “dot” position. To ignite, it is switched to the “spark” mode and held in the pressed position until it stops. At the same time, activate the piezo ignition button until the burner ignites. If necessary, press the piezo several times. After the flame appears in the burner, hold the handle for about 10 seconds until the thermocouple warms up.

Another option is how to light a Lemax gas boiler. It has a main burner and a pilot burner. Initially, the handle is in the “dot” position. To light the boiler, turn the handle to the “spark” position and hold it for 10-60 seconds. At the same time, press the piezo ignition button until fire appears in the pilot burner. If after releasing the handle the flame goes out, you should repeat the manipulations again, but hold the handle longer. To immediately turn on the main burner of the Lemax boiler, you need to turn the knob to position 1.

How to set up the heating system after starting the boiler

Heating system adjustment

To set up the heating system, we will need to carry out minor manipulations with the control valves. The fact is that almost all installation schemes for individual heating systems have one small drawback - the last batteries from the boiler, as a rule, do not have enough thermal energy. It simply does not reach there in the required volume and we will need to eliminate this deficiency by evenly distributing the supply of hot water between all heating devices.

This is not difficult - the control taps of the first two or three batteries need to be tightened a little. If you go from the boiler, then the tap of the first battery is turned halfway, the second a little less, and the third even less. Here you will have to experiment - it may take several days to achieve uniform heating of all batteries. But this no longer matters, because in general the heating system works normally, and the house is warm.

How to start a heating boiler

This is how, without any effort, the boiler is started for the first time and the heating system is set up. As you can see, there is nothing complicated about it, and it is not worth the money that service center representatives charge for it. Better spend it on purchasing an electronic room temperature control system - this programmer will reduce the energy consumption of a wall-mounted heating boiler!

(Votes: 3)

Problems when igniting a gas boiler

In some cases, when igniting, the operation of the gas boiler is blocked. You can unlock the device by pressing the “Restart” button.

Often the cause of blockage is excessive accumulation of air masses in the heating system.

In this case, it is necessary to remove excess air from the radiators. To do this, a Mayevsky tap or automatic valve is installed in the upper fitting of each of them. In the first case, you will need to place a basin under the tap and open it - air hissing along with a small amount of coolant will come out of the battery. Carrying out similar manipulations with each radiator will allow you to release excess air from the entire system. In the second case, the automation itself will release excess oxygen. Note! The release of air masses is accompanied by a drop in pressure in the system.

Sometimes the ignition of a gas boiler is blocked due to problems with the circulation pump - a corresponding error is displayed on the screen. Sometimes air accumulates in it, as a result of which the blades do not rotate freely and become jammed. Then you need to turn them manually. To do this, remove the lid of the gas boiler, find the central bolt and unscrew it, then turn the shaft in the direction indicated by the arrow. There should be an air vent above the pump. Its lid is pulled up and the air is allowed to escape.

Ignition may be blocked due to the fact that sufficient gas is not supplied to the burner. In this case, check whether the gas valve is open, whether the gas pipe is clogged with anything, and whether there is gas in the line.

After the first start-up, the heating system may make gurgling sounds for some time. They are produced by air bubbles, since it is impossible to get rid of all the excess oxygen immediately. This is not a malfunction, the air will gradually leave the system and the sounds will disappear. Further operation of the gas boiler is described in the attached instructions.

All main error codes and their interpretation

Let's look at the main error codes for Buderus boilers:

| Code | Decoding | Ways to fix the problem |

| H11 | Problems with the DHW temperature sensor | Check the contact group, determine the functionality of the sensor, and replace if necessary |

| 2P | Coolant overheating | Check the contacts, determine the condition of the circulation pump |

| 3A | Fan stop | Check the contacts, replace the fan with a new one |

| 4C | Heat exchanger overheating | Stop the boiler, check the functionality of the circulation pump and the extract air temperature sensor, call a technician |

| 4U, 4Y | Short circuit or break in the forward line (supply) temperature sensor | Check the condition of the sensor and contacts, clean and reconnect them, if necessary, replace the sensor |

| 6A | No flame | Check the presence of gas in the system and in the boiler equipment, call specialists |

| 3C, 3L, 3P, 3Y | Fan failure | Check connection and functionality, replace |

| 6C | The system sees a flame on an idle burner | Moisture on contacts or control board, poor ground contact |

Recommendations for use

- If the gas valve malfunctions, it is necessary to check it and adjust the settings. If the heat exchanger is covered with a large layer of scale, this greatly reduces heat transfer and significantly increases fuel consumption. In such a situation, the boiler makes a cracking or noise. This occurs due to the accumulation of salts, which slowly fall off the surface over time, which is why the noise is heard. They can be removed using special reagents.

- Often you have to deal with components wearing out too quickly. The main reason for this is timing. In this case, the gas boiler can automatically turn on and off. When the water in the circuit cools down, a signal is received from the thermostat that the water has cooled, in which case the boiler turns on.

To learn how to choose a gas boiler, see the following video.