Long-burning boilers have high heat transfer and produce a softer, more even temperature.

But they also have a significant drawback - their high price.

Therefore, it makes sense to try your hand and make a stove yourself.

If you decide to make a long-burning solid fuel boiler with your own hands, finding the drawings is half the success. But first, let's figure out what basic structures exist.

What kind of solid fuel boiler can you make with your own hands?

You can make almost any boiler at home, because everything is done by people.

But some parts can only be completed in the factory.

Therefore, it is important to evaluate your experience and capabilities (tools, materials, time).

And understand the main types of heating devices and their features. By increasing degree of complexity, boilers can be divided into:

- Conventional boiler-furnaces with a hob, a water jacket on the sides and grates.

- Vertically located shaft-type units with combustion occurring from above.

- Pyrolysis boilers.

Classic solid fuel boilers with the usual combustion method

The most striking representative of such boilers is an ordinary stove, only made of steel. The fuel is placed on the grate and burns, heating the water circuit with a flame.

To increase the efficiency of a conventional boiler, turns are made, pipes are welded across the chimney to allow coolant to pass through, etc. They can be horizontal or vertically directed.

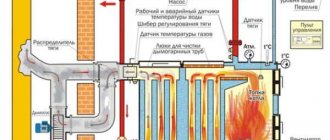

Construction of a long-burning boiler from the inside

Horizontal fireboxes are usually lower and have a cooking surface on top that transfers heat directly into the room. Structurally, it is possible to connect such boilers with a brick pipe or wells of a classic furnace, which significantly increases their heat transfer.

Brick wells that conduct hot flue gases not only increase the efficiency of the burned fuel, preventing the gases from flying directly into the street, but also serve as heat accumulators.

Mechanism of operation

There are various types of solid fuel boilers and heat exchangers for them, which can be designed independently. Vertical and horizontal brick structures are popular. They work as follows:

- By burning fuel, the air is heated and, rising, is discharged through the chimney.

- When moving, the heated air transfers heat to the heat exchanger, which, in turn, heats the water.

- H2O circulation occurs (cold water is replaced by hot water).

There is another type of heating device - a brick mine boiler, the distinctive feature of which is the loading of fuel through a special hatch. For its construction, rectangular heat exchangers are used, which are made of sheet metal, equipped with several rows of vertical pipes that pass flame and heated gas through them. This type of boiler allows you to change the combustion duration by adjusting the height of the loading area (shaft) and air supply.

Top combustion boiler

Its very name suggests that here the combustion process proceeds in reverse: from top to bottom. This is done to slow down the burning of fuel, since the flame usually goes up and ignites all the wood at once.

So, the design of this device: a vertically standing pipe, or rather two large-diameter pipes that fit into one another. Between them there is a water jacket.

To supply air, this design has a telescopic pipe, which rises up before adding fuel and descends with it as the wood or coal burns. To make this design you will need:

- Pipes for housing with a diameter of 450 and 400 mm.

- For an air preheating chamber with a diameter of 280 and a length of 350 mm.

- For a telescopic supply pipe, sections of approximately 300 mm in length with such a diameter that they fit into each other are 89 mm, 76 mm, and 60 mm.

- And thick sheet metal for making doors; for a pancake that presses on the fuel and transfers air to it for combustion; to cover the top and bottom of the boiler, etc.

- The door for storing fuel measuring 250 x 210 is located at a distance of 579 mm from the base. At the very bottom there is another smaller door for cleaning. Grate bars are not provided in this model.

The “pancake” design is a hollow part made of two identical washer-disks with a diameter of 300 - 350 mm. The discs are welded around the circumference with a steel tape, so that air gets inside only through a 60 mm supply pipe. And to supply air to the firewood, many holes are drilled in the lower part of the disk.

Long-burning boilers are an order of magnitude more expensive than their short-burning counterparts. To save money, you can assemble the structure yourself. Do-it-yourself solid fuel long-burning boilers: materials for manufacturing and operating features.

Read about how to properly design a roof heating system here.

If you decide to build a two-story house, then to make it warm and cozy, you need to properly organize the heating system. In this article https://microklimat.pro/sistemy-otopleniya/montazh-sistem-otopleniya/sxema-otopleniya-dvuxetazhnogo-doma.html you will learn what schemes are used for heating a two-story house and what is unique about each of them.

Option made of brick and metal - cheaper and simpler

The use of brick will make it easier and cheaper to create a bottom-burning mine boiler. We make only a vertical type heat exchanger from metal. It can be made

- from sheet material;

- from sheets of metal with pipe insertion;

- only from pipes.

The highest efficiency is a purely pipe heat exchanger, but it is also the most difficult to manufacture. The appearance is shown in the figure, the dimensions are selected by the manufacturer.

We lay out the ash chamber on a solid concrete foundation and install a grate. We install a heat exchanger and lay walls around it using high-quality bricks. When laying, we install two doors. The lower door is placed so that you can ignite the fuel and clear the firebox and ash from ash. You can install two separate doors instead of one large one. The upper door is used for loading firewood and coal; it can be placed on the front of the boiler, or on top in the form of a hatch.

The figure below shows a general view of a mine boiler with brick walls.

A few notes on the laying of brick walls of the boiler and installation. A cladding thickness of half a brick will be sufficient. We set the heat exchanger so that the hot water outlet is at the highest point. This will prevent the creation of air pockets and improve water circulation. The laying is carried out with bandaging of the seams, rising 2–3 cm above the exchanger. We lay out the chimney from brick or install it from metal.

Mine type

They are distinguished by their considerable height (can reach one and a half meters).

The firewood is stacked to its full height, ignited from below, where the combustion process occurs, and the flame torch is directed to another section, connected at the bottom to the main boiler.

The combustion products, passing further through the heat exchanger, cool and are removed into the pipe.

This boiler design allows the use of pyrolysis combustion. To do this, a damper is installed that limits the air supply and is connected to a draft and temperature sensor. And in the second chamber, when air enters, combustion of the released gases occurs.

Mine-type boilers cope well with wet firewood and sawdust. We can say that this is an ideal option for wet firewood.

Procedure for assembling a shaft-type boiler, step by step

Suitable for manufacturing is steel with a thickness of at least 4 mm, preferably heat-resistant.

Elements of the inner side of the firebox and heat exchanger are installed on the base and secured in several places. Then the back wall and supports for the grate are installed. The diagonals are carefully checked, and only after that the parts are finally welded. After this, the heat exchanger pipes are installed.

Drawing of a shaft-type boiler with measurements

The next step is to assemble the outer side of the boiler, which is both the water jacket and the lining. The outer side is welded in a circle through spacer studs, so as not to swell and wave.

The chimney is led out through the rear wall so that a door can be installed on top for cleaning the second chamber. In total, there are three doors:

- Ash pan, for cleaning slag ash and providing air access.

- Furnace room, for loading firewood and sawdust (more convenient from above).

- For cleaning the second chamber and replacing the brick (top).

The secondary chamber is sometimes lined with brick; it heats up and helps burn off the gases coming from the firebox.

It is also important to consider:

- Incorrect design will result in the unit smoking when adding firewood.

- This design is more suitable for installation in a boiler room separated from the living space.

- Since firewood must sink under its own weight as it burns, it is important to stack it correctly. Otherwise the combustion stops.

- If you plan to use sawdust, then you need to load it on top of the burning firewood (and it is advisable that the sawdust be dried). But coal is extreme for this model.

- In all seams and joints, the metal is applied with an allowance of 5 mm. This allows for better welding of the part on both sides.

- At the end of the work, you can go over all seams with welding sealant.

If you install a mine boiler that is too powerful, you will have to limit the combustion force by cutting off the air supply, and this will lead to the formation of a large amount of condensation, which makes it difficult to clean the internal surfaces and reduces the service life of the iron.

Foundation for a cast iron structure

creating a foundation

The foundation has another property - it protects the floor covering and the floor structure itself from the influence of elevated temperatures. An excellent material would be liquid brick or so-called rubble. These elements do not perceive temperature, and therefore do not accumulate heat. To create an additional foundation with your own hands, you only need a monolithic slab made of these materials.

This design is replaced by legs that are welded to the bottom of the boiler. In order to hide them from prying eyes, it is recommended to cover them with bricks.

In this simple way you can create a boiler with your own hands. The only requirement for builders is to study the drawings and materials. Careful study of the video will allow you to get answers to important questions, understand the essence of the work and its specifics, and obtain the final version of the ideal product for heating the room on an ongoing basis or during a visit to the dacha. If you make a cauldron correctly, it will warm not only the body for a long time. But also the soul. After all, every master should be proud of his creation, whatever it may be.

With pyrolysis combustion of solid fuel

A pyrolysis boiler is similar to a regular mine boiler, with a grate and the usual ignition of wood from below.

But it is characterized by the fact that the fuel does not burn in it, but smolders, releasing gas, which later burns separately (thanks to the supply of secondary air).

Such a unit has a water circuit both in the combustion chamber and in the afterburning chamber.

It is equipped with a draft sensor, dampers for adjusting the air supply and, in some models, a fan for pumping it up. A properly configured heating device has a high percentage of heat transfer.

A pyrolysis boiler requires dry fuel - ideally if the humidity is up to 10%.