In order for heated water to fully circulate in a closed system, a certain pressure is needed. Typically for domestic boilers these values range from 1.5 to 2 bar.

A decrease in these indicators leads to the fact that the coolant does not have time to heat up and move through the system, creating an impressive temperature difference at the inlet and outlet. This leads to automatic shutdown of the boiler and termination of the heating system. Let's look at why this happens and how you can deal with the problem step by step.

How to check the pressure?

Pressure can be checked using a pressure gauge

Each boiler has a pressure gauge that displays the pressure of the heating system. The initial setup is carried out by a representative of the company with which an agreement was concluded for the installation and maintenance of gas equipment. As the temperature of the coolant increases, the pressure also increases. If gas is added, but the pressure does not increase (the system itself does not maintain the set pressure), then you need to look for the reasons.

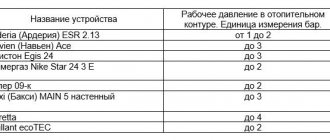

The pressure sensors in each boiler are different, as are the recommended parameters. In the instruction manual you can find all the recommendations regarding the normal pressure gauge values.

The control sensor can be displayed on a common display or located inside the structure. In any case, it performs the only function - monitoring the pressure in the system, and if it is low, then heating, or rather the lack of heat, will make itself felt.

Devices that control water pressure

In order to control the optimal liquid pressure in a gas boiler, pressure gauges and thermomanometers are used. Gas boilers contain various elements that are responsible for regulating the parameters of the equipment and maintaining it in working condition. This system operates under constant monitoring. Some systems use electronic sensors instead of conventional dial gauges. They are needed to transmit and receive information to an electronic unit, which processes it and displays it on the screen. Another approach is also possible - if the heating unit does not have a pressure gauge, it is equipped with a safety group.

Thermomanometers

Security group nodes

The following security group nodes exist:

- Pressure gauge or thermomanometer - for monitoring temperature and pressure in the heating circuit;

- Automatic air bleeder – prevents the circuit from becoming airy;

- Safety valve - relieves coolant pressure when it increases excessively.

Open make-up tap

If the heating system does not have an expansion tank and water is filled directly from the water supply, it is important not to forget to close the tap. As soon as the pressure in the system has reached the required level (depending on the boiler), the tap valve is closed.

What happens if you don't do this? As long as there is water in the water supply, pressure is created in the system and everything is fine. Once you turn off the water supply, it can leave the circuit through an open tap, which will lead to the boiler stopping.

The situation is similar with double-circuit boilers. The lack of water when the tap is closed is hardly noticeable, but if you open the hot water valve, the coolant will leave, which will lead to a sharp drop in pressure.

Norm and control

After some time, the operation process may cause malfunctions in the operation of the boiler. This occurs due to the negative impact on the heat supply system. Such a negative influence can be called both excessively high and low pressure, measured in atmospheres. In this case, the normal level is 1.5-2 atmospheres. Why does the pressure in a gas boiler drop?

If we talk about private households, here, as a rule, autonomous heating systems powered by single-circuit and double-circuit boilers are used. Double-circuit boilers have become especially widespread. In addition to heating, such units provide water heating. One circuit in them heats the coolant circulating through the pipes, and the other ensures the operation of the hot water supply system.

How to recognize?

The sequence of actions is as follows:

- Check for cold water in the pipeline.

- Pay attention to the smell of hot water (when using a double-circuit boiler). If it smells unpleasantly of rust and mustiness, and has a yellowish or gray tint, then this water is definitely from the heating system.

- Check whether the tap valve for recharging the system is closed.

Expert opinion

Grebnev Vadim Savelievich

Heating system installer

You also need to check the serviceability of the feed tap itself. If the pressure in the system does not change when it opens and closes, then the mechanism needs to be replaced.

What can lead to traffic jams in the circuit?

The importance of air vents cannot be overstated. Traffic jams in the circuit can lead to different processes:

- circulation disturbance;

- pressure surges;

- reduction in the efficiency of heating equipment;

- corrosion of metal.

Autonomous air vent

Installing an air vent in the heating system prevents the formation of plugs and pockets. When bumping into them, the coolant stops. Sometimes plugs cut off entire sections with radiators from the circuit. At the same time, the pressure in the system increases. When it reaches a critical level, an emergency release of coolant occurs. This, in turn, leads to a drop in pressure. At the same time, there are many cases when air collected in the batteries, the circuit continued to work, only half of the radiator became cold. This significantly reduces the heating efficiency and slightly increases the cost of its operation.

For open systems, one of the most serious threats is rust. At the same time, the question of how to remove air from the heating system arises only at the design stage. Such circuits are assembled at an angle from pipes with a large diameter, so there is a lot of water in the system. Considering the fact that the coolant is in contact with air and draws it into circulation, the oxygen level in the pipes is more than sufficient. Since it takes a long time to remove air from the heating system, oxygen reacts intensively with the metal. The result of the interaction is the formation of corrosion on the inner walls of the pipes. Rust sometimes eats up the tank so much that you have to replace it.

The direct consequences of traffic jams in the circuit entail indirect ones, which are no less dangerous:

Occurs if the valve for bleeding air from the heating system and all sensors are in good working order and working correctly. Due to the increase in pressure, an emergency release of the coolant occurs, which leads to a decrease in its quantity in the circuit. After cooling, there will not be enough fluid in the system, and the pressure will drop sharply. If it does not correspond to the minimum required to turn on the boiler, the heater will not turn on. And from this moment in winter, the countdown begins when the pipes defrost. Depends on how insulated the house is. Sometimes this happens in just three hours. In this case, unpleasant news awaits you at home from work;

This occurs if there is a malfunction of the valve for bleeding air from the heating system, or the temperature-controlling equipment. An unlikely situation, although possible. The results of this are very disastrous. At best, repair or replacement of the boiler; at worst, injury; rupture of the circuit and release of the hot water fountain.

A very likely situation is that the joints may not be tightened enough. As the pressure increases, they cannot withstand and crack. At the same time, hot coolant flows from the pipe like a fountain. Not only does the circuit need to be repaired, but the neighbors also need to repair the ceiling, since you flooded it thoroughly. This is the kind of chain that can be caused by simply airing the system.

Coolant leak

System depressurization

A leak involves depressurization of the system at any part of it (especially at the joints), which leads to the release of water and a decrease in its quantity. This leads to a drop in pressure, which can be restored by replenishing the deficiency. The problem is often encountered by owners of aluminum radiators, which quickly oxidize during operation.

The most popular models of Navien Ace wall-mounted boilers

The most reliable Navien boilers, the work of which can only be met with positive reviews, are distinguished by an optimal price-quality ratio. They are divided into two categories:

- Ace ATMO. Traditional boiler with an open combustion chamber. Equipped with atmospheric exhaust of combustion products.

- Ace TURBO. An advanced boiler equipped with a turbocharged burner and a special SMPS control system that regulates the gas combustion process.

Important! Navien Ace gas boilers can operate in both automatic and manual modes, which allows you to more accurately set the boiler operating parameters and eliminate operating errors as much as possible.

How to recognize?

To find a leak, and this is not so easy, you need to conduct an audit. For this:

- Take a napkin and blot all the pipe joints from the boiler to the final radiator. If there is a leak, the wipe will display droplets of liquid.

- Carefully inspect the radiators and the floor underneath them. The presence of streaks, dry and rusty spots are signs of a leak. Run your hand along the bottom and shine the flashlight. There should be no deformation or color changes.

- Check the taps. Sometimes they leak liquid, albeit in small quantities, but over time this leads to the need to add it to the system.

Don’t forget to check the boiler itself for leaks. All joints must be completely dry.

Hard water is the enemy of the system

The condition of the inner surface of all elements of the heating circuit is affected by the quality of the water used as a coolant. If it is hard, rich in salts and minerals, then when heated it will form scale and sediment, which over time will damage the equipment and cause blockages in the system. And those, in turn, will affect the pressure in pipes and radiators.

As a preventative measure, it is better to fill the circuit with specially prepared, demineralized water. If this is not possible, the boiler must be cleaned regularly. It is better to entrust this work to an experienced professional who is well acquainted with the construction of expensive equipment. He will disconnect the heat exchanger and wash it with special reagents.

In the case of large amounts of deposits, the entire system can be subjected to a similar treatment. But only real professionals in their field can cope with this task.

What to do?

The problem can be solved by adding fluid to the system, but first the leak itself must be eliminated.

To do this, follow these tips:

- Leak in the radiator section - turn off the heating, drain as much water as possible, and then disconnect the battery. Mark the location of the leak, dry it, clean it and seal it using cold welding. If the hole is too large, then you can simply remove this section by separating them from each other.

- Leaking in a panel radiator - you can try to seal the leak by cold welding, but in most cases you will have to replace the panel with a new one.

- Leaks at the joints - the soldered structures are cut off, and a blank suitable in size is made from a new piece of pipe. Soldering is performed using a special soldering iron.

- Leaking faucets - replacing the element with a new one.

Expert opinion

Grebnev Vadim Savelievich

Heating system installer

If there is a leak in the boiler itself, where the water is heated, then you must call specialists so that they can diagnose and carry out repairs. Without skill, experience and appropriate permission, making adjustments to the operation of gas equipment is extremely dangerous.

Preventing the formation of air jams

The following preventive measures against the occurrence of air jams are applied:

- Correct installation of pipes and connections of heating devices. Most problems are caused precisely by mistakes made at this initial stage.

- Correct commissioning of equipment to prevent air pockets.

- Checking for functionality. This is done using a compressor. It is necessary to apply pressure, the level of which is ¼ higher than its normal operating value. If it does not weaken within 30 minutes, then everything is in order and the system is ready for operation. If the pressure drops sharply, then leaks are possible, which should be promptly identified and eliminated before starting operation.

What to check first

If you know what the normal pressure in a gas boiler should be, and notice periodic surges, you need to make sure that individual parts of the safety block on the heat exchanger are working. The following elements are checked:

- pressure gauge;

- air vent valve;

- safety valve (it is advisable to connect it to the sewage system so that boiling water does not drip onto the floor if it is triggered);

- automation.

Frequent switching on of the gas boiler: 5 main reasons

Expansion tank malfunction

Sometimes the problem of pressure drop is associated specifically with the expansion tank. It can be built into the boiler body, or it can be located outside it (then water is poured manually through the tank). If there are signs of malfunction of this element, bleeding with pressure measurements will be required.

Conclusions on the topic

So, if you notice that the pressure in the boiler has begun to drop, do not panic, the pressure gauge may simply be faulty. If there is an additional measuring device, compare the readings. If they are different, then check the electronic display, there may be an error number indicated there.

For repairs and maintenance, contact a professional: you need to know the operating principle of a gas boiler and understand the features of its design. The technicians will quickly diagnose and correct all faults.

What to do?

The sequence of actions is as follows:

- Close the water inlet and outlet valves from the system.

- Drain the system until the pressure gauge in the boiler reads zero.

- Record the pressure in the expansion tank with the fitting open.

- Connect a regular hand pump and pump up the pressure until water flows out of the tank by gravity.

- Pump out all the water and tank.

- Release the air, then run the coolant into the system, equalizing the pressure to the recommended 1.1-1.3 bar (on the expansion tank).

Expert opinion

Grebnev Vadim Savelievich

Heating system installer

After such manipulations, the expansion tank usually works well. If it is not possible to do such work, then call a specialist.

What are the advantages of Navien Ace boilers

Navien Ace is a double-circuit version of a wall-mounted boiler. It is equipped with an open combustion chamber with natural release of combustion products. The advantages of Navien boilers are eloquently demonstrated by the instructions for their operation - they work even in conditions under which competitors’ equipment fails.

Did you know?

To increase the service life of Navien boilers, they are made of stainless steel, since stainless steel has a fairly high thermal conductivity.

Among the main advantages of Navien Ace boilers it should be noted:

- versatility;

- simplicity of control commands;

- compactness;

- High-quality anti-corrosion material was used in production;

- fully electronic, Russified control system;

- compliance with high European standards (quality, comfort, safety);

- reliability and resistance to various conditions (voltage surges up to 30%);

- the ability to work in a frankly emergency situation (low gas and liquid coolant pressure, low-quality gas, unstable pressure in the water supply system);

- economical fuel consumption;

- environmental friendliness (mainly carbon dioxide is emitted);

- acceptable price.

Important! In the event of power surges, the SMPS function in the unit is activated, and the boiler continues to operate uninterruptedly.

Airing the system

Air getting into the system is inevitable. No matter how well the installation work is done, there is always some air in the circuit. Most often, the cause is not cracks in radiators, but the use of aluminum batteries.

Few people know (and sellers don’t always talk about it), but when aluminum comes into contact with water, it undergoes an oxidation reaction, which results in the release of hydrogen.

As a result, we have the following: there is less coolant, hydrogen escapes through the valves on the radiator, and the pressure in the system drops.

Before using the heating system, be sure to check the radiators for air pollution. A minute's work will help you avoid serious problems with your equipment and protect you from costly repairs.

Operating principle of the Navien boiler

The operating principles of modern gas boilers are almost the same for all manufacturers, the only differences are in the configuration of the equipment and the internal arrangement of the actuators. The flow diagram of water in the boiler is shown in the figures. The Navien boiler works either to maintain the required temperature in the CO, when heated water from the first heat exchanger is pumped by a circulation pump in a large circle, or in the DHW preparation mode. The DHW mode is a priority, which means that if it is necessary to heat the water, a special three-way valve switches the circulation to the DHW plate heat exchanger, and the coolant flow through the heating circuit is blocked. The signal to switch the boiler to the DHW preparation mode comes from the flow sensor located on the hydraulic unit with the make-up tap.

How to recognize?

Signs of a large amount of air in the system are:

- The batteries are too hot at the minimum boiler settings - the air heats up faster than the water.

- The boiler often goes out - a temperature difference is created at which the automation is triggered.

- The pressure on the pressure gauge changes abruptly.

Airiness leads to the accumulation of air in certain parts of the radiators, forming air pockets. They cause certain parts of the batteries to remain cooler than others. And if you put your ear to the battery, you can clearly hear gurgling and squelching.

Why are changes dangerous?

With low pressure, radiators on upper floors or distant rooms do not warm up well.

Low and high pressure lead to malfunctions in the entire heating system or breakdowns that require expensive repairs.

When the indicators are reduced, the automation (for modern models) stops the energy supply and the boiler turns off. If heating is stopped for a long time during the frosty season, the pipes, radiators, and boiler heat exchanger will be destroyed.

In addition, if the rate is low, the pressure may not be enough to effectively pump coolant throughout the system. The upper floors and radiators furthest from the riser pipes will remain without heat.

An important indicator for the operation of a warm water floor. The maximum length of the circuit reaches 100–120 m, which creates resistance to the movement of the coolant. If the pressure is insufficient, the circuit will stop heating.

With increased pressure, water begins to leak through the threaded connections of pipes and radiators. Possible destruction of structural parts.

What to do?

The problem can be solved very simply: you need to release excess air and add water to the system. For this:

- WITH

Using the key, carefully open the drain mechanisms at the top points of the radiators. This should be done starting from the closing battery towards the boiler. - Place a container under them, as some of the water will come out along with the air.

- Be prepared that during the procedure there will be hissing and hot water together with steam can lead to burns. Allow the system to cool for 15-20 minutes.

- Close the drains with the key and open the water filling valve of the system or add coolant manually.

- Check the pressure and then start the heating.

This simple manipulation will equalize the pressure and solve the problem.

Expert opinion

Grebnev Vadim Savelievich

Heating system installer

When bleeding air, make sure the pump is functioning. It must pump water through the system, otherwise it will not be possible to completely expel the air.

Navien boiler error 03

In gas boilers, the presence of a flame on the burner is checked by a special sensor - an ionization electrode. The operating logic of the unit is to continuously check for the presence of a flame after opening the gas valve. Symptoms of error 03 on Navien boilers can be divided into two groups:

- unsuccessful attempts to ignite (no flame appears)

- ignition occurs, but the flame goes out

If ignition does not occur, you need to check:

- gas pressure at the inlet and outlet of the gas valve (can only be carried out by a qualified specialist using special equipment - a differential pressure gauge)

- condition of the ignition electrodes (compliance of the gap with the manufacturer’s standard, contamination of the electrodes). The normal distance between the electrodes is 3.5-4.5 mm.

- integrity of the insulation of the electrode power wire (you can visually verify that the spark breakdown occurs specifically on the body of the gas burner, and not somewhere else)

- correct setting of the boiler power on the DIP switch (valid if there is a problem during the first start of the boiler or after replacing the electronic board)

- presence of voltage on the ignition transformer

Error 03

on the Navien boiler will also appear when combustion is unstable (intermittent flame) or if the control unit is unable to detect the presence of a flame. In this case, you need to make sure that the connection between the ionization electrode and the control board is reliable, check that the boiler is grounded and that there is no contamination on the electrode. Unstability of combustion can be caused by an increase in fan speed, so you need to make sure that the yellow hose going from the turbine to the APS sensor is securely connected and not damaged.

If during the checks it was not possible to normalize the operation of the boiler, diagnostics of the boiler board, repair or replacement will most likely be required. We recommend watching a video in which one of the users simulates error 03 on a Navien boiler:

Malfunctions of the pressure gauge and boiler automation

If all possible reasons for the decrease in pressure in the system have been eliminated, and the boiler continues to go out due to low readings on the pressure gauge, you need to make sure that it is working properly. This measuring device can only be tested using special equipment, so you cannot do without calling specialists.

In some cases, the problem lies in the central control board, which generates incorrect signals that affect the pressure in the system. A complete diagnosis will be required that will answer all questions.

When should you definitely call a professional?

If it is not clear why the pressure in the gas boiler drops, you will need the help of an experienced specialist. He will confirm that there are no leaks and will repair the gas boiler "Ariston", "Baksi" or another model. If you have never had to restore boiler equipment yourself before, you should not attempt DIY repairs. Amateur activities without knowledge of the circuits and operating principles of the units can damage the entire system.

Defects in the heat exchanger

In order to repair equipment, it is necessary to carry out a number of complex measures. First of all, it is important to determine why the pressure in the boiler drops in a double-circuit installation. If the problem is related to malfunctions in the expansion tank, it means that the wrong volume was selected or the membrane was damaged. Repairs will require re-calculations or replacement of the tank. You will need specialized equipment to find the source of the problem if the heat exchanger has been damaged due to heavy use and wear.

To prevent numerous problems in the operation of the heating system, which includes pressure reduction, it is important to carry out comprehensive prevention and follow a number of rules of use. Be sure to ensure that the pipeline and heating elements are connected correctly, since many mistakes are made during the installation stage.

Problems with measuring equipment

Sometimes pressure gauges give erroneous readings. Low pressure readings on the measuring equipment can be explained by a malfunction of the device itself. If there are no visible defects, it is worth checking the automation and instrumentation. During operation, they may fail and display incorrect values. It is very difficult to find such an error on your own, so it is recommended to take professional help from specialists. How to solve the problem of pressure drop in the boiler, and how to increase it.

Raising pressure in the boiler

If the reason is a malfunction of the expansion tank, then its volume was calculated incorrectly or the membrane was damaged. In this case, you should either more accurately calculate the required volume, or simply replace the tank

Don't worry about the pressure starting to drop immediately after the initial start - this is normal. There is a large amount of air present in a circuit that has recently been filled with tap water. Over time, it will turn into bubbles and be removed from the pipeline, and the circuit parameters will return to normal. To remove bubbles more quickly, you should use a manual air release. Before a set of actions to increase the pressure in the system, you need to make sure that it is tight. To do this, you need to inspect the following parts of it:

- heating appliances - leaks often appear at the junctions with pipes, and leaks that occur between separate sections are also possible;

- pipes - even very small cracks can often lead to coolant leakage;

- fittings - often cause leaks;

- boilers - models with two circuits have a complex internal structure: for example, you should carefully inspect the circulation pump, three-way valve and heat exchanger.

Preventing pressure loss in the boiler

In order for the heating system to function correctly and be safe for life, you need to:

- Before purchasing a boiler, be sure to correctly calculate its power. For a two-story house, a small 7 kW parapet boiler will clearly not be enough.

- Installation and installation, as well as the first start-up, must be done by professionals with special permission.

- The pressure is set taking into account the standards and requirements specified by the manufacturer in the operating manual.

- Do not ignore periodic cleaning of the system and the boiler itself using special products.

- Get your gas equipment checked annually to prevent breakdowns at the most inopportune moment.

And remember the main thing: if the pressure drops constantly, then you need to look for a reason that lies deeper than air in the system and a malfunction of the expansion tank. You will be helped by specialists who will diagnose and help resolve this issue.

Preventive measures: how to avoid problems

For trouble-free and safe operation of your gas heating boiler, it is enough to follow a few recommendations:

- Before purchasing a heating boiler, consult with professionals: it is very important to correctly calculate the required power, as well as understand what additional functionality may be needed;

- perform high-quality installation. Any gas equipment can only be installed by employees of specialized organizations; independent intervention in gas networks is prohibited. During installation, all requirements of the manufacturer must be observed so that you are not denied a warranty in the future;

- Carry out regular maintenance. Experts recommend once a year: before the heating season or immediately after it. Specialists will clean your boiler, replace all gaskets, measure the pressure inside the system, release excess air, and check the tightness of all components;

- Read the instructions for your equipment and comply with all requirements specified there. In this case, the boiler will operate in the mode recommended by the manufacturer, which will have a positive effect on its service life.

Questions and answers

I often hear gurgling sounds in the expansion tank, after which the pressure on the pressure gauge drops slightly. After a while, when the boiler turns on, the pressure equalizes. What could be the reason?

It is necessary to check the operation of the expansion tank. To do this, you need to pump it with a pump and record its pressure data. If for some reason it does not hold pressure even in the absence of water, it will need to be replaced.

When there is severe frost outside, I add water to the tank every 3-4 days. Does it evaporate so quickly or do we need to look for another reason?

If the pressure on the pressure gauge drops and there is not enough fluid in the system, you need to look for a leak. Perhaps these are small holes, the water from which immediately evaporates, so you do not see the expected puddles. Check all joints and radiators, and then diagnose the expansion tank itself.

The pressure on the pressure gauge drops sharply when I turn on the hot water. Double-circuit boiler. The temperature in the batteries immediately drops. What is the reason?

Such signs indicate the release of water from the system into the central water supply. Check that the supply valve is closed and that it is working properly.

Causes of pressure drop

The pressure in a gas boiler may drop when:

- coolant leaks from the heating system;

- power failures;

- expansion tank defects;

- improper operation of equipment or poor installation.

If the operating pressure decreases, the boiler stops working: water stops flowing into the heat exchanger, so the automation stops the operation of the equipment. Next, we will look in detail at the most common causes and tell you how to fix them.

Pressure drops when hot water is turned on

The most common problem. If, when the hot water is turned off, the pressure quickly recovers, then there is a problem with the make-up tap: it is either not closed tightly or is faulty. In this case, the pressure between the heating circuit and the water supply system is equalized, but as soon as the tap opens, it drops sharply.

Such a malfunction is dangerous not only due to disruption of operation, but also leads to increased oxidation of pipes, the formation of salt deposits and complete blockage.

In addition, air leaks into the heating circuit or malfunctions of the 3-way valve may be faulty.

Water leaks

If low pressure is constantly observed during boiler operation, then water leaks are possible in the connecting units, radiators or expansion tank. In this case, it is necessary to check the entire heating system for leaks, even if water does not drip from a closed boiler.

To avoid problems, carry out regular maintenance before the heating season: specialists will check the entire system for leaks, and also replace worn gaskets and seals.

Air jams

Cracks and depressurization can lead not only to leaks, but also to air being sucked into the heating system, which causes the formation of air bubbles. Sudden pressure surges can also be caused by improper filling of the circuit with water or its high temperature (more than 85 degrees).

Determining the presence of air locks is quite simple: if in some part of the system the pipes are cold, most likely an air lock has formed there.

The problem is also easy to solve. Simply release excess air through special bleed valves.

Expansion tank defects

The expansion tank performs two functions in the system: when heating water, it stores excess water and also balances pressure changes.

The tank consists of two compartments (with air and water), which are separated by a membrane. As the water heats up, it expands and puts more pressure on the membrane, compressing the air. When installing the tank, air is pumped inside through the nipple from above. Over a long period of use, it may begin to leak air, causing the pressure on the membrane to cease.

In this case, the only solution is to completely replace the tank; it is impossible to replace only the nipple. But before that, be sure to check the tightness of all other parts of the system - there may be problems in them.

Cracks in the boiler heat exchanger

During operation, microcracks appear in the heat exchangers, which begin to let water through and also suck air into the system. Determining this malfunction is quite problematic: the water inside the boiler evaporates very quickly. The problem can only be solved by welding cracks or completely replacing the heat exchanger.

Error in the operation of measuring instruments

If the pressure gauge shows low pressure, but the boiler is still working efficiently, there are no leaks or cracks anywhere, and all system components are working properly, then the control device itself may be faulty.

This can be checked by installing an additional pressure gauge at the boiler inlet. Replace the faulty device.

Dump valve problem

The safety valve (or relief valve) is mounted separately and is needed to balance the pressure in the heating system. The spring presses on the valve; as soon as the pressure exceeds the norm, the spring compresses, opening the valve and releasing either air or water.

After 7 cycles, the spring wears out and ceases to perform its function: the pressure either jumps or constantly decreases. In addition, a constant leak will appear.

Try turning on the tap. If the problem persists, then the mechanism will have to be replaced: repairing the valve is not recommended.

Low pressure or surges in a new gas boiler

Pressure surges during the initial start-up of new equipment are quite common: there is still a lot of air in the circuit, which will be released with the help of drain valves and the pressure will return to normal.

Static and dynamic pressure

If we explain in simple terms the role of static pressure in a closed heating system, we can put it something like this: this is the force with which the liquid presses on the radiator and pipeline, depending on the height. So, for every 10 meters there is +1 Atm. But this applies only to natural circulation. There is also dynamic pressure, which is characterized by the pressure on the pipeline and radiators while driving. It is worth noting that when installing a closed heating system with a circulation pump, static and dynamic pressure are added, taking into account the characteristics of the equipment. Thus, a cast iron battery is designed to operate at 0.6 MPa.