The operation of a new, correctly installed heating boiler, as a rule, has a silent mode. This aspect is one of the quality indicators of heating device manufacturers. But sometimes even when a new boiler is operating, unpleasant noise occurs. This may take some time until all parts of the boiler fall into place under the influence of temperature changes.

After prolonged use and quite often, the boiler begins to make noise and hum, making uncomfortable sounds. This problem can have several causes and should only be addressed by a specialist. It is important to take preventive and repair actions in a timely manner in accordance with safety regulations.

When does the clicking occur?

How to understand why a gas boiler clicks? As a rule, clicks can be heard when turning a gas boiler on and off. And also during cooling and heating. Below are the most common reasons:

- During startup, a large amount of gas is generated. This gas flashes as soon as the device is turned on, causing us to hear noise.

- The cause of the extraneous sound may be a malfunction of the three-code valve or the ignition mechanism. Also, the reason may be hidden in a clogged chimney. This leads to the formation of a mixture of gas and air. A dirty wick is also accompanied by clicking noises. If the problem is not corrected, cravings will worsen over time.

- Due to incorrectly installed brackets, the balance of thermal expansion occurs. Because of this, blockages occur in the lower part of the boiler body, which can cause extraneous sounds. Often clicks can be heard when there is a large evaporation of liquid.

- There may be malfunctions in the operation of the pump itself; it is necessary to check it for any problems.

- A sharp drop in temperature in the boiler. The device cools down, making characteristic sounds.

- An extremely rare, but still possible cause of clicking sounds is improper installation of pipes.

Incorrect burner installation

Often the cause of noise, clicking or whistling is due to improper installation of the burner. To check, you will need to evaluate the level of gas pressure leaving the burner and the recommended indicators in the equipment instructions.

The appliance is noisy when heating water

Modern boilers operate silently, so vibration, noise, and other sounds are a cause for concern. Why does a gas boiler click? What could be the reason:

- Incorrect installation and configuration.

- The elements are simply worn out.

- Oxygen content exceeded

The water in the pipes is oversaturated with oxygen, so bubbles form when heated. This causes noise and vibration not only from the boiler, but also from heating radiators.

Air has formed in the system

If the boiler is knocking, it is necessary to bleed the air in the pipes. Modern batteries have taps installed. Air is released when the taps are unscrewed.

How to remove air from the battery yourself?

The accumulation of air in batteries after a break in the heating season is not a rare occurrence. This is a common problem not only in private homes, but also in apartment complexes. Its solution is not a complicated process. Heating batteries and radiators are equipped with Mayevsky taps. They are located on the side of the batteries. In appearance, most often they resemble a valve.

To bleed air from the battery, you need to:

- Prepare a cup or bucket for water that will flow from the tap when unscrewed;

- Open the tap and let out the air;

Attention! This must be done carefully, as there is a risk of getting burned by the steam!

- Tighten the valve after water flows from the tap.

.

What problems can you fix yourself?

Let's look at the malfunctions of Navien gas boilers and how to fix them yourself.

The reasons for the appearance of error 01 are a blockage in the heat exchanger or a decrease in the volume of liquid in the system, or failure of the circulation pump. To resolve this issue, it is recommended to do the following:

- check the pump and coil for short circuits;

- bleed excess air from the heating system, if any;

- Check the pump impeller for damage.

Error 02 is usually accompanied by the following malfunctions: warm water first flows out of the hot water supply, and then cold water flows in; on the remote control, the water temperature rises sharply to a maximum, and then quickly drops. The heating works fine. The cause of this problem may be:

- lack of coolant;

- airiness of the system;

- the circulation pump cannot work fully;

- the flow sensor is not functioning;

- the distribution valve is closed.

You can troubleshoot the problem as follows:

- adjust the pressure;

- expel excess air from the system;

- open the distribution valve.

Most often, the cause of this error is air locks in the hot water system. Water entering the circuit is heated to the required temperature, but when air enters the heat exchanger it sharply increases to critical levels, which causes a malfunction with code 02.

error 03 appears in a gas boiler this may indicate that the flame sensor is clogged or its wiring is broken. The situation can be corrected by adjusting the wires or cleaning the sensor from adhering deposits. Fine-grained sandpaper removes dirt well.

Error 10 usually appears in the following cases:

- the chimney is clogged;

- The fan is not working properly or the pressure sensor is not connected correctly;

- The wind is blowing strongly into the chimney.

You can fix the problems as follows:

- check the presence of draft in the chimney, clean the pipe if necessary;

- see if the fan is connected correctly to the pressure sensor.

Scale formation

A high salt content in water leads to scale deposits on the walls of the device. When heated, the salts will make themselves known by hissing. Because of this, the device heats up much more slowly. The radiator needs to be cleaned once a year. To do this, you will need a reagent, a special pump through which the reagent is poured into the device and rinses it from the inside.

Scale in the boiler - how to deal with it

In radiators, water does not move as quickly as in pipes, and the sedimentation of suspended matter is many times higher. Regular cleaning of radiators is necessary. You can flush the entire system at once or separately the radiators using a compressor unit. To flush, the radiator is connected to the compressor, and dirt is cleaned from it with water pressure.

Sometimes it is enough to simply flush the system with strong water pressure. Chemical reagents are used in cases where the situation with scale deposits is extremely advanced.

Scale formation deforms the device

Under the influence of chemicals, cracks may form in radiators that were clogged with salts. In order to prevent an emergency, before starting the system, all equipment must be checked for readiness for operation.

Infrared heating panels

Causes of extraneous noise in various models

Why does the Navien gas boiler click regularly? There are two possible reasons: scale formation and problems with the coolant.

How to fix the problem yourself:

- disassemble the device;

- clean or replace the heat exchanger;

- check the taps;

- reduce the water temperature.

Extraneous noise is also observed during operation of Beretta brand gas boilers.

Typical reasons:

- poor heat transfer in the heat exchanger, scale formation;

- Wrong pipes are connected.

Why does the Concord gas boiler whistle? The most common reason is increased load in cold weather. The boiler power declared by the manufacturer does not correspond to reality and in practice the figures are lower.

For example, if the documentation indicates 13 mbar, then in reality it is 10 mbar. The device should not be set to maximum.

It is recommended to clean your gas boiler at least once a year. For this purpose, you can contact a service center or carry out the procedure yourself.

In a Baxi gas boiler, noise occurs most often when the heating function is turned on. To identify the cause, the bypass should be checked, and the valve should be cleaned and adjusted. Users of AOGV devices often complain about whistling. The cause is scale and a clogged filter.

Vailant boilers hum after turning on the heating function and turning off the fire. The first reason is that the heating circuit strainer is clogged; cleaning it will correct the situation. The second reason is a malfunction of the valve on the bypass line. Adjusting the valve will help solve the problem.

The cause of noise in Ariston boilers is poor coolant circulation. The problem will be solved by blowing the heat exchanger with a compressor. If the Ardelia gas boiler is humming, you should check that the pump settings are correct. If the situation cannot be corrected in this way, then it is recommended to replace it with a new circulation device.

Fan problems

The fan operates in models with a closed chamber and forced removal of combustion products. Why does it make strange sounds when rotating, whistling:

Fan malfunctions can often occur. Then, when rotating, it can cause various extraneous sounds. The cause may be insufficient lubrication. The lubricant tends to dry out quickly due to exposure to high temperatures. As a result, the bearings fail.

The accumulation of dirt and dust in the blades is another cause of squeaking. The fan needs to be removed and cleaned.

The accumulation of dirt and dust in the blades is another cause of squeaking. It is necessary to clean them to get rid of squeaking when rotating. The fan is used for the smoke exhaust function and also removes residual gas combustion products.

Conclusions and useful video on the topic

The reason for the noise during operation of the gas boiler:

Whatever gas boiler is installed in your home, first of all you should make sure that it is installed correctly. Equipment requires regular preventive inspection. This will allow problems to be identified and corrected in a timely manner.

It is recommended to periodically clean the coolant from dirt and scale. These simple manipulations will allow the device to work as long as possible, efficiently and without extraneous noise.

Have you ever encountered a gas boiler that slams, clicks, whistles or makes noise? How did you resolve this problem, or what services did you contact? Share your experience with readers in the comments and ask our experts any questions you have.

Excessive pressure in the heating pump

The pump provides high pressure; it is necessary to adjust its settings. Excessively high pressure in the system can provoke an emergency.

A low amount of water in the system may cause the device to overheat. Try lowering the thermostat. You may need to add water to the device to the required level.

Heating pump

- If the boiler seems to “howl”, the gas valve may be set incorrectly, check the jumpers.

- At high power, the source of extraneous sounds may be the gas meter.

- The valve was worn out and began to rattle. It needs to be replaced. If the problem is not solved and the boiler is still noisy, you can replace the valves with ball valves and install a rubber gasket.

- If the above measures do not help, you may need to replace the cooler.

How to prevent noise

To avoid the appearance of extraneous sounds during the operation of the fireplace, it is necessary to ensure timely maintenance of heating equipment. It includes lubricating parts, removing carbon deposits and dust, cleaning components and monitoring water levels. It is equally important to control the gas supply so as not to provoke an increase in pressure.

If you do not control the water level in the pipes, noise caused by water hammer may appear. It is caused by the force of inertia, due to which the liquid cannot instantly stop in the pipes.

The column in the gas boiler clicks

Clicking noises occur in automatic and semi-automatic boilers. Possible causes of problems:

- The gas heater does not light up. The contacts on the ignition unit may have come out of alignment. A complete replacement of the part will be required, since it is not possible to disassemble it. In addition, the reason may lie in dead batteries.

- If the gas water heater clicks after turning off the water, the water regulator may be damaged. Inside the block there is a rod with legs, which is connected to the ignition block.

- When the water is turned off, a metal spring returns the rod to its original position. The rod may jam due to a rusty rod. The ignition unit produces a spark when switched on. This is what causes the speaker to crack. The malfunction can be caused by a worn out frog membrane, then a new one must be installed.

Poor traction also causes noise in the column. The cause may be metal-plastic windows or scale in the heat exchanger. The reason will be determined by an experienced technician when inspecting the column.

Noise diagnostics

The operation of a boiler with a water heating circuit is often accompanied by noise. It not only brings significant discomfort, but can also be potentially dangerous for everyone in the household. Therefore, it is not worth leaving this problem without a solution.

Before identifying the cause of the deficiency, the nature of the extraneous sounds should be determined. This will help in diagnosis and increase the chances of successfully fixing the problem.

The most common defects of boilers in a fireplace include:

- quiet knocking in the boiler;

- a crackling sound that occurs when the heating system is turned on;

- regular appearance of hum;

- vibration;

- periodically repeating clicks.

All of these signs indicate that the problem needs to be corrected. If you ignore them, the situation may be resolved by a complete breakdown of the entire heating system.

Expert opinion

Filimonov Sergey Vinokurovich

Heating equipment repairman

A loud bang that occurs when igniting may indicate gas accumulation. To avoid undesirable consequences, it is necessary to evaluate the condition of the electrodes, burner and connections.

The gas boiler hums and whistles

A gas boiler can make noise throughout the entire apartment, thereby interfering with sleep. Is it possible to get rid of this noise? In fact, the cause of the noise lies in the chimney. In this case, the chimney needs to be enlarged and expanded. The narrower it is, the stronger the rumble.

Operating principle of combined heating boilers

Often the gas boiler begins to hum loudly. The reason is the stabilization system, which regulates the level of gas pressure that enters the combustion compartment. To prevent sounds from interfering with a comfortable existence, it is better to locate the boiler room away from the living space. If it has already been built next to your home, you can solve the issue by ensuring soundproofing of the room. There are a great variety of materials for this.

If the boiler starts to boil like an electric kettle, it means the primary heat exchanger is clogged. Finding out whether there is a blockage is quite simple. You need to set the boiler to the maximum temperature and turn on the supply valve so that there is a small flow of water. At around 80 degrees the hum increases. There is only one way out - clean the heat exchanger.

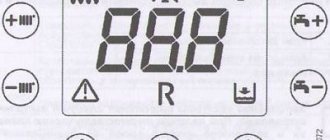

User manual

Navien gas boilers are operated automatically, with minimal human intervention.

The owner only needs to observe the readings on the display and respond in a timely manner to the appearance of an error code.

In addition, the user determines the operating mode - summer or winter:

- Summer mode is determined only by DHW heating.

- Winter mode starts the heating system simultaneously with the supply of hot water.

The display has a button with a corresponding icon (indicating a snowflake or a sun).

If it is necessary to adjust the extract air temperature or other parameters of the heating system, the winter operating mode must be turned on. Exhaust temperature is adjusted when the radiator icon is flashing.

If it lights up steadily, the display shows the current temperature. By pressing the “radiator” button so that the icon flashes, press the “+” or “-” buttons to change the set coolant temperature.

The icon stops flashing after a while (a few seconds), and the boiler will begin to heat or cool the coolant in accordance with the instructions received.

Clicking when turned on

Why does a gas boiler click? A faulty three-way valve is one of the reasons. This part serves to switch the operation of the unit from heating hot water supply (DHW) to heating, and vice versa. If it is faulty, it must be replaced. It cannot be repaired.

A loud bang occurs when the spark ignites for a long time. It is necessary to diagnose the unit: burner, igniter, electrode, contacts and connections.

- Wick clogged . When turned on, a popping sound is heard. This indicates that the chimney or wick is clogged. This feature is inherent in semi-automatic units. Inspection and cleaning of the wick is necessary.

If the chimney is clogged, there will be problems with draft. You can check it in a simple way:

- Light a match and bring it to the ventilation.

- If the flame tilts, there are no problems with draft; if it burns evenly, there is no draft, the chimney is clogged.

- The injectors are clogged . When heating, the device makes noise, ignition does not occur. Turn off the gas supply and clean the holes with a thin wire.

- Incorrect installation . When exposed to high temperatures, the metal expands, and when cooled it returns to its original position. When the heating is turned on, the pipes expand under the influence of hot water, and clicking sounds occur as they heat up. To do this, prudent craftsmen create a hole for thermal expansion.

- The heat exchanger plates are clogged . Dust, soot, and soot accumulate in them. This can lead to an explosion of the boiler. To remove soot, you will need to remove the boiler body and clean it. In addition, the mesh at the bottom of the boiler can become clogged with dust.

- Problems with the circulation pump . To get rid of the problem, turn off the gas valve before starting work.

Types of boilers

On the market you can find products from Navien in a fairly wide range, where the following models are especially popular:

Wall mounted equipment available in two variations

The devices are able to function normally even with an unstable supply of electricity and gas. The units are equipped with turbocharging and a frost protection system.

Floor-standing units

Ideal for installation in private homes. They provide the room with hot water and heat. Advantages: compactness, simplicity of design, ease of use. The power indicator can vary from 11 to 34 kW.

Condensation products

With a high power rating and economical energy consumption. The passport of a boiler of this type indicates an efficiency level of 108%. The main advantage: the unit can significantly reduce space heating costs.

If the boiler makes noise during operation

If you hear noise while the gas boiler is on, it means there are certain problems. First you need to discover the reasons, and then begin the process of getting rid of the annoying sound:

- Water may make noise in the pipes. This may indicate a malfunction in the heating supply. If action is not taken to correct the situation in time, some heating element may fail.

- Extraneous sounds - noise, clicks in the heating radiator or radiators significantly worsen the quality of living in the apartment. If the heating pump or other system component is noisy, we advise you to first try to localize the cause of the extraneous sounds. To do this you need:

- Trace the periodicity and frequency of occurrence of various sounds.

- Try to trace exactly when the sounds occur - with an increase/decrease in temperature or pressure.

- Make sure that the source of the sounds is the boiler and not other equipment in the boiler room.

Character of noise

Pay attention to the noise, but it could be:

- Uniform monotonous.

- Uneven, with a crash.

Uniform noise can occur even when operating a new, recently installed boiler, but the second one can occur only after some time.

Is the noise in a gas boiler dangerous?

No, not dangerous. There will also be no defects or threats to operation in the heating system. Noise can only create discomfort in living rooms.

How to get rid of noise?

The only option to get rid of noise in a working boiler is to reinstall the system from open to closed. Reworking the system will not affect the ability of it to operate without a pump. In addition, there will be an excellent opportunity to install an auto-recharge system and a weather-sensitive automatic system.

Lime deposits: the cause of noise in the boiler

Often, extraneous sounds do not appear immediately, but after a certain period of operation of the device. Why does the boiler make noise in this case? The thing is that lime deposits cause noise. They form on the walls of the heat exchanger after a certain period of operation.

Why is the gas boiler still clicking? The cause may be lime deposits. They cover the walls of the heat exchanger from the inside, due to which the temperature of the internal walls of the heat exchanger begins to increase sharply, which also affects how long the equipment can last. In this case, we will hear clicks, knocks, and noises.

It is necessary to carry out maintenance of the boiler at regular intervals, regularly clean the device from soot, scale, dust, and dirt. This will significantly increase the service life of the boiler and prevent problems with its operation.

Causes of noise in heating equipment

The new gas boiler operates virtually silently. However, over time, the unit begins to make noise.

This is a sign of hardware failure:

- scale formation;

- the fan has failed;

- wear of device components;

- manufacturing defects;

- incorrect settings or installation of the boiler.

To understand why a gas boiler makes loud noise, you need to listen to the noise the equipment makes.

If the hum is heard directly from the boiler, then you should check the water level and add it if necessary. If noise is heard from radiators or piping, then air has entered the system and must be removed. Extraneous noise in the pump itself indicates a manufacturing defect.

Clicking sounds that occur at short intervals indicate problems with the fan. If the boiler hisses or whistles, it means that a lot of scale has accumulated in the device

If the circulation pump breaks down, this element often needs to be replaced. The gas supply to the system must be adjusted from time to time. High pressure is undesirable.

Problems with the exhaust fan

If extraneous noise occurs at intervals, you should check the fan. Its task is to systematize the operation of the smoke removal system, due to which combustion products are removed from the boiler with the intensity necessary to ensure the complete safety of others.

The fan blows through the system, clearing it of combustion residues, and also serves to remove smoke. The longer the boiler operates, the greater the fan wear

The main reason is age. Most likely, you just need to replace the fan with a new one. The second reason that leads to rapid wear of the cooler is its location above the burner at the top of the device.

Under constant exposure to high temperatures, the bearing lubricant quickly dries out, causing it to wear out. To fix the problem, you also need to replace the fan.

Another reason for the appearance of extraneous noise effects is that the part may be clogged with dust, to remove which you need to do the following:

- Inspect the fan. If necessary, it should be cleaned. The main blades are located inside the housing. You need to remove dirt and dust from them, and then lubricate the bearings.

- If the problem cannot be solved, replace the outdated valves with new ball valves.

- If the previous two steps did not bring results, reinstall the cooler.

It is better to entrust the replacement of parts to a gas boiler repairman from a service with which an agreement has been concluded for the maintenance of devices and the supply of blue fuel. Timely and competent replacement of worn parts will eliminate the need to buy a new unit.

Scale deposits on the walls of the heat exchanger

Thanks to the heat exchanger, heat is redirected from gas to water. If the water is hard, then scale may form in the heating system as it heats up. To remove mineral deposits deposited on the walls, it is recommended to regularly chemically flush the heating system and clean the heat exchanger.

A household chemical for cleaning the heat exchanger can be purchased at the store. Craftsmen often use 4% vinegar for these purposes. After cleaning, parts should be rinsed with water.

This problem is noticeable after 15-20 minutes from the moment the gas boiler is started. The reason for the sound is the narrowing of the passage for water. As a result, steam and small bubbles are formed. Scale reduces the efficiency of equipment, as well as its heat transfer and wear resistance.

You can descale the unit using chemicals containing soda and similar substances. You can do this yourself. To do this, remove the heat exchanger, remove the casing and unfasten all connected pipes. A special chemical solution must be poured into the device for 2-5 hours.

Lack of water in the heating system

If there is not enough water flowing through the heating system, the boiler begins to make noise due to overheating. This is because air pockets form inside, interfering with the normal circulation of fluid in the system.

Airing the system leads to incorrect operation of the boiler. If there is not enough water in the pipe section, an air lock will form. At the same time, the heating device partially cools down, and water cannot circulate normally in the system, so it overheats by the burner. At the same time, a dull whistle or howl is heard

Airing leads to the following problems:

- the circulation of water in the coolant decreases or stops;

- The boiler automatically turns off due to overheating of the coolant.

Reasons why air ends up in the heating system:

- violation of sealing during repair work;

- violation of the integrity of the system;

- drainage of water from the DHW circuit.

To make the device work, you need to adjust the thermostat. You also need to make sure that the thermostat is installed correctly, add water, and adjust its supply and circulation.

The Mayevsky valve, which is mounted at the end of the radiator, will help get rid of air in the system. It has a fitting that, when opened, allows access to the inside of the battery. The faucet is most often installed at the top of the device, where warm air accumulates.

You can also use an air separator. The device collects air that collects into bubbles as water flows along the circuit. When excess air has been completely removed from the pipes, replenish the coolant through the make-up tap and make sure that the boiler operates without any extraneous sounds.

Arranging a perfectly sealed heating system will prevent the accumulation of air in the coolant. This is troublesome and expensive, but it will eliminate the occurrence of extraneous noise in the gas boiler.

Consequences of low pressure

Reasons why pressure in the system may decrease:

- water leak;

- breakdown of the boiler expansion tank;

- long interruption in electricity supply;

- Incorrect setting of the gas boiler.

If the pressure in the system drops, the boiler begins to make loud noises. Your task is to first check if there is a leak in the heating circuit. A simple napkin will help you with this; use it to wipe all joints and joints. Once the source of the leak is discovered, it must be eliminated.

If the pressure in the system drops, the boiler stops working because it is blocked automatically. Lack of water in the heating circuit leads to overheating, it is detected by sensors, after which the boiler turns off automatically

The cause of pressure changes may be cracks in the expansion tank or heat exchanger. To identify their location, all water should be removed from the system, and then air should be pumped into it using a compressor. In places where microcracks form, air will leak out with a characteristic whistle. The appearance of microcracks indicates wear and the need for complete replacement.

This occurs as a result of frequent flushing of the system with chemical reagents, due to poor quality metal, a sharp increase in pressure in the line, and water hammer. If you can remove and repair the heat exchanger yourself, then you can try soldering the resulting microcracks.

To prevent such problems, it is recommended to regularly inspect the boiler, as well as install auxiliary equipment that will allow you to control the pressure by displaying the value on the screen. Standard pressure indicators are 1.5-2 atmospheres.

Incorrect unit setting

Incorrect adjustment or installation of equipment can also cause a valve or bypass to whine. Extraneous noise may occur as a result of improper load redistribution.

If the operating power of the unit exceeds the permissible values, vibration occurs as a result of excess pressure and the pump begins to rattle

If the sound of metal hitting metal occurs during heating or cooling, uncompensated heat expansion occurs in the device. The reason lies in incorrectly installed radiator mounting brackets.

If you don’t know why your gas boiler is constantly whistling, you should first check the settings. The rules and sequence of actions when setting up a gas boiler can be found in the technical documentation for the unit; operating parameters can be found on the nameplate attached to the equipment body.

Other causes of whistling

The gas unit may whistle due to:

- Excessive pressure formation in the pump. It needs to be adjusted, otherwise the increased pressure may cause an accident.

- Incorrectly adjusted valve. Problems arise when setting up the bypass.

- Valve rattling.

In addition to the main ones, there are indirect reasons why a gas boiler whistles:

- the settings are incorrect;

- the boiler is not connected correctly;

- nodes are worn out.

Dry and wet type of device

Such pumps are divided into the following types: with a “dry” and “wet” rotor. In the first case, the motor of the pumping device is placed in a separate module, and the rotor rotates through a clutch.

Noise occurs during operation.

Why is the heating pump humming?

Dry type equipment creates noise through the operation of a fan that cools the engine. This device is used in large houses. In them it is mounted in a separate room.

Wet-type devices operate with low noise levels, since the rotor is immersed in a coolant that cools the operating engine. Such a device can be placed close to residential premises. The noise level will not create any discomfort.

Reasons for the formation of sounds and pops

Sharp sounds and pops have the following causes:

Semi-automatic boiler wick