Other articles on this topic:

For heating and hot water supply of apartments and small private houses with one bathroom, double-circuit gas boilers are usually used.

In large houses with several sanitary rooms, single-circuit gas boilers with a storage boiler for preparing hot water are more often used for heating. This system provides more comfortable use of hot water in the house.

Read: Hot water supply for a private country house

The apartment in the new building with apartment heating is equipped with a Protherm Gepard 23 MTV double-circuit gas boiler. Next, let's look at setting the boiler power using this apartment as an example.

Gas boilers of the Protherm Gepard series are almost a complete analogue (a simpler version) of the Protherm Panther boilers. This article describes in detail the adjustment and power settings of gas boilers Protherm Gepard and Protherm Panther.

It should be noted that the company that produces Protherm series boilers at its other plant produces gas boilers of the famous Vaillant brand. Vaillant gas boilers are in a higher price category due to the use of higher quality materials for the manufacture of heat exchangers. But in design, other parts used, and service menu settings, Vaillant brand gas boilers are very similar to Protherm boilers.

The principles of regulation and power settings described in this article are also suitable for gas boilers of many other brands and manufacturers.

Internal structure of the gas boiler Protherm Gepard 23 MTV and Panther 25.30 KTV (Panther)

Setting a gepard or panther gas boiler to a power below the minimum

At the third stage, the minimum boiler power is adjusted to a value lower than specified in the instructions.

Such adjustment is not necessary in all cases, but only when the first and second stages do not bring the required result. As in our case, when at the first stage we use the “-” button to set a new boiler power value = 9 (the minimum possible setting corresponds to 8.5 kW).

It should be noted that adjusting the boiler power using the method described below is also useful in other cases, since it allows, through an experiment, to adjust the heating power of the boiler in accordance with the actual power of the heating circuit. The actual power is usually less than the calculated one.

Before carrying out work on setting the minimum burner power, you must:

- Fully open thermostatic and other valves on radiators and set the room thermostat to maximum temperature. The thermostat that controls the heated floors is set to the maximum permissible temperature so as not to overheat the floors.

- In the custom menu of the boiler, set the maximum operating temperature, which is set by the owners in the coldest weather, adding another 5 °C. Usually this is not less than 65 °C. If the owners do not remember it, or on a new boiler, set the factory setting of the maximum temperature of 75 ° C in the menu. The boiler burner will have to automatically turn off at a temperature 5 °C higher, i.e. at 80 °C.

- Cool the heating circuit to a heating water temperature below 30 °C.

Next, we start the burner in heating mode, select line d.52 in the service menu, press the “mode” button and see on the display the value of the gas valve stepper motor position parameter in the factory minimum power mode.

By removing the front cover of the boiler, we visually observe the size of the flame in the burner. In our example, the factory setting was displayed on the display, the number = 72, and the flame height in the burner was quite high.

Using the “-” button we set a new parameter value in line d.52, for example =20. 3 seconds after the change, when the new value is automatically confirmed, we observe a significant decrease in the flame height in the burner. This indicates that the useful power of the boiler with the specified setting will be greatly reduced.

Next, observe on the display the increase in temperature in the direct heating pipeline at the outlet of the boiler. Typically, the temperature increase stops when it reaches a value less than the set value, for example 52 °C. The boiler is running, but the temperature does not increase (or changes very, very slowly). This means that a power balance has been achieved between the boiler and the heating system at this established water temperature.

At this moment, we increase the parameter in line d.52 of the service menu, set a new value = 30 - the temperature begins to rise again and stops again, for example at 63 ° C. Again we add the parameter value in line d.52 =35 and so select the parameter until the temperature stops at a value slightly higher than the maximum, for example 77 °C.

Reasons for clocking (pulse operation) of the boiler in heating mode

The operating manual states that the useful thermal power of the Protherm Gepard 23 MTV boiler is adjustable from a maximum of 23.3 kW. to a minimum of 8.5 kW. The factory setting for power in heating mode is 15 kW.

The total area of the apartment, which is heated by the boiler, is 60 m2. To heat the apartment, heating devices (radiators) with a total maximum thermal power of 4 kW are installed.

The installers installed the boiler and put it into operation, “forgetting” to carry out the commissioning work. The boiler was started to work with the factory setting of maximum power in heating mode of 15 kW.

It is obvious that a heating system with a maximum power of only 4 kW will not be able to accept the thermal energy produced by the boiler with a power of 15 kW. The power of the boiler burner is controlled automatically within certain limits. But the huge difference in the power of the boiler and heating devices leads to the fact that the boiler automation is not capable of bringing the boiler power in line with the needs of the heating system without additional settings.

Building regulations do not recommend installing boilers with a useful power that significantly exceeds the power of the heating system in a house or apartment.

The large difference between the power of a gas boiler and the power of heating devices, among other disadvantages, leads to cyclical operation of the boiler.

By the way, about other disadvantages of an overly powerful boiler. The service instructions for the Protherm Gepard 23 MTV boiler indicate its efficiency in heating mode: 93.2% at maximum thermal power (23.3 kW.) and 79.4% when operating at minimum power (8.5 kW.) Imagine how The efficiency will further decrease if this boiler has to work with a 4 kW heating system. Please note that a double-circuit boiler operates in heating mode most of the time throughout the year, with minimal power. At least 1/4 of the gas spent on heating will literally fly uselessly down the chimney. This will be the price to pay for installing cheap heating and hot water equipment in your home.

Excessive cyclicality, impulsiveness of work, or, as people say, “boiler clocking” is manifested in the fact that the boiler burner, after being turned on, quickly turns off when the set temperature is reached in the straight pipe at the outlet of the boiler. But the radiators remain not heated to this set temperature - the water heated in the boiler simply does not have time to reach the heating devices. That is, the boiler produces more thermal energy per unit time than a less powerful heating circuit is capable of receiving. Therefore, the temperature of the water leaving the boiler rises quickly and it turns off earlier, without having time to heat the radiators.

After a short time, the circulation pump supplies the heat exchanger with the remaining cool water from the heating system return pipe and the burner turns on again. Then everything repeats again.

A high-power heating system has an increased pipe diameter and radiator volume, which means less hydraulic resistance. In larger systems, water does not flow exactly the same, it flows faster, at a higher flow rate (liters per second). During the rapid passage through the boiler heat exchanger, each liter of water only manages to heat up by 15-20 degrees Celsius. And in order to heat this liter to a given temperature, the water in the heating system must pass through the heat exchanger several times.

Low-power heating systems have thinner pipes, smaller radiators, higher hydraulic resistance and water flows slower. If you heat slowly flowing water with the same power, then the water that enters the heat exchanger immediately, at one time, will heat up by 40-60 °C, immediately to the maximum temperature, and the boiler will turn off. And the water remaining in the system, which has not reached the boiler, will remain cold until the next clock cycle. This is what happens in the boiler if its power is not adapted to the heating system.

The size of the flame (burner power) in the boiler is controlled electronically using a complex algorithm, which takes into account the time from the start of the burner, the temperature value, the rate of temperature change in the heating circuit, and the temperature difference in the forward and return pipes. I don’t know all the intricacies of the control algorithm, but the automation, without additional service settings, does not ensure normal operation of the boiler at a power below the minimum specified in the technical specifications.

In a properly configured heating system, the temperature difference in the forward and return pipes should be no more than 15 °C.

Clocking reduces the service life of the boiler and increases gas consumption

Any person, even without being a mechanic or electrician, knows that the most difficult operating mode for equipment is the moment of startup, turning on mechanical and electrical equipment. During the start-up period, the greatest wear is observed, and failures most often occur. An increase in the number of starts as a result of cyclicity consumes the operating life of very expensive parts of the boiler the most - gas and three-way valves, circulation pump, exhaust gas fan.

To ignite at the moment of starting, the maximum amount of gas is supplied to the burner. Part of the gas, before the flame appears, literally flies into the pipe. Constantly “re-igniting” the burner further increases gas consumption and reduces the efficiency of the boiler.

Some cyclical operation of a gas boiler is provided for by its normal operating mode. For example, regulating the temperature in a room without a thermostat or using a two-position thermostat occurs by periodically turning the boiler burner on and off.

The task of regulating the boiler power is to eliminate excessive cycling - clocking caused by the lack of adaptation of the boiler settings to the heating system.

To eliminate boiler clocking, it is necessary to equalize the power of the boiler and the heating circuit

You can do this in two ways:

- Reduce the boiler burner power to a level at which the automation can ensure normal operation of the boiler with the connected heating system.

- Increase the maximum power of the heating circuit by installing additional radiators or replacing existing ones with more powerful ones.

You can use both methods at once. Reduce the difference between the power of the boiler and the heating circuit by replacing and installing more powerful radiators. And then, compensate for the remaining difference by adjusting the boiler power.

The second method is more expensive, but sometimes you have to choose it. The fact is that, in order to save money, builders often install radiators in the house without a reserve of thermal power. As a result, in order to maintain the required temperature in the premises, in frosty conditions it is necessary to supply heating water to the radiators at a maximum temperature of more than 75 °C. At this temperature, organic dust particles decompose (burn) on the radiators and an unpleasant odor appears in the rooms. In addition, the high temperature of the coolant shortens the service life of polymer pipes and other parts of the heating system made of plastic and rubber.

Sometimes, the power of radiators is simply not enough to maintain the required thermal conditions even at the maximum heating water temperature. Before adjusting the boiler power, I recommend determining the need, and, if necessary, increasing the power of the radiators by 20 - 30%, at least in the coldest rooms.

When replacing radiators, it is necessary to take into account that the expansion tank built into the boiler is designed for a volume of water in the heating system of no more than 50 liters for a Gepard boiler, and 70 liters for a Panther. If the amount of water as a result of installing new radiators turns out to be greater, then it is necessary to install an external expansion tank.

The external expansion tank is connected to the return line of the heating system closer to the boiler. In this case, it is better to disable the built-in expansion tank.

Read: “Membrane expansion tank - volume calculation, pressure setting, connection”

Purpose and device

This type of gas valve can be regulating or shut-off and can be controlled manually or using an automatic system. In design and purpose, this element resembles its standard counterpart, with the difference that the locking part in it is driven by an electromagnet, supplemented by a movable core. When voltage is applied to the coil, it begins to push or pull in the core, which is connected to the rod. This part is intended for use in industrial installations, domestic heating systems and in the water supply sector. The valve device has a standard design:

The housing for installation is made of non-magnetic metal alloys or durable plastic. Its optimal tightness allows the valve to be used in a variety of environments. The process of controlling the part is carried out via wires that are connected to the electrical contacts of the sensor located on the outside of the housing.

Bypass valve

If the batteries in the room warm up unevenly, then it is necessary to increase the speed of the coolant. To do this, the bypass screw is turned clockwise.

If, when the heating is turned on, the liquid in the radiators begins to make noise, this is a signal to reduce the speed of the coolant. This is done by rotating the screw in the opposite direction. To set up and measure, you need to use a pressure gauge or digital differential pressure gauge. It will indicate the nominal pressure, which should not be more than 0.2-0.4 Bar.

How does a gas valve work?

Most gas units have a SIT valve. It includes the following elements:

- gas pressure measuring port at the valve outlet;

- adjusting screw for minimum and adjusting nut for maximum fuel consumption;

- lid;

- inlet pressure measuring port.

The gas boiler valve consists of a shut-off and modulation coil. When a voltage of 220 V is applied to the shut-off valve, a minimum volume of gas is supplied to the burner in accordance with the factory settings. The voltage is then transferred to the modulation coil. The processor, depending on the operating mode (power), supplies voltage with different modulation frequencies, regulating the amount of gas passing per unit time.

To set the boiler gas valve to minimum power, you will need a differential pressure gauge, a wrench and a screwdriver. The setup process includes the following steps:

- Remove the protective cap covering the differential valve screws.

- Open the fitting to measure the gas pressure supplied to the burner - turn the locking screw 1.5-2 turns counterclockwise.

- Connect the pressure gauge hose to the inlet fitting.

- Turn on the heating mode and disconnect one wire of the modulation coil - this is necessary so that the valve supplies gas to the burner to a minimum, which will correspond to the minimum power of the unit.

- According to the pressure gauge readings, set the minimum gas pressure on the burner. To do this, rotate the internal screw located under the protective cap. At the same time, fix the outer nut.

The dynamic fuel pressure at the gas valve inlet ranges from 1.4 to 2.4 kPa. If measurements show that the pressure is outside the specified limits, it is necessary to call gas specialists.

In the factory power range, there is no need to manually reset the gas valve. This is required in order to transfer the unit to a power lower or higher than the values stated in the instructions. Often, valve adjustment is needed if the performance of the device does not correspond to the heated area of the house or apartment.

Why the gas boiler turns off - reasons and methods for solving problems

How to connect a thermostat to a gas boiler?

Setting the gas valve when the boiler is “clocked”

A problem such as “clocking” of a gas boiler can be solved by adjusting the gas valve. It usually occurs if the power of the unit significantly exceeds that required for a given area.

To prevent the device from “clocking” in heating mode, it is necessary to reduce the outlet pressure. This is done by turning the adjusting screw counterclockwise.

To stop “clocking” in DHW mode, reduce the maximum pressure. This can be solved by rotating the adjusting nut counterclockwise.

However, in more modern models, “clocking” is eliminated automatically. For example, setting the gas valve of the Buderus boiler is done by blocking the cycles:

- hold the button with the wrench for 5 seconds;

- select the duration of intervals from 0 to 15 minutes using the arrow buttons.

It is recommended that adjustments of this kind be carried out only by service center specialists, especially if the boiler is under warranty. Otherwise, if you damage the valve, the company will void the warranty and you will have to buy a new part.

From the article you will understand the principles of adjusting pressure, thrust and power during operation of the device. Find out the probable causes of problems along with options for eliminating them. If you need to tune the boiler, use our materials. Do not forget about the safety rules, and you will successfully configure the device and fix minor problems.

You should be interested in the settings of a gas boiler long before purchasing, taking into account your needs and various features. We have written which parameters can or should be changed in the device you are using. The new device should be configured and prepared for operation, and some undesirable aspects can be corrected.

Setting up the boiler yourself

Correct adjustment of a gas boiler is needed for:

- saving resources;

- comfortable stay in the room;

- increasing the service life of equipment.

First of all, it is necessary to correctly determine the power of the heating equipment

It is important to take into account the features of the room: the number and area of windows, doors, the quality of insulation, the material from which the walls are made. The minimum calculation is based on heat loss per unit of time

As you know, the heating power is directly dependent on the modulation of the gas burner. If you have an electronically controlled unit, then the thermostat is activated and connected to the room thermometer.

The adjustment is carried out automatically: the thermometer measures the temperature in the room. As soon as its indicators drop below comfortable levels, it sends a signal to start the burner or increase the flame power.

In normal mode, the thermometer monitors the temperature in only one room. But if you install valves in front of each radiator, there will be control in every room.

You can adjust the burner manually by operating the gas valve. This is true for atmospheric boilers with an open combustion chamber. For example, in the Protherm Cheetah and Protherm Bear models, the valve is controlled by an electric motor. To change the settings you need to go to the service menu. Usually this work is performed by a specialist, and the user himself acts according to the instructions.

However, it is still necessary to know how to call up the hidden menu for adjustments. Let's look at a few examples.

Before going to the menu and setting up, you need to perform the following steps:

- open the taps on the batteries;

- the room thermostat must be set to maximum values;

- in the user settings, set the maximum temperature mode, which you usually set at the lowest possible temperature outside. The burner always turns off when the readings are 5°C higher than the set values. For example, at 75°C, shutdown will occur upon reaching 80°C;

- The coolant should be cooled to 30°C.

For Protherm Gepard:

- You need to hold down the Mode key on the panel. As soon as you see zero on the display, set the value to 35 by pressing “+” and “-“.

- Next, press Mode to confirm;

when d.0 lights up on the screen, you need to enter the line number in the menu. These manipulations are also performed by pressing “+” and “-” d. (number). In order to set the maximum burner power, you need to select d.53, for the minimum - d.52.

- In order to proceed to the selection of a parameter, Mode is also used, it changes “+” and “-“.

- The installation receives automatic confirmation.

- Return to the original menu and hold Mode.

While making adjustments through the panel, monitor the change in flame and temperature intensity.

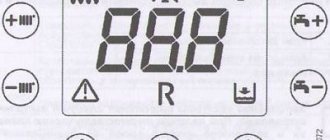

Display of the gas boiler Proterm Panther

For Proterm Panther the procedure is different:

- Hold Mode for about seven seconds.

- Next, enter code 35.

- The entry is confirmed.

- When d.00 appears on the left side of the screen, you must enter a number using two buttons.

- Then change the parameter on the right side of the screen using the 3 keys.

- After confirmation, click mode to exit the menu.

KSU-2P control kit.

The following modifications are available for boilers operating on gas fuel:

- KSU-2P-1-G (as part of control and signaling units BUS-1 and switching element unit BKE-1) - for boilers with natural circulation with vacuum;

- KSU-2P-2-G (as part of blocks BUS-2 and BKE-1) - for boilers with natural circulation with pressurization;

- KSU-2P-3-G (as part of blocks BUS-3 and BKE-2) - for direct-flow boilers with supercharging.

The supply voltage of the kit is a three-phase network 380/220 or 220/127 V with fluctuations ranging from +10 to -15%. The supply voltage is set using jumpers on the block located in the control and signaling unit (BUS). AC frequency 50 ± 1 Hz. Power consumption no more than 300 VA.

KSU-2P, together with sensors and actuators, provides: two-position regulation of the main technological parameters of the boiler (stabilization of the water level in the drum - for KSU-2P-1-G and KSU-2P-2-G; stabilization of steam pressure - for all modifications); safety automatics (gas supply to the boiler is stopped in case of emergency decrease and increase in gas pressure, decrease in air pressure, increase in steam pressure at the boiler outlet, absence of burner flame, emergency increase and decrease in the level in the boiler drum - for KSU-2P-1-G and KSU-2P-2-G, lowering the vacuum in the boiler furnace - for KSU-2P-1-G, in case of an emergency increase in the temperature of the steam at the boiler outlet and the temperature of the exhaust gases - for KSU-2P-3-G); light and sound alarms with storage of the root cause of the accident; issuing signals to the control panel about turning on the set and stopping the boiler; automatic start and stop; working alarm.

The BUS contains functional blocks. On the front panel of the BUS there are operational control and alarm controls (figure below). In addition, the BUS includes intermediate relays used to control the boiler actuators and magnetic starters of the BKE unit 16, as well as to switch the BUS circuits during the execution of the control program.

Emergency mode

To prevent accidents when the boiler overheats above +95°C or the temperature sensor breaks down, an audio signal and an accident indicator are provided. In this case, the automation turns off the fan, and the circulation pump continues to work continuously to cool the coolant, driving it through the heating system.

When the cause of the accident has been eliminated, the automation must be switched to normal operation by pressing the “Exit” button. It is advisable to install sound and light signals notifying about an accident when the operating personnel are located at a distance from the boiler or the heat generator is installed in a noisy place, for example, in factory premises.

In this case, to output an external alarm in the device connection diagram, it is necessary to use an intermediate low-power relay (Fig. 3).

Rice. 3. External relay connection diagram: L – power phase; N – power neutral; PE – protective grounding; KM1 – external relay

In the case when several heating boilers with programmers are used, alarm signals are output to one control center, which allows you to quickly respond to the situation and, thus, prevent or reduce the consequences of accidents.

Let's consider the main advantages

- Efficient operation of the system on different types of gas supply.

- The system does not require connection to the electrical network.

- There is a starting gas filter and a special screw to regulate the fuel supply.

- Possibility of operation of the device at low gas pressure.

- Function to turn off the system when there is insufficient draft or when back smoke occurs.

- Stable temperature conditions.

- Possibility of smooth adjustment.

- Piezo ignition is modeled to make the device as simple and convenient as possible during operation.

- Constant outlet pressure.

- Simple design and compact dimensions of the device.

Setting up diesel burners.

The diesel burner is adjusted after maintenance or major repairs of the boiler, at the first start-up or during operation to achieve the most optimal fuel combustion characteristics. At the beginning of work, the correct installation of the burner device is checked, the safety devices of the boiler are checked, and the condition of the combustion chamber and chimney is checked. For correct settings, it is necessary to determine the rated power of the boiler and the back pressure of the firebox (aerodynamic resistance). Accordingly, the operating ranges of the boiler and burner characteristics must coincide. Based on the rated power of the boiler, it is necessary to select a nozzle with the appropriate fuel consumption, then set the positions of the turbulator equalizing disk, nozzle rod, ignition electrodes and air damper. After this, the boiler is turned on at maximum power and the correctness of the preliminary settings is determined by the color of the flame. For more accurate settings, use a fuel pressure gauge and a gas analyzer. Using a gas analyzer, the temperature of the exhaust gases, the content of carbon monoxide and residual oxygen, and carbon dioxide are measured. If the parameters deviate, the amount of fuel supply or the position of the air damper is adjusted.

Basic work on setting up and adjusting diesel burners.

- Determining the rating of a diesel injector. (flow rate, spray angle, spray cone shape).

- Adjusting the gaps of the ignition electrodes and the retaining washer (swirler).

- Setting the linear size of the nozzle rod.

- Adjusting the opening angle of the air damper or servomotor.

- Setting the fuel pump pressure.

- Adjustment of the torch shape and stability of fuel ignition.

- Checking the quality of fuel combustion and optimizing combustion.

Adjusting the power of a gas boiler

In this case, the task is to reduce or increase the indicator. The indirect method of adjustment involves reducing the supply through the taps: the one located after the supply to the boiler and the one on the downstream side. The range of regulation will decrease, so it is better to prefer direct methods.

To increase power, select an option:

- Adjust the burner to the desired level - relevant for modulating units.

- Buy a more efficient burner.

- Replace the injectors with larger ones. Remember, with an increase in heat transfer from the boiler, gas consumption will increase, the risk of breakdown ahead of schedule, and the efficiency will decrease.

Ideally, it is better to entrust the adjustment to increase power to a boiler specialist. The increase in power for these options reaches 15%. If this is not enough, use additional devices to heat the rooms. Remember to clean the boiler to maintain power levels.

Tubes with micro-torches for an atmospheric burner - such a device operates almost silently, but is characterized by low power, dries out the air in the room and depends on a large number of external factors

Sometimes you have to reduce power. First, it is adjusted through the menu: by parameters of the heat exchanger temperature and anti-cycling time. Then set up the circulation pump. If necessary, change the burner to a modulating one.

Reasons for changing boiler power:

- Increase: it is necessary to re-equip the device at the same time as increasing the power, connect an indirect heating boiler, the heating area has increased.

- Reduction: refusal of one of the functions (heating or hot water supply), part of the functionality (heating of individual rooms, heated floors), reduction in boiler performance.

If there is excessive fuel consumption, it is worth inspecting the secondary heat exchanger and removing residual salts manually or with a chemical compound. Contamination will be indicated by a characteristic gurgling sound when the boiler is operating.

Consumption increases due to the low specific heat of combustion (calorific value) of the gas. The norm is no less than 7,600 kcal m³. Poorly dried fuel's calorific value drops by almost half.

Also adjust the gas valve. They are regulated depending on the structure:

- single-stage ones have only “on” and “off” positions;

- two-stage valves are equipped with 1 inlet and 2 outlets, and they open in an intermediate position;

- three-stage boilers have two power levels;

- With the help of modeling valves, power can be adjusted more smoothly; they have many flame modes, in addition to the “on” and “off” positions.

Look at the color of the flame. If there is a noticeable yellow part, tighten the lower valve to reduce the fuel supply.

845 SIGMA Multi-Function Gas Valve with Power Modulation, Outlet Pressure Regulator and Fuel Control Module - Accommodates a variety of threads and flanges

Set the heating operating temperature on the thermostat again. The principle of its operation is that the rod is turned on. As the temperature drops, the element shrinks and opens the fuel supply. An increase in temperature leads to an increase in the rod, causing gas to flow in a smaller volume.

If there is a lack of air, inspect the damper, boost and temperature regulator. A popping sound when igniting the main burner appears due to clogged air supply paths. Remove dust from them and inlet openings.

Safety system

The security system of a gas boiler includes many elements that can be divided into 2 groups:

- Devices that contribute to comfortable operation of the boiler;

- Devices that are responsible for the safety of equipment.

The second includes a thermostat, a safety valve, as well as a flame and draft control sensor.

The flame control sensor consists of the following elements: an electromagnetic valve that turns the gas supply on and off and a thermocouple. The thermostat maintains the desired temperature of the coolant and protects against overheating. When the coolant reaches a critical point, the module turns the boiler on or off.

As the temperature rises, the location of the bimetallic plate changes, it bends and blocks the pipe through which the gas flows. Thus, the draft control device turns off the fuel supply to the burner.

The safety valve regulates, distributes and shuts off the gas flow. In a heating system, such a device is an integral element of pipeline fittings, which is of great importance in controlling the volume of the coolant.

Fuel moves through an opening in the valve called the seat. In order to turn off the equipment, it must be closed with a piston.

Gas valves come in single-stage, two-stage, three-stage and simulating types.

The first type has 2 operating positions: on and off.

Two-stage has 1 input and 2 outputs. The valve opens after turning to the intermediate position, so activation occurs smoothly.

Three-stage is used for gas boilers with two power levels.

The latter are used to smoothly change the boiler power value.

Automation is used for safety and convenience. The user does not need to perform many tasks independently. This includes selecting a comfortable operating mode, diagnostics, auto-ignition of the burner, etc.

Selection and configuration of equipment

The issues of operating the heat supply system of a private house, in contrast to centralized systems, fall entirely on its owners. And one of the problems that has to be solved is the issue of correct selection of gas equipment.

Experience in operating systems shows that a properly selected boiler should operate for at least 30% of the heating period.

The average value of boiler power consumption per square meter of a heated room (with a ceiling height of up to 3 meters) is about 100 watts.

Practice also shows that installing a boiler or burner with too high a power can create many problems associated with excessive gas consumption, difficulty in selecting the temperature in heated rooms and the reliability of the system.

After selecting and installing the heating system, as well as each time it is started, the following adjustments are made:

- Complete heating of the boiler.

- Full opening of the chimney damper.

- Setting the burner flame to maximum power (the flame should consist of blue and yellow segments).

- Shut off the gas supply valve when lowering to remove the yellow segment of the flame.

- Checking the safety automation and operating modes of the boiler.

Important! Setting the correct flame color of a gas burner is key to complete combustion of gas without the formation of soot that settles on the walls of the firebox and chimney, reducing the efficiency of the system and increasing gas fuel consumption

How to adjust burner power

If the burner significantly exceeds the boiler in power, it may not have enough firebox volume, air flow through the dampers and from the pressurization. In this case, the combustion of the flame becomes uncontrollable, and the burner flame turns yellow.

Incomplete combustion of gas fuel causes soot in the firebox and chimney with combustion products, and part of the energy is dissipated into the surrounding space, increasing fuel consumption.

Photo 1. The shut-off valve helps regulate the gas supply in case of problems with the boiler.

In this case, the burner power can be reduced by closing the gas supply valve when lowering.

However, if the power is constantly set to the minimum value, this will reduce the efficiency and range of adjustments of the system.

Reference! When choosing a gas burner, in addition to the dimensions of the combustion chamber and the geometry of the torch, it is important to take into account the compliance of the passport values of the minimum and maximum power and methods of its regulation, as well as the gas consumption of the burner

High gas consumption

The reason for high gas consumption is often the ineffective operation of the boiler heat exchanger. The coolant passing through the heat exchanger carries with it particles of scale and salts, which can be deposited on the internal walls of the heat exchanger, reducing its thermal conductivity and increasing the amount of fuel required for heating.

Typically, a problem with the heat exchanger is manifested by a characteristic noise emanating from a working boiler, reminiscent of a whistling or gurgling sound, similar to a boiling kettle.

In this case, you will need to manually clean the heat exchanger or wash it with a special compound.

The reason for high gas consumption can also be its reduced calorie content, caused by insufficient drying by the gas distribution company. The norm of the lower calorific value of household gas should be at least 7600 kcal per cubic meter, but in practice the calorific value of gas can be reduced to 4000 kcal.

Installation of a throttling insert in the air duct to the boiler

1 and 2 - throttling inserts prevent excess air from entering the burner.

Manufacturers of all gas boilers, in their installation instructions, require the installation of throttling inserts in the supply air ducts and chimneys. Some manufacturers call them diaphragms or diffusers.

According to the boiler manufacturer's instructions, these inserts are installed when the smoke/air ducts are short, to increase the aerodynamic resistance of the system and reduce the amount of air supplied to the burner. In addition, the throttling insert reduces the impact of wind gusts on the operation of the burner through the smoke/air duct. In what cases to install and what size the insert should be is indicated in the boiler manufacturer’s instructions.

I recommend installing such throttling inserts on all gas boilers and water heaters configured to operate at lower power. Moreover, for any design of smoke/air ducts.

The throttling insert (diaphragm, diffuser) is a disk with a hole in the center. Such a disk in the air duct creates local resistance to air movement. The diameter of the central hole in the disk is selected so that the amount of air that passes through the insert is sufficient for complete combustion of gas in the boiler burner when operating at maximum power.

When there is a shortage of air on the boiler burner, the flame turns reddish-yellow.

To set up and control the operation of the burner and the gas exhaust tract of the boiler, it is convenient to rely on the readings of a gas analyzer that measures the excess air in the combustion products of a boiler operating at maximum power. Optimal combustion parameters are achieved with excess air coefficient values of about 1.7-1.8. Excess air ratio values greater than 1.8 indicate that excess air is flowing through the boiler. The gas analyzer can be rented or rented.

How and why to regulate the power of a gas boiler?

How to adjust the power of a gas boiler?

When setting up a single-circuit or double-circuit gas boiler, you can reduce or increase the power. By adjusting indirectly, you reduce it with taps.

You can increase power like this:

- Set the burner to the desired setting.

- Buy a new burner with higher performance.

- Change the injectors to those with a larger cross-section.

If you need to correctly reduce the power when setting up a gas boiler, then use the menu. Exchanger temperature and cycle time settings. And then they regulate the circulation pump.

Why you need to change the power of the equipment:

- Make it taller. The area of the room has become larger or there is a need to re-equip the device or connect a boiler.

- Do below. One heating, hot water or heated floor was turned off. There are fewer rooms. Boiler performance has dropped.

How to set the gas valve on the boiler?

How to set the gas valve on a boiler depends on the device:

- If the valve is from one stage, then it has an on and off switch.

- And when the valve is more complex in its design - 2 stages, then there will be an inlet and 2 outlets that open in between.

- With three stages there are 2 levels.

- When the valve is modeling, the power can be adjusted softly, adjusting the flame more accurately.

Set the degrees on the regulator. When the temperature drops, the element becomes small and gas flows well. And when the temperature rises, the rod is also larger and the gas flows less intensely.

If you see that there is not enough air, check the damper, regulator, boost. Popping noises during ignition may indicate that the air passages are clogged. It is worth removing dust from them and cleaning water holes.

Features of operation of solid fuel boilers

The process of burning wood or coal is somewhat more complicated than burning the same methane (natural gas). Methane is a simple inorganic compound that decomposes at high temperatures into carbon dioxide and water with some carbon monoxide. Wood and coal are complex organic substances that, when burned, form several substances and gases, some of which are aggressive. This leaves its mark on the longevity of the heat generator. Individual piping of solid fuel boilers is done in order to create an optimal operating mode and thereby extend their service life.

One of the features of the operation of water heating units that burn solid fuel appears after the firebox is ignited and reaches operating mode. If the installation of heating pipelines is carried out directly to the heating installation and, during heating, cold water is passed through the water jacket of the unit, then condensation will begin to form intensively on the internal walls of the firebox. It reacts with combustion products, mixes with ash and firmly adheres to a metal or cast iron surface. The results are as follows:

- The steel walls of the combustion chamber are corroded by corrosion.

- A cast iron firebox is not as susceptible to corrosion, but its rough surface allows plaque to stick, which is very difficult to remove. The same coating will appear on the walls of the steel chamber.

To successfully combat condensate, it is necessary to install a small circulation circuit with a three-way valve; it is not recommended to connect a solid fuel boiler to the heating system directly.

Another feature of the operation of wood heating systems is inertia. When the water temperature in the system is sufficient, the automation closes the access of air to the firebox and stops the process. Nevertheless, combustion continues for some time, the coolant temperature exceeds the set one. The same phenomenon is observed when the circulation pump stops as a result of a power outage. Water in the jacket can boil, forming steam, and destroy the jacket or rupture pipes. To avoid this, a safety group with a relief valve set to a certain critical pressure is installed on the supply pipe or directly in the boiler water tank.

Room thermostat saves gas

To automatically control the temperature in the house, boiler manufacturers recommend using a room or weather-compensated controller with a continuous principle of controlling the boiler flow temperature.

You can also use a room thermostat of a two-position principle (ON/OFF), but with less efficiency.

Boilers of luxury categories, as a rule, are immediately equipped with a remote control unit. Installed on the wall of the room, such a unit allows you to remotely control and monitor the operation of the boiler, and also serves as a room thermostat.

A room regulator allows you to maintain a constant temperature in a heated room with high accuracy. With manual control, the range of temperature fluctuations is larger and deviations are more often towards higher temperatures. Every extra degree in the room leads to an increase in gas consumption for heating. In addition, using a thermostat, you can program an automatic decrease in the temperature in the house during certain periods (at night...). Refusal of manual control of heating temperature and installation of an automatic regulator to maintain the required temperature in the room can significantly reduce gas consumption for heating.

In addition, to change the boiler settings, the owner does not have to run to the boiler room. Custom boiler settings can be changed right in the house, on the thermostat.

A room thermostat or room temperature sensor is always installed in the largest room of a house or apartment.

Room thermostat saves energy

When the boiler operates without a room thermostat, the circulation pump runs constantly, consuming electricity. The room thermostat controls not only the gas burner, but also the circulation pump. The circulation pump, controlled by the room thermostat, operates intermittently, which saves energy and the life of the pump.

Power-on problems

There may be several reasons for such a malfunction:

- There is no voltage in the network (or it has decreased too much, it has become less than 150 V).

- No gas.

- The boiler is blocked by a protection system that was activated due to a critical error (overheating above 98°).

There may be other reasons for failure. First of all, you should check the voltage in the network.

The boiler is capable of compensating for fluctuations of up to 30%, but with more significant changes, it simply will not start. You can solve the issue by using a separate outlet and installing a stabilizer.

If all possible causes have been checked and eliminated, but the boiler continues to be silent, you should call a technician. Perhaps the cause was a failure of the control unit, a breakdown, or another serious problem.

You should not attempt to resolve the issue yourself; this may cause the final destruction of the unit.

Thermocouple in the gas control system (gas control)

If you decide to install a solid fuel boiler in your country house, you do not need to worry about what will happen if the fire suddenly goes out. However, when you use gas equipment, you need non-volatile automation that can shut off the gas supply as quickly as possible if the burner suddenly goes out. For these purposes, modern gas boilers are equipped with a gas control system. How does it work?

The system consists of two main parts: a solenoid valve and a thermocouple. One end of the sensor is placed directly in the burner flame, and the second is connected to an electric valve, which consists of a core with a winding, a cap, a return spring, an armature and a rubber band that shuts off the gas supply.

Photo 4: Non-volatile gas control system for stoves and boilers

The gas control works quite simply. By pressing the gas button, you push the rod inside the coil, charging the spring. According to the instructions for igniting a gas boiler, the supply valve must be held pressed for about several tens of seconds. This time is necessary for the thermocouple to warm up and sufficient voltage to appear at its ends to hold the valve inside the coil.

At the moment when the burner goes out, the thermocouple begins to cool, the voltage at the ends of the thermocouple decreases and at some point, the return force of the spring outweighs the electromagnetic force holding the rod inside and returns the valve to its original position, cutting off the gas supply. This process usually takes several tens of seconds.

Automation responsible for safety

According to the rules set out in the regulatory documentation (SNiP 2.04.08-87, SNiP 42-01-2002, SP 41-104-2000), gas boilers must have a safety system. The purpose of this block is to urgently shut off the fuel supply in the event of any breakdown.

The presented diagram shows an automation system that allows you to regulate the functions of the gas device, with a detailed image of all the components

The principle of safe operation of the gas boiler automation system is based on monitoring instrument readings.

The control unit monitors the following factors:

- Gas pressure. When it drops to a critical level, the supply of flammable substances is immediately stopped. The process occurs automatically using a valve mechanism pre-set to a certain value.

- Gas supply. Responsibility for this property in volatile devices lies with the maximum or minimum relay. The mechanism of operation is to bend the membrane with the rod as the number of atmospheres increases, which leads to the opening of the contacts of the heating device.

- No flame in the burner. When the fire dies out, the thermocouple cools down, causing current production to stop, and the gas supply stops due to the gas valve being closed by the electromagnetic damper.

- Presence of traction. As this factor decreases, the bimetallic plate heats up, which causes a change in its shape. The modified element presses on the valve, which closes, stopping the flow of flammable gas.

- Coolant temperature. Using a thermostat, it is possible to maintain this factor at a given value, which helps prevent overheating of the boiler.

The possible malfunctions mentioned above can cause the main burner to go out, resulting in the possibility of gas entering the room, leading to fatal consequences.

This figure shows a schematic design of the functioning of the control automation, designed to prevent overheating of the system or other disturbances in its operation

To avoid this, all boiler models must be equipped with automatic devices. This is especially true for outdated models, where such devices have not yet been provided by manufacturers.

Maintenance of Baxi gas boiler

Almost all gas boilers have the same design, regardless of the manufacturer. Through the heat exchanger, thermal energy from fuel combustion is transferred to the coolant. A gas boiler may have 1 or 2 heat exchangers. During operation, the heat removal surface becomes contaminated with soot, and scale forms inside the gas boiler. Due to these contaminants, the characteristics of thermal transfer are reduced, therefore, energy consumption will increase.

In order for the Baxi gas boiler to operate in economical mode, it is necessary to periodically carry out maintenance of the system

Particular attention should be paid to units with bithermal heat exchangers, which are difficult to clean due to their design

Cleaning the secondary DHW heat exchanger from scale

It is known that when water is heated in the DHW heat exchanger, hardness salts are deposited.

Depending on the degree of hardness of tap water, the amount of water used and its heating temperature, the heat exchanger must be cleaned of scale at intervals, every 1 - 5 years .

Read further:

Read:

Cleaning the heat exchanger of a gas boiler or geyser from scale. Green arrow - DHW water flow (flow) sensor

What is automation for a gas boiler

After the gas boiler starts up, control over its operation is entrusted to a specialized device, which begins to operate within the framework of the program embedded in it. One of the main points of using automation for gas boilers is to ensure the safe operation of the device. And also all models automatically regulate the maintenance of the required and preset heat temperature in the rooms.

According to their functionality, automation for gas boilers is divided as follows:

- devices that are volatile;

- devices in which control devices are volatile.

The first type uses models that require electrical energy, they have a fairly simple design and operate on the principle of residual power. A pulse signal is received from a sensor that controls the temperature, also called a temperature sensor, and a valve operating on an electromagnetic principle, following the instructions of such a signal, closes and opens, thereby either interrupting the gas supply or, conversely, provoking it.

The second type includes energy-dependent devices that operate based on the properties of the physically used substance, the one that circulates inside the circuit of the device itself.

In what cases is it necessary to adjust the burner flame?

An atmospheric gas burner for heating equipment often fails. It is equipped with models of both wall-mounted and floor-standing boilers. The injection burner of floor-standing equipment reduces its efficiency for various reasons:

- Burner power is too high. This happens when a high-power burner is purchased for small heating equipment. At the same time, there is not enough space for combustion, the air flow for such power is weak, which leads to the transition of the flame from blue to yellow, sooting of the combustion chamber and chimney.

- If the chimney is poorly cleaned, the boiler draft deteriorates. At the same time, waste combustion products are poorly removed, and the air flow is small. This worsens combustion and the flame turns yellow.

- A defect in the burner itself does not make it possible to correctly adjust the complete combustion of the fuel.

- Due to pressure changes in the gas supply system, well-regulated equipment can release large amounts of unexhausted gas into the chimney. Partially it settles with soot and soot. A large layer of soot reduces traction and increases fuel consumption.

- Starting heating equipment after repair.

- The presence of extraneous noise during operation of the boiler or gas burner.

- Changing the type of fuel.

Conclusions and useful video on the topic

On the presented video you will find brief instructions for installing a gas boiler equipped with an automatic Eurosit system.

A modern gas boiler is a rather complex design that provides many useful functions. The automation of most models greatly facilitates their operation, taking over the control of the mechanisms and monitoring their operation. .

This significantly increases the level of safety during the operation of the heating system, and also increases its efficiency by selecting the optimal mode.

Do you need to adjust the automation of your gas boiler? Do you want to tackle this problem yourself and want to clarify some points? Feel free to ask your questions under this article, and our experts will try to help you.

Or have you successfully adjusted the automation and want to share your experience with other users? Write your tips, add photos depicting the main points - your recommendations will be very useful to other owners of the same boiler.

Fan control

Let's consider the principle of fan control in automatic and manual modes. In the first case, the temperature controller automatically selects the fan rotation speed according to the type of fuel selected in the program and the temperature sensor readings. The fan speed can be changed from 0% to 100% in 10% increments. When the set boiler temperature is reached, the programmer maintains it by smoothly adjusting the fan power. And when the temperature exceeds the set value by 5 °C, the fan turns off completely. If the temperature of the outlet coolant drops below a preset value, the programmer turns on the fan and then smoothly regulates its power, preventing the temperature from lowering. Thus, stability of the set coolant temperature is achieved.

Using the programmer, you can set the type of fuel used - this helps to use fuel more efficiently. When heating with wood, wood briquettes, pellets, you must select the “Firewood” function; peat briquettes, brown or hard coal – “Coal”; “Shtyb” – selected when firing with anthracite (fine coal). The specifics of the programmer's operation in manual mode are shown in the graph in Fig. 2. A fan with a constant power in the range from 0 to 100% forces air into the combustion chamber. The required power can be set in 10% increments in the programmer menu. The automation turns off the fan when the set temperature is reached. When the temperature in the boiler drops below the set hysteresis value, the fan automatically turns on. In this mode, the automation is programmed to periodically “blow through” the boiler. In the controller menu you can set the duration and frequency of this function. It is also useful when connecting non-standard heating systems.

Rice. 2. Fan operation schedule in manual mode

In manual mode, the boiler is extinguished by turning off the fan when the temperature drops below the set value, since the programmer determines this as complete burnout of the fuel and further operation of the fan is impractical.

Recommendations for choosing a device

Oddly enough, you can still find budget models of wood-burning heaters on sale that are not equipped with any automation. Most of them have in the basic configuration only a sleeve mounted inside the water jacket. To automate such a boiler, you will have to buy and install a draft regulator yourself.

Hence the first recommendation: when choosing a heat generator, pay attention to the presence of such a sleeve and an ash pan door that rises upward.

A boiler with the ability to install a regulator (left) and with manual control (right)

To choose the right mechanical regulator, you must adhere to the following recommendations:

- the force developed by the drive (indicated in the product data sheet) must be enough to lift the door;

- select the temperature control range from 60 to 90 °C;

- make sure that the operating stroke of the drive is sufficient to fully open and close the sash;

- The threaded connection on the body must match the mating part in the boiler, usually ¾”.

You should also pay attention to the location of the liner in the boiler body. It can be on top, front or on the side panel. For the first option, you need to select a device that can work in a vertical position, for the other two - in a horizontal position. There are traction regulators, for example, Regulus rt3, which work in any position and have 2 adjustment scales.

Manufacturers

Let's look at the most popular companies that produce gas valves.

Dungs

A German company that is one of the most popular in the production of gas control valves.

Dungs products began appearing on the Russian market in 1999 and were able to firmly consolidate their position. Users constantly purchase products from this manufacturer because they are distinguished by high quality, reliability and long service life.

Double gas valve device DUNGS type DMV

The only drawback that can be noted is the high price.

The most technologically advanced development of the Dungs company in the mass segment is the Dungs DMV-D valve - this is a two-way device, which, in fact, is a connection of two independent valves in one compact body. Thanks to its technical characteristics, it can function in high pressure working environments (up to 500 mbar). The cost of devices starts at approximately 12,000 rubles.

SIT GROUP

The Italian manufacturer SIT GROUP began its activities in 1953. The company has existed for more than 60 years and during this time has managed to establish itself extremely positively. The company's products are widely used due to their optimal price/quality ratio.

Gas valve SIT 845 SIGMA

The Sit 845 Sigma valve is the most popular device that can be bought in the budget price category. The 845 Sigma gas valve has a two-way design that can be mounted on gas-consuming appliances from most common manufacturers; it is also suitable for a gas boiler. This valve is equipped with an electric drive, so its operation requires a constant voltage of 220 Volts, in the absence of which the valve locking mechanism takes the closed position. The main advantages of 845 Sigma are the minimum period of valve activation and compact dimensions.

The model allows you to adjust the limit level of gas pressure at the outlet. The device is installed on a pipeline using a flange connection. The valve for the Sit 845 Sigma gas boiler can be purchased for about 6,000 rubles.

p, blockquote 25,0,0,0,0 —> p, blockquote 26,0,0,0,1 —>

Thus, the gas valve is responsible for the automatic supply of gas.

Source

Automation: to trust or not?

Temperature sensor diagram for boiler automation.

The control system allows you to select the boiler operating mode depending on the presence of people in the room: the boiler setting should be such that during a long absence of residents, the temperature in the room is significantly lower.

However, you should only take advantage of the opportunity this setting provides if one of your neighbors is looking after the house. During a long absence, an emergency shutdown of the boiler may occur, and if the outside air temperature is low, then after a certain time the temperature inside may become negative, and the entire heating system will fail due to this setting. And there are plenty of reasons to stop the boiler.

This could be an emergency power outage or a decrease in the network voltage to a value below 190 V. Other reasons: strong wind entered the combustion chamber through the chimney and extinguished the burner; due to condensate freezing, the cross-section of the chimney decreased. A decrease in gas pressure, which is very likely in our time, can also cause an emergency shutdown.

Before using the settings provided by the automatic control system, you should ask your neighbors to monitor the condition of the boiler when the residents are not in the house.

A debate sometimes arises among experts about which mode of operation of gas boilers has an advantage: continuous or mode of alternating operation and shutdown, for example, as in a refrigerator. By what indicator should such settings be assessed? Practice shows that regarding the duration of operation of the fan, circulation pump, burner, igniter and other elements, none of the modes has an advantage.

If, in order to save money, you specifically reduce the gas pressure, then such a setting can lead to faster burnout of the burner.