Among the huge number of types of heating equipment on the market, one of the traditional options for use in a private home is a long-burning boiler.

Long-burning solid fuel boiler

Using the most modern scientific developments, engineers were able to build a boiler that can operate for up to 7 days on one load! This is not fantasy, this is already reality! Despite the rather large dimensions of the device and its bulkiness, this is the most practical and economical solution for heating a large area today!

A long-burning boiler can be used as the main combustion source, which explains its great popularity in many remote areas of the country where there is no other option for heating a home.

TT long burning boiler for a large house

Unlike a classic boiler, where heat is released by the flame during fuel combustion, a long-burning device works according to a completely different scheme. The long-burning boiler is a completely new and improved design.

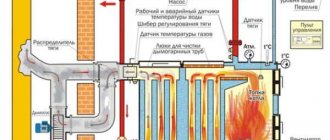

Construction of a solid fuel boiler

In conventional TT boilers, one load of firewood or coal ensures combustion for 6-7 hours, which is not very economical and requires constant monitoring in order to maintain optimal temperature conditions. Long-burning appliances can maintain heat for 7 days with one load of firewood or coal.

What accounts for this difference in raw material consumption and how is this productivity achieved? This is what we will talk about in this article.

Operating principle of a long-burning boiler

Solid fuel boilers appeared relatively long ago, but all of them, regardless of model and manufacturer, had one significant drawback. Fuel had to be constantly added as it burned. It was ineffective and not economical. This situation continued exactly until 2000, until the Stropuva company found a way to eliminate this problem. It is to engineer Edmuntas Štropaitis that we owe the invention of the long-burning boiler.

Today, this is the most practical and functional device for heating a private home or cottage, the performance level of which reaches 70 and sometimes 100%. But, unlike classic pyrolysis boilers, which are also characterized by good efficiency, such units can maintain heat for 7 days with just one batch of fuel!

What are its main technical features and what makes this device so economical and effective?

Long-burning boiler design

The operating principle of a long-burning solid fuel boiler is similar to pyrolysis units. The main heat is generated not from the combustion of wood or coal, but from the gasification of solid fuel. The combustion process takes place in a closed space, from where wood gas is released through a special telescopic pipe.

After this, the gas is directed into the heater nozzle, where diffusion (mixing) occurs with secondary air pumped by the fan. Thus, a continuous process will occur until the coals or firewood are completely burned. In this case, the combustion temperature sometimes reaches 1200 degrees.

Internal structure of a long-burning boiler

The effectiveness of this principle lies precisely in the fact that solid fuel is consumed very slowly, as needed, which significantly increases the efficiency of such a heating device. But not only high performance is the advantage of this design.

Important . Solid fuel (pyrolysis) long-burning boilers have very high efficiency compared to the classical design. It is equal to 95%.

As a rule, the whole point of long-lasting combustion is that not the entire load of coal or firewood burns out at the same time, but only the top layer. Due to the fact that air is supplied from above and not from below, fuel burnout occurs gradually, in its upper layer.

Long burning principle

When this layer burns out, the air supply is turned on, and exactly as much as is needed to burn the top layer. This ensures such a burning duration and the ability to control the process.

It should be said that this version of the heating device is acceptable exclusively as a heating system. If you need to think about a water heating system for domestic needs, then you should look for other options.

If the option is selected specifically for heating a large house, then such a device is an excellent alternative to electric and gas appliances.

The best pellet boilers with hopper

Buderus Logano S181

German single-circuit solid fuel boilers Buderus Logano series S181 are presented in three models with a power of 15, 20 and 27 kW. They are used to heat low-rise residential and industrial buildings with an area of up to 216 sq.m. The equipment is designed to work with fine fractions of coal or pellets.

Watch the product video

Design features

Structurally, the products consist of two blocks installed in direct contact:

- the boiler itself with a combustion chamber, heat exchanger and control unit;

- a spacious bunker for storing fuel reserves with the ability to dose it into the combustion chamber.

To activate the mechanisms and operate the automation system, a power supply of 220 volts is required. The boiler is capable of heating the circulating coolant up to 80o C.

The heat exchanger is designed for a pressure of 3 bar. In case of overheating, automatic protection is triggered. Human participation in regulating the combustion process is almost not required. The efficiency of models in this range is 88%.

ACV TKAN

The lineup

The line of solid fuel boilers of the Belgian ACV brand is represented by household and industrial units with a power from 60 to 300 kW. They have one heating circuit for coolant circulating through the building’s heating system. The installed electrical equipment requires connection to an alternating current network of 220 volts.

Watch the product video

Design features

The unit consists of a housing with elements located inside it: a combustion chamber, an ash pan and heat exchange equipment. A spacious hopper with a supply of pellets is attached to the side. The heat exchanger is made of copper. This material conducts heat excellently, is not afraid of corrosion and is almost resistant to the adhesion of layers of scale and dirt. The equipment can withstand a pressure of 3 bar and heats the circulating water to 80o C.

Such boilers are designed for long-term operation without human control. Their efficiency reaches 90%.

Zota 15S Pellet

The lineup

Pellet boilers of this Russian brand are represented by a long range of heating devices with a power from 15 to 130 kW. They have one heating circuit and are used exclusively for heating rooms. Maximum parameters of the circulating coolant:

- pressure 3 bar;

- temperature 95o C.

In case of overheating, a lock is triggered. The device is distinguished by the presence of a large bunker designed to store a supply of pellets and feed them into the firebox. It allows you to leave the boiler for a long time without direct human control.

For the automation and transport line to function, the unit must be connected to a household electrical network. On the rear wall there are fittings for connecting a chimney with a diameter of 150 mm and heating pipelines of 2".

Watch the product video

Design features

If there are no pellets, you can switch to using regular firewood. To do this, you will have to install the additional grate included in the delivery set and disconnect the secondary air supply tubes. Boilers of this brand are not only simple and unpretentious, but also achieve an efficiency of 90%.

Features of the design of a long-burning TT boiler

Typically, the design itself and the large dimensions of such a device already tell the consumer that it’s all about the large volume of the loading chamber. However, the duration of combustion here is determined not by a large amount of resources, but by slow smoldering.

TT boiler design

Duration of combustion is ensured through the use of special techniques. Today there are 2 main long-burning systems used in such devices. These are the Canadian system Buleryan and the Baltic Stropuva.

The second system is less common in our country due to the high price and large number of technical parameters. But the Burelyan system is fundamental in the production of long-burning boilers presented on the modern market today.

It is a small oven that consists of two chambers. In the first (lower) chamber, solid fuel burns, resulting in the formation of gas. It enters the second chamber, which is located above the first. Here the hot gas mixes with air and further combustion occurs. High heat transfer and good air circulation are ensured by pipes located from bottom to top along the circumference of the boiler cylinder.

TT long burning boiler

Of course, the duration of boiler combustion up to several days is determined by the need to load a large volume of fuel. For this purpose, the loading chamber door is located not at the bottom, but at the top of the boiler. The entire lower part is filled with fuel.

Large loading chamber ensures long burning

The smoke pipe is located at the top of the boiler, which is connected to the chimney. And at the very bottom you can see the ash pan, which is necessary for collecting ash and systematic access for cleaning.

If in conventional stoves the ash pan plays the role of a ash pan, supplying a portion of oxygen, then here the ash pan plays exclusively the function of collecting combustion residues, so its door is sealed. Where does the air come from? At the top of the boiler there is an air chamber, which simultaneously plays the role of a recuperator (here the flue gases heat its walls). That is, the air from the air chamber arrives already heated.

TT boiler

At the top of the chamber there is a damper that regulates the supply of air to the fuel. To ensure that oxygen is dosed into the chamber, there is an air distributor in the boiler, which is connected to the air chamber by a long telescopic pipe.

As the fuel burns, the distributor lowers along with the top layer of burning raw materials, which ensures a constant supply of oxygen. In order to return the distributor to its original position, it is enough to pull the cable with the ring up. By the way, the remaining fuel in the chamber can be determined by the position of the cable.

As a result of this design, manufacturers are able to achieve productivity (efficiency) of up to 85%, and adjustable power from 50-100%.

Video. The operating principle of a long-burning TT boiler.

The principle of this design explains the high environmental friendliness of long-burning boilers. The percentage of carbon dioxide released into the atmosphere is very low.

The raw materials for combustion are usually coal, peat briquettes, firewood, and coke. But in addition to ordinary firewood, you can use any waste from the woodworking industry. This waste is crushed to a fine powder and then pressed into granules called pellets. Fuel can be combined - it all depends on the model.

Pellet boiler

The large volume of the loading chamber and the insufficient flow of oxygen into the combustion chamber significantly increases the overall efficiency of the TT boiler; taking these factors into account, the smoldering process occurs extremely slowly and can reach up to 7 days. Pyrolysis boilers are also good, but they are very demanding on the quality and moisture content of the source fuel. Yes, here productivity will also decrease with wet wood, but not as much as in a pyrolysis boiler.

Many models work on the basis of bulk wood substances (sawdust, wood chips), on peat briquettes or on the basis of wood pieces and sections.

various fuels for the boiler

Due to the fact that oxygen enters the chamber in limited doses, the smoldering process occurs very slowly. But at the same time, the resources loaded into the boiler are sufficient to produce generator gas with high thermal conductivity. Through a ceramic nozzle, it rushes into the main combustion chamber, where the active combustion process continues. In this case, the process is accelerated and supported by additional air created by the fan.

The flame itself is formed by mixing gas and air, and is intensified by the use of fans.

Due to the complexity of the design and volumetric dimensions, such units are mainly used for heating large premises and large country mansions. For a small dacha or a one-story house, it is simply not economically justified to purchase such a boiler. The productivity of such units is too high.

TT boiler for large rooms

The high performance of long-burning boilers is also achieved thanks to the favorable location of the heat exchanger, which is a water jacket. The design of the unit helps to evenly heat the water circuit around the entire perimeter. The temperature of the exhaust gases does not exceed 130-150 degrees. The heat released in the boiler warms up the coolant as efficiently as possible.

When choosing a long-burning boiler for your home, let's go over its main technical characteristics and note the advantages and disadvantages.

Popular models

The most famous suppliers of solid fuel units are the following brands:

- Lithuanian Stopuva;

- German Buderus;

- Czech Wattek;

- Belgian ACV;

- Austrian Wirbel;

- Russian NMK, Zota and TeploGarant LLC.

Among the models on the market from various companies, there are several popular devices.

Stropuva Mini S8

A power-independent unit serving an area of up to 80 square meters. m. Works with three types of fuel and is distinguished by its small size. Equipped with a convenient vertical firebox door.

The special design of the ash pan allows you to reduce the need to clean it to twice a month. One bookmark is enough for daily heating; the pellets burn out in 48 hours.

Advantages:

- high efficiency;

- quality of construction;

- safety;

- presence of a thermometer.

Flaws:

- heavy weight;

- The rough surface of the door makes it difficult to clean.

Reviews

| Roman Oborin: | Igor Falaev: |

| “Economical and compact unit, burns for a long time. It consumes little fuel, heats the house well, and does not produce soot. The only negative is that it’s a bit heavy.” | “A small, convenient barrel, the device is immediately ready for use, you don’t need to assemble or screw anything in. The door handles are of high quality and reliable, they do not open spontaneously. It takes a long time to heat, it can burn for up to 20 hours.” |

Teplodar Cooper Expert-15

Russian model with the ability to install a burner.

In the upper half of the housing there is a fitting for air outlet. Compatible with firewood, coal and briquettes. Three air entry zones and top combustion ensure long-term heat maintenance. At the bottom there is a water reservoir that prevents excessive heating of the floor. A steel plate protects the door from heat. You can additionally attach a draft regulator.

Advantages:

- possibility of installing a pellet or gas burner;

- convenient door placed at an angle;

- continuous burning for 24 hours.

Flaws:

- complexity of installation;

- small firebox.

Reviews

| Oleg Egorin: | Semyon Ivin: |

| “It’s a convenient boiler, you can buy an additional burner, it works for a long time and even after switching off the house remains warm.” | “It’s not a bad unit, it’s enough for almost a day of heating, but it consumes a lot of fuel. Convenient door design for stowage." |

ZOTA Topol-16VK

A device with a water circuit at an affordable price. The triangular shape of the pipe avoids blockages and increases the service life of the device. To refuel the boiler, you can use firewood, coal and pellets.

The model is distinguished by a spacious firebox and the possibility of top and side fuel storage.

Advantages:

- low price;

- ease of use and cleaning;

- efficiency.

Flaws:

- low efficiency.

Reviews

| Vladimir Kharitonov: | Alexey Zaitsev: |

| “A high-quality device at an affordable price for its segment. Works flawlessly." | “The device is pleasant to use, cleans without problems, you can load different types of fuel, both briquette and regular.” |

Teplodar Cooper Expert-22

The device is small in size, capable of operating in 4 modes: fast heating, classic, medium and maximum. Combustion from top to bottom ensures uniform and longer combustion of the material and good heat transfer.

The upper cleaning hatch is protected by a steel screen that prevents burning.

Advantages:

- two hatches for cleaning;

- inclined door for top loading;

- top burning function.

Reviews

| Evgeny Zherdev: | Ivan Alaev: |

| “Sophisticated heating adjustment, you can adjust the burning duration from 30 minutes to a day. Easy to clean, special cleaning accessories included.” | “A high-quality model, the design allows you to connect heating pipes from either side. The device comes with a heating element and a thermomanometer.” |

Stropuva S30

Solid fuel boiler for placement in commercial and residential premises. Equally effective for year-round and seasonal use. It is characterized by high efficiency, is independent of power supply and is compatible with a variety of fuel materials.

The device has compact dimensions and is environmentally friendly. The duration of firewood burning is up to 30 hours, briquettes can smolder for up to 2 days.

Advantages:

- safety of use;

- high efficiency;

- durability;

- build quality.

Flaws:

- high price.

Reviews

| Kirill Malin: | Maxim Kansky: |

| “It burns for quite a long time, it is demanding on the quality of fuel. Soot forms on the outer skin.” | “It uses fuel economically and can be cleaned without any problems with a special powder. The downside is the high price.” |

Model characteristics:

| Model | Stropuva Mini S8 | Teplodar Cooper Expert-15 | ZOTA Topol-16VK | Teplodar Cooper Expert-22 | Stropuva S30 |

| Number of circuits | 1 | 1 | 1 | 1 | 1 |

| power, kWt | 8 | 15 | 16 | 22 | 30 |

| Combustion compartment | Open | Open | Open | Open | Open |

| Non-volatile | Yes | No | No | Yes | |

| Heated area, sq. m | 80 | 150 | 160 | 220 | 300 |

| Control type | Mechanical | Without control panel | Without control panel | Without control panel | Mechanical |

| Fuel | Firewood, wood briquettes | Firewood, coal | Coal and wood briquettes, firewood, coal | Firewood, coal | Firewood, wood briquettes |

| Efficiency, % | 85 | 75 | 75 | 85 | |

| Installation | Floor | Floor | Floor | Floor | Floor |

| Coolant heating, °C | 60-95 | 50-95 | 95 | 50-95 | 60-95 |

| Maximum water pressure in the circuit, bar | 1,5 | 3 | 3 | 3 | 1,5 |

| Weight, kg | 145 | 148 | 108 | 165 | 257 |

| Price, r | 52000 | 34500 | 29500 | 42400 | 85000 |

Specifications

- Long-burning boilers, which can operate for up to 7 days, mainly operate on peat briquettes or wood shavings. There are also universal devices that allow you to work with different fuels, but its length should not exceed 40 cm. Otherwise, you will have to prepare firewood yourself.

- The higher the humidity of the feedstock, the lower the performance of the heating device will be. Therefore, for combustion, manufacturers recommend using fuel with a moisture content of no more than 20%.

- On average, 1 boiler load provides up to 7 days of continuous burning.

Firewood moisture content

Advantages:

- High performance. Perhaps this is one of the main and significant advantages of such bulky units. The average efficiency is at least 90%.

- Environmental friendliness. Carbon monoxide entering the chimney is used as the main source of flammable gas formation.

- Relative availability and inexpensive price of solid fuel.

- Automation of the work process. Some models are equipped with a remote control that allows you to set the desired temperature.

- Saving time and resources.

- Autonomy of work. Can be used as the main heating device.

- High fire safety. Long-burning boilers are equipped with an alarm sensor that is triggered in any emergency situation.

- High reliability of the design. With proper operation of the equipment, the boiler will last for decades.

But no matter how efficient, economical and productive these boilers are, there are some disadvantages of such devices.

Flaws:

- Large dimensions.

- High price.

- Regular cleaning required.

Automatic boilers running on wood chips and coal

This option of automatic units should be preferred by residents of regions where the cost of coal is comparable to the price of pellets. Otherwise, their operation will cost more.

The main advantage is higher efficiency rates. However, coal emits a significant amount of soot and tar, which leads to less environmental friendliness. Equipment maintenance is carried out more often, as more ash is released during combustion.

For coal boilers, there is a requirement for the size of combustible material granules: from 4 to 25 mm in diameter. This is necessary for the smooth operation of the screw conveyor.

Security measures

In order for a long-burning solid fuel boiler to serve for a long time and not cause burns or accidents in the house, you should follow simple rules for operating this device.

- Do not allow the system to overheat. Given the high inertia of the boiler, it cools down extremely slowly. Therefore, it is important to monitor the temperature control mark. This is especially true for pipes made of metal-plastic or plastic. If the outlet temperature is 110-115 degrees, this will lead to dire consequences. The pipes may simply melt. To do this, it is necessary to use cooling heat exchangers and switching valves when installing the heating system.

Indoor ventilation system

- Under no circumstances should a shut-off valve be installed in the pipeline between the expansion tank and the boiler.

- The room must have ventilation for air flow.

Security measures

- Do not light the boiler if there is no water in the expansion tank.

- Do not place flammable objects on the boiler.

Device Features

Solid fuel boilers have such functional systems as:

- temperature control;

- smoke removal;

- coolant turnover;

- firebox

The supplied fuel burns in the firebox. This causes its walls to heat up and transfer high temperature to the water circulating through the water jacket. There are pyrolysis and classic boilers. In classic ones, the fuel simply burns, releasing gas. In pyrolysis, fuel and released gas are burned in different systems. This increases power, efficiency and reduces chimney requirements.

However, pyrolysis equipment is demanding on the level of fuel moisture - no more than 20%. The owner of the boiler must have a supply of firewood at all times, which has been drying for at least a year.

The firebox has double walls. The coolant is poured between these walls. As a rule, water is used. Sometimes water is mixed with antifreeze. Such equipment is most common in central Russia.

After the coolant has heated up, it passes into the heat pipe. The water then passes through the pipes, heating the room, and returns to the boiler. To speed up the circulation of the carrier, special pumps are used. Smoke removal equipment looks like pipes with a heat insulator extending from the boiler to the street. In some models they are equipped with forced ventilation systems.

Water machines require careful attention to temperature. To avoid an accident, you need to make sure that the water does not boil. Fuel combustion can be stopped by reducing the intensity. To protect the system, cooling-type heat exchangers are used. Water is supplied to them directly from the water supply. In case of water supply interruption, you need to have a spare container of cold water. To shut off the flow of overheated water, a special shut-off valve is used.

Will the boiler really work for 7 days on 1 load of fuel?

Owners of dachas and private houses, when choosing a solid fuel boiler, are most interested in such parameters as price, power and combustion duration per load of fuel.

TT long burning boiler

Let's take a comparative look and stick to these basic criteria to determine which device will be the most effective.

- Type of fuel. The effectiveness of the device largely depends on this. Not all raw materials are designed for long-term combustion. Firewood, for example, produces maximum performance when it burns quickly. But peat briquettes are capable of releasing heat for a long time, maintaining the optimal temperature. An excellent solution would be a universal model that works on several options at once.

- Boiler material.

It also depends on the raw material. When using coal, it is better to give preference to choosing a boiler made of steel, but for firewood, cast iron structures are more suitable. TT steel boiler

- Boiler power. This parameter depends on the volume of the loading chamber. The larger it is, the longer the boiler can burn with one load.

- The weight of the structure determines the material. A cast iron apparatus will be almost 20% heavier.

- Product price. This is a very conditional parameter. But if a boiler is purchased for the purpose of being the main source of heating, then you should not save, because the performance of the device and the comfortable microclimate in the house depend on this.

In any case, if the seller states that this boiler will work for 7 days on one load of fuel, be sure to take the trouble to look at the technical data sheet, because no matter how much he praises the features and advantages of the device, it is in the passport that its standard burning time will be stated.

Burning time does not always only depend on the chosen model. This parameter is influenced by the type and quality of fuel, room area, ceiling height, and quality of home insulation.

Burning time depending on the type of fuel

Prices: summary comparison table

| Model | power, kWt | Efficiency, % | Combustion chamber volume, l | Cost, rub. |

| Week KO-60 | 60 | 92 (but highly dependent on fuel) | 160 | 130 000 |

| Teplodar Cupper PRO 22 | 22 | 85 | 35 | 39 000 |

| NMK KVO MAGNUM 20 TE | 20 | 80 | 79 | 62 000 |

| Bastion M-KST-20 P | 20 | 85 | 70 | 38 000 |

BoilersLong burning boilersRussian-made boilersBoiler manufacturersSolid fuel boilers

Correct installation of the boiler: step-by-step instructions

Many consumers, purchasing a solid fuel boiler and expecting from it the effect of long-term and economical burning of raw materials up to the stated up to 7 days, after some time pay attention to the fact that the device does not provide the declared efficiency. And the point here is not at all the poor quality or defective boiler, but the mistakes made during connection.

Do-it-yourself TT boiler installation

Of course, given the complexity of the design and the responsibility of this event, many entrust the installation of a long-burning TT boiler to craftsmen. However, following our detailed step-by-step instructions, you can install the boiler yourself, without outside help. Although you can’t do this without an assistant, because the device weighs at least 50 kg.

At the stage of preparatory work, you should immediately think about where the boiler will be installed. Ideally, of course, to equip a separate boiler room.

boiler room in a private house

Considering that solid fuel does create some dirt, such a heating system should be installed in a separate non-residential building. But if the boiler power is small (does not exceed 30-35 kW), then you can simply separate (zone) the main room from the “boiler room”.

Ventilation diagram in the boiler room

To ensure that people servicing boilers and igniting them do not have breathing problems, the boiler room must be equipped with a ventilation system. Clean air must come from the street.

Prepare the following tools:

- Locksmith set (adjustable, open-end, ring wrenches).

- Building level.

- Circular Saw.

- Screwdriver and set of bits.

- Marker.

- Caulk gun.

Locksmith tool set

In addition to the solid fuel heating boiler itself, you will also need to purchase materials to connect the boiler to the heating system.

- Steel coupling (3 pieces).

- Ball valve with drive (2 pcs) with a diameter of 50 mm.

- Metal pipe for connecting the boiler.

- Sealant (fireproof).

- Plumbing winding.

Stage 1. Preparing and protecting the premises.

The issue of fire safety should be approached with all responsibility.

- We decide on the place where the boiler will be located. If an outdated model is being replaced in a house with a more modern and efficient one, then the place along with the chimney has already been prepared. If the heating system is designed from scratch, then you should immediately consider the gas exhaust system and the location of the boiler in the room. The location for installing the boiler should provide convenient operation and direct access. The room where the solid fuel boiler is installed must be non-residential.

Boiler location

- The base on which the boiler will be placed must be covered with a metal shield. In this case, the dimensions of the shield should be 25% larger than the device itself. If the power of the device exceeds 50 kW, then such a unit should be installed on a concrete screed foundation. As a rule, the height of such a foundation should be 100-150 mm above the floor level. In this case, the foundation must have a screed separate from the floor.

Installing the boiler on a metal sheet

When installing a low-power unit, it is allowed to install the boiler on a rough concrete screed.

Be sure to check the level of the foundation slope. It should be perfectly smooth. If necessary (if the floor is not level), a brick foundation should be laid.

- Draw a marker or chalk on the floor where you will install the boiler and carefully double-check all distances. Maintain distance from walls (regulated by SNiP). The distance from the combustion door to the wall must be at least 125 cm. The distance between the side parts and the back of the boiler and the wall must be at least 700 mm.

- Apply a layer of plaster 25 mm thick to the wall adjacent to the front of the boiler (where the firebox and door are located). Additionally, we install a metal sheet at a level 25-30 cm above the boiler.

Protecting the wall behind the boiler

- Remove the new boiler from its original packaging.

- Place the boiler on the prepared foundation and again check with a level how level the device is. The gas outlet pipe should be at the same level as the chimney pipe. If the line is not smooth, traction may be disrupted during operation.

- Insert all the necessary boiler elements supplied separately (ash pan, doors).

Fire safety standards

Review of the best manufacturers and prices

There are many models of heating units available to the modern consumer. Making a choice in such a situation is quite difficult. Understanding popular models and manufacturers will help simplify the situation.

Germany

German-made boiler equipment is the standard of quality. The models have a high level of efficiency and operate without failures. It is not surprising that systems manufactured in Germany have the highest cost, about 450–600 thousand rubles.

First of all, it makes sense to pay attention to the heating systems Buderos, Heiztechnik and ThermoFLUX.

Prices for solid fuel boilers Buderos

solid fuel boilers Buderos

Italy

Among the Italian-made models there are many universal options. For example, Lamborghini Ecologik series boilers can operate on wood, coal, peat and briquettes. And after installing additional equipment (adapter door, pellet burner, auger and hopper), pellets will also be suitable as fuel.

Italian models have an average price category. Brands that have proven themselves in the market: Lamborghini, D'Alessandro Termomeccanica, Faci.

Prices for solid fuel boilers Lamborghini

Lamborghini solid fuel boilers

Türkiye

Turkish boiler systems belong to the middle price segment. They have a good quality automatic feeding system and are equipped with a convenient control panel. One of the most popular manufacturers is Totem, which produces silent boilers with easy temperature control. The brands Emtas and Termodinamik are also known.

Russia

Russian automatic boilers are in constant demand on the domestic market. Manufacturers have achieved significant success through the introduction of modern design methods, new manufacturing technologies and continuous improvement of designs.

The models have an attractive appearance, high-quality assembly, good automation and benefit in terms of price. Their cost starts from 80–100 thousand rubles, which is relatively inexpensive compared to imported analogues. The most famous brands: Danko, Pereko, Obshchemmash Peresvet, Obshchemmash Valdai, NMK Magnum.

Japan

Japanese products are characterized by a high degree of automation. Many additional built-in functions significantly increase ease of use. The models are also distinguished by an ergonomic shape and high-quality materials for manufacturing, usually steel with anti-corrosion treatment.

Prices for automatic solid fuel boilers made in Japan are not inferior to the cost of models from Germany. The most popular manufacturers: Kentatsu, Rinnai.

Prices for solid fuel boilers Kentatsu

solid fuel boilers Kentatsu

Serbia

The Serbian manufacturer Radijator produces universal, highly environmentally friendly units that are equipped with an overheating protection system and are resistant to ash deposits. Allows to obtain an efficiency of about 90%. Pass mandatory quality checks.

China

Most Chinese products are not of high quality and reliability. The exception is units of the Chinese brand Roda (the manufacturing country is usually Türkiye). The design of the models makes it easy to clean the flame tubes, which maintains high combustion efficiency. The average cost of such equipment is 150 thousand rubles. Check out the link for the best heating batteries for an apartment.

Video. Connecting a solid fuel boiler to the chimney.

- Set up a security group.

The main task of this group is to relieve pressure in the network when it grows critically. The safety group is mounted directly at the outlet of the supply pipe. Considers 2.9-3 Bar to be normal pressure. If it is exceeded, the safety valve should operate. In addition, the security system includes a pressure gauge used to control pressure and an air vent. Security group

Attention! Under no circumstances should shut-off valves be installed on the section of pipeline between the boiler and the safety group.

Stage 4. Connect the boiler to the heating system.

- According to SNiP standards, before starting the boiler, it is necessary to conduct a hydraulic test under pressure with a holding time of 24 hours.

To do this, open the shut-off valves, all taps and connect the water. Use the control valve to raise the pressure to 1.3 atm. This test should show you that there are no leaks. Pay special attention to threaded and welded connections.

- We light the boiler.

To set fire to wood or peat, you need to put wood chips or paper in the chamber. Once the boiler is lit, close all doors tightly. After a stable flame has appeared, you can open the door and load the main amount of firewood. Never use flammable liquid for ignition.

First lighting of the boiler

- During the first test run, an unpleasant chemical run may be present. This may be due to the fact that the remaining factory oil is burning through. Soon the foreign odors will go away.

If you have connected everything correctly, then the pressure should not drop during the test period and, accordingly, there should be no leaks anywhere. Now you can put the boiler into operation. If during the test period any problems were identified, then you should disconnect the boiler from the system, wait for it to cool completely and begin to eliminate errors.

With proper installation and connection of the boiler, you will quickly appreciate its high performance and efficiency, which will allow you to maintain a comfortable microclimate in your home. And the video instructions will help you take into account all the necessary nuances of installing the boiler.