Any heating boiler is connected to at least four lines:

1) Power supply . Required for the control and safety automation system located inside the boiler, for example: ignition control. 2) Fuel supply line . For gas boilers, these are connections to the low pressure line or to the pipes of the gas holder (liquefied gas storage) 3) Heating system lines . If the boiler is single-circuit, then there are only two pipes: forward and return lines (output and inlet to the heat exchanger). If the heater is double-circuit, then two more pipes are added: cold water inlet and heated water outlet. 4) Combustion products emission line . The boiler must also be connected to a chimney that provides unhindered smoke removal, and if the boiler is installed in a closed combustion chamber, it must also be connected to the heating unit with combustion air.

Each of these connections must be made in compliance with the rules and regulations governing each type of connection. The electrical part must meet the requirements of the PUE . The water and fuel lines are regulated by the relevant SNiPs, which specify everything from the type of connection used to the choice of sealing materials. These connections must ensure absolute tightness and the ability to maintain it under conditions of high pressure, which is especially important for coolant pipelines.

Fuel gas connections, as you might guess, in addition to tightness, should also be made taking into account the organization of protection of the fuel line from possible mechanical damage. Checking the tightness of the gas system at home is carried out by supervisory services by pumping air into the system under a certain pressure. After the control period (at least one week) has passed, the pressure will be checked again. The pressure difference between the start of the test and its completion should be minimal. Only in this case will a permit to operate the heating system be obtained.

Basic installation steps

The installation technology implies the following sequence:

- Preparatory work.

- Placement of fasteners and direct installation of the boiler.

- Connection to water supply, gas and electrical networks (in that order).

- Connection to the chimney.

- Filling the system with water, checking, test run.

Preparation for installation

First of all, the gasification project is approved and implemented: gas is supplied, a ball valve, meter and trap are installed (it is strictly forbidden to do these works yourself; only certified specialists have access). Separate wiring is laid for the power supply, with the obligatory inclusion of a voltage stabilizer in the circuit to protect the automation; provision is also made for providing the wall-mounted boiler with grounding. The presence of all required components is checked and the instructions are studied again. Before starting, the gas boiler, mains and radiators are flushed from debris and foreign particles. These actions are relevant both when commissioning a new system and when replacing a heating device.

Mounting and connecting the boiler

The kit includes a special bracket and clamps; please note that the latter are not always suitable for the wall material; sometimes they are purchased separately. The selection of these parts is extremely important when installing a wall-mounted gas boiler; they must withstand a load exceeding the weight of all equipment. The fasteners are placed parallel to the floor, as level as possible, otherwise the automation will fail. The boiler is hung on the wall, the level is checked and only if there are no distortions is it connected to the heating main. It is planned to dismantle the unit and drain the coolant using appropriate shut-off valves.

How to turn on after shutdown

The boiler is turned on by pressing the corresponding button . If the shutdown occurred due to external reasons (lack of gas in the main line, water or electricity outage), then you must first make sure that the supply of the necessary resources is restored.

If any components or parts fail, causing the boiler to shut down, the cause must first be eliminated - replace or repair the problematic component or part, restore oxidized contacts, etc. Otherwise, the boiler will not start, and the installation will immediately be blocked by the self-diagnosis system .

Positive qualities of the device

Products of this type are produced by the German company of the same name, which began its activities back in 1731 with the production of cast iron for its subsequent processing. At the end of the 19th century, the company began producing sectional boilers for heating systems. Such a long period of existence indicates the seriousness of intentions in the field of thermal technology.

If we talk about the advantages of devices for heating coolant, then first of all we should highlight the most basic of them.

- A long period of operation is ensured by the design itself, which assumes low tension in the base unit.

- The high efficiency of the units makes it possible to organize the most efficient heating systems for homes and technical premises.

- The high quality of the equipment is explained by the accumulated experience in the field of heating devices.

- Due to the wide range, you can choose the right product for a specific situation without much difficulty..

- The price of products varies in a fairly decent range , due to which the number of consumers is large.

- A high level of safety makes it possible to avoid situations that could lead to a fire.

- Due to the ease of installation, all work can be done with your own hands , thereby saving financial resources.

- Long-lasting combustion is achieved due to the design features of the devices.

This is how the boiler looks in a modern interior.

Note! An additional advantage that Buderus solid fuel heating boilers have is their ease of maintenance. All details of the device are thought out to the smallest detail.

Features of the Buderus Logamatic 2107 control system:

- Designed for a low-temperature boiler installed in a one or two-family house;

- The MasterController microprocessor board performs regulation, control and monitoring tasks. It enables the implementation of special Logamatic functions, including: automatic heating curve detection to smoothly reduce the boiler water temperature depending on the outside temperature, pump logic to protect against condensation, dynamic switching for optimal burner control, priority hot water heating and optimized hot water heating water;

- Safety devices;

- Quick expansion of functions by installing additional modules: FM241 (control of one heating circuit with an actuator), FM242 (for control of a two-stage or modulating burner), FM244 (for control of a solar collector). In addition, it is possible to install a BFU or BFU/F remote control (with a radio clock for automatic summer/winter time switching).

The Buderus Logamatic 2107 control system provides one important function - economical and environmentally friendly heating mode, by reducing the number of burner starts.

All Buderus Logamatic control systems are supplied in a housing made from recyclable plastic, with a universal quick installation system, color and number coded connectors, fully wired and protected against TV and radio interference.

Source

Gas boiler Buderus Logamax u072 24k

The Buderus company, founded in 1731, is currently part of a holding with the world-famous Bosh concern.

This significantly increased the capabilities and increased the production capacity of the company . Gas boilers are just one of the various activities of a company that produces a wide range of equipment.

The company entered the Russian market relatively recently - in 2004. A plant was built in Engels that assembles gas boilers from branded components. This allows for cost reduction, which is ultimately reflected in the price for the end user.

The Buderus Logamax u072 model line is represented by 4 power options, optimal for use in private homes or apartments.

The 24 kW model is the most popular. It has the optimal combination of technical characteristics and price, suitable for use in various modes or conditions.

For which rooms is it best suited?

Buderus Logamax u072 24k boilers are designed for use in rooms with a maximum area of 240 m2.

This is optimal for private houses, apartments, commercial or public premises, offices.

It can be used in industrial buildings if they do not have a large number of openings or technological hatches that disrupt the heating mode and change the temperature in the room.

Setting up and adjusting Buderus boilers

All heating units require regular balancing and adjustment of parameters. In most cases, a full range of such work is performed during boiler servicing. However, there are situations when unscheduled adjustments are required. For example, after an emergency stop, with a decrease in productivity, with repeated errors generated by automation or after upgrading the system.

Our center’s specialists are ready to carry out both one-time adjustments of your heating unit and take it for long-term maintenance. We are authorized to work with the entire Buderus model range, and our craftsmen have all the necessary licenses and certificates.

Boiler adjustment includes activities such as: warming up; checking the chimney and safety automation; control and debugging of the ventilation system, fuel supply and electrical network. We provide an official guarantee for all types of work.

For additional information on all types of services provided by our center, you can call our 24-hour hotline or come to our office.

__________________________________________________________________________

Servicepoint - attention to detail

Additional bonuses for you

- 24/7 service.

We work without holidays and weekends, around the clock. You can call our call center at any time. We will immediately take your application to work! - Privilege card.

At the beginning of our cooperation, we will give you our bonus card. You can save money when ordering our services. - Personal expert.

It's always easier to contact someone you know! We also think so and therefore we will assign a personal manager to you. He will be in touch all the time and will monitor your every request.

What functions does it have?

Wall-mounted boilers Buderus Logamax u072 24k are double-circuit models of gas units.

They are capable of simultaneously heating the house (preparing coolant for the heating circuit) and preparing hot water for domestic needs. The letter “K” in the boiler marking means “Combined”, i.e. double-circuit.

The range of boiler functions is quite wide:

- The ability to independently detect problems using a self-diagnosis system.

- There is protection against freezing of the system.

- All models are adapted to Russian technological conditions.

- The electronic ignition function makes using the boiler much more convenient.

- The flame is constantly monitored; if it disappears, the boiler operation is immediately blocked.

- When installing additional devices, it is possible to control the operation of the boiler via a smartphone.

The functionality of boilers is abundant; according to some owners, it is even somewhat redundant.

All capabilities are implemented through a control board, the operation of which is similar to the actions of the brain of a living organism.

A system of sensors distributed across all units of the unit constantly monitors the operation and immediately signals the occurrence of malfunctions, failures or breakdowns.

IMPORTANT!

Buderus Logamax u072 24k boilers are sensitive to power fluctuations, which can cause the control board to malfunction and cause a series of errors. To eliminate this possibility, you should use a voltage stabilizer that ensures that the power supply remains constant.

Company advantages

- Affordable prices.

- Fulfillment of all conditions within the time limits specified in the contract.

- Qualified specialists and high-quality work that meets all standards and requirements.

- Relevant supporting documents for the right to carry out work and qualifications of working personnel.

- Guarantees for work performed

Contact our service department and your Ferroli boiler will work efficiently and smoothly for many years, and you will save on repair work and get rid of unnecessary problems.

To solve your problem, you can call a specialist. Fill out the form, briefly describe your problem and we will call you back for a consultation.

Free consultation

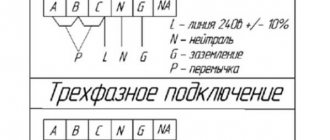

Connecting a wall-mounted boiler to the electrical network

Most modern wall-mounted gas boilers are equipped with sophisticated automation. It controls many processes, turning the heating boiler into an autonomous mini-boiler room, the operation of which requires virtually no intervention from the owner. Obviously, the control unit and various sensors require an electrical connection.

Double-circuit wall-mounted boilers are available in two versions: with a conventional socket and with a cable for connecting directly to the machine. In any case, they must be powered from the mains through an individual machine. If you purchased a model with a plug, then the individual socket for the gas boiler should be located next to it, but in no case under it. This is one of the safety requirements so that in the event of a coolant leak, a short circuit does not occur.

Photo 3: Installing a voltage stabilizer for a wall-mounted boiler

A gas boiler requires mandatory grounding. For these purposes, you can purchase a point grounding kit. It is installed in the basement or next to the house and occupies a small area of about 0.25 m².

Boiler automation is very sensitive to the quality of the supply voltage. If the level of the sinusoid at the input is insufficient or the shape is not ideal, the devices quickly fail. To prevent frequent breakdowns and extend the service life of the unit, it is necessary to connect voltage stabilizers for gas boilers. To avoid shutdowns of heating equipment in the event of power outages, you should additionally purchase an uninterruptible power supply.

How to start a boiler

To turn on the boiler, use the “On” button located on the control panel.

For normal operation of the unit, it is necessary to correctly connect all power supply electrodes, it is especially important to have a connected grounding electrode.

NOTE!

If it is not there, the operation of the ignition equipment and control board will become impossible, which is why the boiler will either simply not start, or will immediately generate an error and be blocked. The use of conventional sockets for connecting is excluded; special samples with an active neutral are required.

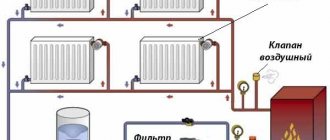

Installation and installation of Buderus boilers (Buderus) - Boiler piping:

As a rule, installation work does not end with the installation of the boiler. In most cases you may need additional strapping. For example, in order for a wall-mounted boiler unit to not only warm a house, but also heat water, it is necessary to create a second circuit. This is quite easy to do, thanks to additional equipment from the Buderus supply program.

Piping may also be required if the boiler needs to be connected to a water heater, radiators or underfloor heating system; install a pump, expansion tank, measuring or control equipment; install manifolds, hydraulic switches and other components.

You can order all elements and parts for tying the system in our center. In addition, we are ready to undertake not only any installation work, but also further maintenance of your equipment.

A little about the manufacturer

Buderus is a large manufacturer of heating equipment and other climate control systems. While producing heating equipment, Buderus also supplies components, accessories and additional equipment:

- pumps;

- chimney equipment;

- various fittings and fittings;

- expansion tanks and other components, both self-made and from well-known European manufacturers.

Buderus is a German company that actively promotes innovative equipment on the domestic market, which makes it possible to significantly save energy resources and reduce emissions into the atmosphere.

The company sets itself the following main objectives in the production of equipment:

- reducing the cost of operating installed systems;

- increasing equipment efficiency;

- caring for ecology and the environment.

Solving these problems, Buderus offers energy-efficient heating equipment - solid fuel boilers of its own production, as well as a full range of services for installation, connection, startup, adjustment and maintenance of this equipment.

Advice! Buderus is a reputable company that respects its existing and potential clients. People who use the equipment and services of this company always recommend it to friends and leave only positive reviews about the quality of equipment and service.

Choosing a chimney for a gas boiler

Any wall-mounted gas boiler needs a chimney. Depending on the model, this can be either a traditional chimney or a small horizontal chimney that can be led outside directly through the wall of the house.

Photo 4: Installation of a coaxial chimney for a turbocharged boiler

In double-circuit boilers with an open combustion chamber, the combustion process occurs with the help of air from the room in which the heating device is installed. Typically, such models are installed in specially equipped boiler rooms. To remove combustion products, they are connected to traditional chimneys for gas boilers made of ceramic or stainless steel.

Wall-mounted boilers with a closed combustion chamber (turbocharged) use outside air in their operation. It is supplied inside the device through one of the channels of the coaxial chimney. The second channel is used to discharge flue gases into the atmosphere. A coaxial chimney is very easy to install and you can connect a gas boiler to it yourself.

Advantages and disadvantages

- High efficiency (from 91%)

- Copper heat exchanger

- Circulation pump

- Built-in expansion tank

- Gas control

- Frost protection

- overheat protection

- Pump blocking protection

- Safety valve

- Auto diagnostics

- Flame modulation

- Connecting external control

- Power-on indication

- Auto-ignition

- Thermometer

- Pressure gauge

- Electronic control

- Information display

- Air vent

- Separate chimney

- Liquefied gas

- Volatile

- Warm floor

- Room thermostat

- Remote control

- Built-in boiler

- Programmer

Familiarization with technical characteristics

Below we discuss the main parameters of the products of the most popular “Logano” series. The information is provided in the form of a comparative table to make it easier to make a choice. All models are made of steel or cast iron, as these materials have the most suitable properties.

Logano G221 products presented.

Having made preliminary calculations of the heating system for the building, you can familiarize yourself with the technical data of the boilers.

| Products | Power in kilowatts | Efficiency in percent | Pressure in bars | Material |

| S111-2 | 12-45 | 86 | 2,5 | Steel |

| S121-2 | 21-38 | 85 | 2 | Steel |

| G221 | 20-40 | 78 | 3 | Cast iron |

| G221A | 25-30 | 80 | 4 | Cast iron |

The Logano S121-2 boiler is demonstrated.

Recommendation! When operating boilers operating on solid fuel, it is necessary to use firewood whose humidity does not exceed 20 percent. Otherwise, the power of the devices will be noticeably reduced.

The error does not clear

Sometimes users and specialists who carry out diagnostics cannot reset the error and conclude that the control unit is faulty. The main reasons why the error may not be reset:

- the error cannot be reset until the fault has been eliminated (for example, lack of pressure in the boiler)

- poor contact between the reset button and the control board (often seen on Vaillant TEC boilers)

- the reset order is broken (in some cases you need to hold Reset for a certain time)

- A malfunction of the information board (display board) is rare, but possible.

At the same time, when the user’s board is changed, everything works because there is no error on it. Everything will work until the next error appears, and if the reason is not figured out, they will replace a working board every time.

From practice, we often received serviceable units for repair that simply had not cleared the error. It is often impossible to convince (especially specialists) that there is a possibility of a problem with the error reset. “We know everything, we can do everything, 20 years of experience - we checked everything, the error does not reset - the control board is faulty!”

Repairs and error codes

Heating installations from Buderus are considered extremely reliable and are characterized by a long service life, but do not forget about timely diagnosis and prevention. A number of these simple procedures will significantly save your money and nerves, as they will minimize the risk of breakdowns or accidents.

Error 6a (2nd indicator flashes) appears if the unit cannot detect a flame on the burner. In order to control the flame, a special electrode was invented; during combustion, a small current charge flows through it. The control board monitors this current at all times. If the current disappears, then this kind of error appears.

The reasons for this can be varied - from incorrect regulation of the gas valve and poor contact to a breakdown of the sensor that controls the flame.

In order to fix this error, there are 2 ways:

- hold the “OK” button lightly pressed until the failure signal disappears, after which the device will begin to function again;

- turn the power on and off completely.

Error code 3c (4th indicator is on). When this error occurs, the board responsible for controlling the unit does not receive the required signal from the pressure switch. Thus, the contacts may not close after the fan starts operating. A pressure level switch is installed to determine the conditions for the release of combustion products.

To correct the error, you will have to carefully inspect all the accompanying elements and check their functionality, and if necessary, clean them from clogging.

If the fan functions, there will be no problems with the existing chimney and pneumatic relay tubes. It is necessary to thoroughly check the operation of the pneumatic relay itself, creating conditions for its discharge and checking for the presence of a special click.

Error code 4c (the very first indicator on the screen flashes) appears either at a low pressure level or at an elevated temperature at the outlet of the heat exchanger. In this case, you need to use a pressure gauge and double-check its readings. If the pressure level in the system is low - less than 0.5 bar, you just need to recharge the product.

Error code 2e (first 3 indicators flash). The error lies in a fairly rapid increase in the supply temperature, that is, the coolant leaving the heat exchanger heats up quite quickly. This may be due to poor-quality circulation of the coolant present in it. And the reasons for this may be a malfunction of the circulation pump or poor performance of the device, a heat exchanger clogged with debris or scale, or air accumulation in the system. Repairing the pump, cleaning the heat exchanger and bleeding air from the system will help eliminate this problem.

If the unit does not heat hot water and the indicator does not show any error, the cause may be a malfunction of the flow sensor. To do this, you need to clean the sensor fan.

For a review of the Buderus boiler, watch the following video.

Modern home heating products are designed so that all their components are accessible for repair and easy to maintain. Home owners can easily eliminate a number of errors themselves, without the help of a specialist, for example, by recharging the device or detecting a blockage in the chimney.

User manual

Operating the boiler is not particularly difficult . The user is not required to perform any special actions other than the current temperature setting or switching the boiler to winter or summer mode.

In addition, in the summer you need to drain the water from the heating system, and at the beginning of the next season you need to fill the system again. This is also performed by the user, guided by the readings of the pressure gauge on the unit body .

If an error appears on the display, you must reset it by pressing the “OK” button and holding it in this position until the error disappears.

This is done because the control panel often perceives voltage surges as signals from the corresponding self-diagnosis sensors. If it appears again when you restart it, you need to call a technician.

Download instructions

Download instructions for Boderus gas boilers.

Buderus boiler connection diagrams

There are standard classic diagrams, illustrated in the installation instructions for Buderus boilers of one series or another. However, in practice, the diagrams almost always undergo changes to optimize the wiring, adjust to the geometry of the furnace room and the relative position of individual components of the heating system.

The heating systems of country houses, although similar to each other, are only in general terms. In reality, no matter how diverse the areas and layouts of buildings are, their heating systems are just as different. Departures from standard schemes can also be caused by:

- connecting the pool heating heat exchanger,

- placing a volumetric buffer tank to which you plan to connect alternative heat sources: solar collectors, solid fuel boiler or fireplace insert with a water circuit.

Complications of the circuit cannot be avoided when implementing the connection scheme for Buderus cascade boilers, when the system is designed to use several gas boilers operating together or alternately. A modern approach to building such systems is the use of special units - hydraulic arrows, which ensure equalization of temperatures and pressure of the coolant in several circuits connected to it.

Service

Buderus boilers are serviced by specialists from service organizations.

It must be done annually; the necessary procedures include cleaning the heat exchanger, removing soot from the chimney, inspecting and adjusting the contacts of the control board.

It is not recommended to perform independent maintenance of the boiler; you can only clean the body of dust or soot that appears on it during operation.

IMPORTANT!

Carrying out any work on your own is regarded as termination of the warranty agreement by the owner, therefore, for repairs or maintenance, you must use the services of technicians from the warranty workshop.

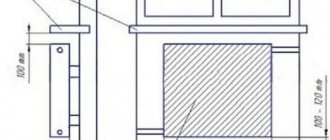

Installation of solid fuel units

These units are installed in a private house in dry rooms, the dimensions of which are directly proportional to the dimensions and power of the unit. The walls of the boiler room must be plastered or covered with sheet iron. Their connection diagram implies the presence of supply and exhaust ventilation, which will provide good draft.

The boiler is installed level on a horizontal foundation covered with a layer of sheet iron. The foundation should be 10 cm larger than the base of the unit along its entire perimeter. The safety zone on the firebox side is at least 40 cm.

There are installation standards for operational safety, which are specified in the installation requirements or are freely available in open sources of information. They must be followed!

Tools and materials

To connect to the heating system you need to purchase:

- two ball valves with a coupling-fitting connection with a diameter of 50 mm;

- two bends of the same diameter;

- pressure gauge;

- safety valve;

- automatic air vent;

- two ball valves with a diameter of 15 mm;

- three steel couplings with a diameter of 50 mm;

- transitions 57 x 32 mm with a wall of 3 mm;

- bends 57 x 3.5 mm;

- chimney with gate valve;

- pipes 57 x 3.5 mm;

- heat-resistant sealant;

- plumbing winding;

- circulation pump.

Harness

The unit's piping is equipped with a safety system, which consists of a heat accumulator, a three-way valve for mixing cold water, and a thermostat. What need to do:

- place the boiler on the foundation;

- connect the heating pipes with the obligatory use of ball valves, sealing the joints with plumbing tape;

- make grounding and connect the power cable;

- install a safety system (pressure gauge, safety valve, automatic air vent);

- assemble the chimney, sealing the joints of the elbows with heat-resistant sealant;

- fill the heat exchanger with water;

- check the location of the grate, ignition valve, cleaning plug, etc.;

- Reduce the pressure in the heat exchanger to operating level;

- install the dampers in the chimney and firebox to the required position;

- carry out laying firewood.

In general, any heating equipment can be connected to a heating system with your own hands if you use the right approach and have basic knowledge and skills.

Malfunctions and expert advice

No one is immune from boiler breakdowns, however, to reduce them to a minimum, it is best to trust the installation of equipment to highly qualified professionals and masters of their craft.

Since gas boilers from this brand are automatic, all possible errors associated with equipment breakdowns and malfunctions are displayed on a convenient LED display. To reset the error, you can reboot the boiler, since sometimes there are regular failures and errors that appear on their own, even if everything is fine with the boiler. To do this, you need to hold the reset button for about 4-5 minutes, but if the error code is displayed again, it will still have to be eliminated.

Error codes and ways to solve them are indicated in the instructions, which should be studied in detail before putting any boiler model into operation.

Let's look at the list of the most common faults.

Burner not turning on. To solve this problem, you should switch the heating regulators and control system to the “on” mode. With this problem, the gas exhaust sensor very often triggers. If after 15-20 minutes the operation of the boiler has not been restored, the chimney shaft should be cleaned, and it may also be necessary to purchase new sensors that have failed.

If there is no spark in the boiler, you should pull out the ignition cable and turn on the ignition. If outside sounds are heard during this process, the burner will most likely need to be replaced. Sometimes the reason may be in the electrodes. If there are no sounds, the transformer should be inspected.

If the burner does not light, and all methods have already been tried, then most likely the problem is accumulated air, which should be removed

To do this, you need to open the gas valves, measure the pressure and only then remove excess air.

If there is no current, it is very important to check all connections according to the instructions and assembly of the boiler model. It is very important to be mindful of tension as well as loose connections.

When the current is low, it is important to clean the electrodes - most likely they are clogged.

Since some parts of boilers are very often exposed to moisture, they should be monitored, otherwise over time they may oxidize and become unusable. It is best to carry out timely cleanings rather than purchasing new expensive parts. Cleaning is especially recommended if the sound of boiling water is heard in the boiler. Many professionals agree that any boilers need to be inspected by a specialist at least once a year or a year and a half.

It is especially common to meet customers who have a problem with the heat exchanger. This is due to the fact that it is on this device that deposits of salts most often occur, which adversely affect even the highest quality metals, contributing to their destruction.

If very loud noises are heard during prolonged heating of water, this may also be due to the formation of salts, plaque or scale on the internal parts of the boiler. Sometimes problems can be caused by improperly configured hardware.

Error 6A

Error 6A, displayed on the display of wall-mounted gas boilers Buderus Logamax U 072 on absolutely all models with a power of 12, 18, 24, 28 and 35 kW, signals the absence of a flame on the burner. To control the flame in the combustion chamber, an ionization electrode is installed on the burner, through which a small current flows during gas combustion, that is, a certain amount of free electrons and negative ions, which are transmitted to the control board via wire. If for some reason the ionization intensity drops below a certain level, the control board, after three attempts to ignite the burner, displays an error code on the display and the boiler goes into trouble!

This malfunction is extensive and a large number of elements will have to be checked.

You need to start with the most basic thing, this is to make sure that the gas valve is open, what if someone turned it off, and that’s why there is no gas!

Secondly, you need to make sure there is sufficient gas inlet pressure. To do this, connect a pressure gauge to the gas valve fitting and make sure that the pressure is between 17 and 25 mbar.

Third, while the pressure gauge is connected to the gas valve, check that the gas operating pressure adjustment in the minimum and maximum modes is consistent. But this is only in the case when the boiler can work for a short time after resetting the error. If the boiler does not start, then you will not be able to do this.

Fourthly, you need to check the gas fittings themselves for the presence of power and the serviceability of the coil and solenoid valve.

If anything is faulty, the gas fittings must be replaced.

Then we move on to inspecting the electrode and wires. Here you need to check the wire for breaks and its reliable connection to the electrode and the control board. There should be no cracks or chips on the ceramic part of the electrode, and the metal rod itself should be clean and located at a distance of about 8 mm from the burner.

Next, fifthly, be sure to check the flue gas system for correct assembly and, as trivial as it may sound, for the absence of foreign objects and debris in it. And if the malfunction appears in winter, then there is a possibility of ice forming on the chimney head.

Sixthly, the heat exchanger and burner in the combustion chamber must be clean and free of dust and soot. Otherwise, the lack of proper combustion due to lack of oxygen and carbon deposits can lead to incorrect readings from the ignition electrode, and to be honest, you don’t want to suffocate from carbon monoxide! I recommend maintenance at least once a year!

And lastly, seventh, this is a malfunction of the board, which can be checked with a multimeter by measuring the voltage on the coil and electromagnet. If there is no voltage, then you need to replace the board with a new one!

This error 6A is critical and after eliminating the fault the boiler will not start on its own, so you need to manually press the RESET button and reset the error.

Using the sequence when troubleshooting, you can eliminate any non-functioning component and start the boiler so as not to freeze in winter. If I helped you solve the problem, then I did everything right! Support me with your thumbs up and subscribe to the channel! Until next time, see you!