This topic will cover:

- electrical diagrams of boilers;

- possible causes of boiler breakdowns and ways to eliminate them,

options for connecting electric boilers will also be considered for:

- two-wire single-phase network;

- four-wire three-phase network with a neutral wire.

For the two connection methods, you need to know that when connecting any electrical equipment, and we are talking about electric boilers that are equated to this category, the connection is made with grounding.

In this topic, the casings of electric boilers are subject to grounding.

Why does this need to be taken into account? - Then, in the event of a breakdown of the conductor phase insulation on the metal parts of the body and a person accidentally touches the body of the electric boiler, the current potential in the human body decreases.

Replacing the heating element

Replacing the heating element and other elements, as well as diagnostics to determine the cause of the malfunction, is carried out in a passive way when the electrical equipment is disconnected from the external alternating voltage source.

This issue cannot be resolved on your own if you are not an electrician and such work is carried out accordingly if you have knowledge of the regulatory documents of the electrical safety approval group.

So what is the need for these details? — You may ask, if in this or that case there is a malfunction, you can call the electrician directly.

Well, let's put it this way - knowledge of electrical and electrical engineering will not be superfluous for you.

Connecting an electric boiler

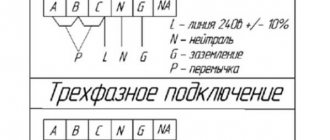

Let's consider connecting the EVAN S1-30 electric boiler to a four-wire, three-phase network with a neutral wire.

The fifth PE conductor in the diagram in Fig. 1 is grounding and is connected to the body of the EVAN S1-30 electric boiler. Reading the connection diagram:

The electric boiler is equipped with so-called buses; a network cable with a plug is connected to buses N, A, B, C. From the buses, three phases A, B, C have branching. One branch of phases A, B, C is connected to the first contacts of the heating elements of two blocks.

The second branch from the same four buses is connected through a starter to the second contacts of the heating elements of two blocks.

Here it should be taken into account that for each individual block with heating elements, each individual heating element is connected to phase wires as follows:

Phase A and neutral wire N from the busbars are connected to the control panel. In its combination, the control panel is connected to a voltage of 220 V, the conductors from the control panel are connected:

- with pump;

- with air temperature sensor;

- with thermostat sensor;

- with self-resetting thermal switch.

The control panel consists of electronic elements that are not indicated in the diagram.

For electronic elements, diagnostics are outlined in this blog.

After carrying out repairs to replace one or another electrical part:

- block with heating elements;

- self-resetting thermal switch

and other parts included in the electrical circuit, it is necessary, before connecting the electric boiler to an external source of alternating voltage, to check the electrical circuit of the boiler for resistance. Diagnostics of the resistance in the electrical circuit of this circuit is carried out either with an ohmmeter or a multimeter with the appropriate function.

If, as a result of measuring resistance, the device indicates a zero value, in this example you should reconsider the connections you have made. A zero resistance number indicates a short circuit in the electrical circuit.

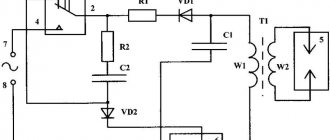

Consider the following electrical circuit for two types of boilers EPO-7.5 and EPO-9.45. The electrical circuit shown in Fig. 2 is identical and the difference here is only in the power of electric boilers. Let's follow the connection diagram:

These types of electric boilers are connected to a two-wire, single-phase network. The PE grounding wire is connected to the heating element block and to the body of the electric boiler. The phase wire from the phase bus in this circuit has a branching, one wire with phase potential goes to the control panel and is connected from the control panel to the first contacts of the heating elements,

Commissioning works include

Connecting the boiler to the electrical network;

Filling the system with coolant;

Removing air from the heating system;

Bringing the pressure to normal in accordance with the requirements of this operating manual (when using an expanzomat);

Trial run;

Adjustment of the system and shut-off valves;

Before installing the boiler, check the correctness and quality of installation of the heating system with natural circulation. The pipes of the heating system must be located so as to facilitate the natural circulation of the coolant. In this case, the maximum coolant level should not exceed 30 meters to the boiler level (working pressure in the boiler is not higher than 0.3 MPa). If it is impossible or undesirable to achieve natural circulation of the coolant in the heating system, it is necessary to use a circulation pump. The heating system must have an expansion tank communicating with the atmosphere. When using a membrane-type expansion tank, a safety valve must be installed at the outlet of the boiler in front of the ball valve, designed for a pressure of no more than 0.4 MPa. Since when the safety valve is activated, coolant or steam may be released through its drain hole, it is necessary to connect a drain to it sewer system. Ball valves are installed at the inlet and outlet of the boiler, which are used during dismantling, repair and maintenance of the device.

Installation of shut-off valves on the pipeline connecting the expansion tank to the heating system is prohibited!

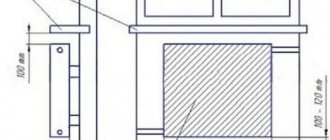

The pressure testing of the heating system with the boiler after installation is no more than 0.4 MPa. The boiler must be mounted in a vertical position. The control panel is mounted vertically at a height of 1.4-1.7 m from the floor on walls and structures in well-lit rooms.

Technical features of boilers

The product range of boilers is represented by the following series:

The “Standard” series is represented by the “Economy” and “Standard” models. All boilers of the standard category are characterized by the ability to smoothly adjust the coolant temperature and are equipped with an input for connecting a circulation pump. The design of these boilers is extremely simple and consists of a metal cylinder, in the lower part of which there is a heating element, and in the upper part there is a temperature regulator sensor.

The line of this series is rich in models of varying power - from 2.5 kW to 30 kW. For heating large areas, the additional installation of a circulation pump and an expansion tank is required. Typically used as electric boilers for home and small offices.

Devices in this category differ in their equipment - for example, depending on the power, the models contain a certain number of heating elements and connectors for connecting room temperature sensors.

Among private property owners, devices of this series are most in demand.

Electric boilers "Evan" have different technical characteristics in this series, depending on the presence or absence of a three-stage switch, a built-in circulation pump, and an electronic control unit. Accordingly, more expensive models have all three mechanisms, while economical models only have a three-stage power switch. The boiler power range is from 3.5 kW to 30 kW. They are used as electric boilers for homes, offices, and warehouses.

Boilers of this series have very high power characteristics - thus, the model range is represented by units with heating output from 36 kW to 480 kW. The boilers have (not in all models) four-stage power regulation, protection against short circuits, inappropriate pressure, overheating and overload.

Review of model range and prices

EVAN electric boilers are divided into the following classes:

- "standard-economy";

- "standard";

- "comfort";

- "luxury";

- "VIP";

- "professional".

All boilers use tubular electric heaters made of Backer stainless steel (Czech Republic), which are characterized by increased reliability and long service life. In most models, both water and non-freezing liquid intended for heating systems can be used as a coolant. The coolant temperature is adjustable from 30 to 85 degrees.

When choosing heating equipment, two main criteria can be distinguished - power and the type of fuel on which the device will operate.

Electric boilers "standard - economy" class

Electric heaters of the “standard-economy” class are the most budget model in the range of EVAN devices; they are used both in homes and in dachas. A 20 percent reduction in the price of equipment compared to the “standard” class is due to the absence of a housing that combines the boiler and control panel.

Models of this class are called EPO and include models of 12 standard sizes, designated as follows: electric boiler EPO 2.5, where the number indicates the power of the heating equipment in kW.

Specifications:

- The power of electric boilers of this class ranges from 2.5 to 30 kW with a high efficiency of 99%.

- The operating voltage of the boiler used is from 220 V or 380 volts and depends on the brand of the boiler.

- Depending on the brand, heating equipment uses one or three heating elements and uses one-stage or three-stage remote control panels. EPO 2.5 uses a built-in remote control.

- To ensure safety when heating water or liquid to a set temperature, the thermostat turns off the boiler, and when the temperature drops below the set temperature, it switches to heating mode.

- As protection against overheating, a self-resetting emergency sensor is used, which is triggered when the water temperature ranges from 89 -95 degrees.

- The system includes a connector for connecting an air temperature control sensor or a remote control module (except EPO-2.5).

During installation, a floor-mounted installation option is used. The dimensions of the heating equipment used come in two sizes: 505 x 200 x 160 mm and 565 x 270 x 220 mm and depend on the brand of electric heaters. Net weight varies from 6.5 to 13 kg. Estimated prices from 7800 rub. up to 28800 rub. The warranty on all boilers is 18 months.

Electric boilers standard class

Equipment in this series are used as the main or auxiliary heat source for heating residential, commercial and small industrial buildings.

Boiler units of this class include the following models:

- Evan S1,

- Evan S2,

- Evan NEXT.

in equipment of this class, a self-resetting emergency sensor is used as protection against overheating, which is triggered at a liquid temperature in the range of 89 -95 degrees. In models up to 9 kW, there is the versatility of connecting to single-phase 220 V or three-phase 380 V networks.

Boilers of this class use heating elements consisting of blocks of several heating elements made of Backer stainless steel (Czech Republic). The block design of the heating element with a threaded connection makes it significantly easier to replace.

Electric boiler EVAN C2 of the “Standard” class is an improved analogue of the popular C1 model, has 12 standard sizes of boilers with a power from 3.0 to 30 kW and an efficiency of 99%.

EVAN C2 models are designed for heating country houses, the private sector, various types of retail and warehouse premises. Can be used as both the main and backup heat source.

Peculiarities:

- The control panel and electric boiler are installed in a single heating equipment housing.

- The system includes connectors for connecting a circulation pump and for connecting an air temperature control sensor.

- Wall mounting is used.

- The boiler dimensions come in two sizes: 650 x 250 x 150 mm and 650 x 250 x 180 and depend on the brand of the boiler. The net weight of boilers varies from 12.5 to 21.5 kg.

Estimated prices from 9640 rub. up to 32,400 rub. The warranty on all electric boilers is 18 months.

Evan NEXT models are represented by 6 types of boiler units, with a power from 3 to 14 kW, efficiency 99%. These boiler models are designed for heating various types of premises, similar to EVAN C2, they are economical, ergonomic, easy to install and operate.

EVAN Next is the best option for use as a backup heat source during the main operation of gas or solid fuel equipment. The control panel is installed on the boiler body.

Peculiarities:

- Power control systems use 2 or 3 stages, depending on the type of equipment. A distinctive feature is the quiet operation of the electric boiler.

- The system includes a block for connecting a pump that circulates liquid.

- The dimensions of the boiler units are 600 x 205 x 105 mm, the net weight of the electric units varies from 5 to 6.6 kg.

Estimated price from 8495 rub. up to 12370 rub. The warranty period is 12 months.

Prices for "EVAN" C2

EVAN S2

Comfort class electric boilers

They have the largest range of various electric heating devices with increased energy-saving characteristics.

The following models belong to the comfort class:

- "Evan WARMOS-1V",

- "WARMOS-M",

- "WARMOS-RX"

- EVAN UNIVERSAL.

Evan WARMOS – 1V

Electrical heating equipment "Evan WARMOS - 1V" is a model range of 12 standard sizes with a power from 3.75 to 30 kW, using 3 heating elements and three power levels. During operation, the required number of stages is automatically selected to maintain the specified coolant temperature. The coolant temperature setting is set with an accuracy of 1°C in the range +5°C – +85°C.

Main characteristics:

- In models up to 12 kW, a special feature is the quiet operation of the boiler unit.

- Stable operation is ensured at low (up to 180 V) and high (up to 260 V) voltage.

- The boilers use an independent emergency shutdown circuit and perform self-diagnosis of faults. When starting the boiler at temperatures below “0” (the case with non-freezing liquid in the system), the boiler’s operability is maintained, “-0” is displayed on the indicator

- The system includes a block for connecting a circulation pump and a block for connecting an air temperature control sensor.

- Dimensions of two standard sizes: 580 x 305 x 160 mm and 640 x 380 x 245 mm, net weight of electric boilers is in the range from 13 to 24.5 kg.

- Heated area from 37.5 to 300 sq. m.

Estimated price from 16,420 rubles. up to 36960 rub. The warranty period is 24 months.

WARMOS-M

The WARMOS-M models use 8 types of boilers with a power from 7.5 to 30 kW, with three heating elements and three power levels, when turning on/off power levels there is a time delay, the operating efficiency is 99%.

To protect against overheating, an emergency self-resetting sensor is used (operation temperature - 92±3°C), and to protect against dry start-up, a minimum pressure sensor and a flow switch are used, which monitors the presence of coolant circulation in the heating system.

The coolant temperature is adjusted in the range from 30 to 85°C.

The device includes:

- block for connecting an air temperature control sensor;

- circulation pump is an essential element of the heating system;

- thermomanometer, which allows you to visually monitor temperature and pressure;

- emergency operation indicator;

- The built-in circulation pump Wilo RS 15/5e is used to circulate the coolant.

The energy efficiency of the device is achieved through thermal insulation of the electric boiler body, which reduces heat loss.

Peculiarities:

- Wall mounting method is used.

- Dimensions of boiler units are 635 x 380 x 245 mm, net weight from 25 kg to 29 kg.

- Heated area from 75 to 300 sq. m.

Estimated price from 26,790 rubles. up to 44660 rub. Warranty period - 24 months.

WARMOS-RX

WARMOS-RX models provide a new level of energy efficiency using an intelligent control algorithm. There are 8 standard sizes of boiler units with a power from 7.5 to 15 kW. The efficiency is 99%.

Main characteristics:

- Increased energy efficiency of the devices is ensured due to 2 and 3-step smooth changes in power consumption and quiet operation. 3 thermal electric heaters are used.

- The coolant temperature is adjusted in the range from 8 to 85°C with an accuracy of 1°C.

- An intelligent algorithm for selecting the level of average power consumption in 1% increments is provided, as well as automatic temperature maintenance by changing the power consumption and electronic non-contact control of the heating elements.

- The system uses a built-in Wilo RS 15/5 circulation pump, and a connector for connecting an air temperature sensor and an air temperature control sensor are supplied included.

- Ensures stable operation of the electric boiler at low (up to 160 V) and high (up to 260 V) voltage.

- The boilers use protection against high (3.5 bar) and low (0.7 bar) pressure in the system, and also provide protection against overheating of power actuators and erroneous connection of power by the client.

- When protecting against overheating, an emergency self-resetting sensor is used (operation temperature – 92±3°C).

- To control the operation of the devices, a control panel is provided with intuitive navigation through settings and operating modes.

- The boiler control system provides self-diagnosis of faults and automatic switching to the operating phase in the absence of one of the phases.

- Installation method: wall.

- Dimensions of the boiler units are 633 x 373 x 235 mm, net weight 24-25 kg.

- Heated area from 40 to 150 sq. m.

Estimated cost from 26,850 rubles. up to 40550 rub. Warranty period - 24 months.

EVAN UNIVERSAL

The EVAN UNIVERSAL model uses 12 types of equipment with a power from 36 to 120 kW. Heaters of this class have an intelligent control algorithm that significantly reduces the number of power switches. This helps to increase the service life of equipment units.

These boiler models provide up to 7 power levels. The required number of stages in the boiler operation is selected automatically. It is possible to limit power in manual mode.

Characteristics:

- The boiler is controlled using a graphic display with a user-friendly interface.

- The boilers use automation elements produced by the Finnish company Kaukora.

- Automatic heating control is carried out based on a weather-dependent algorithm.

- Emergency shutdown in case of overheating above 92°C is implemented regardless of the operation of electronic components. When the coolant cools down to 70°C, the system goes into normal operation.

- It is possible to connect the EVAN GSM/Wi-Fi Climate remote control module.

- An outdoor temperature sensor is included in the equipment.

- Ensures stable operation of electric boilers during voltage surges from 180 V to 260 V

- Installation method: wall.

- Dimensions of boiler units are 615 x 400 x 250 mm and 765 x 450 x 250 mm, net weight 34.5-51.5 kg.

- Heated area from 360 to 1200 sq. m.

Estimated cost from 82,700 rubles. up to 116,400 rub. Warranty - 24 months.

Luxury electric boilers

Boilers of this class “Evan Expert” are intelligent mini-boiler autonomous equipment with preset settings. The boiler control system ensures maximum safety, energy efficiency and full automation of the device using a unique weather-dependent algorithm based on analysis of both outside and room temperatures. Boilers with a power of 7.5 to 27 kW are used, efficiency is 99.5%.

Features of expert equipment:

- To control the settings and operating modes of the boiler, a graphic display with intuitive navigation is used.

- The boilers use three heating elements. Nine-stage automatic power control is used depending on the current level of heat loss.

- The boiler includes a built-in Wilo RS 15/5 circulation pump, a 12-liter expansion tank, and an automatic air vent. The delivery set includes a room temperature sensor and an outdoor temperature sensor.

- To protect the system from overheating, the system uses an emergency self-resetting sensor. The sensor response temperature is 92±3°C.

- A circuit breaker is used as protection against short circuit currents and overloads, and a safety valve is used against overpressure.

- The boilers provide protection in the event of a malfunction or failure of temperature and pressure control sensors (break or short circuit).

- The boiler operation safety complex is complemented by such functions as monitoring the presence of phases and automatic switching when a phase is lost to the working one, emergency shutdown of heating independent of the controller, anti-freezing of water or other liquid in the heating system.

- To facilitate the work of various service departments, the system provides self-diagnosis of faults, archiving of time and error codes, power consumption statistics, as well as a unique debugging mode, within which you can check the operation of each of the boiler controls.

- The boiler control system provides the ability to connect the EVAN GSM/Wi-Fi Climate remote control module and the ability to directly connect the “warm floor” system to the boiler.

- It is possible to control boiler units located in a cascade (special connector), control DHW and control a three-way valve.

- Dimensions of electric boilers are 775x420x302mm, net weight 34-37 kg.

- Heated area from 75 to 270 sq.m.

Estimated price from 51,000 rubles. up to 61,460 rub. The warranty is 24 months.

Professional class electric boilers

They are, among other things, powerful industrial equipment for heating production areas with multifunctional capabilities. Models "Evan EPO" are presented in 31 standard sizes. Devices with power from 36 to 480 kW (36-240 kW and 300-480 kW) are used, efficiency is 99%.

Various types of boiler units use from 6 to 32 heating elements using 2, 3 or 4 power levels; the number of their use in some models is determined automatically.

Features of Evan EPO:

- The system smoothly regulates the temperature of water or permissible liquid in the range from 30 to 85°C, protection against overheating is provided by an emergency self-resetting sensor (operation temperature – 92±3°C). The number of contactor operations is reduced hundreds of times due to a smoother change in coolant temperature (96-480 kW).

- Protection against short circuit currents and overload is provided by a circuit breaker (from 132 kW), and from overpressure by a safety valve (300-480 kW).

- The boiler package includes a connector for connecting an air temperature control sensor/EVAN GSM/Wi-Fi Climate remote control module.

- The control system provides diagnostics of coolant overcooling and protection against it (96-480 kW), as well as diagnostics of contactor sticking, light and sound alarms (96-480 kW). It is possible to use a fast heating mode (300-480 kW).

- The voltage range at which the product remains operational is 180-250 V (96-480 kW).

- Some types of boilers have microprocessor control.

- Installation method: floor-mounted, control panel – wall-mounted or floor-mounted, depending on the power of the equipment used.

- Depending on the type, boiler units can have the following dimensions: 512x390x180 mm, 310x430x185 mm, 300x500x230 mm, 660x440x250 mm, 900x615x325 mm, 905x1360x1060 mm.

- The weight of the equipment is in the range of 31-450 kg.

- Heating area from 360 to 4800 sq. m.

Estimated cost from 41,890 rubles. up to 648,500 rub. Warranty - 18 months.

Prices for Evan EPO

Evan EPO

VIP class electric boilers

VIP class electric boilers include devices from the EVAN range, which are entirely manufactured in Finland.

These include boiler units:

- PIKKUWATTI,

- TEHOWATTI,

- ECOWATTI,

- and FIL.

The power of electric boilers of this class ranges from 3 to 1600 kW. Models TEHOWATTI and ECOWATTI have two circuits and are combinations of a heating heater and a water heater.

VIP class ELECTRIC HEATING BOILER TEHOWATTI

The boiler has a fully automatic operating mode. The minimum required power is automatically selected and, depending on the outside air temperature, the coolant temperature is regulated. It is possible to change the power in seven stages.

The electric boiler includes a built-in circulation pump, a DHW tank made of stainless ferrite steel with a volume of 270 liters and a built-in expansion tank with a volume of 12 liters.

To protect the electric boiler, a safety valve is installed in the electric boiler and a safety-mixing valve group is installed in the water heater.

There are two types of boilers with dimensions 1900 x 600 x 600 mm:

- TEHOWATTI 13: power - 13 kW, heated area 130 sq. m, device weight 90 kg, estimated price 5357 euros.

- TEHOWATTI 21: boiler power - 21 kW, heating area 210 sq. m, weight 100 kg, cost approximately 6273 euros.

The warranty period is 24 months.

VIP class ELECTRIC HEATING BOILER EСOWATTI

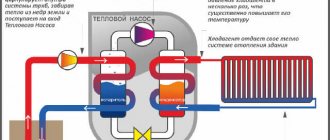

The electric heating boiler represents a new generation hybrid heating system, which provides the possibility of using external energy sources, including a heat pump and solar collectors. The automatic boiler system is capable of controlling two heating circuits, as well as a solar charging system and a heat pump.

The heating equipment consists of an electric boiler and two independent tanks, of which the lower one acts as a buffer tank for an external energy source, and the upper one is a hot water tank made of ferritic, acid-resistant stainless steel. The equipment includes a built-in pump for liquid circulation.

Characteristics:

- Boiler power 13 kW, hot water power 3 kW, seven-stage change is possible. Thermal regulation is carried out using data on the outside air temperature.

- The protection system includes a safety valve in the electric boiler and a safety-mixing valve group in the water heater.

- Installation method: floor.

- Heating area 130 sq. m, dimensions 2020x600x600 mm, weight 130 kg.

The approximate cost is 8148 euros. Warranty - 24 months

VIP class ELECTRIC HEATING BOILER PIKKUWATTI

The boiler includes a built-in pump for water circulation and a built-in expansion tank with a volume of 12 liters, as well as a limit thermostat and automatic boil-over control.

Main characteristics and features:

- The power of the equipment used is 13 kW with the ability to change the power in seven stages.

- There is a fully automatic operating mode with temperature control depending on the outside air temperature readings.

- The boiler is adapted for heated floors.

- Installation method: wall-mounted.

- Heated area 130 square meters, dimensions 266 x 598 x 590 mm, weight 30 kg.

Estimated cost 3193 euros Warranty - 24 months.

VIP class ELECTRIC HEATING BOILER FIL

Heaters are available in two versions: FIL SPL – for heating, FIL-B – for heating and hot water production, with a power range from 31.5 to 1600 kW.

Multi-stage electric power control is carried out: 7 power levels in FIL-B models; 7 and 15 – in FIL SPL models. The boilers use acid-resistant flanged heating elements.

Reliable automation makes it possible to use different remote control methods and provides protection against boiling over (over 120 kW).

Installation method: floor.

The dimensions of heated areas, weight, dimensions and cost depend on the type of equipment used:

- minimum and maximum heating area 315-16000 square meters;

- maximum dimensions and weight: 1400 x 600 x 815 mm, 2530 x 2025 x 1150 mm, 140 kg-1450 kg;

- the cost of the equipment is approximately 6,130 - 139,669 euros.

Warranty - 24 months.

Evan boilers: pros and cons

Among the disadvantages of electric heating boilers for the Evan home are the dependence on electricity and its high consumption. However, the listed disadvantages are more or less characteristic of most electric heaters. Regarding Evan boilers specifically, many owners complain about the noisy operation of the devices, unreliable heating elements, frequent relay breakdowns and failure of the boiler automation.

Therefore, when choosing a boiler, it is better to consult with a company specialist, because the causes of breakdowns are often caused by operating conditions, instability of the supplied electricity, incorrectly executed connection diagram of the electric heating boiler and other reasons not related to manufacturing defects.

Speaking about the advantages of these Russian boilers, they usually highlight their low cost, ease of installation, a huge selection of models and ease of operation. In addition, the devices have all the advantages of electric boilers as such.

In this series, they note the absence of the need to prepare fuel and install a chimney (as is required in the case of gas and solid fuel boilers), high efficiency (99%) and a level of safety (subject to high-quality electrics).

Connecting an electrode boiler

We will not describe in detail each stage of work. How to connect radiators, connect metal-plastic pipes. You can watch all these steps in the video instructions. The Galan electrode boiler connection technology is considered quite popular today.

As you can see, the installation is considered quite simple. Anyone can do it with their own hands. Now we will tell you about what rules you need to take into account when installing an electrode boiler with your own hands. An electrode boiler uses a lot of electricity, so it's best to look into cheaper heating options. To ensure your system is reliable, you need to consider the following recommendations:

Before connecting the electrode boiler, you need to configure the coolant. The Galan company recommends using a special liquid “Argus-Galan”. This fluid must be changed every 5 years. You also need to remember that it is strictly forbidden to use “Arctic” and “Antifreeze” liquids.

- The old heating system must be flushed to remove salt deposits. Dirty radiators can negatively affect the density of the coolant. To flush your energy carriers, it is recommended to use a special inhibitor “Protector”.

- The electrode boiler cannot be connected without grounding. We recommend using copper wire as a conductor. The ground wire must be connected to the terminal marked “0”.

- The coolant consumption should be 8 liters per 1 kW of power. Thanks to this, you can reduce energy costs.

- A deaerator valve must be installed at the highest point of the system. Also, connecting an electrode boiler cannot be done without installing a pressure gauge.

Shut-off valves must be installed behind the expansion tank.

- The heater body must be installed in a vertical position. Any imbalance can negatively affect the operation of the system.

- When choosing a radiator, the product must be installed from bimetal. These metals have fewer impurities and do not affect the electrode boiler.

- When installing an electrode boiler with your own hands, you cannot use cast iron batteries. These products can get dirty quickly and therefore use a lot of heat.

- If necessary, several heaters can be installed in series. It is fashionable to use a group of boilers in a two-story house.

Now you have learned how to connect an electrode boiler in a house or apartment yourself. As you can see, connecting the electrode boiler does not take much time.

We recommend reading: installing an instantaneous water heater.

Features of connecting electric boilers

Even for a non-specialist, the connection diagram for an electric heating boiler is clear, so installing the device will not be difficult. To understand how to install, you should know what devices you will be working with and what their purpose is.

So, during installation you will have to mount the boiler itself, various regulators, and an expansion tank on the wall (or on the floor). Depending on the purpose, one or more main circuits are connected to the boiler. Also, depending on the model, installation of a circulation pump and boiler unit may be required.

Before proceeding with installation, you should familiarize yourself with a document such as the connection diagram for an electric heating boiler, which the manufacturer encloses with the package of documents for the unit. In accordance with this document, the device is connected to other devices in the heating network.

It should be borne in mind that if the boiler power does not exceed 3.5 kW, it can be plugged into an outlet. Otherwise, electrical installation is carried out directly from the junction box.

Moreover, if the power of the device exceeds 7 kW, the use of a three-phase network of 380 V will be required. The boiler must be protected by an RCD and a circuit breaker.

We should not forget about grounding the wiring.

More on this topic on our website:

- Gas boilers Proterm Bear 30 KLOM - technical characteristics and features Heating boilers “Bear” from the Slovak manufacturer Protherm are completely independent of electricity; the source of thermal energy is gas fuel. Proterm Bear 30 KLOM.

Electric boiler EVAN EPO ECONOMY - review and reviews from owners These electric boilers of the ECONOMY series, produced by , which has now ceased to be independent, and were bought by the large NIBE holding, are completely.

Solid fuel boiler KChM 5 - technical characteristics and reviews KChM 5 boilers are produced by the Kirov plant, founded in the 18th century. Over the years of operation, the boiler has proven itself to be very reliable.

Heating gas boiler Danko - technical characteristics and reviews is Ukrainian. In addition to gas boilers, the company produces a number of other heating devices - solid fuel and.

Delivery terms

The delivery driver can provide loader services only by prior arrangement for an additional fee.

Upon delivery to the Buyer, the seller is responsible for the appearance of the goods until the moment of acceptance and transfer to the Buyer. Claims regarding the appearance and configuration of the delivered goods, in accordance with Art. 458 and 459 of the Civil Code of the Russian Federation, can only be presented before the goods are transferred by the Seller to the Buyer. From the moment of acceptance and delivery of the goods, the seller’s obligation to transfer the goods is considered fulfilled. The fact of acceptance of the goods by the Buyer is confirmed by a signature in the “Purchase and Sale Agreement” in the column “Acceptance and Transfer Certificate”. If the appearance or configuration of the goods does not correspond to the proper quality, the buyer has the right not to accept the goods and not to sign the documents.