Electric boilers are almost ideal from a practical point of view. They do not require the installation of a chimney, the organization of proper ventilation, and imply a minimum of communications around them. However, operating costs when heating with electricity are among the highest: many times higher than when heating with gas, wood or coal. Heating a house with an area of 80 square meters can cost up to 9-10 thousand rubles per month.

It is also worth considering that an electric boiler for heating a house with an area of 80 square meters is a powerful unit that requires connection to a three-phase network (380 V), since a single-phase (220 V) will not be able to operate at full power.

Requirements for boilers for heating a private house with an area of 80 sq.m.

Manufacturers produce devices in accordance with GOST standards. The equipment must meet safety requirements.

Depending on the model, electric boilers are equipped with a circulation pump, expansion tank, and heating block. The package should include a pressure gauge, a thermometer for measuring pressure and water indicators.

The devices also have an air vent and a safety valve. In case of malfunctions, the equipment should automatically turn off or give a special signal.

Electric boiler and double tariff

One of the significant reasons for using an electric boiler for heating is the possibility of using double tariffs for the use of electricity. Reducing fees during the night period allows you to significantly reduce costs.

A two-tariff meter makes it possible to pay much less for electricity used at night than during the day and allows owners of electric boilers to save money

You will need to purchase and install a two-tariff meter. It is worth noting that double-circuit models of equipment with heating elements supply hot water to the collapsible tap with a characteristic noticeable delay. As a result, some of the heat is lost, which reduces the effect of saving electricity.

It makes sense to supplement such a design with an external heat accumulator that can maintain the high temperature of heated water for a long time. Such a device is quite effective when using a two-tariff meter.

Water is heated at night, stored warm and used during the day, energy consumption during the day is reduced, as well as electricity bills.

Types of electric boilers

Manufacturers offer different models of heating units. The devices are single- and double-circuit. The latter, in addition to heating the house, provide owners with hot water.

The equipment is also divided according to the type of heating element:

- heating element. It represents a tube with a tungsten spiral surrounded by crushed quartz. When the device is turned on, current passes through the wire and it heats up, thereby increasing the temperature of the water circulating in the tank.

- Electrode. It is located in the tank and has phase “0”. When an undistilled liquid (and it has electrical resistance) passes through a container, it heats up.

- Induction coil. This is a metal rod wrapped in cable. When current is passed, vortex flows arise, thereby heating the circulating liquid.

Boilers are also 1- and 3-phase, floor-mounted and wall-mounted.

Device and features

The 220V heating equipment has a rectangular base with a control panel.

This explains the numerous advantages of the device: fairly compact size, absence of noise and smoke, as well as clear automated control of the unit on the front of the boiler. Two more advantages of the unit are the good quality and simplicity of the power circuit switches - starters, switches, etc.

An electric boiler is easy to install, since there is no need to create a special boiler room . The device is safe and environmentally friendly, as it does not emit combustion products harmful to humans.

As for the disadvantages of 220 V electric boilers, there are few of them: consumption of a large amount of electrical energy, scale formation on the heating elements.

In addition, in places where there is a problem with frequent power outages, it is better to install an uninterruptible power supply.

An electric heating boiler 220 V, in comparison with other heating devices, has one important feature: the presence of a heating element or electrodes:

- A heating element is a nichrome spiral in electrically insulating packaging, located in a special aluminum tube. The heating element is attached to the bottom of the water tank, its leads come out. The big disadvantage of using an electric boiler with a heating element is corrosion of the tube coating.

- The electrode heater is a two-blade equipment . A pair of electrodes are placed on an insulating base and attached to the bottom of the water tank. A current passes between the ends of the electrodes, which heats the water with high efficiency (more than 95%).

IMPORTANT!

The design of an electric boiler for heating a 220 V home also includes a control panel that ensures the safe operation of the device.

The electric boiler control unit contains:

- various operating modes;

- safety system in emergency situations (for example, when the coolant overheats or changes in pressure in the heating line.

Advantages and disadvantages

The equipment has the following advantages:

- simple installation, no difficulties during operation;

- the devices do not make noise during operation;

- absence of a chimney, as a result of which harmful combustion products are excluded;

- the ability to choose the required size;

- environmental friendliness;

- temperature adjustment.

The only disadvantage is the dependence on an uninterrupted supply of electricity. If the latter is absent, the operation of the devices stops.

Power calculation principle

Typically, the indicator is calculated based on 1 kW per 10 m². This does not take into account heat loss. For example, the climatic features of the area, the material of the walls, the number of windows and even the height of the ceiling. Therefore, it is better to take a reserve of about 20%.

Although each building is individual, you can first consult with a specialist.

Pressure in a closed system

Heating standards depend directly on the type of building for which heating is supplied. That is why each specific case must be considered separately:

- For a private home, a pressure of 1.5-2 bar will be normal. If the pressure gauge shows a high number, then this condition is considered critical. If the meter reaches 3 bar, this can lead to an accident in the system: the tightness will not withstand this pressure, and the entire structure will break.

- For high-rise buildings, external factors do not affect such a structure, then the pressure standards in it range from 8 to 9 bar. However, this is typical for new houses. Older buildings can be heated at pressures up to 5 bar.

Pressure in a closed system

Installation and connection rules

Installation of an electric boiler is carried out by an employee of an organization that has the appropriate permit to perform such work. Responsibility for fires and electric shocks during operation lies with the person who carried out the installation. You are only allowed to separate the pipes and connect the radiators yourself.

During installation, grounding of the device body is considered a prerequisite. In addition, the cross-section and material of the cables must be observed (the manufacturer indicates the data in the instructions). If the requirements are ignored, a short circuit may occur.

Electrical connection

The power supply circuits are the same for all electric boilers, the only difference is the number of phases. Devices with a power of up to 12 kW are connected to a single-phase 220 V network, more than 12 kW - to a three-phase (380 V). What you will need for installation:

- power cable with copper conductors;

- differential circuit breaker or combination of RCD + conventional circuit breaker;

- ground loop.

A VVG cable of any type is used as a power line; the number of cores depends on the number of phases - 3 or 5. Select the cross-section of the current-carrying part according to the power of the heat generator, usually this parameter is indicated in the product’s operating instructions. To simplify the task, we present the data for different boilers in the form of a table.

The rating of the differential circuit breaker also depends on the power consumption of the heater; the operating current is 30 mA. For example, to protect the power line of a 3 kW (220 volt) unit, you will need a device rated at 16 A; for a power of 16 kW (380 V), you need a 32 A difavtomat. The exact ratings are indicated in the product data sheet.

To independently connect a wall-mounted electric mini-boiler room, you need to remove the front panel, run the power cable inside and connect the wires of the corresponding colors to the terminal block contacts. As a rule, the neutral wire is indicated in blue, grounding in yellow-green. The control box of the induction and electrode boiler is connected in the same way.

Electrical connections between the control cabinet and the heating block of an electrode or induction boiler are made according to the individual diagram presented in the instructions. As an example, we give a connection diagram for the popular Galan electric boiler.

Automation diagram for single-phase 220 V network

The temperature of the coolant here is monitored by overhead sensors installed on the metal sections of the supply and return pipelines. The devices are connected in series with the contacts of the thermal relay that controls the magnetic starter. When the upper temperature threshold is reached, the circuit breaks and the starter turns off the heating.

Connection diagram for connecting the boiler to a three-phase 380 V network

Criteria for choosing electric boilers for heating 80 square meters

When purchasing a unit, determine the model in advance and study the characteristics of the equipment. For example:

- device power;

- efficiency;

- floor or wall option;

- single- or double-circuit device;

- storage tank volume;

- functions (for example, protection against freezing and overheating, self-diagnosis);

- presence of a circulation pump;

- heating element type.

Other criteria are also taken into account - service life, warranty repairs.

Types of electric boilers

- Heating element boilers - heating elements are used as a heating element and are considered the most common. The water is heated by electric heating elements. The big disadvantage of such boilers is that if the water is hard, then scale forms on the heating elements and the power is significantly reduced, but electricity bills do not decrease.

Efficiency is not lower than 93%.

New heating elements heating boilers.

- Electrode boilers - water is heated by passing an alternating electric current through it. They are considered one of the most economical. Efficiency, according to manufacturers, is not lower than 98%. DO NOT use distilled water as a coolant. For systems with electrode boilers, special compositions are commercially available that improve the electrical conductivity of water.

Electrode boilers.

- Induction boilers are similar in structure to a transformer. Efficiency 98%. They are considered one of the most durable and economical boilers.

Induction boilers.

Rating of popular models

According to reviews from owners, a good home heating device is the Kospel EKD.M3 8 electric boiler. This is a double-circuit device with a heating element. The maximum thermal power of the equipment reaches 8 kW. The unit is electrically controlled with a display and has a room thermostat.

The main functions of the device include automatic diagnostics, a programmer and power-on indication.

The boiler is equipped with a safety valve, a circulation pump and a built-in 130 l boiler. The volume of the expansion tank is 12 liters. The maximum water pressure in the DHW circuit is 6 bar, the heating system is 3. A similar unit weighs 115 kg, equipment dimensions (width, height, depth) are 58 × 174.5 × 63 cm.

A popular model for heating a private home is the Navien EQB 8HW electric boiler. This is a single-circuit device with a power of 8 kW. It is mounted on a vertical surface, has electronic control with a convenient display and pressure gauge.

The unit comes complete with a built-in circulation pump, safety valve and expansion tank. Among the main functions of the boiler, automatic diagnostics and power-on indication are noted. System pressure is up to 3 bar. The unit weighs 19 kg, equipment dimensions are 40x69.5x24.5 cm.

Reliable technology is represented by the single-circuit model Kospel EKCO.L2N 8. Its power is 8 kW. The wall-mounted unit is equipped with a heating element, has electronic control with a display and 6 power levels. The primary heat exchanger is made of stainless steel

The equipment includes a built-in circulation pump and a 6-liter expansion tank. There is a room thermostat and an air vent.

The main functions of the device include protection against pump blocking and power-on indication. The dimensions of the device are 41.8x71x25.1 cm.

A good single-circuit device for heating a private home is the Kospel EKCO.M1 8z boiler, equipped with a heating element. The unit comes with electric control and has 6 power levels. The device is mounted on the wall.

The package includes a room thermostat and an outdoor temperature sensor. There is a circulation pump, an air vent and an expansion tank. Among the functions of the electric boiler, automatic diagnostics and power-on indication are noted. Additionally, you can connect a heated floor.

The maximum pressure in the heating system is 3 bar. The equipment weighs 16 kg, dimensions – 38x66x17.5 cm.

A popular model among consumers is the Kospel EKCO.R2 8 electric boiler with a power of 8 kW. The single-circuit device is equipped with a heating element and is electrically controlled. Mounted on a vertical surface.

The package includes an expansion tank, a safety valve and a room thermostat. Equipment functions include self-diagnosis and frost protection. The device weighs 18 kg, dimensions – 38x66x17.5 cm.

Heater installation instructions

Electric water heating boilers of all types are designed for wall mounting and are equipped with mounting brackets or clamps. There is no point in explaining the marking and driving of dowels - every homeowner knows how this is done.

For reference. Universal electric wood-burning and coal-fired boilers, described in our other material, are sold in a floor-standing version.

Another question is how to choose the right room and specific location for installing the electric boiler. On the one hand, regulatory documents do not prohibit installing a heat generator in any room. On the other hand, there are rules for the use of electrical installations (PUE), which impose restrictions on the placement of high-power thermal power devices.

The wall version can be hung even in the corridor, but all communications will have to be pulled there

We will give some general recommendations on how to properly install an electric boiler in a private home:

- Considering the high current in the circuit of operating electric heaters, it is better to install the devices in a separate technical room, for example, a furnace room or garage. The goal is to limit access to power electrical equipment and protect devices from moisture.

- New heating elements can be placed in the kitchen or hallway. But keep in mind an important nuance: you will have to pull the main line of the heating system and a powerful power cable there. It is unlikely that these communications will fit harmoniously into the interior, unless the pipes are sealed into the wall.

- When installing the heat generator on a wooden wall or other combustible partition, comply with the requirements for wall-hung gas boilers. Place a sheet of roofing steel or basalt cardboard under the back of the body adjacent to the wood, as shown in the photo.

- Provide approach and access to the heater for ease of connection and maintenance. Install induction and electrode boilers in such a way that an expansion tank and pump are placed nearby. Place the control cabinet at a height of 1.5–1.8 m from the floor.

Recommended clearances to the Proterm Skat boiler unit specified in the instructions - Lay the cables above heating and sewer pipelines so that they are not flooded with water in the event of a breakthrough.

- Heating pipes should not load the connecting fittings of the unit with their weight.

Important! Be sure to connect the body of the electric boiler to the grounding bus. If there is none, make a grounding loop outside and lay it in the boiler room. Find detailed instructions below.

As a rule, an electric heat generator acts as a backup device for the main solid fuel or gas boiler. This means that heat generators and auxiliary equipment need to be configured correctly to ensure a minimum of pipeline crossings. Think and draw a diagram in advance.

Tips and tricks

The unit should be selected after first considering what the equipment is needed for. For example, if domestic hot water is required, then a double-circuit electric boiler is suitable. Moreover, the number of people living in the house is taken into account, since the tank capacity is different.

Be sure to look at the available functions, whether there is control using a remote control. Some people choose a device so that it fits into the overall interior.

An important criterion is the power and efficiency of the equipment. Pay attention to the presence of protective automation, control unit and other parameters. If it is difficult to choose the right option, it is better to consult a specialist.

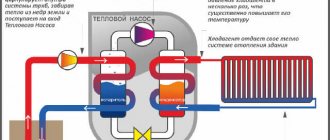

Circulation pump in a closed system

Circulation pump in a closed system

Due to these structural elements, the functioning of the entire system occurs. There are models on the market of different capacities, which are determined by a combination of several factors. The size of the pipes and the material of their manufacture, the number and presence of radiators, if there are thermostatic fittings, the length of the pipes, as well as how the equipment works are taken into account.

There are standardized tables from which you can select a pump. They need to focus on the area of the room that needs heating or the power of the system as a whole - you can build on this data when searching for a suitable option.

Harness

Earlier in the article it was mentioned that pumps in a closed system are mounted on the return pipeline. A few years ago this was a mandatory requirement for installing the system, but now the owner can do it as he sees fit.

The pump is manufactured using durable materials that can withstand temperatures up to 90 degrees.

If the design operates with natural circulation, then during installation it is better to make sure that the pump in case of wear or breakdown can be replaced without removing the coolant. Ideally, the station should operate even without a pump. To implement this idea, it will be enough to install a bypass - this part allows the coolant to flow without the participation of other elements.

If you are dealing with a closed system that uses forced circulation, then a bypass will not help here. This design option cannot function without a pump. However, here you already need a filter and two taps, which are located at the inlet. With the help of ball valves, you can disassemble the structure at any time if it needs repairs or replacement of worn parts. The filter performs a standard function - it prevents the system from clogging. To further secure the system, a check valve is installed between these two parts, which closes the path for the coolant in the opposite direction.