Currently, heated floors are not a luxury, and are installed everywhere in both private homes and apartments. They accommodate different floor coverings, and laminate is no exception.

Although until recently experts did not recommend this combination, today manufacturers have developed a huge line of products that can be combined with heated floors. When laying laminate flooring, it is necessary to place a special underlay that will reduce the temperature effect to a minimum, thereby extending its service life.

How to choose a substrate for a heated floor

Choose a substrate for an infrared floor with good characteristics; only in this case will you properly arrange the heating system. Signs of a high-quality and safe substrate for infrared heated floors:

- high level of reflection;

- service life more than 100 years;

- efficiency;

- excellent thermal and waterproofing properties;

- resistance to temperature fluctuations;

- ease of execution;

- sound and vapor barrier;

- fire safety;

- resistance to deformation.

There is a huge variety of insulation on the market for heating electric and water structures. The most effective and safe ones include:

| Groups | Materials | Examples |

| Natural | Jute | "Jute inter-crown insulation" |

| Suberic | "Izospan" D, DM, FB | |

| "Sedacor" thickness 10/4/2 mm | ||

| Artificial | Lavsan underlay for heated floors | PPE laminated “Termoizol” foil, thickness 2-10 mm |

| "Merilon" foamed polyethylene | ||

| "Euro-insulation" foil insulation | ||

| Polystyrene | "Izolon" foil foam, 2/4/5/8/10 mm | |

| "Stenofon" foam insulation | ||

| "Folgoplast" | ||

| Expanded polystyrene | "Polifom" | |

| "Izobond" | ||

| Polyethylene foam | "Multifoil" from Valtec | |

| "Energoflex" polyethylene foam, thickness 3-5 mm | ||

| Polyvinyl chloride foam | "Arbiton Izo-Floor" extruded polystyrene foam |

The cost of a heat-reflecting substrate for a heated floor varies between 300-900 rubles, it all depends on the thickness and manufacturer.

Characteristics of a quality substrate

Laminate boards are a beautiful, aesthetic pleasure, but by no means cheap. Therefore, accompanying materials must be of high quality. You should not use budget substrates with expensive, elite boards - this can lead to bad consequences. There are cases when, in combination with low-quality materials, a laminate board simply swells. To avoid mistakes, you need to know what characteristics high-quality materials should have.

So, among the main properties there is a soundproofing effect, leveling functions, neutrality to substances containing alkalis, thermal insulation characteristics, and resistance to moisture. Also, various domestic rodents and insects “do not like” a good product - they do not choose such material for arranging a nest or a food source.

In addition, a good product has microventilation characteristics. This property allows condensation, which will inevitably accumulate, to evaporate. The backing also significantly reduces the load placed on the locking joint of the laminate board.

Also, when choosing materials, reflectivity, high resistance to temperature changes, vapor barrier, resistance to various deformations, environmental friendliness and ease of installation are very important.

Do not think that the product for heated floors can no longer be used anywhere in construction. The underlay is a completely universal solution that can be used with parquet floors and regular laminate flooring.

Soundproofing properties

When people walk on laminate floors, a loud impact noise can be heard. This is due to the peculiarities of installation technologies, as well as the small thickness of the finishing boards. Often, the thickness is about 8 mm.

The board springs underfoot and all sounds are perfectly transmitted according to the membrane principle. In order to absorb these impacts, a substrate is used. Construction stores today offer laminate boards that are already equipped with a backing, but such boards are quite expensive. Rolled or sheet materials are a much more profitable purchase in terms of savings. As for sound insulation abilities, they are different for different types of materials. Manufacturers indicate the exact characteristics on the packaging.

Leveling properties

Often, heated floors are installed in a concrete screed. Even with an ideal finish, the screed is not always as smooth as required by the laminate. Such a finishing coating simply cannot be laid on a bare screed. Due to the heating of the floor, the board will simply swell. Also, if you lay laminate flooring on a bare floor, gaps may appear in uneven areas at the joints of the boards.

An expanded polystyrene-based substrate can smooth out these defects in the subfloor, but using such a substrate under a laminate for a heated floor will be redundant. This is unacceptable, because over time this could damage the locks on the boards.

Moisture-proofing characteristics

Laminate practically does not tolerate moisture. Prolonged exposure has a very negative effect on this finish. Laying should be carried out on a completely dry screed. The substrate will protect the coating from moisture and condensation and create an excellent microclimate under the board.

Thermal insulation characteristics

You should know that substrates are an excellent heat insulator. Together with a heated floor, such products will be very effective, but without it, the floor surface will not warm up well.

Why use a substrate?

For a water heating system, a laminate with certain characteristics is selected. It is more durable, but at the same time elastic. When heated, it expands, and when cooled, it restores its original shape without deforming or drying out.

The slats can withstand temperatures of 40 0C well, despite the fact that the maximum floor temperature is no more than 25 0C. They are resistant to moisture, but its amount must be minimized.

An underlayment must be placed under the laminated flooring. For water underfloor heating, its thickness should not be more than 3 mm. Why is an additional coating installed under the laminate?

- Laminate cladding is laid on a flat screed surface or self-leveling floor, but, unfortunately, it is not always possible to create an ideal coating. The underlay is designed to soften minor unevenness of the rough foundation.

- A wooden covering laid on a concrete screed creaks a lot. The additional layer plays the role of sound insulation.

- The slats are able to move; expand and contract. Experts say that the canvas can expand by 10 mm per season. This is due to temperature changes. At the same time, a large load is placed on the connecting locks. They may become unusable. The backing will reduce the load on the locks.

- When installing underfloor heating, condensation forms on the cladding surface. An additional protective layer protects the cladding from moisture.

We recommend: What characteristics does a two-core heated floor have?

Laminate, like parquet, is a material that retains heat for a long time, so additional thermal insulation is not installed on the cladding. The task of floor heating installers is to create a system that would effectively heat the floor surface. With an additional thermal insulation layer, heating the flooring will require a lot of energy, so insulation is abandoned.

The underlay for a heated floor should be thin and allow air to pass through well. Pay attention to resistance to moisture and high temperature. Choose insulation that is inert to the chemicals of the concrete solution or mixture for the self-leveling floor. An important factor is the bactericidal properties of the material so that fungus and mold do not form in it.

Natural and synthetic insulation is used as a protective layer for lamellas. The most effective natural coverings are cork and pine needles. Among synthetic ones, it is recommended to use polyethylene foam, polystyrene foam, and combined products. Which underlay is most suitable for additional protection of laminate flooring during underfloor heating?

How to choose a substrate for water-heated floors

Any underfloor heating system must provide high heat transfer. At the same time, thermal energy should not go to an unknown place. If the heated floor is based on water technology, then in the event of a possible accident, the substrate will also serve as a waterproofing agent.

Often, manufacturers use foil as a base for the substrate. It perfectly reflects heat, which will not be spent on heating the ceiling of neighbors on the floor below. If the thickness allows, the foil can be in its pure form, or based on various polymers. Along with good thermal insulation, a high-quality substrate also has high waterproofing characteristics.

For water heated floors, manufacturers offer products made from extruded polystyrene foam or from cork material in rolls. Isoplast is also used. But still, one of the most reliable and popular is foamed polystyrene.

In some cases, special molded foam-based coverings can be used. It is very easy to attach system pipes. Rolled materials should not be secured in any way. The substrate is laid on a layer of insulation, and then pressed against the reinforcing screed.

Types and characteristics of various substrates

When purchasing a shelf, you need to navigate the types and types of this material.

You can find “Lavsan” on sale. This coating is based on foamed polyethylene. The top layer of the material is metalized and has reflective properties. This material can withstand various aggressive environments. This substrate is perfect for infrared heated floors, as well as electric ones.

"Lavsan" differs in power density. It is necessary to select the appropriate material based on the finishing coating. So, for a laminate, a coating with a power density of 150 W per M2 is suitable. If you lay a material whose power density is higher, the coating will deteriorate due to overheating.

The market also offers expanded polystyrene. It is a cellular insulation, which has a very high temperature threshold. The material does not lose its characteristics at temperatures from -180 degrees to +180. Also, polystyrene foam is wrinkle-resistant, and its soundproofing properties are also very high. The covering is either foil or polypropylene. This material is an excellent choice for working with water systems.

The peculiarity of this substrate is that it is produced in sheets with ready-made markings, which greatly simplifies the installation process. On sale you can find slabs with a thickness from 20 to 50 mm.

The cork backing is very environmentally friendly and hypoallergenic. This material consists of compressed cork oak bark with a binder. Among the advantages is that this substrate is not eaten by mice and other rodents. Cork is ideal for laminate and all types of heated floors. Cork does not burn and is also very resistant to various types of mechanical stress.

Polypropylene is a combined material based on polyethylene foam, one side of which is covered with a layer of foil. This structure allows for excellent heat retention. The material is practical and also very durable. For an electric heated floor, this product should not contain aluminum, since there is a risk of short circuiting.

Functions

Laminate has long been deservedly very popular. This finishing coating is inexpensive, easy to install, and has an attractive appearance. When it is planned to install heated floors in a room, the presence of a shelf will allow you to isolate the laminate from the floor and concrete base. If you do not use a backing, then over time, a backlash will form at the joints of the laminate boards. If you walk through these areas, the flooring will begin to knock and make other unpleasant sounds.

To prevent such troubles from arising, substrates are used. Their thickness ranges from 2 to 5 m. Today, products with increased thermal conductivity characteristics are used specifically for the installation of heated floors.

Such a product can solve several important problems at once. Thus, the material will take on the role of additional insulation, will absorb loads, and will also be able to level out minor differences in height that remain after finishing the subfloor. With backings, the laminate board will not creak.

The substrates are laid between the heating elements of the heated floor and the laminate. Manufacturers of such boards recommend rolled polyethylene as this material. It is believed that this is the best and most suitable option of all those that the modern market offers. This polyethylene-based material works well in combination with alkali concretes and cements. Polyethylene perfectly withstands various aggressive effects of chemicals and prevents the appearance of various microorganisms.

How to prepare TP for a meeting with laminate

Before laying the laminate, you need to do several important things: let the self-leveling floor dry for 1.5-2 weeks before laying the laminate, do not turn on the heating during this time; turn on the heated floor, set the regulator to a comfortable temperature - you need a week of operation in this mode, during which time the moisture will leave the screed as much as possible; bring laminate into the room and turn off the floor so that the material “gets used” to the new temperature and humidity conditions. Wait 2-3 days - now you can lay the underlay and laminate.

After installation, it must be possible to ensure stable temperature and humidity in the room.

And when the heating season begins, it is necessary to gradually increase the floor temperature by 2-3 degrees per day to the one recommended by the manufacturer (usually +27 degrees).

At the end of the heating season, the floor temperature is also reduced to +15 degrees by 2-3 degrees per day. After this, you can simply turn off the thermostat. With each new season, this entire procedure will need to be repeated: if the homeowner does not want to quickly say goodbye to the laminate, he should not make sudden movements with the thermostat - only slow warming up (and at the end of the season, a slow decrease in temperature).

It is important to limit the heating temperature of the flooring to 26-27 degrees, so it will retain all its performance characteristics for a long time.

Underlay for warm electric floors

The underlay for an electric heated floor is structurally similar to the options described in the previous section. But almost all models of such warm floors do not require preliminary installation of waterproofing material under the substrate.

The surface is pre-leveled. Then a substrate is laid on it, onto which a special mounting tape is attached. The heating cable is attached to it with special brackets.

Important! When installing under electric heated floors, it is not recommended to use a material such as a foil backing under the heated floor. This is explained by the fact that metal (foil) is a conductor, and if contact is broken in the system, the probability of a short circuit is very high

The most suitable material in this case is a substrate made of the following materials:

- PP (polypropylene);

- Penofol (metalized film);

- Cork;

- Foamed polymers.

The leader in thermal insulation for underfloor heating is Energofloor Compact.

Types of lining materials

Foil polystyrene.

High heat/noise insulation characteristics, water resistance. The heat-reflecting effect is provided by a layer of foil. One of the most expensive substrates. Another foil backing for water heated floors is foamed polyethylene coated with foil. Two-millimeter thick film. Reflective effect, good heat/noise insulation characteristics. Cons: wrinkles easily, not waterproof enough. The price is the lowest.

Single-sided polyethylene: one side is foil-coated, the other is laminated with polyethylene. Thickness is 8 millimeters, waterproofing is better than the previous material, the price is higher.

Foil self-adhesive polyethylene 8 mm thick. All the necessary characteristics are in order, easy to install, and hides minor unevenness of the base well. The price is average.

In addition to foil, reflective Mylar film is used for laminating polyethylene. The thickness of such a substrate is three millimeters, and the price is higher than that of foil polyethylene. The material is valuable when laying electric floors, because... does not conduct current (unlike foil). For installation under a water floor, it has no advantages over foil pads.

Cork lining for a warm water floor. Does not crack, does not rot, and is resistant to fungal infections (unlike most wood materials). High thermal insulation and noise-absorbing characteristics, environmental friendliness. There is no thermal expansion. Not the most expensive material, since in fact it is made not from balsa wood, but from crushed oak bark.

Cork comes with or without a foil layer. In the second case, the foil is purchased separately and placed between two layers of insulation. The material is sold in slabs and rolls.

Extruded polypropylene. All the necessary characteristics are excellent, there is a foil layer. Mechanical strength, heat resistance. Sold in mats up to ten centimeters thick. The price is average.

A separate category of lining materials is a substrate for a water-heated floor with bosses. On most substrates, pipes are laid according to markings, and reinforcing mesh is used for fastening. The surface of the mats with bosses consists entirely of raised projections, between which pipes are laid.

The bosses not only mark the laying line, they also fix the pipes, preventing them from moving to the sides. Additional fixation - with clips and staples (not required for all mat models).

The mats () are made of polystyrene foam: a material with low thermal conductivity, waterproof, and a good sound insulator. If there is no foil layer, installation of reflective metal plates is necessary.

Another advantage of such mats is that they are equipped with locks for connecting to each other, which greatly simplifies the installation procedure. Minus - they are expensive compared to other materials.

Laying technology secrets of specialists

Follow the following list of work stages when laying the infrared film underfloor heating:

- Prepare a hole for the thermostat.

- Provide power to your system by choosing a convenient outlet.

- Carry out thermal insulation work. Use reflective insulation. Correctly calculate the thickness of the lavsan substrate layer under the infrared heated floor, it should be within 3-5 mm.

- When laying insulation, fasten it with mounting tape and direct the film towards the wall with a thermostat, this way you will significantly reduce the size of the wire.

- Maintain a distance of 10-20 cm near the walls. If there are installed heaters, such as a fireplace, stand back at least 1 meter.

- Lay the substrate evenly under the infrared heated floor under the laminate, watch the density of the material. If you do everything correctly, the approximate value will be 150g/m2.

- Lay the film carefully along the joints.

- Use IR film systems to heat floors with underlays.

- Cut the coating only in bright areas.

- Tape the joint edges and outer sides with tape.

- Insulate the ends of the film, stick on bitumen insulation.

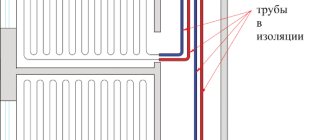

- Place the wires in the thermal insulation of the covering.

Carry out professional work taking into account the type of heating system and the selected material of the heat-reflecting substrate.

Order a consultation with a specialist for the correct selection and installation of the substrate for film heated floors: infrared, electric, water. Call or leave a request on the website.

Heating a home using underfloor heating is becoming increasingly popular. These systems vary in the type of heating elements, allowing you to choose for any home. In order for such a heating system to operate efficiently and reliably, it must be properly insulated. To ensure that the heat does not escape in vain, the underfloor heating is intended. It is made of heat-reflecting materials that will retain heat.

General Tips

Regardless of the type of heating system, there are universal recommendations for installing laminate floors. Their implementation will reduce the risk of unpleasant situations arising due to the fault of builders.

- The cement-sand screed must be perfectly dry, humidity no more than 1.5%. To do this, it is necessary to warm up the floors before laying laminate flooring, and at the same time, reliability tests of all individual elements of the system are also carried out. The heating should be turned on approximately two weeks before the start of laying the finishing coating; every day the temperature increases by only 5°. The base should cool down over the next week.

The screed must not only be level, but also perfectly dry.

- After completing the installation of the laminate, the first start-up of the system should be done at the same pace as for drying - no faster than 5° per day. The maximum floor surface temperature cannot exceed +27°C.

- Please note that heated floors are not installed under furniture and household appliances. There are two reasons: elements overheat and heating inefficiency due to lack of air movement. And if over time you need to change furniture or change its location, then what to do with heated floors? Conclusion - do not rush to make the final decision about installing heated laminate floors.

Infrared film for heated floors does not fit under furniture and appliances

The quality of a heated floor depends on many factors, and they all play an important role. You should not simplify the work and neglect some technological steps or advice. Real repair of a heated floor will cost at least an order of magnitude more than the virtual financial savings at the installation stage.

Prices for Tarkett laminate

Tarquette laminate

Video - Warm floor with your own hands in an hour

Secrets of installing underlays under infrared floors

In order for the film system to function correctly, it is necessary to install the components as efficiently as possible.

Proper installation of the heated floor underlay is also very important, and when working with it you should know some features:

- If the underfloor heating substrate is made of fiberboard or magnesite tiles, it is laid on a screed covered with aluminum foil;

- If it is made of a polymer metallized film, then it is placed under the film with infrared resistors, the reflective side up;

- The insulating material is laid in a continuous mass over the entire surface.

If individual elements of the substrate require connection, this can be done with tape or regular adhesive tape, which will provide additional vapor and waterproofing properties.

The underlay for a modern heated floor is very important when installing the system. This detail will allow you to fully experience the capabilities of heating systems and help the house retain heat inside.

Today, heated floors are no longer a luxury item. There may be several options for the design of such an additional heating system. It all depends on the type of heating element. These systems are compatible with most finishing floor coverings, including laminate. When using it as a finishing coating, a special underlay for laminate flooring is used. This product will allow you not to waste precious heat, since it consists of modern, highly efficient materials with a heat-reflecting effect.

Expanded polystyrene

To insulate floor cladding, 3 types of expanded polystyrene are used: non-pressed, pressed and extruded. Pressless polystyrene foam is installed for low-load flooring, but most often the insulation is used to insulate walls. For a water floor, pressed or extruded polystyrene foam is chosen under the lamellas.

- The material is porous. Air bubbles are located in the cells, distributed evenly over the entire surface. This characteristic ensures the moisture resistance of the coating.

- Density 40 kg/m3. This is enough to straighten out unevenness in the subfloor and reduce the mechanical load on the slats when moving along the floor.

- Withstands temperatures up to 75 0C.

- Has good sound insulation properties.

- For water heating, a material with a thickness of no more than 3 mm is used, because polystyrene has low thermal conductivity. Otherwise, heating the floor surface will be ineffective.

For floor coverings, it is recommended to choose a material with a non-perforated surface. The contour promotes better heat transfer, but for a warm floor it is necessary to retain the heat on the coating. A smooth surface will reduce heat loss.

Expanded polystyrene is produced in the form of sheets or in the form of an accordion: the sheets are interconnected; product length 10 m; Installation of insulation occurs quickly. The insulation is highly durable. For a water floor, it is recommended to use the “Solid” or “Aberhow” substrate.

Expert answer

Hello, Valery.

The information you received about materials for laying laminate flooring on warm floors is completely true. The fact is that cork is one of the best heat insulators of natural origin. In a heated floor system, it will prevent the transfer of heat from the water circuit to the final coating, therefore, when installing underfloor heating, this type of substrate is used last.

It would be ideal to lay the laminate directly on the screed, but this is not recommended for many reasons, ranging from the need to eliminate minor unevenness in the concrete base to sound insulation. It is best to take a backing made of perforated EPS (extruded polystyrene foam), which is designed specifically for heated floors. If you do not find such material, you can use sheets of foamed polyethylene - it has the highest heat transfer coefficient among similar materials.

In Europe, when installing TP, special construction cardboard is often used as a substrate, the heat transfer coefficient of which is almost equal to the thermal conductivity of the laminate. We should not forget that the thinner the lining layer, the more efficiently the warm floor will work. That is why the thickness of the substrate should not exceed 2 mm. Of course, this will require maximum care when arranging the sand-cement screed - differences in heights per 1 m should not exceed 1-2 mm.

As for specific brands, in practice, Quick-Step Uniclic 2 in 1 or Arbiton Izo Floor Thermo (perforated) underlay shows excellent results - they are precisely intended for use in underfloor heating systems. Finally, I would like to remind you that when choosing materials for finishing a finished floor, preference should be given to those whose packaging contains information that the products are intended for installation together with underfloor heating systems.