The last characteristic of this list was discussed a lot and fiercely on FORUMHOUSE, the conclusion is: “it does not add health.” Laminate emit formaldehyde even at normal temperatures, and as the temperature rises, the emission also increases. But many manufacturers have developed a special coating that is resistant to constant heating - such a laminate does not crack, does not form cracks, and behaves much better than a wooden floor, which is why people still choose it.

There is also now a laminate with enhanced environmental safety properties, E0. It is less common on sale than the more dangerous E1 and E2, but when choosing a laminate, you must take into account that a real, non-counterfeit product is quite expensive.

Features of the water heating device

The operating principle of this type of heating is to heat the floor surface with hot water transmitted through pipes. Pipes are usually laid in a concrete screed. Concrete is characterized by good thermal conductivity; moreover, it not only transfers heat from the pipe circuit to the surface, but also distributes it evenly.

This is what a water heated floor system looks like.

When installing heating in private houses, pipes are connected to boilers of all types, including solid fuel. The necessary components of the system are a circulation pump and a device for regulating the flow rate of the coolant or its temperature, designed to maintain the temperature of the water.

Installing a “warm floor” in an apartment is a more complicated procedure compared to a private house. Many regional authorities prohibit connecting pipes to a central heating or water supply system in apartments. In the absence of such a prohibition, as a rule, the need for an examination is established by law. If these rules are violated, the least trouble will be a fine. The worst situation is an accident in the heating network of your neighbors.

Attention! Connecting a “warm floor” to centralized heating or hot water supply is possible if there is a separate pumping and mixing unit. If there is an elevator unit in an apartment building, then metal-plastic pipes are not used to move the coolant.

There are certain restrictions on surface temperature in rooms of various purposes and characteristics.

| Purpose and characteristics of premises | Temperature, °C |

| Residential | 26 (average) |

| With high humidity | 31 (average) |

| Non-residential | 31 (average) |

| Above the pipe | 35 (max. allowed) |

| Children's | 24 (max. allowed) |

Arguments of opponents of the use of laminate in water heating systems "warm floor"

Not everyone agrees that laminated panels can be used as an underfloor heating component. The following arguments are put forward:

- Laminate is a wood-based material. Therefore, it has low thermal conductivity, which prevents effective heat transfer. However, thanks to the concrete screed, which evenly distributes heat from the pipes, the small thickness of the panels and the use of special products, this disadvantage is minimized.

- The second argument is the likelihood of releasing harmful fumes when heated. This problem can be avoided by using a thermostat that prevents the coolant from overheating.

A thermostat for a warm water floor will help avoid overheating of the coolant.

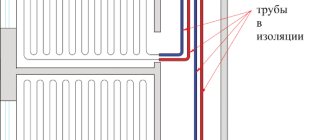

Installation of pipes on a concrete floor

If you decide to make a water-heated floor under the laminate yourself, you should know the procedure. Laminate can be laid on both concrete and wood surfaces. Let's look at the technology for laying water-heated floor pipes on a concrete base.

- The work should be done before installing the doors and finishing plastering the walls.

- You need to make sure whether the height of the doors in the living room allows you to install a heated floor, since its height is at least 14 cm (the height of the doorway is approximately 220 cm). It doesn’t hurt to calculate the heat loss at home using a calculator on the Internet - it should not be higher than 100 W/m2.

- It is necessary to make a niche in the wall and install a manifold cabinet above the floor, where there are no wires. If there is automation, then you need to make recesses for the electrical wiring and connect the main pipeline with the return supply. You can use an easier option: install a manifold cabinet on the wall, closer to the center of the house, and run pipes to it. If there is a project, then act according to it.

- Prepare the rough surface to avoid air pockets and traffic jams: remove debris, seal cracks, level the floor, removing differences (the norm is 5 mm). If this is not done, the hydraulic resistance in show jumping will increase.

- Waterproofing polyethylene film placed on the surface provides good protection from moisture.

- Install a damper tape with a width of 6 to 12 mm along the perimeter of the walls at floor level. This polyethylene tape helps compensate for the expansion of the screed due to heat.

- Lay insulation (expanded polystyrene, its density is 30 kg or more per cubic meter of surface area) with a thickness of 5 to 10 cm.

- Place a poppy mesh, polystyrene or special tape on the floor.

- Lay pipes without joints with a diameter of 16 to 20 mm in a “snake” pattern in narrow passages, and a “snail” pattern in rectangular rooms. The “snail” method has a number of advantages: less pipe needs to be bent, 90 degrees, there are almost no hydraulic losses, heat is evenly distributed.

You need to start laying the “snake” from the cold wall to the warm one, in steps of 100-300 mm. Pipes are placed 150 mm or more from the walls. If the pipe has a diameter of 16 mm, then the length of the loop is up to 100 m; if it is 20 mm, then 120 m. When laying in a “snail” manner, visually divide the surface into the main and edge zones. The step along the edges of the floor will be more frequent (10 cm), since there may be cold walls there; in the rest of the area – a step of 20 cm. If the room is large, then use 2 pipe loops. - Install a collector block and a heated floor mixing unit in the manifold cabinet. Connect the Euro pipe to the manifold outlets with cones, without confusing the supply with the return.

- Take a photograph of the floor surface with laid pipes so that you don’t disturb them later with screeds.

- We perform pressure testing of the system in this order: first we close the ball valves in front of the mixing unit, then we set the pressure with the pump, 6 atmospheres is enough, and check that everything is working properly.

- The cement screed (cement-sand mortar or semi-dry mixture) is poured under a pressure of 6 bar. It should be no higher than 4.5 cm from the top of the pipe. After 3 days, the operating pressure value is established, and only after 20-28 days do we supply heat to the pipes.

- After the screed has hardened, we set up the flow meters (the temperature should be the same on all return pipes) and set the necessary parameters on the pumping and mixing unit.

- If there is automation, then we install drives, a thermostat and controllers.

- We lay the underlay and laminate on the flooded water-heated floor.

What types of laminate are suitable for laying on a water-heated floor?

All types of laminate are suitable for organizing heated floors. The documentation supplied with the stoves may indicate: the recommended operating temperature, usually 27...29°C, and additional data on the optimal heating mode.

Plates are produced using several technologies:

- Using formaldehyde resins. Such materials are used at temperatures not exceeding +26°C, due to the likelihood of evaporation of toxic formaldehydes. The product is popular due to its low price; it is used in combination with thermostats that avoid overheating.

- Based on acrylates. This is the best laminate in terms of non-toxicity.

The level of evaporation from the floor covering is indicated by the letter E. Modern laminated panels have class E1, which allows the use of the material in an underfloor heating system.

conclusions

In conclusion, I would like to say the following. The performance of the home heating system “warm water floors”, which interacts with the laminate, is quite successful and effective. By following all the rules and features of the installation technology, adhering strictly to the criteria for choosing the material, you can guarantee yourself the necessary comfort and coziness inside the heated room.

You should not experiment with laminate flooring. Overheating and flooding with water can negatively affect the quality of your floor. If you want to have beautiful and pleasant-to-touch floors in your home, make sure that the indoor humidity is not below 50-60%.

How to choose a laminate and underlay for a “warm floor” based on the thermal resistance coefficient?

Thermal resistance coefficient is a value inversely proportional to thermal conductivity. For materials used as a finishing coating for a heated floor, this characteristic is used, denoted by the letter R. The unit of measurement is m2*K/W. The lower this coefficient, the better the thermal conductivity of the product. European standards limit the value of R to 0.15 m2*K/W. It is equal to the sum of the thermal resistance coefficients of the laminate and the substrate, indicated in the accompanying documentation for the product. The ideal option is if the amount is 0.1 m2*K/W. The thermal resistance coefficient depends on the thickness of the slab and the density of the structure.

If the total value of R exceeds 0.15 m2*K/W, then negative consequences are possible:

- inefficient heating operation with increased energy consumption;

- release of toxic substances into the atmosphere;

- overheating and destruction of the finishing coating;

- short working period of the pipeline.

In combination with laminate, thin substrates with a low thermal resistance coefficient are used. Moreover, the same materials can be used for water and electrical systems. One product option specifically designed for underfloor heating is XPS underlays, made from dense extruded polystyrene foam. The characteristics that make it possible to use this material in underfloor heating are high density and low thickness.

Use polystyrene foam underlay when laying laminate flooring on a heated floor system

Features of laying waterproofing materials

The installation of this type of flooring requires special approaches to solving waterproofing issues. This will avoid emergency leaks and protect the floor from moisture, the development of fungi and pathogenic microorganisms. The best solution would be to lay film material.

For these purposes, they usually follow the following algorithm:

- The base is cleared of debris and removed as much as possible from dust particles with a vacuum cleaner.

- The waterproofing film is laid with an overlap of at least 5 cm.

- Using a hair dryer and a blowtorch, all joints are soldered, achieving maximum insulation.

- Additionally, you can use construction tape, which will ensure the integrity of the coating.

Which laminate is suitable for finishing a water-heated floor?

The higher the class and thickness of the products, the less the slabs are susceptible to drying out and changing geometric parameters due to temperature changes and other negative factors. However, on the other hand, the thicker the panels, the lower their thermal conductivity.

For rooms of various functional purposes, laminated panels of different classes are used. Conditionally heated rooms are divided into several zones:

- Bedroom – lounge, bedroom, living room. Matte products with antistatic effect and noise-absorbing characteristics are suitable. The load here is low.

- Working - kitchen. Material with a moisture-resistant coating is purchased for it. The joints between the panels are sealed.

- Entrance hall, corridor. Wear-resistant panels from classes 32-33 are suitable for this zone.

- Plumbing facilities, balcony, loggia. Since the likelihood of water getting on the floor is very high, “aqua” laminate is used for such rooms. Class – from 32.

There are no restrictions on the choice of laminate class for heated floors: choose thickness and moisture resistance depending on the room (bedroom, kitchen, corridor).

Rules for laying and operating water-based “warm floors” with a laminate finish

To ensure efficient operation of the underfloor heating system, the following rules must be observed:

- Do not cover the floor with rugs and carpets, which create conditions for overheating of the finishing panels and failure of the heating system.

- Do not install furniture in areas where the water circuit is located.

- Do not place water circuits under heating radiators.

- Provide floor ventilation. For this purpose, a gap of 10-12 mm is left along the walls, which is covered with a plinth at the final stage of installation work.

- Use thermostats in the system to ensure compliance with the required temperature conditions.

What do you need to remember?

- Laminate flooring is sensitive to temperature changes . This especially applies to rapid and sudden temperature changes. You need to warm up the floors gradually, no more than 6-10 degrees per day.

- The temperature on the surface of the finished laminate floor should not exceed 29-30C .

What are thresholds for laminate flooring: materials of manufacture and methods of fastening the molding You can find out about the types and rules for installing beacons for floor screed here

Our article explains the advantages and average cost of building a house from aerated concrete.

Preparation for laying laminated panels

After installing the heated floor pipes into the screed, the heating of the system is turned on, which is stopped on the day of delivery of the laminated panels. Laminate does not tolerate sudden temperature fluctuations, so before laying it, it is left for three days in the room in which installation will take place.

After completion of installation work, the temperature in the room should be maintained at approximately the same level for three days (at least). With the beginning of the heating season, the temperature of the underfloor heating is increased gradually - from 15-18°C by about 3°C per day, until the optimal temperature regime is reached. Finish heating, gradually reducing the temperature to 15-18°C.

Suitable heating systems for laminate flooring

For standard brands of laminate, electric and infrared heated floors are used. Electrical systems are universal and can be used for all types of flooring, including laminate. Kits for a specific room area are offered for sale. Available in the form of mats, cable and film. The floor level rises only 1 cm.

Film infrared floors are inexpensive, the process is less labor-intensive, can be completed in almost a few hours and eliminates the need to fill a screed. Quick installation involves connecting the material spread over the surface to the thermostat.

The disadvantage of electric and film floors is the expensive power supply, the rapid cooling of the surface during an emergency power outage, which often leads to the impossibility of restoring the structure.

Recently, modern laminate flooring options suitable for water floors have appeared on the market.

Installation procedure

Installation of laminated panels is carried out on a ready-made screed or flooring system.

- If the building design allows the installation of a water heating system in a concrete screed, then this option is usually chosen.

- In houses with wooden floors, the slabs have to be laid on a stacked structure, since they may not be able to withstand the weight of the concrete screed.

Attention! For both installation options, the base surface must be completely flat.

The process of installing screed on a heated floor system.

Before starting installation work, the concrete screed is treated with a primer to compact the top layer and remove dust. In this case, waterproofing measures are not required; the substrate is laid directly on the concrete. The substrate without the foil layer is laid on the walls with an overlap of 50 mm. The joints are taped with non-metallic tape.

Laminated panels are mounted on a substrate with a gap between them and the wall of 10 mm. It is recommended to start work from the far left corner of the room. To bandage the seams, the slabs are laid offset in rows. So, if in the first row a whole panel is first installed, then in the second row it is shortened by 30-40 cm.

After completing the work with the screed, the substrate under the laminate is laid directly on the concrete, then you can begin laying the laminate.

What materials are best to use?

- Cement-sand screed best ensures heat transfer from the coolant to the environment.

Therefore, it is better to choose it for your floors. There are options when pipes are laid in a dry screed. This option is faster, but less efficient in terms of heat transfer. Half of the heat with such a screed will go to the lower floor or basement. - you choose must be of high quality . Thanks to this, the boards will not deform and dry out when heated. The thermal conductivity of high-quality laminate is higher than that of low-quality laminate .

- A high-quality underlay for pipes significantly increases the efficiency of a heated floor. It is best to choose a high-quality substrate with the highest caking resistance .

Panel connection types

The principle of laying slabs is almost the same for concrete and floor surfaces. Connection methods can be: glue and lock. The first option is not applicable in this case, since rigidly fixed panels are deformed when heated, so only interlocking “floating” installation is allowed.

- Click locks. Snap-on products ensuring high reliability of the connection. The planks are connected at an angle of 45° and then snapped into place. At the same time, a characteristic sound is heard, thanks to which the connection got its name. Even when heated, there are no gaps or deformations. The requirements for the quality of the base are moderate.

- “Lock” locks (drive-in). Tongue and groove connection. A perfectly level base is required. Any deformation may cause the connection to break, leading to the formation of gaps.

Compliance with the rules for choosing a substrate and laminate, the technology for laying them when doing DIY work and subsequent operation ensures the installation of a decoratively attractive and durable floor covering.

What are the advantages of this gender?

Comparing with other floor devices, we can highlight the most characteristic advantages that distinguish us from others:

- during operation, the temperature of the water floors remains constant at an average of about 50°C, which provides savings on overall heating of the room;

- it is environmentally friendly, it can be installed in any room without fear of an allergic reaction to the components of its system;

- completely safe to meet sanitary and hygienic standards;

- installation equipment is the most common;

- there is no phenomenon of generated electromagnetic flux, as, for example, with electric floors;

- compatible with all types of floor coverings: ceramic tiles, linoleum, floorboards, natural stone, laminate.