The pumping and mixing unit and the manifold group of the water heated floor are designed to regulate the circulation of the coolant in the circuits, control the pressure in the heating system, eliminate air pockets and control the temperature. How the manifold for a heated floor is assembled, the basic connection diagrams and common mistakes, we will consider further. You can read about the device and principle of operation here

Why do you need a heated floor collector?

The “water heated floor” system is an effective way to uniformly heat all rooms in the house. Installation of this type of heating without a collector group is possible provided that a single circuit is laid. However, the maximum possible length of one pipe should not exceed 70 m, which effectively covers seven square meters. Thus, on average, a minimum of 2 circuits will be required per room.

Pumping and mixing unit with a minimum number of circuits

When laying water heated floors simultaneously in several rooms without turning on the collector, it will be impossible to regulate the main indicators of the correct operation of the heating system. The absence of a collection group is fraught with serious problems:

- Inability to regulate pressure in the heating system and bleed air;

- If the water heated floor pipe is damaged, you will have to turn it off completely in the entire house;

- Uneven heating of the premises of the house.

Improper functioning of the system will lead to costly repairs. If you have some skills, it is possible to install the unit without involving specialists. It is enough to purchase a manifold group that matches the parameters of the pumping and mixing unit and connect them in compliance with the technology.

Is it worth automating the system?

First of all, it's worth talking about weather sensors. They allow you to adjust the coolant temperature based on the temperature outside the window of your home. You could do this yourself, but frosts come unexpectedly, for example, when you are sleeping, so in the morning the house can become significantly colder; it is in such situations that weather sensors will not allow you to freeze.

Weather sensors are often installed with indoor temperature sensors, which shift the valve 1/20th if the temperature in the house is lower than necessary.

What does a heated floor manifold consist of?

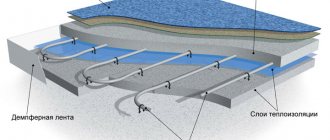

The control system for a water heated floor is a combination of valves, sensors, actuators and other elements. The principle of operation of the collector is simple - the heated coolant passes through the circuits, cooling and returning to the starting point for reheating. The design mixes circulating liquid of different temperatures, which allows you to obtain optimal parameters for heated floors.

A standard mixing and distribution unit for a heated floor assembly consists of:

- Mixing unit (1) for diluting hot water from the boiler. Mixing occurs automatically due to the presence of temperature sensors and a servo drive used as a thermostat.

- Circulation pump (2) on the coolant supply pipe. The pump provides the system with the correct pressure to improve heating efficiency;

- Distribution comb (collector group) (3), equipped with outlets for connecting water circuits and flow meters for zonal distribution of circulating fluid through pipes. As well as a bypass (5) to prevent overheating of the pump.

INTERESTING: Decorating a house with siding: practical tips and instructions

Assembly of the collector unit

In addition, expensive models of collectors contain thermal sensors (4) that regulate the temperature depending on the temperature, and an air vent (4) for bleeding air plugs.

Mixing valves

When connecting the manifold, two types of mixing valves are used: two-way and three-way. They are designed for mixing liquids: hot, which comes from the boiler, and cooled, respectively, from the heating circuit. They are controlled manually or automatically - requiring additional installation of a servo drive or control device.

Three-way ones are used, as a rule, for collectors intended for heating large rooms with an area of more than 200 square meters. m. Such schemes also include weather-dependent sensors, which are programmed to determine the required floor temperature based on external conditions.

Two-way ones are used for rooms with a smaller area - less than 200 m2. In such a scheme, the floor temperature is controlled by a valve. If necessary, he himself adds hot liquid coming from the boiler or, conversely, water from processing. If the collector is configured correctly, overheating of the floor is completely eliminated. Two-way valve circuits provide smooth and stable adjustment.

There are many other collector schemes and installation types.

Accessories for water heated floors

The complex design of the mixing unit and collector group is complemented by many auxiliary parts that play one or another role in regulating the operation of warm water floors:

- The thermostatic valve is controlled manually or automatically using an electrothermal drive.

- Hydraulic balancing of the loops of the underfloor heating system occurs through tuning valves (there are options with or without flow meters).

- Ensuring constant pressure is achieved using an overflow valve, which redirects excess liquid to the bypass.

- The radiator balancing shut-off valve is used to open/close the water supply between the collector and the heating system.

- A bypass with a bypass valve, an expansion tank, a safety valve, as well as communicators and controllers are responsible for the trouble-free operation of water-heated floors and continuous monitoring of the operation of the heating system.

The mixing unit may have two or three way mixing valves. The first option is considered more reliable, as it allows you to limit the flow of water directly from the boiler using a balancing valve and thermostatic control units. This protects the circuit from exposure to boiling water, which is especially valuable when using polypropylene pipes.

The 3-way valve design is more versatile in terms of recommended heating area. Unlike two-way units, which cannot serve more than 200 m², a three-way valve creates optimal pressure in heated floors of any size.

Types and principle of operation

Collector devices differ in the material from which they are made - brass, plastic or stainless steel. And also by type of valve:

- With two-pass - the design feature is continuous heating of the coolant. Heated water is supplied continuously, and shut-off valves regulate its volume. As a result, the surface is heated evenly, while overheating of the system is not possible. But this model is not suitable for rooms whose area is more than 200 m2.

- With three-way - universal equipment, recommended for large rooms. According to the technology, installation with a servo drive is allowed (we suggest you learn more about servos in more detail) and various automation. The valve is capable of creating optimal operating pressure, adjusting the temperature level and the amount of coolant supplied.

Kinds

In addition, there are 4 types of collectors:

- Simple - a tube with shut-off valves, having internal and external threads. The model is cheap, but there is no function for setting up the system. To install such a collector on heated floors, additional elements are required.

- Equipped with valve outlets for adjustment, and valves for connecting circuits - a Chinese device. It is not uncommon for a structure to leak, but repairs are not difficult, just change the gasket. The distance between the supply and return pipes does not coincide with European standards, so various devices are required.

- With control valves and Eurocones - an expensive model. It does not have ball valves, but there are fittings and adjustment valves; a servo drive can be installed on them, which will regulate the temperature in the line.

- With flow meters - they are located on the supply pipe of the manifold, and on the return pipe there are sockets for servos. This device is intended for heated floors with circuits of different lengths; the presence of flow meters allows you to regulate the volume of coolant in each circuit.

Any model is equipped with outlets for draining water and air.

Principle of operation

The general principle of operation of the unit, regardless of the type of valve (two or three-way), is to distribute the flow of water along the loops of the heating floor, which circulates under the influence of the pump. The amount of coolant entering each branch is controlled mechanically or automatically by a servo drive.

The work process looks like this:

- Coolant heated to 60 - 80 degrees is supplied from the source to the comb through a thermostatic valve;

- A flow of chilled water from the return flow comes from the distributor;

- The shut-off valve has a head that regulates the temperature of the fluid;

- The mixed two streams are fed into the mixing pump, then the water is distributed through the pipelines.

When the heating temperature of the coolant in the main decreases to the required level, heated water from the source is mixed in, a two or three-way valve is responsible for this.

Assembly of the finished kit

The simplest and most reliable way, but more expensive, is to buy a ready-made set of pumping and mixing unit and manifold group. The assembly manual for the factory kit contains step-by-step instructions, allowing even an inexperienced craftsman to assemble it with his own hands.

Assembling a complete set of pumping and mixing unit and manifold group

The connection of underfloor heating pipes to the collector is made taking into account the throughput of the distribution combs and a drawn up diagram indicating the sizes of the pipes, their connection points with the elements of the heating system and the places of installation. Work on connecting the water circuit is carried out after installing the collector and protection system (bypass, air valve).

INTERESTING: How to install a toilet with your own hands

At the end of the work, the connections are checked for leaks. To do this, the underfloor heating manifold with a flow meter is connected to the main pump, which pumps up the required pressure, and the system is left for 24 hours. If the set parameters have not changed during the day, the mixing unit can be safely operated. All inspections must be carried out prior to laying the final floor covering.

If you set out to assemble a water heated floor distribution system yourself, rather than buy a ready-made kit, then consider cheaper DIY design options.

From a profile metal pipe

Collector group from a profile pipe

Before manufacturing the collector, it is necessary to draw up a diagram with the location of all elements of the assembly. It is better to choose steel pipes with a square cross-section as the manufacturing material. This type is easy to process, which significantly reduces labor costs for installing pipes.

Manifolds made of profile pipes are used in the heating circuit of objects with a large number of circuits and a hydraulic separator. Square pipe parameters – 80*80 or 100*100 mm

The step-by-step process for producing a prefabricated distribution structure is as follows:

Assembling a collector from a metal profile pipe

Settings

As a rule, a special balancing table is attached to the diagram, on the basis of which the comb can be adjusted according to two parameters: circuit length and heating load.

The table relates the circuit number and the number of revolutions from the position of the balancing valve - “closed”. Set up the comb like this:

- remove the cap from the valve that serves to protect it;

- close the valve all the way - use a hex key for this;

- determine the number of revolutions for a given circuit;

- turn off the valve to this number;

- The remaining circuits are configured in the same way.

Correct configuration and connection of the collector are necessary for long-term operation and efficient operation of the system.

Manifold made of polypropylene pipes

If polypropylene pipes are used for production, you should pay attention to the presence of a reinforcing layer in them. In its absence, the plastic structure may be subject to deformation due to the current temperature conditions.

Detailed technical process for assembling the collector group:

Assembling a collector comb from polypropylene pipes

Mixing units made of polypropylene have an important advantage over their metal “counterparts” - low cost. Otherwise, you will have to come to terms with a number of shortcomings:

- Polypropylene manifolds are installed in systems with a small number of outlets (no more than 5 pieces);

- Flow meters cannot be installed;

- A larger protective box is required due to the massive structure;

- Be sure to have a set of specialized tools and soldering skills.

Assembling a distribution manifold from individual elements

For those who do not have special tools, you can assemble a comb from separate ready-made elements. It is better to select components from one manufacturer.

The circuits are connected according to the chosen scheme, adhering to the main rule - pipes with warm coolant are fixed at the top. Pipes with cooled coolant are secured from below.

At the final stage, it is necessary to carry out pressure testing and a control start-up of the heating in order to timely identify hidden or obvious deficiencies in the structure made.

Tips for installing a warm water floor collector

Using a factory kit eliminates a number of common mistakes when installing a unit. The finished manifold group for underfloor heating is already equipped with the necessary valves and other important elements.

Be sure to consider the following recommendations:

- The calculation of the thermal load on the circuit is calculated before installation, and based on the data obtained, the balancing valve is adjusted;

- The cabinet for the mixing unit is placed in a place located at the same distance from the connected pipes;

- The dimensions of the collector box should be selected according to the dimensions of the device;

- Under the block, be sure to provide space for bending each contour;

- For a possible increase in water circuits, it is worth leaving several free pipes;

- The most efficient heating system is obtained by introducing a powerful circulation pump;

- When installing multiple pumps, be sure to use check valves.

INTERESTING: How to lay metal tiles on a roof?

Diagram of pump-mixing and manifold assembly

Among other things, it is better to entrust the development of a heating floor collector circuit to professionals, even if you plan to assemble it yourself. The fact is that making accurate calculations without the appropriate knowledge is quite problematic. Saving on a qualified calculation of the parameters of the collector unit can lead to serious costs in the future.