Almost every modern home has a water supply system, the obligatory element of which is a hydraulic accumulator for water. At the same time, some private property owners are wondering why it is needed at all, is it possible to do without it? In this article we will try to find out.

This knowledge will help you avoid many problems that may arise during operation. By the way, hydraulic accumulators are widely used not only in everyday life, but also in industry.

Myth 1. The hydraulic accumulator is designed to maintain constant pressure in the water supply system.

This phrase can be found quite often in descriptions of hydraulic accumulators. Variations - the hydraulic accumulator creates constant pressure, etc.

Let's start with the fact that a membrane (rubber bulb) in a metal casing is simply not able to create any pressure, either constant or “variable”. The pressure is created only by the pump. Whatever pressure the pump provides, the same pressure will be in the accumulator. The only thing that can be said is that the hydraulic accumulator, in the absence of water flow, maintains the pressure created in it and contributes to its smooth decrease with the start of water collection and a smooth increase after closing all the taps. Those. without it, the pressure would change instantly, but with it it changes smoothly, due to a change in the hydraulic volume by stretching and compressing the membrane. This is the main point of using it. For the correct functioning of the system with the ubiquitous pressure switch, a smooth change in pressure is required, which is ensured using a hydraulic accumulator.

There is no need to talk about constant pressure in a standard system with a pressure switch and a hydraulic accumulator. The whole point of the functioning of such a system comes down to the fact that the pressure is constantly changing, due to which the operation of the pump is automated using a pressure switch. There can be constant pressure only with a constant flow rate, but as soon as the water flow rate changes (an additional tap is opened or closed), the pressure instantly changes. All that a hydraulic accumulator can do is to give the system inertia, which is what is actually required of it. Constant pressure in systems with variable flow can only be achieved by using a frequency converter, when the pump rotation speed changes depending on the water flow.

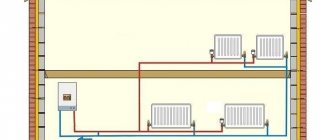

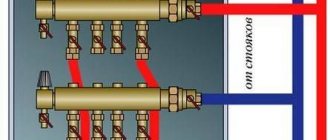

Installation of several hydraulic tanks

Some users are faced with the problem of how to connect an additional tank to the water supply line if there has been an increase in consumption or the volume of the storage tank is too small for normal operation. Installing two hydraulic accumulators is not particularly difficult; they can be assembled by connecting them in parallel, using an additional adapter fitting, a flexible hose or cutting a water pipe.

The advantage of a system with two tanks is its high reliability in case the rubber membrane ruptures in one of them.

Rice. 8 Hydraulic tank in the frequency control unit for pumps

Drain the water correctly

If you leave the liquid in the pumping station over the winter, the liquid will freeze and rupture the parts, and the expensive device will become unusable. To prevent this from happening, the entire water supply system must be properly prepared for winter. What does that require:

- First of all, the station is disconnected from the power supply.

- Then, you need to disconnect the suction hose, it should be taken into account that the water that remains in the system will flow.

- To relieve pressure, the drain valve is raised completely; if it is not there, the nearest tap or valve is opened.

- The pressure pipe or hose is removed.

- The pressure in the accumulator should be determined; it should be 1.5 bar or slightly more.

- When there is no necessary device or the magnitude of the force is less, use any sediment and work with it until the water supply from the suction pipe stops. If this procedure is not carried out, the liquid may remain inside, the station’s hydraulic accumulator may break, and then in the spring you will have to spend money on replacing it.

- After this, the pumping station is assembled and removed until spring. In order to preserve the equipment, it can be taken away from the dacha.

- The water is drained from all hoses and pipes.

A successful result of the work on preserving the station will be the absence of liquid in the pipes of the entire system in the house.

Treat basement and cellar for mold

The end of the summer season is the right time to treat the cellar and basement so that a “mold kingdom” does not develop in them over the winter. First of all, in dry weather, take all the jars outside and dry the room, and then treat the walls and other structures with an antiseptic (this procedure must be repeated every few years).

As an antiseptic, you can use a solution of copper sulfate (100 g per 1 liter of water).

Those who like to solve problems in a radical way recommend using a sulfur smoke bomb to treat the basement. Seal all ventilation holes in the empty room, cover metal parts (if any) with polyethylene. Check that there is no one in the house (you will have to leave it for a day), and then light the fuse of the checker, go out and close the doors tightly. Upon return, thoroughly ventilate all areas.

Hydraulic accumulator maintenance

This is a device that is constantly under pressure and experiences dynamic loads. Therefore, you should always monitor it, in much the same way as you monitor the condition of a car’s tires - before each trip.

Visual inspections for leaks alternate with pressure measurements in the chamber. To do this, at the end opposite the inlet pipe, remove the cover under which the spool is located. Air or nitrogen is pumped through it. Pressure is measured with a car pressure gauge.

A clear sign of a device malfunction is a constant decrease in the amount of pumped atmospheres. Most likely, the integrity of the rubber diaphragm is broken, and air is escaping into the system.

How to replace the battery membrane:

Prepare your lawn for winter

The first step is to clear the lawn of debris. A layer of fallen leaves or branches will inhibit photosynthesis and can also provide an excellent home for pathogens and pests. The lawn also needs to be mulched to preserve the sown grass and reduce moisture evaporation. Do not forget about cutting the grass - this procedure in the middle zone can be carried out until the end of October. Moreover, the mowing height should be 1-2 cm higher than usual (i.e., if during the season you cut the lawn to 4 cm, now the grass height should be 5-6 cm).

In the first half of October, do not forget to feed the lawn with phosphorus-potassium or special autumn lawn fertilizer (according to the instructions). If holes and bald spots have formed on the cover, they need to be “patched” by adding soil and sowing seeds.

Purpose, device, principle of operation

First, let's clarify the terms - the hydraulic tank and expansion tank are not the same devices. A hydraulic accumulator is used in water supply systems of a private home, designed to supply water using a pump from an external source, while an expansion tank is installed in heating and hot water supply systems in order to stabilize their pressure and prevent the occurrence of water hammer.

Let's consider the main functions of a hydraulic tank in water supply systems:

the device prevents wear and tear on the pump due to frequent activation - since the tank constantly contains water, the pump will only start when it is empty, which will have a positive effect on the durability of the unit; the hydraulic accumulator reduces the likelihood of water hammer occurring in the pipeline when the pump is turned on; it also maintains stable pressure in the system, preventing pressure fluctuations when several taps are used simultaneously; The tank provides a constant supply of water, which is especially important in country houses with problematic power supply.

Pumping station with hydraulic accumulator

The hydraulic tank device consists of a metal tank itself and a membrane located inside it, which divides the tank into two chambers - one for water, the second for air. The water chamber is made of butyl, a sanitary-safe type of rubber; the liquid stored in it does not come into contact with the metal walls of the tank. Water is supplied and drained through two threaded pipes to which pipelines are connected; the pipes have identical diameters.

A pneumatic valve is responsible for regulating the pressure in the air chamber. Large volume hydraulic accumulators (100 liters and above) are equipped with a check valve, which is needed to bleed air from the water chamber. A similar function in small tanks is performed by a shut-off valve. The standard air pressure in the hydraulic accumulator is 1.5-2 Bar.

The operating principle of the hydraulic tank is quite simple. Initially, the pump pumps water into the tank, and when the storage tank is filled, the pressure switch detects this and turns off the pump, stopping the supply. Then, as the water reserve is used, the relay detects a decrease in pressure, turns on the pump and the cycle repeats.

Types of hydraulic tanks and features of their calculation

Depending on the shape of the body, this equipment is divided into two types - horizontal and vertical hydraulic accumulator. There is only one design difference between them - vertical tanks with a volume of more than 50 liters are equipped with a valve to bleed air, which accumulates in the water chamber and reduces the efficiency of the device. In horizontal tanks with a volume of 50-100 liters, the tap is located in the end part on the side of the body.

In all hydraulic accumulators with a volume of less than 50 liters, air is bled from the water chamber by completely draining the water. The shape of the tank is selected based on the size of the room where it will be installed. There are no tricks here - you need to take the tank that best fits into the space allocated for it.

More difficult is choosing a tank based on performance parameters. Here you need an equipment calculation that will help determine its required volume. The calculation is performed using the formula: O = K*Rmax*(Dmax + 1)*(Dmin+1)/(Dmax-Dmin) - (P + 1), in which:

- K is the power coefficient of the pump connected to the hydraulic tank;

- Rmax - the highest planned flow rate of liters of water per minute;

- Dmax — water pressure level in the tank to turn off the pump (Bar);

- Dmin — water pressure limit for turning on the pump (Bar);

- P - air pressure in the hydraulic tank (Bar).

The pump coefficient depends on the power of its engine:

- power 0.55-1.5 kW - coefficient 0.2;

- 2-3 kW - 0.375;

- 4-5.5 kW - 0.625;

- 5-9 kW - 0.875.

Calculation of almost any hydraulic accumulators for domestic water supply stations will show that it is necessary to use a tank with a volume of 25-50 liters. This is the optimal volume for most pumps for wells and wells, which will be enough for a complete water supply for a private home.

A little about relay adjustment

Setting the accumulator pressure switch

Do not forget about the seriousness of adjusting the relay - this is a delicate procedure that must be treated with extreme caution. One minor error in adjustment can lead to damage to the entire system, which means wasted time and money on repairs.

In addition, the warranty does not provide for breakdown of the unit in such cases.

How to adjust the pressure switch

Initially, it is necessary to achieve the optimal pressure in the accumulator. This can be done by disconnecting the pumping station from the power supply and draining all accumulated liquid in the tank. Now, using a special compressor with a sensor, create the optimal pressure level in it. Then remove the cover over the relay, giving full access to the small and large adjustment spring.

Setting the minimum pressure is achieved by turning a large spring: to increase the indicator - clockwise, to decrease it - counterclockwise.

As you can see, you can handle most of the problems yourself, without the help of specialists. This will help you save money and, most importantly, give you a new experience in working with pumping stations.

The tank of the pumping station plays a very important role - it accumulates water. Those. When you open a tap, water will flow out of it without turning on the pump itself until the pressure in the system drops to a threshold value. But during operation, the pump’s hydraulic accumulator is subject to various influences, as a result of which defects may appear that disrupt its normal functioning. For example, in our case, the flange rusted, and one fine evening a thin stream of water splashed out of it. The flange itself could not be found in stores, and therefore replacing the pump accumulator, which was found in almost every specialized store, became inevitable.

So, let's get down to the work itself. In our case, we have a 24-liter Gilex hydraulic accumulator. The products of this company are relatively inexpensive. This largely determines their wide distribution.

The first step is to de-energize the pumping equipment. This should be done for two reasons - firstly, so that the pump does not turn on during work, and, secondly, to avoid contact between water and electricity.

Next, you should drain all the water from the system. You can, for example, flush the toilet or open a water tap. And we wait for a dull click from the relay, which will signal that the pressure in the system has dropped.

The next step is to place a basin or other container under the connecting hose of the accumulator and pump. Although the pressure in the system dropped, the water remained in it. And in considerable quantities. And then you can twist the hose itself. An adjustable wrench is suitable for these purposes. To quickly drain the water from the system, you can unscrew the filler plug.

As soon as the water has drained from the tank and hose, we begin to remove the automatic pumping station. To do this, it is enough to unscrew just two bolts with a 13mm wrench, which secure it to the hydraulic accumulator. The photo shows a bolt with a hex hole. I couldn't find such a nozzle. Therefore, I used pliers to hold the bolt shown in the photo, and unscrew the nut from below with a 13mm wrench. That’s it! Tank dismantling is complete.

Then you can repair the “24 G hydraulic accumulator” or replace it with a new one. Reassembling the pumping station is performed in reverse order. Those. First, we attach the automation to the tank with two bolts and screw on the water hose. Upon completion of work, you should check the pressure in the accumulator with a pressure gauge through the spool on the housing. Its value should vary between 1.5 and 2 atm. If it is lower, then you should pump up the air with a conventional machine pump or compressor.

How should you drain water from a gas boiler?

Select a boiler

During long-term operation of an autonomous space heating system, the user sometimes has to drain water from the radiators and from the gas boiler. To avoid damaging your expensive gas appliance, flooding the room, and harming yourself, follow the instructions below.

Rules for draining water from a gas boiler:

- Turn off the water heating following the equipment manufacturer's instructions.

- We turn off additional equipment that ensures the circulation of working fluid through the heating system.

- We turn off the taps that disconnect the radiators from the boiler.

- If you are using a double-circuit boiler, then turn off the taps that turn off the hot water supply system and the cold water source from the heating equipment.

- We turn off the gas.

- We check that the boiler is not functioning and the water in it is not heating up.

- We are waiting for the temperature of the water in the boiler to drop to about 30 degrees.

- We check the reliability of the connection between the drainage system and the sewer system.

- Open the tap to drain water from the gas boiler.

- Open the tap located at the water inlet to the boiler.

Draining water from the hot water supply system:

- Check the position of the tap on the pipe supplying cold water to the boiler.

- Open the drain valve.

- Open the tap located in front of the check valve.

The information is not a public offer. The prices indicated are recommended; the company reserves the right to change prices. www.thermona-rus.ru

Video of the subtleties of filling a closed system

By observing caution and starting rules, you can independently cope with adding water to the old system. At the first start, checking and filling should be done by the technicians who installed the heating

If you do not have the skills, do not try to fix the leak or replace the coolant in the circuit yourself. Entrust the work to a specialist - the master will select the optimal media, a cleaning agent that will not damage the internal surfaces, and will correctly fill the system.

One of our readers is interested in how legal it is for the management company to pay for draining the heating system riser during the work of replacing heating radiators in an apartment? Let us recall that we have previously considered the question of . Today we will look at this topic in more detail.

Indeed, before you start replacing heating appliances in your apartment, you need to turn off the central heating riser and drain the water from the heating system. There are no other options, because even in summer there is residual water in the batteries.

You can entrust the process of draining the coolant only to representatives of the management company servicing your home, or hire another specialized organization, while coordinating the shutdown with the management company.

In this case, you will have to pay for the service provided in both cases. The cost of turning off the riser for each area and even for each house may vary - the final price is determined by the management company of the house. The fact is that prices and tariffs for services and work performed by housing services at the request of residents are not regulated by the state in any way. Therefore, each office has its own tariffs.

The cost of the work is indicated in the price list for paid services, which you can view by contacting the management company of your home. In addition to the service of disconnecting the riser itself, a fee is also charged for draining the coolant (water) in the radiators, as well as for filling the heating system after all the work has been carried out.

In addition, if the riser is turned off during the heating season, then the payment will be added hourly. In winter, the riser can be turned off for a maximum of three hours (to avoid freezing), but usually only an hour is enough for repair work. If the temperature outside the window drops to minus 30 degrees, then turning off the risers is prohibited!

We invite you to familiarize yourself with Salaka in tomato sauce, almost Swedish style.

Determining a location for a water supply station

When choosing a location for a pumping station, you need to focus on the characteristics of the hydraulic pump. Every ten meters of a horizontal pipe between the water source and the pump reduces its suction capacity by 1 m. If they are expected to be separated at a distance of more than ten meters, then the pump unit model must be selected with an increased suction depth.

An automatic station for an autonomous water supply system can be located:

- on the street in a caisson near a well;

- in an insulated pavilion built specifically for pumping equipment;

- in the basement of the house.

The stationary external option involves installing a caisson and laying a pressure pipe from it to the cottage below the ground freezing level. When installing a pipeline that operates year-round, its laying below the depth of seasonal freezing is mandatory. When installing temporary summer pipelines for the period of residence at the dacha, the pipeline is not buried below 40 - 60 cm or is laid on the surface.

If you install the station in a basement or basement, you will not have to worry about the pump freezing in winter. You just need to lay the suction pipe below the freezing line of the soil so that it does not freeze in extreme cold. Often a well is drilled right in the house, which then significantly reduces the length of the pipeline. But such drilling is not possible in every cottage.

Installation of water supply pumping stations in a separate building is possible only if the equipment is operated during periods of positive temperatures. However, for areas with very low winter temperatures, this option, designed to operate all year round, must be insulated or a heating system installed. It is better to immediately install the pumping station directly in the heated house.

When choosing a location for a water supply station, it is necessary to take into account the temperature limits specified in its passport by the manufacturer:

Recommended insulation for a well made of concrete rings

| Type of insulation | Features of the material | Installation technology |

| Styrofoam | Inexpensive, has good thermal conductivity, does not deform, and does not absorb water. Not resistant to rodents and insects. Sold in the form of ready-made elements corresponding to the sizes of reinforced concrete rings. | The walls of the well are cleaned of debris, façade glue is applied tightly, without gaps. Styrofoam is attached. If the foam does not adhere well, you can secure it with concrete dowel nails. Any barrier insulation material is laid on the foam. The trench is filled with earth and compacted. |

| Extruded polystyrene foam | Resistant to low temperatures, aggressive environments, and withstands loads well. Approximately 20% more expensive than polystyrene foam, produced in the form of slabs. | Installation is no different from installing foam plastic. The joints are sealed with polyurethane foam. The insulation is wrapped with rolled waterproofing material. |

We invite you to see how a member of our portal with the nickname pdp000 insulated his well

The insulation of the blind area is made of EPS, the walls of the ring are insulated with expanded clay. An insulated lid-liner is also made.

You can insulate a well with a little blood. Here are a few methods tested on FORUMHOUSE.

- Our user with the nickname Accurate covers the concrete ring of the ring with plastic film. Since then, the water supply pipe has not frozen even once - it was heated by well water, and the water did not freeze because the film did not allow the cold to pass through.

- Our participant with the nickname Hodok has been insulating a well from the inside for 40 years. Attach two frames made of thick wire in the form of inverted letters P to the last ring at a distance of 25 cm from each other. They descend to ground level. On them, Walker places two semicircles cut out of iron - this creates a flooring on which a plastic film is placed. He covers all the cracks with the same film, puts old clothes inside and leaves the well until spring. But this needs to be done when stable frosts arrive, so that the improvised insulation does not get wet from the fumes from the well.

Chemical flushing of the system when needed and how to do it

The frequency of chemical flushing depends on the quality of the water used. Many people do not flush the system at all; in the case of a special coolant, this is normal practice. But the use of water is associated with the formation of scale and other deposits, which reduce the efficiency of heat transfer and significantly increase fuel consumption.

Flushing the system is carried out using a special pumping unit, which can be rented for a while. The system is washed with a special solution of cleaning chemicals, which is selected according to the type of pipes, radiators and heat exchanger material in the boiler. In special cases, the boiler is washed separately.

When flushing, it is important to close the taps of all auxiliary equipment: expansion tank, pumps, bleed valves, etc. At one point, the pipeline ring must be closed, and on both sides of the valve there are connections for connecting flushing hoses

At one point, the pipeline ring must be closed, and on both sides of the valve there are pipes for connecting flushing hoses.

Flushing is carried out in two stages: first, the system is pumped with a chemical solution for 40-60 minutes, then the chemical is washed out with clean water several times.

Preparation of siphons for washbasins, sinks, sinks.

If you have a plastic sewer system and, accordingly, plastic siphons, then theoretically you can not prepare them for winter. The water plug in plastic siphons is small in volume, plastic has higher thermal insulation properties than metal or ceramics, in addition, plastic can be slightly deformed, so usually the water that does not have time to evaporate from the siphon before frost freezes a little slower than in ceramic the toilet bowl or cast iron elbow and turning into ice, the siphons do not break. If you have cast iron siphons, then it is necessary to remove water from them for the winter. This can be done in several ways, for example, using a kvak (plunger) to push water from the siphon further along the pipe. If you don’t have a plunger, you can try blowing it out with a bicycle or car pump, or carefully insert a cloth between the drain grate and gradually soak up all the water. After removing the water, plug the drain hole with a stopper or a rag (it is advisable to press the rag on top with something heavy) so that odors from the sewer network do not enter the house.

I have been using these technologies for 15 years now and so far everything is reliable. And yes, do not forget to drain the water from the tank. One of my friends did everything correctly, but did not drain the water from the tank. When the frost came, the seal of the gasket in the tank was broken, the water flowed into the bowl and froze there. As a result, the toilet had to be replaced.

I hope, dear reader, the information presented in this article has helped you at least a little understand the problem you have. I also hope that you will help me get out of the difficult situation I recently found myself in. Even 10 rubles of help will be of great help to me now. I don’t want to burden you with the details of my problems, especially since they are enough for a whole novel (at least it seems so to me, and I even started writing it under the working title “Tee”, there is a link on the main page), but if I’m not mistaken in your conclusions, then there will be a novel and you may well become one of its sponsors, and possibly heroes.

Once the transfer is successfully completed, a thank you page with an email address will open. If you would like to ask a question, please use this address. Thank you

For terminals, Yandex Wallet number 410012390761783

For Ukraine - hryvnia card number (Privatbank) 5168 7422 0121 5641

Verification methods

The air that was pumped into the tank by the manufacturer gradually leaves through the rubber membrane. The rarefaction of the cavity with gas leads to a strong stretching of the “pear” while it is filled with water. Without proper resistance, the membrane quickly loses its properties and may burst or tear. Pressure measurements are taken with a special device - a pressure gauge. It is better to use the car version as it will show the most accurate results.

Typically, the manufacturer indicates in the documentation the number of pressure checks in the accumulator per year. On average, measurements should be taken at least 2 times every 12 months. Before starting, you must completely empty the water tank and disconnect the pump from the power supply. When the system is connected to electricity, you should carefully monitor the situation. The operating pressure must be indicated in the battery passport.

To check the tank, you need to unscrew the decorative cap that covers the nipple. You need to connect a car pressure gauge to the spool. The measuring device must have a minimum error. Cheap plastic pressure gauges will not work, as they will show completely different data. After measurement, the result should be compared with the passport one; if it turns out to be less, then the tank should be pumped up using a compressor. Leave the accumulator for a day. Next, a check size is made; if the pressure is normal, then you can put the system back together. If the pressure is exceeded, then the air is released a little.

If the battery is used in summer conditions, it must be checked before the start of the season. In case of any deviations from the norm, unscheduled measurements must be made.

The main reasons for draining water from a heated floor system

There can be quite a few reasons why you need to drain the water from the heating system pipeline yourself - from the upcoming long absence of residents from the house to replacing the water in the system with antifreeze. In order to do everything correctly and not cause damage to the heating system, we will look in more detail at how to drain the water from a heated floor yourself.

A common reason for the need to drain the coolant is the preservation of the heating system for the winter when using ordinary water in the circuit. Before the onset of cold weather, this event is mainly carried out at dachas and country houses that are not used in winter. To simplify and speed up the draining process, special equipment is used.

Another equally important measure when operating underfloor heating is preventive maintenance on the heating system. Boiler water contains a lot of impurities, which, when heated, precipitate or form layers on the walls of the pipeline. Due to a decrease in the internal clearance of heat pipes, the circulation of the coolant in the system is disrupted and heat transfer decreases

For this reason, when using water, the coolant must be drained once or twice a year.

Due to a decrease in the internal clearance of heat pipes, the circulation of the coolant in the system is disrupted and heat transfer is reduced. For this reason, when using water, the coolant must be drained once or twice a year.

A water circuit filled with antifreeze does not suffer from this problem. In this case, the coolant is replaced every 3-5 years - provided that the boiler is operated without overheating (for heated floors, the maximum permissible heating temperature threshold for the coolant is 45-55 0 C).

Another reason for the need to drain the coolant may be the liquid losing its physical properties. A change in the characteristics of antifreeze occurs after overheating - the solution begins to foam, filling individual sections of the heat pipes with foam, which disrupts the circulation of the coolant in the system and reduces heat transfer.

Failure to comply with the technology for installing heated floors, or the use of materials not intended for contact with chemicals, causes the occurrence of corrosive processes in the heating system, as a result of which the circulation of the coolant is also disrupted and leaks in the water circuit occur.

Naturally, you will have to drain the water from the heated floor pipeline when replacing it with antifreeze - modernization.

These are the main reasons for the need to empty the underfloor heating system and, regardless of the base, the water must be drained in accordance with all the rules, following safety precautions and observing the technological sequence of the component operations.

Composition and order of preventive work

To maintain the functionality of water heating, there is a whole range of measures. Certain types of work are carried out at different intervals.

Performed annually:

- Preventive inspection of gas boilers.

- Checking the functionality of the automation.

- Boiler room alarm test.

- Chimney inspection/cleaning.

- Heating pipeline inspection.

Once every 3-5 years the following may also be carried out:

- High pressure system testing.

- Chemical flushing of the system.

- Replacing the coolant.

- Calibration of automation devices.

It is clear that the frequency of some work is a purely individual concept. For example, when using well and borehole water for heating, it is recommended to carry out annual flushing without chemicals, and if you have a plunger pump, test the system annually with high pressure. More specific recommendations are provided by equipment manufacturers and the organization that installed the system.

How to properly preserve a well?

If you do not plan to come to your dacha during the cold season, then you need to mothball the well. This needs to be done in September-October (depending on the climatic characteristics of the region), before the first frost sets in. The sequence of work should be as follows:

- Draining the pumping station for the winter.

- Lifting a submersible pump from a well.

- Drying the pump.

- Draining water from the hydraulic tank.

- Placing the station for storage.

Please note: every design of a water intake system must provide a point for draining water from the pipeline. Without this, safe and durable operation of a water well is impossible.

In order for the pumping station to work properly, you need to drain the water from the entire system for the winter - this is called conservation. To do this, the following work is carried out:

- Removing water from the pipeline line (you need to drain it from all plumbing fixtures that are in the dacha);

- Water is removed from the pipes by opening the taps (must be provided for in the design of the autonomous system);

- Pumping water from the toilet siphon and sink.

To prepare the pump for the winter period, you need to make sure that after pumping out the liquid, the inside of the station is completely dry. After this, find a warm place for the equipment where the equipment will be stored safely for several months.

What pressure should be in the accumulator

There are several methods for accurately selecting the capacity of a hydraulic accumulator tank, but the main principle is the selection principle based on the capacity of the storage tank. The initial data are the number and nature of water consumption points, the power and type of pump, the maximum permissible number of its starts, the desired water pressure in the network

It is also important how much water from the tank can be used before the next time the pump is turned on, as well as during power outages. The permissible difference in water pressure is set during the process of setting up the pressure switch. The water reserve in the accumulator (which usually amounts to up to half of its total capacity) can be determined with sufficient accuracy from the theoretical capacity of the tank and the pressure drop in it:

The water reserve in the accumulator (which usually amounts to up to half of its total capacity) can be determined with sufficient accuracy from the theoretical capacity of the tank and the pressure drop in it:

- For a tank up to 50 l, with a pressure difference of up to 1 atm - 15.0...12.5;

- For a tank up to 100 l, with a pressure difference of up to 1 atm - 30.0...16.5;

- For a tank of more than 100 liters, with a pressure difference of up to 1 atm - 70.0...55.0;

- For a tank up to 50 l, with a pressure difference of up to 1.5 at – 13.5...8.0;

- For a tank up to 100 l, with a pressure difference of up to 1.5 at - 25.0...20.0;

- For a tank of more than 100 liters, with a pressure difference of up to 1.5 atm - 55.0...40.0.

The volume of the hydraulic accumulator tank is determined with sufficient accuracy using the following practical relationships:

- For surface pumps with a power of up to 1 kW - at least 25 l;

- For surface pumps with a power of more than 1 kW - at least 50 l;

- For submersible pumps with a power of up to 1 kW - at least 20 l;

- For submersible pumps with a power of up to 1.5 kW - at least 50 l;

- For submersible pumps with a power of up to 5 kW - at least 100 liters.

The capacity of the hydraulic accumulator tank also depends on the number of water points and the number of people living in the house. For example, for a small family with modest needs (one tap in the kitchen and shower room, + bathroom), 50 liters will be enough, and if there is a bathroom, a capacity of at least 100 liters will be required.

The capacity of the device in question also depends on the location of its installation. A vertical hydraulic accumulator, which is mounted at the highest point of water intake (for example, at a height of 4.5...5 m), adds about a third to the design pressure value, which will allow the pump to turn on less often. However, it should be taken into account that the room for installing the hydraulic accumulator must have a minimum temperature difference, i.e., either be well insulated or be constantly heated during the cold season. Fluctuations in relative humidity should also be minimal.

The habit of selecting everything with a margin for the volume of the hydraulic accumulator is not suitable. The fact is that if the volume of water in the tank stagnates for a long time, then, firstly, the inner surface of the tank suffers, and, secondly, the quality of the water itself deteriorates (especially if the installation of the water supply scheme did not include the installation of biological filters) . In this case, you will have to frequently drain the water from the container, and a large hydraulic accumulator will be of little use.

Most manufacturers claim the ability of the housing and connecting fittings to withstand constant operating pressures of at least 10 at. When choosing, the nominal temperature rise of the water that the membrane material allows is also taken into account. For high-quality materials it cannot be less than 70...100°C.

The manufacturer of such products in our country is the Jeelex brand. Hydraulic accumulators from Aquasystem (Italy) and Reflex (Germany) are also popular.

Specifications

Regardless of the depth of the well (8,10, 15 or 20 meters), all pumping stations are divided into domestic and industrial.

For a private home, household units are used. However, they may have different operational characteristics In order for your unit to meet the family’s water needs, as well as the parameters of the hydraulic structure, when choosing, you must pay attention to the following technical characteristics:

- equipment power, measured in W;

- device performance in cubic meters per hour (this characteristic is selected after determining the residents’ water needs);

- liquid suction height or the maximum level to which the pump can lift water (these characteristics depend on the depth of water intake, for example, for wells 15-20 meters deep, you need a unit with an indicator of at least 20-25 m, and for wells 8 meters deep, a device with a value of 10 m);

hydraulic accumulator volume in liters (there are units with a volume of 15, 20, 25, 50 and even 60 liters); pressure (in this characteristic it is necessary to take into account not only the depth of the water surface, but also the length of the horizontal pipeline); additional protective functions will not hurt (protection against “dry running” and overheating); It is also important to consider the type of pump used. For example, a submersible pump is mounted in a well, so it does not make noise during operation, but its repair and maintenance is more difficult to carry out

A surface-type unit is easier to maintain and repair, but makes more noise during operation.

To make it easier for you to choose a unit suitable for a country house, we provide approximate technical characteristics of such a device:

- the power of the device should be in the range of 0.7-1.6 kW;

- depending on the size of the family, a station with a capacity of 3-7 cubic meters per hour is sufficient;

- the lifting height depends on the depth of the well or well;

- the volume of the hydraulic tank for one person is 25 liters; with the increase in family members, the volume of the storage tank should increase proportionally;

- the choice of a device based on maximum pressure should be made taking into account the depth of the hydraulic structure, the length of the horizontal pipeline leading from the unit to the house, as well as the height of the house (if there are points of water consumption on the upper floors: bathrooms or bathrooms);

It would be good if the device has protection against dry operation. This is especially important for hydraulic structures with unstable water levels. Then the pump will not be able to pump out all the water and run idle; In addition, a surface-type pumping station will need protection against motor overheating. The thing is that in submersible units the motor is constantly in the water, so it is effectively cooled. But the motor of a surface station can easily overheat and fail. To prevent this from happening, you need overheating protection, which will operate in time and turn off the pump.

Theory first

Autonomous water supply system with hydraulic accumulator

If in a water tower water pressure is created due to gravity - and the higher the container is located, the greater it is, then in a hydraulic accumulator external pressure on the liquid is used for this. Therefore, for these devices, height is not important, and neither is space.

Classification of hydraulic accumulators

They are divided into two groups:

- Mechanical, in which pressure is created by the force of a compressed spring, elastic membrane or load.

- Pneumatic - in them gas is pressed onto the water, which is also under pressure. Flexible membranes made of rubber or similar materials are used to separate water and gas.

In small autonomous water supply systems, it is the latter type that is used, since it is simpler in design and cheaper to maintain. In the future we will talk about them.

Hydraulic accumulators are a compact replacement for water towers

Water supply with a hydraulic accumulator can easily be provided by a small village with up to 1-2 thousand residents. The author of these lines, working in the public utilities sector, converted more than 10 rural water pipelines in a similar way.

Moreover, the cost of purchasing and installing a hydraulic accumulator is an order of magnitude less than replacing a completely worn-out (mainly due to corrosion) Rozhnovsky tower with a new one.

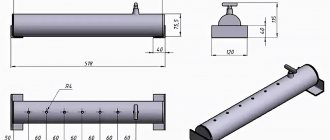

Hydraulic accumulator device

Sectional view of a hydraulic accumulator

As we have already said, we will talk about pneumatic hydraulic accumulators (another name is hydropneumatic accumulator). Their design is extremely simple; in fact, it consists of several parts.

- The body is usually metal. Air is pumped into it (in industrial batteries for special liquids this can be nitrogen, but for relatively small volumes of water it is just air).

- A membrane is fixed in the body; it is a rubber bag (bulb). It is connected by a pipe to a water supply system, and water is pumped into it under pressure from a pump from the water supply system. As you know, it, unlike air, is incompressible, so the latter is compressed. When water is removed, air expands and displaces it.

- In order to pump air, a pipe with a spool is installed into the volume between the body and the bulb. In most cases, it is completely similar to those used on car tires.

- Additionally, pressure gauges and relay sensors can be installed on the hydraulic accumulator.