Properties of water as fuel

The formula of water is known to almost everyone - H2O. It contains two hydrogen atoms (H2) and one oxygen (O2). They are connected to each other by a covalent bond. Here it is worth recalling the essence of any fuel. These are substances capable of oxidation under the influence of an oxidizing agent, which is oxygen.

The function of an oxide in water can be performed by an oxygen molecule (O2). Hydrogen (H2) becomes a kind of fuel. When it burns, it releases 3 times more energy than when using conventional natural gas, and 2 times more than when burning gasoline. It was these properties that formed the basis of the idea of using water instead of fuel.

Public transport on hydrogen

In European cities, hydrogen public transport is starting to appear on routes - although only in pilot mode.

For example, unmanned minibuses powered by hydrogen fuel have appeared in Estonia, and 10 trolleybuses travel around Riga that use hydrogen in case of a power outage or breakdown. This trolleybus runs without refueling all day, only stopping in the evening at the only gas station in Riga (private cars also refuel there).

There is also a hydrogen bus in Riga - for now it runs on one route in test mode: we need to estimate how much fuel it will need in winter, when it will need to heat the interior. In two years, 12 buses in Riga will be powered by hydrogen.

And “hydrogen” taxis appeared in Copenhagen. The taxi fleet, however, is still small - only 20 cars.

Utility vehicles have also begun to switch to hydrogen. For example, two hydrogen garbage trucks appeared in Freiburg (Germany).

Hydrogen fueled garbage trucks appeared in the German city of Freiburg

Is there an everlasting log?

In reality, this is not a log, but an ordinary metal tank (pipe), welded on both sides. On top along the entire length there are holes in it for steam to escape. The pipe itself also has a hole that can be closed using a valve after the entire volume is filled with water.

You can use cold, but hot will heat up faster. How the device works:

- The tank is placed at the very bottom of the stove. On the left, right and top they cover it with ordinary logs. The stove is lit.

- When heated to a high temperature, water vapor begins to escape from the pipe.

- It enters the burning coals, mixing with air. The specific heat capacity of such a mixture is 2 times greater than that of ordinary air. Water vapor has a heat capacity of 2.14 kJ/kg·K, and air - 1 kJ/kg·K.

The results of such an experiment, according to the statements of those who conducted it:

- Black soot comes out of the smoke. This is explained by the reaction of carbon particles with oxygen.

- The flame becomes more intense, with long tongues.

- Wood burns longer: 1 hour 40 minutes. compared to 1 hour 10 minutes. when burning without an eternal log. Time increases by 40%.

Hydrogen trains

From 2022, the world's first hydrogen train, the Coradia iLint, will be available in Germany. It reaches speeds of up to 140 kilometers per hour and can travel almost a thousand kilometers without refueling - about the same as diesel trains.

So far, two hydrogen trains are running in Germany. The developer of these trains, the French company Alstom, initially planned to build 14 more. But hydrogen trains turned out to be so popular that in 2022, German railway companies have already ordered 41 hydrogen trains.

Portugal also has a hydrogen train, only one, but what a one: the vintage Vouginha, which you can ride in Porto in the summer. This historic train runs on the last remaining narrow gauge railway in Portugal and its carriages have been preserved since 1908.

Back in time: 5 luxury tourist trains in Europe

Why is it still not drowned with water?

Intermolecular water bonds arise and break much more easily than intramolecular ones. Therefore, it was decided to use them in heat transfer processes. Chemists have experimentally found that the energy of intermolecular bonds of water ranges from 0.26 to 0.5 eV (electron volts).

The problem is that to obtain fuel from water, it must be broken down into its components. In simple words, it needs to be decomposed into oxygen and hydrogen, then burn the hydrogen and get water again. Cleavage is achieved by passing an electric current through the liquid.

When boiling, water does not break into individual molecules, but only evaporates. Heating from normal combustion does not cause any other reactions in the liquid. Moreover, this process also requires a lot of energy, which could be used usefully. Eg:

- burning 1 kg of dry wood with a moisture content of no more than 20% gives about 3.9 kW;

- if the wood moisture level rises to 50%, then only 2.2 kW is released from 1 kg.

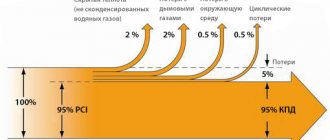

The decomposition of water to produce actual combustion requires significant energy expenditure. Much more of it is needed than will be released when the recovered elements are used again as fuel. An approximate ratio can be given:

- 100% of energy is for splitting;

- 75% of energy comes from burning recovered components.

It is the fact that the reverse reaction of released hydrogen and oxygen releases less energy that is the reason why water is still not used as a fuel for cars and other things. Economically, this method turned out to be unprofitable. It is more feasible to make fuel from garbage. It can be liquid, gaseous and solid.

Is there a "water" car?

In 2008, in Japan, a “water” car was presented by Genepax at an exhibition in Osaka. The fuel could be a glass of tap or river water, or even regular soda.

The device split the liquid into hydrogen and oxygen molecules, which began to burn and give the car energy to drive. Today it is known that the Genepax company went bankrupt and closed within a year.

Airplanes powered by hydrogen

This is still a matter of the future, but active development of hydrogen aircraft is already underway. For example, in France, the European company Airbus has created three prototypes of a commercial hydrogen-powered aircraft. The design of one of them allows the safe storage of hydrogen fuel, so such an aircraft will be able to lift up to 200 people into the air for a flight of 3.7 thousand kilometers - unlike the other two models, designed for 100 passengers over the same route range.

The designers of the same Airbus have developed a removable hydrogen engine for aircraft, which will allow them not to depend on ground infrastructure. Hydrogen fuel is not pumped into it, but is installed in portable capsules. Therefore, aircraft with such engines will be able to refuel at airports without devices for supplying hydrogen fuel.

Last year, the European Union announced a new initiative, RefuelEU: finding solutions for cleaner aviation. Now the European Union is faced with the task of converting up to 1-2% of European aircraft to “green” fuel, including hydrogen.

The EU proposed switching aircraft to renewable fuel

Adding water to regular fuel

Water can be used as fuel for your car as part of regular diesel fuel. This is another assumption that was put forward by “home” inventors. It turned out that when you add a small amount of diesel fuel to a bottle of water, the resulting mixture burns. Moreover, less soot is released, and the combustion process becomes more violent.

Also, during the burning process of a piece of paper dipped into the resulting mixture, a cracking sound appears, but this only indicates the evaporation of the liquid. In addition, shaking does not dissolve the diesel fuel in the water. There will be no homogeneous mixture here. Over time, diesel fuel, like oil or gasoline, collects on the surface.

A similar experiment was carried out with a tractor, into which diesel fuel and water, mixed in certain proportions, were poured. The unit started up and began to rattle, standing still. But that’s all the energy of such fuel is enough for. And there is a high risk that the engine will fail.

Will there be enough hydrogen for transport?

By 2030, the EU aims to produce 40 gigawatts of hydrogen energy annually, and by 2050 hydrogen will supply a quarter of all energy needs. This hydrogen is enough, for example, to provide environmentally friendly fuel to 42 million cars, 1.7 million trucks, about 500 thousand buses and more than 5.5 thousand trains. This is part of the “Hydrogen Strategy for a Climate Neutral Europe” where the EU has identified hydrogen as one of six key strategic areas where significant investment is needed.

Classification of boiler houses

According to their purpose, boiler rooms are divided into:

- heating - to provide heat to heating, ventilation and hot water supply systems;

- heating and industrial – to provide heat for heating, ventilation, hot water supply and process heat supply systems;

- industrial – for process heat supply;

- energy - generating superheated steam to generate electricity in turbine units (SNiP II-35–76 “Boiler Installations” does not apply to such boiler houses).

Based on their location, boiler rooms are divided into:

- free-standing;

- attached to buildings for other purposes;

- built into buildings for other purposes, regardless of the floor of placement;

- roof-mounted, located (placed) on the building’s roof directly or on a specially constructed base above the roof.

According to the reliability of heat supply to consumers, boiler houses include:

- to the first category - boiler houses, which are the only source of heat for the heating supply system and provide consumers of the first category who do not have individual backup heat sources;

- the second category includes the remaining boiler houses.

Heat consumers in terms of heat supply reliability include:

- the first category includes consumers whose heat supply disruption is associated with a danger to human life or significant damage to the national economy (damage to technological equipment, mass defects of products);

- the second category includes the remaining heat consumers.

Main technical characteristics of steam and hot water boilers

The design parameters characterizing the operation of the boiler are indicated in the boiler passport, drawn up by the manufacturer in the prescribed form (Appendix 4 to PB 10-574–03) and kept by the owner for the entire period of operation.

Each boiler must be affixed with a nameplate containing the nameplate data, printed in a manner that ensures clarity and durability of the image.

The following data must be written on the steam boiler plate:

- name, trademark of the manufacturer;

- boiler designation;

- boiler number according to the numbering system of the manufacturer;

- Year of manufacture;

- nominal steam output Dp in t/h;

- working pressure at the outlet in MPa (kgf/cm2);

- nominal steam outlet temperature in °C.

The following data must be written on the boiler plate:

- name, trademark of the manufacturer;

- boiler designation;

- boiler number according to the numbering system of the manufacturer;

- Year of manufacture;

- nominal heating capacity Q in MW (Gcal/h); working pressure at the outlet in MPa (kgf/cm2);

- nominal outlet water temperature in °C.

The designation of the steam boiler includes:

- type,

- steam capacity (t/h),

- absolute (excess) steam pressure pp, (MPa or kgf/cm2),

- type of fuel (G – gas, M – fuel oil);

- Pressurized boilers are designated by the letter N.

For example: DKVR-10/13; E-25-2.4 GM; DE-6.5/14-225 GM; E-1/9-G.

The designation of the hot water boiler includes:

- type – KV (hot water boiler);

- type of fuel (G – gas, M (F) – fuel oil, diesel fuel);

- type of firebox (H – pressurized);

- rated thermal power (MW or Gcal/h);

- nominal water temperature at the boiler outlet, °C;

- gas pressure (Gn – low; Gs – average);

- an automated boiler is designated by the letter “a”;

- C – steel.

For example: KV-GM-10-50; KSVa-2.5-Gs; KVA-3-95; KVA-0.75Zh-115.

On each boiler put into operation and after technical inspections have been carried out, a plate with a format of at least 300×200 mm indicating the following data must be attached in a visible place:

- registration number;

- permitted pressure;

- date, month and year of the next internal inspection and hydraulic test.

Main technical characteristics of steam boilers:

- rated steam output, Dp, t/h – the maximum working amount of steam produced by the boiler for 1 hour;

- parameters of the resulting steam:

- operating (calculated or permitted) steam pressure, rp, MPa (kgf/cm2);

- test pressure, rtest, MPa (kgf/cm2);

- type of steam (saturated, superheated);

- saturated steam temperature, tsat, °C (at operating steam pressure pp or superheated steam temperature, tpp, °C);

- feed water temperature, °C;

- steam and water volume of the boiler, m3;

- volume of water, m3;

- evaporation time of this volume, min.

Main technical characteristics of hot water boilers:

rated heating capacity (thermal power), Q, Gcal/hour (MW) – the maximum working amount of heat absorbed by water for 1 hour of operation; 1 Gcal/h = 1.163 MW;

water parameters:

- working water pressure, MPa (kgf/cm2);

- minimum permissible water pressure pv at nominal temperature tb;

- test pressure, rtest, MPa (kgf/cm2);

- minimum permissible water temperature at the boiler inlet, °C;

- nominal water temperature at the boiler outlet, °C;

- nominal water flow through the boiler, Gw, m3/h, as well as the minimum and maximum permissible;

- hydraulic resistance, no more than, MPa.

General parameters characterizing steam and hot water boilers:

- type of fuel and its characteristics;

- burner type;

- boiler heating surface: radiation, convective, total, S, m2;

- calculated efficiency, gross, % when burning gas and fuel oil;

- resistance of gas and air paths, Pa (mm water column);

- temperature of combustion products at the exit from the furnace, behind the boiler, temperature of flue gases - when burning gas and fuel oil;

- content of O2, CO, NOX in flue gases;

- design indicators: internal diameter of the drums, drum wall thickness, length of the cylindrical part of the upper and lower drums; diameters of downcomers, screen and convective pipes; pitch of screen pipes, their number; boiler dimensions.