This is due to the fact that in many houses there is not only one fireplace, but two fireplaces or two potbelly stoves, a fireplace and a cooking stove, fireplaces on different floors, a fireplace (ground floor) and a gas boiler (basement), a bathhouse in the basement and fireplace on the ground floor, and barbecue and outdoor oven in the gazebo. The owners of two fireplaces in the house do not want to build two chimneys, using excuses: it is uneconomical, a lot of brick will be wasted, one of the planned chimney ducts will be adjacent to a wooden beam or ceiling, or they believe that two brick chimneys weigh a lot.

Questions about the possibility of connecting two fireplaces to one chimney arise due to incomplete disclosure of this topic in SNiPs.

Russia. Excerpts from SNiP 41-01-2003 clause 6.6.9 and rules for pipe and furnace work clause 3.6.3. “For each furnace, as a rule, a separate chimney or duct (hereinafter referred to as the chimney) should be provided. It is allowed to connect two stoves to one chimney, located in the same apartment on the same floor. When connecting chimneys, cuts should be provided in them with a height of at least 1 meter from the bottom of the connection of the pipes.”

Excerpts from SP 7.13130.2009 clause 5.47. “In multi-storey residential and public buildings, the installation of solid fuel fireplaces is allowed, provided that each fireplace is connected to an individual or collective chimney. The connection to the collective chimney must be made through an air seal, as a rule, with connection to the vertical manifold of air duct branches through the floor (at the level of each overlying floor).”

Ukraine. Excerpts from DBN V.2.5-20-2001. G.3. The removal of combustion products from household gas appliances, stoves and other household gas equipment, the design of which provides for the discharge of combustion products into the chimney, should be provided from each appliance, unit or stove through a separate chimney. G.6. Non-household gas appliances (restaurant stoves, cooking boilers, etc.) can be connected to both a separate and a common chimney. It is allowed to provide connecting smoke exhaust pipes common to several units. The introduction of combustion products into a common chimney for several appliances should be provided at different levels or at the same level with the cutting device in accordance with G.3. The cross-sectional area of chimneys and connecting pipes must be determined by calculation, based on the condition of simultaneous operation of all devices connected to the chimney.

The regulatory documents make distinctions for connecting gas devices and solid fuel fireplaces (wood-burning fireplaces and stoves) to one chimney. Building codes state: each stove has a separate chimney, with the clarification “as a rule”. But the Slavs have an interesting mentality - laws are not decree, and everyone loves to experiment without thinking about the consequences. In practice, we encountered fireplaces on two floors connected to one chimney. The upper fireplace had poor draft and smoke was reaching the second floor from the operation of the lower fireplace. The owners built it themselves, then converted the upper open fireplace to a fireplace with a closed firebox. The problems remain.

Theoretically it can be connected. But practice shows that such systems only work under many additional conditions: optimal design and height of the chimney, increased cross-section of the smoke channel, installation of several dampers (complete overlap of the smoke channel), observance of the order of kindling of fireplaces (hearths), regulation of draft in two fireplaces (the most difficult moment). Let's assume several options for operating two fireplaces on different floors with one chimney.

Option 1: only the fireplace on the first floor is heated. It is necessary to prevent smoke from entering the room with a fireplace on the second floor. A fireplace damper on the second floor will not help.

Option 2: only the fireplace on the second floor is in use. It is necessary to prevent flue gases from entering the first floor and to prevent air leakage from below. Should I block the chimney between the first and second floors? But this is problematic for both a modular chimney made of stainless steel and a modular one made of ceramics. The fireplace damper is not suitable - it provides for incomplete blocking of the smoke channel.

Option 3: Both fireplaces are not working. If you do not block the chimney, we will get air exchange between rooms on different floors through the smoke duct, and this is prohibited.

Option 4: both fireplaces are lit. The bottom one melts first. Theoretically, the lower one will burn better - stronger draft. Problems with the fireplace on the second floor - poor draft and smoke, poor regulation of the combustion mode.

Tight dampers solve the problem of smoke entering one of the rooms, eliminating the simultaneous operation of two fireplaces. Smoke on the second floor and poor draft of the second fireplace are the consequences, and the main question is air exchange in the house: how to regulate the draft and combustion modes of wood? How is the supply ventilation arranged in both rooms? What are the air exchange conditions in the house? (the premises are connected via a flight of stairs or complete isolation). There are more questions than solutions. Our opinion: each fireplace has a separate chimney.

For gas chimneys: it is allowed to connect several gas devices to a common chimney. The situation with apartment heating (gas) and the removal of combustion products into a common chimney is different. Closed gas boilers are equipped with an automatic system for regulating combustion and operation when gas pressure drops. Modern wood-burning fireplaces and inserts lack such functions. All furnace work is done either by specialized companies or by licensed professionals. There are no universal recommendations or solutions - they are considered individually.

If two fireplaces on the same floor are connected to one smoke duct, the distance between the connection pipes must be at least a meter, and the cross-section of the chimney must be increased. Both heating devices must operate on the same type of fuel. Simultaneous operation does not cause problems. First, a more powerful hearth is melted.

The removal of flue gases into a common chimney has its own characteristics:

- If fireplaces on two floors have already been built, then it is better to fire them separately (excluding the “suction” of air from the second hearth, completely blocking the smoke exhaust channel).

- It is prohibited to connect a gas boiler and a wood-burning fireplace to the same chimney. Chimneys for a wood-burning fireplace and a gas boiler must be separate, and several separate channels (fireplace chimney, pipe from a gas boiler, ventilation ducts) can be located in a common shaft, and they must be separated along the entire height by sealed partitions.

- The chimney must not be connected to a ventilation duct.

- A tunnel or pass-through fireplace insert, built between rooms, is one fireplace connected to one chimney, with two portals or facings.

Chimney design and connection options, air exchange in rooms, supply ventilation, draft control and combustion maintenance are the main issues when simultaneously firing several fireplaces with a common chimney. There are many questions, but the best solution is for two fireplaces on different floors of the house: one fireplace - one chimney, two fireplaces - two separate chimneys.

Is it possible to connect two stoves into one chimney?

Theoretically, combining furnaces should not cause difficulties, but in practice this requires compliance with certain conditions:

Correctly selected chimney height:

- increased pipe cross-section,

- correct traction adjustment,

- creating multiple dampers,

- alternate lighting of the stoves.

Installing one chimney involves several options. One of them is the construction of stoves on one floor, and the second - on different ones. In the first case, it is necessary to prevent smoke from entering another room. This can be done by installing reliable dampers.

But the dampers will only prevent the entry of smoke during alternate operation of the stoves, so it is important to correctly adjust the air exchange in the pipe.

Features of smoke removal

It is worth remembering that you cannot connect a gas boiler and a wood-burning fireplace to the same pipe. If the stoves are located on different floors, then the chimney must be built in such a way that the combustion products exit from the upper floor first through a dedicated passage running next to the main one. In this case, the height of the partition must be at least one and a half meters. This will allow you to fire two stoves at the same time.

It is worth remembering that the stove that is large is lit first, which will help normalize the draft. The cross-section of the chimney at the place where the two outlet channels connect should be almost twice as large. To exclude the possibility of smoke from getting from one furnace to another, you should make not one, but several tight dampers to ensure reliable shutoff of the pipe.

According to the rules for constructing stoves, if they are located on different floors, then connecting them into one chimney is not recommended. This is done when they are located on the same level. When installing two stoves in one pipe, it should be with the expectation that its length should be equal to 5 meters, if you count from the grate. This is necessary for normal smoke output.

Since the draft in the lower stove will be better, it is worth making it larger and starting heating the house with it. Only after the fire breaks out in it is the second one activated.

Materials and tools used for constructing a two-story stove

To build the structure, you will need the same materials as for the construction of conventional heating or cooking stoves, with the only difference being that a two-story stove has a larger mass and height.

The structure will consist of the following main parts:

- Monolithic foundation;

- Masonry of the bottom, blower and combustion chamber;

- Masonry of chimney ducts;

- Exterior finishing;

- Views, dampers, oven and firebox doors, hob (if necessary);

- chimney;

- Deflector or canopy on the roof.

To build this structure you will need:

- Fireclay fire-resistant brick;

- Ceramic ordinary solid brick made of red clay;

- Fireclay clay or mixture for laying refractory bricks;

- Cleaned quarry sand;

- Cement-sand mixture;

- Cement grade 500;

- Furnace fittings - dampers, inspection doors, grates, combustion doors and ducts;

- Metal fittings – steel angle 50x50 or 60x60 mm;

- Sections of steel reinforcement with a diameter of 8 mm;

- Knitting wire;

- Asbestos sheet.

The tools that will be used are:

- Master OK;

- concrete mixer or solution container;

- buckets for transferring materials and supplying solution;

- power tools for preparing the solution;

- level;

- plumb line

The calculation of the required material is carried out based on the sequential masonry plan. When calculating, a reserve of 5% is made for the amount of fireclay bricks, 10% for red brick, and the same amount must be reserved for facing materials. The reserve for clay and cement mixture is made at least 15%. True, this applies to the case when the masonry is done independently.

What problems might arise?

When building two stoves and combining their chimney, country house owners face the following difficulties:

- smoke on the top floor

- weak traction,

- inability to light the upper stove due to the small height of the pipe.

The first problem can be solved by creating two separate chimneys in the pipe. Thanks to this, smoke will be eliminated, and normal draft will be maintained when the upper stove is operating. You can also connect the upper chimney to the main pipe at an angle.

Smoke may also be due to uneven pipes. If during masonry the builder allowed the appearance of protrusions or, conversely, an increase in the cross-section of the passage, this may affect the movement of combustion products. When it enters an uneven section of the pipe, smoke begins to change its trajectory and form “vortices.” As a result, it can get into the second connected passage and further into the room.

When building two furnaces, you should think carefully about whether it is necessary to connect them into one pipe. If this is possible, then the idea should be abandoned. But if you follow the rules for laying a chimney, no problems should arise.

An exception

Building a two-sided fireplace with your own hands is almost the same as building a regular fireplace, the only difference is the need to equip it with two doors equipped with heat-resistant glass. In addition, you can buy a ready-made double-sided fireplace in a specialized store, and then you will only have to make the foundation for it and lay out the chimney with your own hands.

Both rooms into which the double-sided fireplace doors open should not be accessible. In addition, the firebox should not be located next to the door or windows in the room

This is important not only from the point of view of comfort; frankly, it is difficult to sit comfortably near the door, but it is also important from the point of view of the fire safety of the fireplace. If you have chosen a wall-mounted type of fireplace, then you must remember that it should be placed exclusively near a brick wall

- When building a fireplace, it is necessary to very carefully protect the floor underneath it from exposure to high temperatures. For this you can use fireproof brick or metal sheet. The size of such a platform should be several centimeters larger than the size of the fireplace base.

- When building a fireplace, certain proportions must be observed. For example, the depth of the fireplace should correlate with the area of the room where it is located, approximately 1 to 50. Accordingly, if we are talking about a double-sided fireplace, then both rooms into which the combustion chamber opens are taken into account. And the height of the fireplace should not exceed its depth by more than 2 times.

The fact is that the entire structure must dry very well. And such a long drying time is due to the fact that when building a fireplace, they use bricks that were previously soaked in water. Yes, and the solution needs to dry. If you light a fireplace without waiting for it to dry completely, the entire masonry may become covered with cracks, and such a structure will not last long.

We suggest you familiarize yourself with How to make a pipe in a bathhouse

Unfortunately, for some people the law is not written. If, nevertheless, the option of two fireplaces or a fireplace plus a stove in one smoke channel is being considered, then some nuances should be taken into account in order for such a system to work correctly:

- suitable shape and height of the chimney;

- a channel with a larger cross-section than for one device;

- the presence of several dampers to completely block the smoke channel;

- alternate kindling of devices;

- the distance between the chimney entrances to the channel must be at least 1 meter;

- correct regulation of draft in each fireplace and proper ventilation;

- The fuel in both devices must be the same.

Only by following all these rules can you achieve uninterrupted operation of the chimney when several heating devices are connected to it at once.

Building two stoves or fireplaces and then venting them into one smoke duct can cause problems in the future. These include:

- poor traction;

- smoke on the top floor;

- a short pipe and, as a result, the inability to melt the upper device.

Large plumes of smoke from a second floor fireplace may be caused by an uneven chimney. If during masonry the formation of protrusions was allowed or the cross-section of the passage increased, then carbon monoxide does not exit correctly. Smoke entering an uneven section of the pipe begins to change its trajectory and form “vortices”.

Then he finds himself in a second connected passage and follows it into the room. In this case, it will not be possible to build one chimney; you need to install two pipes. You can also make two outlet channels in one pipe or connect the upper chimney to the main pipe at an angle. Thanks to such solutions, smoke will be eliminated and normal draft will be maintained during operation of the upper stove.

If the final decision was made to make one chimney for two fireplaces, stoves, barbecues, etc., then without the proper experience it will not be possible to fully do this. It is better to contact specialists who have the proper knowledge and experience in arranging such structures.

We invite you to familiarize yourself with Stones for baths and saunas: which ones are better suited and most often used?

What is a fireplace stove and how two different devices are combined

Before considering all the issues related to combining two independent devices into one, you need to understand the difference between a stove and a fireplace, because they cannot always be recognized only by appearance. In operation, the stove and fireplace use fuel combustion, heating the room acts as the main function, but the fireplace must heat only the room where it is located, and it must do this quickly and efficiently. The stove must bring heat into all rooms of the house and retain it for some time even after complete combustion of the fuel.

The main tasks are realized by the structural features. In rooms that do not have large areas, it is not possible to install one and another device at the same time, and no one wants to give up high-quality heating or a cozy fireplace. Especially for such cases, ready-made projects have been developed in which the stove and fireplace are combined in one device.

Construction of a two-story oven with a hob

A two-story stove with a hob is undoubtedly a more interesting design option, combining in itself both a heating device and a device for cooking. Unlike the simplest design, designed only to produce heat, this stove is equipped with a cast iron plate with round holes and ring dampers. This option allows you to use not only wood, but also coal to produce heat, which makes the project quite attractive in terms of rational use of energy resources.

A special feature of the design is that it is large compared to conventional dimensions, firstly, and greater strength, secondly. The increased number of vaults in the project with a hob rationally distributes the heat obtained from burning fuel without overheating the brickwork, which is very important given such a large weight of the building.

Merging options

There are several approaches to solving the problem of combining two structures. Their type depends on the stage at which such a decision was made. The most popular are two ways to accomplish the task.

- Installation of two fireboxes in one housing. As a rule, already at the stage of pouring the foundation it becomes known that the future structure will perform two types of tasks. The body of the fireplace is laid out according to a certain pattern, in which two fireboxes are formed. One firebox belongs to the stove, and the second to the fireplace. Common models are those that are a stove on one side and a fireplace on the other. These devices heat different rooms, and it seems that they function separately.

- Equipping the furnace firebox with a glass door. This allows you to turn a stove into a fireplace with a minimal investment of money, preserving all the functional features of the original device. Thus, a fireplace stove is obtained thanks to an elementary addition.

In general, combining a stove and fireplace made of brick is not so difficult. But the stumbling block is always the chimney. The fact is that, according to calculations, the areas of the smoke channels do not coincide. Metal structures successfully cope with this problem by installing an average option. Brick models often require the installation of two separate chimneys.

Undoubtedly, if two devices are combined into one, then there are only one advantages, however, in the case when the originally built stove was built by your predecessors and you want to make two functional devices out of it, you will have to call a professional craftsman. Even if you plan to carry out all the work yourself, you need a clearly developed plan. It will tell you exactly how to implement the join.

Firebox walls

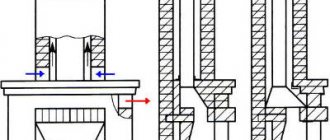

The walls of the firebox of fireplaces with increased heat transfer (Fig. 5.2, 1-3) are placed “on edge” with a distance of 6 cm from the fireplace body to form an air chamber behind the walls. The side walls of the upper firebox 1, in accordance with the recommendations for the design of a classic fireplace, are installed at a slight angle relative to the side walls of the fireplace body. However, experience shows that it is not possible to find the optimal angular position of the walls (and, accordingly, find the angle that defines this position) in fireplaces of a small group (A = 51 cm and A = 63 cm) and the effect of their rotation remains practically zero.

Let us remind you that turning the walls of the firebox is done to better reflect heat into the room. Some experts believe that it is better to use the rotation of the walls to maintain the fuel combustion process, so they try to concentrate this direction in the middle of the firebox. For this reason (due to low efficiency) in fireplace 2 (this is a fireplace A = 51 cm), the side walls of the firebox are placed without turning, they are parallel to the walls of the fireplace body.

The picture is different in the firebox of fireplaces of the medium and large groups, as can be seen from the fireboxes on the right (4-6). But even in these cases, it is impractical to set in advance a specific angle that determines the position of the side walls of the firebox. It is clear that it will depend not only on the width of the portal (dimension A), but also on the selected depth of the fireplace body (and, accordingly, the depth of the firebox). For medium and large fireplaces these values can vary significantly. In our example, the depth of the fireplace body is 2.5 bricks; it could be 3.0 bricks, which could also affect the choice of the angular position of the firebox walls.

Therefore, for fireplaces of medium and large groups, it is also impractical to set the specified angle in advance; usually it is ~ 30 °. The decision is best left to the discretion of the designer or performer.

Rear wall of the firebox

The beginning of its laying (2 rows on edge for fireplaces on the left and 4 and 5 rows for fireboxes on the right) should be placed in a binder with the side walls of the firebox; this is somewhat difficult to do, but the problem can be solved by appropriate trimming of the brick. Let us pay attention to the exception made with firebox No. 4: for laying the first 4 rows, halves of bricks were used, sawn lengthwise: 250 x 60 mm. This frees up an additional 6 cm of the depth of the firebox, or more precisely, its hearth, in favor of placing a fire pit (this is in conditions when the depth of the firebox, and therefore the hearth too, is made minimal)

Firebox No. 4 is the only one where the rear inclined wall is laid in horizontal rows, and the inclined surface of the wall is formed by an angular cut of the brick (20o from the vertical). Accordingly, the outer bricks are intertwined with the side walls, which are laid with a bevel. Due to this, the entire firebox receives strength properties: under temperature loads it does not form cracks and crevices, which, as the solution crumbles from them (with poor, low-quality solutions), can become through.

Pages: — — | — — | — — | — — | — — | — — | — —

Work in two modes

A stove combined with a fireplace can be operated in two modes. These modes differ in purpose and performance.

- In fireplace mode, the focus is on visualizing the combustion process itself. It is necessary to provide the opportunity to observe the flame from anywhere in the room; do not forget that this is one of the functions of the fireplace.

- As for heat generation, it should be presented in the form of directed radiation. Such energy can quickly warm up a resident located nearby.

To be able to switch to fireplace mode, you need to ensure the construction of a vertical, straight fireplace chimney. In this case, a huge portion of the heat will escape along with the smoke, but this design supports intense combustion, during which infrared heat is emitted.

The oven mode must use heat efficiently. For these purposes, some technological features of the structure of the firebox, smoke collector, and chimney are provided. Remember the appearance of the Russian stove; it takes up a good amount of space in the house, despite its relatively small size of the firebox. A channel is installed in the stove body through which smoke and warm air enter the chimney. As it moves through the channel, the air gives off some of its heat to the brickwork.

If a stove combined with a fireplace has two different fireboxes, then issues of switching from one mode to another should not arise, but combining it into one device with a common firebox requires introducing some operating rules. To switch between modes, you need to ensure that the flow of combustion products is redirected into one or the other chimney. This is done using a conventional damper.

Advantages and disadvantages of stove heating

A two-story oven has the following advantages:

- The two-story structure heats large spaces.

- It has very good heat transfer: 2-3 hours of heating are enough to ensure uniform heating and heat retention throughout the day.

- Despite the bulky design and large dimensions, a stove for a private two-story house makes the rooms more comfortable.

Supply of firewood

Among the disadvantages is the need for a supply of fuel. It is necessary to consider a place for storing firewood so that it does not clutter up the space.

The structure has large dimensions, and therefore the room where it will be erected must be spacious.

A very important criterion is the skill level of the stove maker. The operation of the finished structure depends on the correctness of the masonry. If the technological process is disrupted, cracks may appear in the masonry, through which smoke will penetrate into the room, and condensation will form in the chimneys.

If you wish, you can try to do this yourself by studying the relevant literature on working with brickwork and arranging chimneys.

Main types

In words it is quite simple to explain the principle of unification according to which the fireplace stove is built. The real device is complicated by the fact that today it is customary to equip it with additional functions. Thus, there are models with ovens, hobs, niches for drying fruit, barbecues, barbecues, etc.

- Ancient traditions are embodied in modern stoves with benches. Of course, the stove has somewhat lost its purpose, and the stove bench serves, for the most part, to add some color, but it is functional. You can climb on it at any time and warm up. Such stove options require a dedicated area of the room. So think about where you can install it.

- Due to its shape, a wall-mounted wood-burning stove-fireplace does not take up very much space, but it allows you to heat two adjacent rooms at once. It is mounted so that its firebox opens into one room, and the back wall is part of the partition. In a small house, this design will provide warmth in any weather.

- A real center that can gather everyone around it is a stove with an oven and a hob. It can zone a room, allocating space for a full kitchen and a hallway. To welcome guests and prepare a festive dinner, it is enough to light only one firebox. As a result, you can get a warm room, a great view of the burning flame and a lot of cooking possibilities.

Two-story stove with hob and fireplace

A building with one firebox is equipped with a fireplace insert on the second floor; it can also be equipped on the first floor.

The design is equipped with a hob, which is indispensable in the kitchen.

Oven with hob

Order

Masonry ordering requires knowledge and experience. Here it is necessary to take into account the masonry features of each row with all its nuances.

With such masonry, the operation of the equipment is greatly simplified. The construction uses red and fireclay bricks in approximately equal quantities.

Pros and cons of combined devices

A brief summary of the theory described above will be the highlighted advantages and disadvantages of fireplace stoves. Among the advantages it should be noted:

- Combining a stove and fireplace into a single device saves space without losing the basic functional qualities of each of them.

- The ability to switch between modes allows you to use the design for a short stay in the house or as a real heating system.

- The fairly large power of the furnace will ensure heating of the coolant, which means that such a system can be equipped with a water circuit.

- Additional options in the form of a hob, barbecue or oven emphasize the versatility of the stove.

- The radiation of the fireplace and the heat transfer of the stove, when combined, increase efficiency by up to 80%. Using a fireplace stove, you can fill several rooms with warm air at once.

The disadvantages of such devices are rarely discussed, but they exist:

In the first place is the huge mass of the furnace.

- It will not be possible to build a fireplace stove in a hurry, since any arrangement is a rather complex scheme.

- Complexity in structure determines complexity in maintenance. Often it is necessary to clean the channels, for which it is necessary to partially disassemble the labyrinth of the furnace, and this is a rather labor-intensive task.

Construction of a Swedish stove with a small fireplace

Like any other brick structure, the Swedish stove begins with the construction of the foundation. It is the basis and must be carried out extremely conscientiously.

Foundation

Approximate diagram of the furnace foundation

The structure is quite massive, so the foundation must be built reliably. The depth of the pit is determined depending on the composition of the soil and its freezing, but it is better that it is deep enough and ranges from approximately 60 to 80 cm.

- The bottom of the pit is compacted, and a sand cushion 10-12 cm high is placed on it.

- The next step is backfilling with crushed stone; its layer should be at least 15-17 cm thick.

- After this, a monolithic foundation is installed. Before its installation, formwork from boards is installed on that part of it that will rise above the ground.

- A reinforcing mesh (reinforcement) is installed over the entire thickness of the monolithic base, which will give the foundation rigidity and reliability.

- Next, concrete solution is poured into the pit. This can be done in several stages, layer by layer, allowing each layer to set. Moreover, the lower layers can consist of cement and gravel, and the upper layers are a 3:1 sand-cement mixture.

- The foundation should rise above the floor by 5-7 cm.

- When the foundation is ready, a sheet of roofing material is laid on top of it - it will act as waterproofing.

Swedish masonry

Detailed diagram with dimensions and vertical sections

Detailed diagrams and plans clearly show where and how the elements of the fireplace stove are located, and a description of the process will help you avoid making mistakes during operation. A very important piece of advice that an experienced stove maker will give to a beginner is that you first need to lay the entire structure without mortar. This is a labor-intensive task, but such an event will help you understand the internal structure in all its details. Another trick of all masters who master the art of stoves is laying and adjusting each row of the order, also without mortar. When it is completed, the bricks are selected and, if necessary, hewn to the required size, they are immediately laid flat. The procedure will slow down the work a little, but you won’t have to completely redo the entire structure because of one incorrectly laid row.

By carefully following the developed scheme, you can easily install this amazingly useful structure for your home yourself.

Start of masonry. Rows 1 - 6

- The first row is mounted on roofing felt. In order for it to be laid evenly, since the entire harmony of the structure will depend on this factor, it is best to first make markings on the waterproofing sheet - for this you use chalk, a corner and a long ruler. Having an exact outline of the brick laying and strictly following it will make it easy to complete the job. The first row is completely laid out with bricks, according to the configuration and dimensions indicated in the diagram.

- The second row also follows the scheme, but here metal parts are already installed, onto which the fireplace grate will later be welded, or a ready-made decorative grate is mounted and secured.

- The third row is laid out according to the diagram, and the doors of the blower and cleaning chambers are installed on it. And they cover it with pieces of asbestos or wrap it with asbestos rope. To secure the metal elements in the right place, prepared pieces of wire are threaded into the door ears, and it is fixed with mortar and temporarily placed bricks on all sides.

Installation of blower doors

- The fourth row is laid out according to the scheme, and it is notable only for the fact that the bricks coming from both sides of the doors must be installed perfectly evenly, despite the interference that arises from the metal elements.

- On the fifth row, which is best laid out of fire-resistant sand-lime brick, like the entire firebox chamber, the grate bracket is laid on the mortar and the oven box is installed. It is also wrapped in some places with asbestos rope. This is clearly visible in the presented photo.

Metal parts must be covered with asbestos

- On the sixth row, a firebox door is installed - according to the same principle as the doors of the blower and cleaning chambers. It must be wrapped in asbestos and secured with wire.

Continuation of masonry - rows 7 - 12

- On the seventh row, you should work according to the scheme, but a metal strip is laid above the fireplace firebox, on which, in the next row, brickwork will be laid. Moreover, it can lie flat or be curved like a semi-arch.

- The eighth and ninth rows are laid according to the pattern without deviations.

- The tenth row is strengthened with a prepared metal corner in the part where the hob is then mounted. Pieces of asbestos are also placed under its edges. Another cleaning chamber door is placed on the same row.

- The eleventh and twelfth rows are placed according to the pattern without additional elements.

Complex internal channels - from 13 to 24 rows

- From the thirteenth to the fifteenth row, the masonry proceeds according to plan.

- On the sixteenth row, metal strips are installed above the cooking chamber - they will become the basis for the next continuous row of bricks.

- The seventeenth and eighteenth rows are laid following the diagram.

- On the nineteenth row, two doors of the cleaning chambers are placed, securing them in the same way as the previous ones.

- The twentieth and twenty-first have no additions and are placed according to the diagram.

- On the twenty-second row, two more cleaning chamber doors are installed.

- The twenty-third row is going according to plan.

This is how valves are installed

- On the twenty-fourth row, a metal valve is placed on the solution.

Rows 25 to 33 - valve system and transition to the chimney pipe

- On the twenty-fifth, another valve is being installed, next to the first.

- The last door of the cleaning chamber is located on the twenty-seventh row.

- From the twenty-eighth to the thirtieth row, the laying is carried out according to the diagram.

- On the thirty-first row, the last, third valve is installed on the chimney opening.

- The thirty-second and thirty-third rows are the exit to the pipe laying. The pipe is laid out according to the same principle as the last row in the diagram. It fits up to the ceiling.

- In the attic floor, the chimney must be insulated by pouring expanded clay around it for fire safety purposes.

- Next, the head of the pipe is brought out onto the roof and rises above the roof by at least half a meter.

- The passage of the pipe through the roof is sealed to prevent moisture and dust from entering the cracks.

- A special metal umbrella is placed on top of the pipe.

- Metal sheets are laid in front of the fireboxes, or this place can be decorated with fire-resistant ceramic tiles.

One more point is worth noting. If the stove will be plastered or finished with ceramic tiles after construction, then the masonry joints do not need to be aesthetically designed. But, if you plan to leave the brickwork as a decorative design, the jointing should be done immediately using fresh mortar that has not yet set.

Basic requirements for combined models

There are often concerns about the safety requirements for combined fireplaces and stoves. All points, including the correct choice of location, are considered relevant.

It is necessary to plan the installation of a fireplace stove as early as possible. It's not just that you'll have to dismantle the floor to build the foundation. Just the presence of such a massive unit in a room cannot but affect its layout. Therefore, assume in advance that there are no wooden walls or flammable materials nearby. If it is not possible to exclude a dangerous neighborhood, then the entire coating should be provided with fire-resistant insulation.

Proper start-up of a new furnace is considered the key to its reliability. Fulfill all requirements for drying a newly built structure. Other issues related to the safety and compliance of the product are provided for in the finished designs of fireplace stoves.

Two stoves in one chimney

Two stoves in one chimney

Very often people do not know whether it is possible to connect several fireplaces or two stoves into one pipe. In addition, they do not know whether it is possible to use stoves connected to the same chimney on separate floors of the house. And they also don’t know for sure whether it’s realistic to connect a fireplace and a gas water heater at the same time to the smoke duct. All these questions arise for the reason that today often in a private house there is not only a fireplace and a stove, or as many as 2 fireplaces or two stoves, but also fireplaces located on separate floors, gas boilers, baths, various kinds of barbecues and etc.

So, not every owner will want to make separate chimneys for all this, because the owner of the house believes that such construction is uneconomical and will take a lot of bricks and time. In addition, such questions torment many for the reason that they are not fully answered in SNiPs.

We are often asked questions: is it possible to connect a fireplace and stove or two fireplaces into one chimney? How to operate two fireplaces on different floors with one chimney? Is it possible to combine chimneys for a fireplace and a gas water heater into one smoke channel? After numerous questions and requests, consultations, we decided to open up the issue of connecting two fireplaces to one chimney.This is due to the fact that in many houses there is not only one fireplace, but two fireplaces or two potbelly stoves, a fireplace and a cooking stove, fireplaces on different floors, a fireplace (ground floor) and a gas boiler (basement), a bathhouse in the basement and fireplace on the ground floor, and barbecue and outdoor oven in the gazebo. The owners of two fireplaces in the house do not want to build two chimneys, using excuses: it is uneconomical, a lot of brick will be wasted, one of the planned chimney ducts will be adjacent to a wooden beam or ceiling, or they believe that two brick chimneys weigh a lot.

Questions about the possibility of connecting two fireplaces to one chimney arise due to incomplete disclosure of this topic in SNiPs.

Russia. Excerpts from SNiP 41-01-2003 clause 6.6.9 and rules for pipe and furnace work clause 3.6.3. “As a rule, a separate chimney or duct (hereinafter referred to as the chimney) should be provided for each furnace. It is allowed to connect two stoves to one chimney, located in the same apartment on the same floor. When connecting chimneys, cuts should be provided in them with a height of at least 1 meter from the bottom of the connection of the pipes.”

Excerpts from SP 7.13130.2009 clause 5.47. “In multi-storey residential and public buildings, the installation of solid fuel fireplaces is allowed, provided that each fireplace is connected to an individual or collective chimney. The connection to the collective chimney must be made through an air seal, as a rule, with connection to the vertical manifold of air duct branches through the floor (at the level of each overlying floor).”

Ukraine. Excerpts from DBN V.2.5-20-2001. G.3. The removal of combustion products from household gas appliances, stoves and other household gas equipment, the design of which provides for the discharge of combustion products into the chimney, should be provided from each appliance, unit or stove through a separate chimney. G.6. Non-household gas appliances (restaurant stoves, cooking boilers, etc.) can be connected to both a separate and a common chimney. It is allowed to provide connecting smoke exhaust pipes common to several units. The introduction of combustion products into a common chimney for several appliances should be provided at different levels or at the same level with the cutting device in accordance with G.3. The cross-sectional area of chimneys and connecting pipes must be determined by calculation, based on the condition of simultaneous operation of all devices connected to the chimney. The regulatory documents make distinctions for connecting gas devices and solid fuel fireplaces (wood-burning fireplaces and stoves) to one chimney. Building codes state: each stove has a separate chimney, with the clarification “as a rule.” But the Slavs have an interesting mentality - laws are not decree, and everyone loves to experiment without thinking about the consequences. In practice, we encountered fireplaces on two floors connected to one chimney. The upper fireplace had poor draft and smoke was reaching the second floor from the operation of the lower fireplace. The owners built it themselves, then converted the upper open fireplace to a fireplace with a closed firebox. The problems remain.

Theoretically it can be connected. But practice shows that such systems only work under many additional conditions: optimal design and height of the chimney, increased cross-section of the smoke channel, installation of several dampers (complete overlap of the smoke channel), observance of the order of kindling of fireplaces (hearths), regulation of draft in two fireplaces (the most difficult moment). Let's assume several options for operating two fireplaces on different floors with one chimney.

Option 1: only the fireplace on the first floor is heated. It is necessary to prevent smoke from entering the room with a fireplace on the second floor. A fireplace damper on the second floor will not help.

Option 2: only the fireplace on the second floor is in use. It is necessary to prevent flue gases from entering the first floor and to prevent air leakage from below. Should I block the chimney between the first and second floors? But this is problematic for both a modular chimney made of stainless steel and a modular one made of ceramics. The fireplace damper is not suitable - it provides for incomplete blocking of the smoke channel.

Option 3: Both fireplaces are not working. If you do not block the chimney, we will get air exchange between rooms on different floors through the smoke duct, and this is prohibited.

Option 4: both fireplaces are lit. The bottom one melts first. Theoretically, the lower one will burn better - stronger draft. Problems with the fireplace on the second floor - poor draft and smoke, poor regulation of the combustion mode.

Tight dampers solve the problem of smoke entering one of the rooms, eliminating the simultaneous operation of two fireplaces. Smoke on the second floor and poor draft of the second fireplace are the consequences, and the main question is air exchange in the house: how to regulate the draft and combustion modes of wood? How is the supply ventilation arranged in both rooms? What are the air exchange conditions in the house? (the premises are connected via a flight of stairs or complete isolation). There are more questions than solutions. Our opinion: each fireplace has a separate chimney.

For gas chimneys: it is allowed to connect several gas devices to a common chimney. The situation with apartment heating (gas) and the removal of combustion products into a common chimney is different. Closed gas boilers are equipped with an automatic system for regulating combustion and operation when gas pressure drops. Modern wood-burning fireplaces and inserts lack such functions. All furnace work is done either by specialized companies or by licensed professionals. There are no universal recommendations or solutions; they are considered individually.

If two fireplaces on the same floor are connected to one smoke duct, the distance between the connection pipes must be at least a meter, and the cross-section of the chimney must be increased. Both heating devices must operate on the same type of fuel. Simultaneous operation does not cause problems. First, a more powerful hearth is melted.

The removal of flue gases into a common chimney has its own characteristics:

- If fireplaces on two floors have already been built, then it is better to fire them separately (excluding the “suction” of air from the second hearth, completely blocking the smoke exhaust channel).

- It is prohibited to connect a gas boiler and a wood-burning fireplace to the same chimney. Chimneys for a wood-burning fireplace and a gas boiler must be separate, and several separate channels (fireplace chimney, pipe from a gas boiler, ventilation ducts) can be located in a common shaft, and they must be separated along the entire height by sealed partitions.

- The chimney must not be connected to a ventilation duct.

- A tunnel or pass-through fireplace insert, built between rooms, is one fireplace connected to one chimney, with two portals or facings.

Chimney design and connection options, air exchange in rooms, supply ventilation, draft control and combustion maintenance are the main issues when simultaneously firing several fireplaces with a common chimney.

There are many questions, but the best solution is for two fireplaces on different floors of the house: one fireplace - one chimney, two fireplaces - two separate chimneys. Copyright © 2009 CAMMEO

Is it possible to connect two stoves into one chimney?

In theory, such a plan can be implemented, but in reality, this type of system is still able to function normally only under certain conditions, namely under:

- the most suitable height and structure of the chimney;

- larger cross-section for the chimney duct;

- the presence of several dampers to completely block the chimney channel;

- lighting fireplaces one by one;

- correct draft adjustment in both of these fireplaces.

Now I would like to consider the possible operating conditions of a pair of stoves on different floors. So, in the first case, the furnace is fired exclusively on the first floor. At the same time, it is important to prevent the penetration of flue gases into the room where the second stove or other source is located.

Devices

The list of instruments and materials required for the construction of this furnace is given in table. 2. Its design is not particularly complicated, but requires quite high qualifications and accuracy from the performer. Particular attention should be paid to the quality of the masonry not only of the firebox and external walls of the stove, but also of the internal chimney channels, since communication between the stove’s smoke circulations not provided for by the design can lead to its inoperability.

TABLE 1 CHARACTERISTICS OF A TWO-STORY HEATING OVEN WITH SINGLE FUEL

Stove dimensions in plan: fuel section. 890×1150 mm panel of the 1st floor. 770×1020 mm panel of the Nth floor. 770×950 mm Oven height*. 7150 mm Heat-dissipating surface. 20.0 m2 Average heat transfer with a single firing of the furnace per day. 5500 kcal/hour Total daily heat transfer.

132000 kcal Amount of fuel burned per day (dry firewood). 59 kg Heat transfer time after one fire. 24 hours * The full height of the stove is indicated for a ceiling height of 3.4 m. It can be changed by reducing or increasing the number of rows in the masonry from 26 to 46 and from 60 to 82 rows.

TABLE 2 LIST OF DEVICES AND MATERIALS

Red solid brick (selected). 1900 pcs. The brick is fireproof. 170 pcs. The clay is red. 2.1 m3 Fireproof clay. 0.2 m3 Sand. 2.3 m3 Fire door 350×350 mm. 1 PC. Blower door 135×120 mm. 1 PC. Cleaning doors 135×120 mm. 5 pieces. Furnace valves 130×260 mm. 2 pcs. Pre-furnace sheet 500×700 mm. 1 PC. Grate 400×400 mm. 1 PC.

Stove heating is a simple, inexpensive and effective option. If the room is spacious, then a stove on two floors would be an excellent solution. Using a wood-burning stove in a country house or country house helps to provide high-quality heating, avoid dependence on utilities and give the room comfort. If the house is two-story, you will need a heating stove for two floors.

Is it possible to install two stoves into one chimney?

It is important to understand that a gate valve will not help here. In the second situation, only the oven on the second floor is in operation. Here it is already necessary to prevent air from suction from below and smoke from entering the first fireplace. The third option provides for the possibility that both fireplaces cannot be used. Since in a situation where the chimney is not blocked, the air exchange of rooms on other floors will pass through it, which is not allowed. The fourth option involves the operation of two fireplaces. But at the same time, in theory, the lower fireplace will work normally, and with the upper one there will be problems such as smoke, poor draft and poor flame regulation.

By using tight dampers, you prevent smoke from entering one of the rooms where the fireplace or stove is located. However, in this case it is impossible to operate two fires at the same time. When operating two fireplaces, you will get a full room of smoke and poor draft in the second fireplace. And the most important issue here is the regulation of air exchange in the whole house.

How to choose a stove for heating two floors

First of all, when choosing possible options for heating devices for a mansion, you need to decide on the type of fuel that you plan to use for heating. A stove for a two-story house with traditional fuel for this region will allow you to become completely energy independent. Now you won’t have to count cubic meters of gas or kilowatts, and the stove itself will make it possible to comfortably spend the entire heating season.

A two-story stove makes it possible to provide a room with heat at the lowest cost. And even with a certain comfort - the firebox of such a structure is located below, on the first floor. This means that there is no need to constantly carry bundles of firewood or buckets of coal to the second floor. And maintaining a comfortable temperature now becomes much easier - for both the first and second floors you can set your own heating mode by simply closing the damper.

A project is selected for construction depending on the volume of the room and the individual preferences of the owners, it can be:

- Two-story oven with hob;

- Stove-fireplace with open firebox;

- Stove with firebox on two sides;

- A building for burning wood, coal or other types of solid fuel.

When deciding on the type of furnace to build, it is important to remember that such a structure has a large mass, and therefore requires a solid foundation that can withstand a load of several hundred kilograms.

What features does the exhaust of flue gases into one pipe have?

Naturally, such smoke removal has its own characteristics, which we will talk about in more detail. In particular, as already noted, when stoves connected to the same chimney are located on different floors, it is better to fire them separately. Also, you cannot install a gas boiler and a wood-burning fireplace in the same chimney. After all, this type of device must have its own chimneys. But at the same time, you can still install a chimney, a pipe for the boiler and ventilation in one shaft.

However, here too they must be completely separated by special hermetic partitions. Ventilation pipes and chimney pipes should never be shared. And the tunnel fireplace insert, which is located between the rooms, is a separate fireplace with a connection to such a chimney device with two portals. If you plan to connect two fireplaces located on the same floor to a common chimney, then it is important to understand that there must be a distance of at least one meter between them. In addition, in this case it is also necessary to expand the cross-section of the chimney. It is also necessary that two such devices are heated with the same fuel. So, their joint operation should not bring any difficulties. But first you need to melt the more powerful device.

Thus, it is worth saying that when connecting two fireplaces into one chimney, a lot of difficult issues arise. In particular, you need to think through all connection options, take care of proper air exchange, a device for high-quality ventilation, and regulation of draft and combustion. Due to such a large number of questions, we can safely say that it will be easier to build your own chimney for each fireplace. This way you will spend less effort and make everything safer.

Is it possible to install pipes from two sources at different heights and from different sides in a single-pass ceramic chimney, for example, Tona? For example, from a heating stove and a water heater with the condition that they will not be heated at the same time? Or is a two-pass chimney still needed in this case?

It is possible, but with serious restrictions:

- Gas heat generators must only have separate chimneys.

With one firebox

A special feature of a two-story oven is its high heat capacity. It has good heat dissipation. It reaches 5.5 thousand kcal/hour. At the same time, for constant heat, you can heat the stove once a day for 2-2.5 hours, while the bricks heat up well and the air in the room will be warm for a long time. Firewood consumption is no more than 60 kg.

Firewood for one firebox

Description of design and materials

The design of a single-fire stove is designed in such a way that its operating period is significantly shorter than that of stoves with two fireboxes.

The internal structure consists of chimney channels. On the second floor the chimney is laid out vertically. To separate the interfloor heating system, metal dampers are installed. They prevent the free passage of combustion products in the form of gases.

As they linger, the gases begin to cool, forming condensation on the inner walls of the chimney. As a result of exposure to moisture, the masonry begins to collapse. Double-furnace models are better because they ensure quick heating of the furnace, and condensation does not form.

Description of single-fuel design:

- There is one main firebox on the ground floor.

- In terms of dimensions, the building has the following dimensions: 89x115 cm.

- Height – 715 cm.

- Heating panel on the first floor 77x102.

- The second floor is equipped with a shield with smaller dimensions - 77x95.

In order to start laying the stove, you need to stock up on the following tools and building materials:

- To line the stove you will need red ceramic bricks.

- The interior is lined with refractory fireclay bricks.

- To work with facing material, red clay is useful.

- To line the inside of the furnace structure, use refractory clay.

- When mixing clay mortar, you cannot do without sand.

- Grate for furnace equipment (stacking firewood in the stove).

- To prevent accidentally flying coals from falling on the floor and damaging the coating, a steel sheet is laid in front of the firebox.

- Door for the firebox.

- Blower door to regulate the air supply, which is necessary for good combustion of the flame.

- Cleanout doors for installation in the chimney in order to have access to the channels (the number depends on the length of the chimney and design features).

- Valves in the chimney to regulate the release of warm gases.

Is it possible to combine two stoves into one chimney?

As an exception, during reconstruction it is allowed to connect two gas water heaters to one chimney if there is a cut at least 0.5 m high.

- Stoves, fireplaces, solid fuel boilers in existing buildings (note, in existing buildings and not newly built ones), if it is impossible to organize separate chimneys, can be connected to a common duct, provided that there is a cut at least 1 meter high, if the heat generators are located on the same floor and cuts one floor high, if they are located on different floors. The cross-section of the common channel must correspond to the sum of the cross-sectional areas of the chimneys connected to it.

- For Russia - SP 60.13330.2012 SNiP 41-01-2003 “Heating, ventilation and air conditioning”; “Rules for the production of pipe and furnace works” VDPO, agreed upon by the Main Directorate for the Production of Pipe and Furnace Works of the Ministry of Internal Affairs of the Russian Federation and Gostekhnadzor in 2001.

- For Ukraine - DBN V.2.5-20-2001.

- For Belarus - SNB 4.02.01-03

The cross-section of the combined part of the chimney must be equal to the sum of the cross-sections of the connected channels

Building codes do not provide any concessions in case heating appliances are not used simultaneously. Theoretically, operating heaters, even gas ones, in separate mode is possible, but in practice you will not be able to convince either a gas service representative or an Emergencies Ministry inspector of this. They simply won’t sign your documents or turn on the gas. In addition, the standards were not written simply at the whim of engineers; they establish safe rules for the use of heating equipment.

To summarize: for gas appliances - definitely no, for solid fuel appliances - yes, with the above reservations. The standards must be followed, because the fire inspector is required to check the smoke removal systems in your home. We advise you to find the opportunity to install a separate chimney even if all your heat generators use solid fuel. Still, possible draft problems are not worth the money you can save on a chimney. In addition, if you ever change your equipment to gas, there will be no problems with chimneys.

More detailed information can be found in the following documents:

Loading…

When building a new house, many owners of suburban areas think about installing two stoves, but do not know how to properly arrange the smoke outlet. To avoid unnecessary costs and problems, you can consider several options for installing a heating system. To make the combustion products exit more efficient, two stoves should be combined into one chimney.

Video description

Kolpakova stove on two floors.

Pouring the foundation

The stove turns out to be very heavy, so very serious reinforcement will be required Source kamin-expert.ru

To mark the foundation, you need to know what the perimeter of the stove base will be and add 5 cm on each side. In addition, the foundation must fall below the freezing point of the soil by at least 20-30 cm, so that when the soil thaws it does not sag or twist. A possible difficulty here may arise for residents of the northern regions - the filling will turn out to be too deep, but here you can get out of the situation by making a pile-slab foundation. To do this, in the corners and in the center you need to drill holes deeper than the freezing point of the soil by 30-40 cm and install chrysotile (asbestos-cement) pipes Ø150-200 mm there along the upper level of the proposed slab.

To fill the slab, you need to dig a hole at least 30-40 cm deep and up to the top level of the intended finished floor or 5-7 cm higher. A crushed stone cushion 5-6 cm thick should be poured there - you will lay reinforcement on it. Now you need to tie a frame from reinforcement Ø8 mm, a height 10 cm less than the thickness of the slab, and insert at least one rod into the pipes. Place gaskets under the reinforcement frame in several places so that the concrete can completely envelop the metal structure - this is a prerequisite. The frame is connected using a knitting wire with a cell of 200x200 mm, but in no case use welding for this - the frame must be pliable in the event of thermal expansion of concrete.

In order for the foundation to achieve the required density, you need to give the concrete three weeks to harden Source kamin-expert.ru

To prepare concrete for a slab foundation, it is best to focus on M300 (B12.5) - this is the brand and class, respectively. To compose the mixture, you need to use the following proportions: cement/crushed stone/sand/water - 1/2.8/1.9/0.8, only the ratio of water here is very relative - it depends on the moisture content of the sand and crushed stone. When making concrete, you should use the order in which components are added - this way the solution will correspond to the declared brand and strength class. Just add them in the order they are listed in the description - cement/sand/crushed stone, but not water. That is, first you need to make cement laitance, pour not all the water, but half, and while mixing sand and crushed stone, gradually add the rest.

To raise the foundation to the required height, you need to assemble formwork from boards, plywood, OSB or even chipboard. If you do not want to pull out the stands from under the reinforcement frame, then place it directly on a crushed stone cushion, fill half of it with concrete and lift it by about 5 cm so that the solution envelops the metal in all places. The time for complete hardening of concrete is 21 days and if you have this time, then wait, but if you are in a hurry, then laying the stove can begin in one and a half to two weeks.

Features of smoke removal

It is worth remembering that you cannot connect a gas boiler and a wood-burning fireplace to the same pipe. If the stoves are located on different floors, then the chimney must be built in such a way that the combustion products exit from the upper floor first through a dedicated passage running next to the main one. In this case, the height of the partition must be at least one and a half meters. This will allow you to fire two stoves at the same time.

It is worth remembering that the stove that is large is lit first, which will help normalize the draft. The cross-section of the chimney at the place where the two outlet channels connect should be almost twice as large. To exclude the possibility of smoke from getting from one furnace to another, you should make not one, but several tight dampers to ensure reliable shutoff of the pipe.

According to the rules for constructing stoves, if they are located on different floors, then connecting them into one chimney is not recommended. This is done when they are located on the same level. When installing two stoves in one pipe, it should be with the expectation that its length should be equal to 5 meters, if you count from the grate. This is necessary for normal smoke output.

Since the draft in the lower stove will be better, it is worth making it larger and starting heating the house with it. Only after the fire breaks out in it is the second one activated.

Ways to improve traction

If there is poor draft in a chimney, this is usually due to design errors. The desire to explain it by unfavorable weather conditions is unfounded, since these factors are also taken into account when making a competent decision.

What could be the reason? And the reasons may lie in:

- Insufficient height of the chimney as a whole or that part of it that rises above the roof.

- Incorrectly chosen channel section: a pipe that is too narrow cannot ensure the exit of the entire mass of gases formed; If it is too wide, it warms up worse, turbulence in the flow of gases is possible in it, and cold street air can form reverse flows.

- Poor pipe insulation.

- Too long non-vertical sections, especially at the top of the chimney.

- Due to the lack of combustion air in the room, it was necessary to provide an additional supply channel in the chimney design.

- Overturning of the draft by the wind, which occurs due to insufficient height of the pipe above the roof. Air flow turbulence occurs at the roof ridge; on the leeward slope it is directed downward and is capable of blowing flue gases back into the chimney.

It is much more difficult to determine the cause in each specific case, since several factors often act at once, none of which plays an independent role.

To improve draft, it is necessary to change the design of the chimney. And sometimes it’s not too significant - for example, increase the thickness of the thermal insulation on the last one and a half to two meters of the pipe. Sometimes a problem such as excessive traction may arise. You can deal with it using a gate. It is only necessary to provide for its installation before starting the installation of the chimney itself.