When planning to install a fireplace in a wooden house, you need, first of all, to think through the process of integrating it into the building. The problem is that the log house, even reinforced with innovative impregnations, exhibits a high degree of flammability, and moreover, it is constantly subject to deformation. Even after the initial shrinkage, the structure, albeit slightly, still changes dimensions following the dynamics of air humidity. Professionals note that almost all the weaknesses of an open hearth in a wooden structure can be leveled out if the design of the structure is drawn up correctly.

The rough stone texture of the fireplace highlights the natural wood grain of the walls and ceiling Source houzz.com

Fireplace problems in a wooden house

A wooden house, beautiful in many respects, has two significant drawbacks that introduce noticeable specificity into the design of a fireplace in a wooden house:

- Wood is flammable; treatment with fire retardants reduces flammability, but only slightly.

- A wooden frame is subject to significant deformation. Moreover, we are talking not only about the shrinkage of the log house in the first year after being placed under the roof. The house “walks” throughout its entire service life, periodically becoming a little higher or lower, depending on the season and air humidity. This introduces noticeable specificity into the design of a fireplace in a wooden house.

The following two disadvantages are inherent in the fireplace itself:

- Low efficiency; for a classic English fireplace it does not exceed 20%.

- The hearth, even without being lit, works like an exhaust hood if the chimney is not tightly closed with a damper. And when a fire blazes in the firebox, large volumes of air are removed from the room along with combustion products. If there is no flow of fresh air into the room, it may open up and smoke will rush in, causing the firebox to smoke. If you open the windows, you can cool the room and it will become colder than before the fireplace was lit.

What should a fireplace be like in a wooden house so that the disadvantages listed above do not prevent the owners from enjoying life in their own home? Let's consider ways to solve problems depending on the design of our fireplace:

Cast iron fireplace

Ansushkov said that he bought the Marseille 14 fireplace ready-made from a Russian manufacturer.

This fireplace model, which was chosen by the owner of the house, is made in Russia. Although some parts, as Ansushkov thinks, were brought from abroad, from France and Japan. For example, the glass is Japanese, and the cast iron parts are French. Is it so important when it turns out stylish and warm?

anushkov

Heats perfectly, very hot, keeps warm, but the main thing for me is aesthetics, the glass screen is huge, beautiful! Logs and boards up to half a meter fit (45cm in the passport) and burn for a long time on one full stack.

He noted that even during the process of building the house, along with the strip foundation, he poured a podium under the fireplace measuring 1.5 by 1.5 square meters in a frame. And although it was initially planned to build the stove out of brick, later it was decided to purchase a ready-made factory product, a cast-iron stove-fireplace.

Brick fireplace - traditional approach and solidity

Kiln brick is a heavy material, one piece weighs about 3.5 kg. And you need thousands of them. Therefore, the design of a wooden house with a brick fireplace must include the construction of a foundation. Moreover, it is separated from the foundation of the walls, because the load from masonry will significantly exceed that from wooden walls.

Brick is good for its solidity and high heat capacity. Heated by a flame, it will give off soft heat to the room for a long time. There are no special problems with the fire safety of a brick fireplace. If the thickness of the fireplace masonry facing the wall is at least 250 mm, it is enough to lay a 50 mm thick layer of basalt wool between the wall and the fireplace. Other options are to fill the gap between combustible structures and bricks with perlite or vermiculite. You can place asbestos cardboard or felt soaked in clay in the gap. There are many modern thermal insulation materials.

With the right approach, a brick fireplace will be effective:

- It is necessary to optimally calculate the proportions of the firebox, this will allow more radiant energy to be directed into the room. The correct determination of the chimney cross-section will ensure good draft, while not “throwing” too much air into the street.

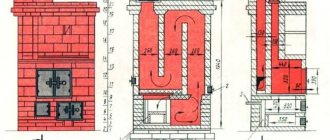

A traditional brick fireplace, despite its apparent simplicity, has a complex structure. All its elements must be mutually balanced. To achieve the best indicators, the proportions of a brick fireplace should be calculated using rather complex formulas, but an acceptable result can be obtained by selecting the dimensions according to this table

- The larger the surface area of the fireplace, especially in the heating zone, the better its heat transfer and the more evenly the heat is distributed. From the point of view of thermal engineering, a complex shape with various ledges, ribs and niches is preferable.

The more complex the shape of a brick fireplace in a wooden house, the higher its heat output

- You can stabilize the draft, prevent the fireplace from smoking, and at the same time minimize the amount of air removed along with combustion products in a simple but reliable way: from the street, from a cold basement or underground, bring an air duct directly into the fireplace grate. A damper or damper should be placed on the supply channel in order to be able to block the air flow in winter, when the fireplace is not heated.

The video shows a corner fireplace in a wooden house with an open firebox and increased efficiency. Notice how the brick surface area has been increased by simple means to increase heat transfer and distribute it more evenly. It is important that this fireplace has a combustion air supply from the street

Insulation of walls and floors around the fireplace

To insulate the walls, multilayer insulating materials are used (basalt wool with a reflective screen, sheets of non-flammable synthetic material), brick.

Properly performed thermal insulation is the key to safety and is carried out using materials such as mineral wool, polystyrene foam, tape tow and others

Before you begin installing the slabs, you need to mark the area around the fireplace within a radius of 75 cm. This is where the multilayer insulation sheets will be attached to a metal profile.

Fire-resistant plasterboard sheets are mounted on top of this layer. The cracks can be sealed with foil. Then reinforcing mesh, putty and painting.

Or the walls near the fireplace can be lined with brick, ceramic tiles, stone, if such a solution fits organically into the design of the room

The flooring around the fireplace must be treated with a facing material that can withstand high temperatures.

The space around the fireplace at a distance of 1.5 meters should be covered with cladding. What are marble, granite and ceramic tiles used for?

Lining the floor near the fireplace protects it from high temperatures, thereby preventing various types of damage

During operation, the fireplace requires constant care, since where there is fire, there is always a risk. It is important to periodically clean the fireplace chimney from accumulation of soot and deposits.

In addition, you need to take care of the appearance of the fireplace and wipe dust from its surface.

How to increase the efficiency of a brick fireplace

By carefully calculating all the parameters of the firebox and laying out the masonry correctly, the efficiency of a fireplace with an open firebox can be increased to 35%. Alas, this is the limit. To double the efficiency of the fireplace, you will have to partially turn it into a stove - equip it with a door. If the door is large and glass, this will not prevent us from admiring the flame. A brick fireplace with a door can have a “stove” firebox shape: not wide and high, but rather long and relatively narrow. This will change the nature of heat transfer towards reducing the amount of radiant heat, but the massive masonry will heat up more. This “reserve” of heat will be transferred into the room for a long time after the fire in the fireplace goes out.

The brick can be replaced with durable, heat-intensive stone, and the firebox can be equipped with glass doors; doors with adjustable air flow can be installed on the ash pan. This type of fireplace is approximately three times more economical than a traditional one.

The second way to increase the efficiency of burning wood is to install a fireplace insert in the brickwork. To avoid overheating, the metal case should not be covered with bricks; a small distance should be left between the steel and ceramics for ventilation. Functionally, this combination is already a closed fireplace insert with a heat-intensive brick casing.

Facing

To give the fireplace a decent look and style, its firebox is lined with tiles or asbestos-based plaster.

When constructing fireplaces with a closed firebox, cladding is a necessary condition. For this, brick, tile, marble, wood and other materials are used.

Plastering the surface of fireplaces is often used.

This method is very common due to its accessibility and simplicity. Important. Plastering is carried out in two passes, the thickness of the final layer of plaster should not exceed 50 mm.

After drying, the plaster is covered with a layer of paint. Heat-resistant plasterboard or ceramic tiles are also used for cladding fireplaces.

Fireplace insert made of steel or cast iron - high efficiency

A steel or cast iron fireplace insert with a glass door is a hybrid of a fireplace and stove. The shape of the firebox is closer to a classic fireplace, which allows for maximum thermal radiation to be directed into the room. Dampers and a door that allows you to see a living flame make it possible to accurately dose the amount of air required for combustion. A metal body with developed fins and a large heat transfer area allows for a significant increase in convective heat transfer into the room compared to a brick fireplace. Thanks to these solutions, the efficiency of modern fireboxes has been increased to 80%. Efficiency, reasonable price, attractive design, compactness and light weight are the undeniable advantages of such fireboxes. It is not surprising that steel fireplaces for wooden houses are the most popular. Their only serious drawback is that they cool quickly. But they warm up a cold room just as quickly; they burn for a long time on one stack of firewood.

Based on a steel fireplace, you can build a full-fledged heating system if you purchase a model with a “water jacket” or a system for supplying warm air through channels

The metal surface of the firebox heats up much more than a brick fireplace with thick walls. Therefore, it cannot be placed as close to the walls. The minimum distance to combustible wooden structures is specified in the firebox installation instructions. If this is not the case, building codes should be followed. They do not specify the conditions for fireplaces, so we focus on the data for steel stoves. It is not allowed to place an unlined iron stove closer than a meter from a “bare” wooden wall. Installing a fireplace closer to the walls in a wooden house is allowed only if they are protected by fireproof heat-insulating screens. There are many protection options; this is a topic for a separate article. One of the inexpensive and simple solutions: basalt wool 50 mm thick, two gypsum fiber sheets and an air gap of 20 mm. Thus, the total distance from the rear or side surfaces of the metal firebox to the wall, taking into account protection, will be 10 cm.

This steel fireplace has thermally insulated back and side surfaces, which allows it to be placed quite close, but not close to wooden walls

Selection of materials and oven

Initially, the author of the thread planned a fireplace to decorate the interior - I wanted to give it more coziness. However, it turned out that the stove heats up very strongly, and one full load is enough to heat one room and two adjacent ones - it even gets hot within half an hour. And the fireplace remains hot for about 4 hours after heating. This is quite suitable as an alternative heating.

The installation of the fireplace stove began with preparing the floor. For the base, porcelain stoneware slabs were chosen, installed on a heated floor with a 150 mm screed. The fireplace was built on a floor covering made of a standard expanded clay block with a distance of 50 mm from the wall. The masonry was made using mortar. This is a cast iron fireplace, so the distance from its walls was minimal - 300 mm. Heat-resistant facing tiles were laid on top of the blocks with glue and sealed with a sealant that was also resistant to high temperatures.

anshushkov

The fireplace gets very hot, from one full fireplace in the room and 2 adjacent ones, it becomes hot within half an hour. The protective shield also heats up, but to about 60-70 degrees Celsius. The fireplace remains hot for about 3-4 hours after heating. But I use it more for aesthetics; I usually make only 1 bookmark.

Expanded clay block was not chosen by chance. According to the user, he had previously studied thermodynamics and thermophysics, so he understood perfectly well that, due to its hollowness, the expanded clay block heats up less, and therefore the risks are reduced. This was the main factor when choosing expanded clay blocks rather than bricks.

And to improve heating, the hero gave good advice:

ansushkov

It is very important to install a heat-removing convector on the first pipe, I don’t remember what it’s called, it was difficult to find, they usually suggest not installing anything, this is not correct, due to convection, the heat extraction is higher and the heating of the room is better.

Ansushkov painted the stainless steel with black heat-resistant paint. The choice was made not only because of the style of the stove, but also because stainless steel itself quickly loses its original color.

Navigator6989

Super! I’m also planning an Invicto stove with a black chimney. It will be located near the outer wall between two windows. The house is made of timber, so I decided to do without any imitation and line the inside wall with facing bricks (half a brick) with a bandage to the timber.

Features of the box design and lining of the metal firebox

It is especially important to take into account the specifics of a wooden house if the firebox is placed in a box:

- The wooden wall inside the box should be protected from the heat of the fireplace no less than when it is installed openly, the required distances should be maintained, and heat-reflecting screens should be installed.

- There should be ventilation holes at the top and bottom of the box to prevent overheating. There can be several gratings, preferably on three or at least two opposite sides of the box. If their total area is not indicated in the instructions, we take 0.15 m2 for both the lower and upper holes.

- It is necessary to protect the wooden ceiling from overheating. A simple solution is not to raise the fireplace box directly to the ceiling; it is enough to leave a free space of 35-40 cm. At the same time, the problem of shrinkage and seasonal deformation is eliminated. The box must be closed at the top, and its horizontal “lid” must be thermally insulated no worse than the vertical walls.

The box cap is not brought to the ceiling, which reduces its heating

- If the design solution includes a box up to the ceiling, you will have to divide it by height. In the upper part there is a separate section with a height of at least 30 cm. It must be separated from the main box by thermal insulation material, and also have its own ventilation vents with a total area of at least 0.02 m2. It should be taken into account that due to possible subsidence of the frame, the box cannot be mounted close to the ceiling. Calculating the required gap size is not easy; only an experienced specialist can do this. The resulting gap can be closed with a cornice attached to the ceiling.

The outer walls of the box have not yet been mounted, but we can see its internal structure. The steel fireplace is separated from the wooden walls by an air gap, a sheet of gypsum fiber board and a layer of foiled basalt wool. A gap is left between the box and the ceiling for shrinkage. The box itself has an additional “cooling” section at the top, the horizontal surfaces of which will also be thermally insulated. Flexible steel pipes coming out of the fireplace body - air heating ducts, the chimney has not yet been installed

Protecting wood from overheating

As already noted, it is extremely important to protect the wooden parts of the house that are in close proximity to the fireplace from overheating. Otherwise, fire cannot be avoided. In addition to the load-bearing floor beams, the wall behind the outer layer of facing material also needs protection. To do this, a so-called fire wall is constructed from brick. Its height should correspond to the height of the fireplace.

Such a wall can also be built from foam concrete blocks or gypsum . A protective gasket is also needed between the firebox and the facing slabs. Heat-resistant basalt wool is suitable for this. We also make a 30-centimeter collar on the floor around the fireplace from heat-resistant materials.

Chimney in a wooden house

When installing a chimney in a wooden house, the following rules must be observed:

- The thickness of the walls of a brick chimney in places where it passes through combustible structures (floors, roofs) must be at least 25 cm. The wood should not be adjacent to the masonry; it should be separated by a layer of thermal insulation.

The procedure for installing a fireproof cutting of a brick chimney when passing through a wooden ceiling. Increasing the wall thickness to 38 cm made it possible to reduce the thickness of the thermal insulation layer to 5 cm

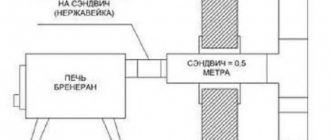

- As for steel chimneys, in a wooden house we recommend using double (sandwich) pipes thermally insulated with basalt wool, the inside of which should be made of heat-resistant high-alloy steel. An exception is the first section from the fireplace; at a height of about 25-40 cm, it is better to make it from a single pipe to prevent overheating of the junction of the firebox and the chimney. The minimum distance at which double pipes can be installed from wooden structures depends on the thickness of the sandwich insulation, but should not be less than 130 mm. Passages through floors and roofs must have a fireproof design.

General diagram of a metal chimney along with passage elements in a wooden house

- The arrangement of the passage of the chimney through the ceiling and roof must take into account the primary and seasonal shrinkage of the log house. The apron, which covers the passage from below and from above, must be “floating”, regardless of the type of chimney, and be able to move relative to the pipe.

An example of a floating structure for the passage of a steel chimney through a ceiling

Foundation construction

The fireplace base is installed separately. Under the influence of high temperature, the base underneath will move; it would be more correct to separate it from the base of the building. The reinforced concrete base, which has dimensions slightly larger than the area of the fireplace, is placed at the depth of soil freezing. Broken bricks and parts of rolled profiles are placed in a pre-prepared pit. During pouring, 1 share of cement and 3 shares of sand are taken. Do not forget to cover the hardened foundation with roofing felt or roofing felt to ensure the required waterproofing.

Video: the difficulties of installing a fireplace in a wooden house

This video shows, using a specific example, how to properly install a fireplace in a wooden house.

We have mentioned only the main features of installing fireplaces in wooden houses; there are many more points that need to be taken into account. Everything related to fire requires special attention, increased attention and careful adherence to fire safety rules. We recommend that you trust the design and installation of fireplaces and stoves exclusively to professionals with the appropriate knowledge and experience.

Permanent address of the article

Shiber

Another important element of such a fireplace stove is a damper installed above the starting convection pipe. Ansushkov recommends making the chimney straight, since such a chimney has better draft and heats up faster. In addition, this is also a safer way to install a fireplace stove in your home.

ansushkov

The gate was placed immediately above the starting convection pipe. It is a must to install. Enlarge the photo and you will see it. A straight chimney is really better, the stove is very powerful, the draft is strong, it heats up instantly, and therefore it is safer with a straight chimney. And after one full charge, I don’t recommend charging the second one right away, it heats up like hell, my volumes are large, although one floor has a 3.8 m ceiling, the living room and kitchen are combined, it gets hot. The convector at the starting point also helps distribute the flow. The stove itself holds heat for a long time - cast iron.

The passage of the pipe through the ceiling itself is made of non-combustible blocks, a sandwich chimney, the main main reduction in temperature in the first section through convection.

Advantages and disadvantages

A fireplace in a country house is a decorative element that creates a unique design of the room and an attractive design. Another advantage is that it provides an additional source of heating for the home. Disadvantages are usually due to the arrangement of the firebox:

- Difficulties associated with the installation and arrangement of the fireplace area. The construction of an open fireplace is possible only if this possibility was provided for at the initial stage of construction of the house and a separate foundation was poured for the structure. It is necessary to follow the order of installation, including the stage-by-stage delivery of the structure for acceptance by the registration authorities.

- An inspection of the combustion chamber and chimney duct by an employee of the Ministry of Emergency Situations, carried out before connecting the chimney. Work on completing all the paperwork may take more than one year.

- Features of wooden structures - complete shrinkage of the house can occur no earlier than after 6-7 years. Construction of the fireplace can only be done after this time has been completed.

- Limitations related to the size of the room. The dimensions of the portal increase taking into account the selected material. A home can be built in a room no smaller than 25 m².

During installation, you should not sacrifice current safety requirements to give the heating device an attractive appearance. The required dimensions of the combustion chamber and smoke exhaust must correspond to those specified in SNiP. Before carrying out work, it is necessary to make correct thermal calculations and develop a fireplace design. This can protect the house from unwanted negative consequences.

Recommendations from professionals

To build a high-quality fireplace for heating rooms, you need to take into account certain features. The fire source must be installed in such a way as to minimize the likely risk of fire. There should be no flammable objects nearby; a fire extinguisher must be installed near the fireplace.

The following expert advice will help you build a fireplace correctly:

- The wall near the combustion chamber must be fireproof. Moreover, an additional layer of thermal insulation made of aluminum foil or other metal alloys is laid.

- The floor near the fireplace should be covered with non-combustible materials - metal, porcelain stoneware or stone. This will prevent fire caused by falling sparks.

- To protect the ceiling from elevated temperatures, partitions made of metal lathing and plasterboard are used.

- For the installation of a smoke exhaust duct, it is recommended to use a two-layer material.

A fireplace cannot always heat a building completely, since the bulk of the thermal energy is lost through the chimney. In this case, the best design may be a fireplace stove, which makes it possible not only to heat the house, but also to cook food. To heat the house, you can connect a water heating circuit.

Read more: fireplace stove for long burning.