Coolant and its parameters

Coolant (working fluid) is a gaseous or liquid substance used in machines for energy conversion, in the case of heat exchange to produce heat or cold.

In boiler rooms, the coolants are water and steam, the main physical characteristics of which are temperature, pressure, specific volume or density. Temperature is a measure of the thermal state or degree of heating of a body. The thermal state of a body is characterized by the average internal energy of the body, the intensity of thermal vibrations of its atoms. The higher the temperature, the greater it is. Body temperature can increase or decrease depending on whether heat is supplied or removed from the body as a system.

Pressure is a quantity that characterizes the ratio of a normally (perpendicular to the surface) directed force to the surface area on which it acts. In the heating industry, three types of pressure are most widespread - atmospheric, excess and absolute.

Atmospheric is the pressure of air on the ground and on objects located on it. A device for measuring atmospheric pressure is called a barometer in meteorology, and the pressure itself is called barometric and is designated Pbar.

Excess pressure P from6 characterizes its excess above atmospheric pressure. This pressure is measured by a manometer, therefore it is also called manometric.

Absolute pressure Pabs is the pressure of a liquid or gas in a closed vessel. It is equal to the sum of atmospheric and excess pressure:

Absolute pressure can be greater or less than atmospheric pressure. If the pressure is below atmospheric, it is called rarefaction (vacuum). If the pressure in a closed vessel is less than atmospheric, then:

In practice, the following multiples of pascal units are used:

0.1 MPa); mmHg Art. (millimeters of mercury, 1 mm Hg = 133 Pa); mm water Art. (millimeters of water column, 1 mm of water column = 9.81 Pa).

All these pressure units are related to each other using appropriate conversion factors.

Physical atmosphere (air pressure at sea level equal to 760 mm Hg at a temperature of 0 ° C)

The specific volume V0 of a gas, water or steam is the volume of a unit mass of a substance. For example, for a gas with a volume V m3 and a mass t, kg, the specific volume, m3/kg, will be:

The density p of gas, water or steam, as well as any solid substance, kg/m3, is the reciprocal of the specific volume:

Source

Purposes of hydraulic calculation

The objectives of hydraulic calculation are as follows:

- Select the optimal pipeline diameters.

- Link pressures in individual branches of the network.

- Select a circulation pump for the heating system.

Let's look at each of these points in more detail.

1.

Selection of pipeline diameters

If the system is branched - there is a short and a long branch, then on the long branch there is a large flow rate, and on the short branch - less. In this case, the short branch should be made from pipes of smaller diameters, and the long branch should be made from pipes of larger diameter.

And, as the flow rate decreases, from the beginning to the end of the branch, the diameters of the pipes should decrease so that the coolant speed is approximately the same.

2.

Linking pressures in individual branches of the network

Linking can be done by selecting the appropriate pipe diameters or, if the possibilities of this method have been exhausted, then by installing pressure flow regulators or control valves on individual branches.

Adjustment fittings may be different.

Budget option - install a control valve - i.e. valve with smooth adjustment, which has a gradation in setting. Each valve has its own characteristics. During hydraulic calculations, the designer looks at what pressure needs to be extinguished, and the so-called pressure discrepancy between the long and short branches is determined. Then, based on the characteristics of the valve, the designer determines how many revolutions this valve will need to open from the fully closed position. For example, by 1, 1.5 or 2 turns. Depending on the degree of opening of the valve, different resistance will be added.

A more expensive and complex version of control valves is the so-called. pressure regulators and flow regulators. These are devices on which we set the required flow rate or the required pressure drop, i.e. pressure drop on this branch. In this case, the devices themselves control the operation of the system and, if the flow does not meet the required level, they open the cross-section and the flow increases. If the flow rate is too high, the cross section is blocked. The same thing happens with pressure.

If all consumers, after an overnight decrease in heat transfer, simultaneously opened their heating appliances in the morning, then the coolant will try, first of all, to flow to the appliances closest to the heating point, and will reach the furthest ones after hours. Then the pressure regulator will work, covering the nearest branches and thereby ensuring a uniform supply of coolant to all branches.

3.

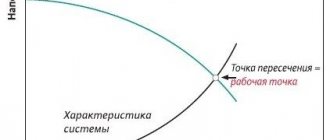

Selection of a circulation pump by pressure (pressure) and flow (supply)

If there are several circulation pumps in the system, then if they are installed in series, their pressure will be summed up, and the flow rate will be total. If the pumps operate in parallel, then their flow rate is summed up, and the pressure will be the same.

Important: Having determined the pressure loss in the system during the hydraulic calculation, you can select a circulation pump that will optimally match the parameters of the system, ensuring optimal costs - capital (cost of the pump) and operating (cost of electricity for circulation)

Coolants and their parameters

7.1 In centralized heat supply systems for heating, ventilation and hot water supply of residential, public and industrial buildings, as a rule, water should be used as a coolant. The possibility of using water as a coolant for technological processes should also be checked. The use of steam as a single coolant for enterprises for technological processes, heating, ventilation and hot water supply is allowed during a feasibility study. 7.2 The maximum design temperature of network water at the outlet of the heat source, in heating networks and heat receivers is established on the basis of technical and economic calculations. If there is a hot water supply load in closed heat supply systems, the minimum temperature of the network water at the outlet of the heat source and in the heating networks must ensure the possibility of heating the water supplied to the hot water supply to a standardized level. 7.3 The temperature of network water returned to thermal power plants with combined heat and electricity generation is determined by technical and economic calculations. The temperature of network water returned to boiler rooms is not regulated. 7.4 When calculating temperature schedules of network water in district heating systems, the beginning and end of the heating period at the average daily outside air temperature are assumed to be: 8 °C in areas with a design outside air temperature for heating design of up to minus 30 ° C and an average design temperature of the internal air of heated buildings 18 °C; 10 °C in areas with a design outside air temperature for heating design below minus 30 °C and an average design temperature of internal air in heated buildings of 20 °C. The average design temperature of the internal air of heated industrial buildings is 16 °C. 7.5 If the heat receivers in the heating and ventilation systems do not have automatic individual devices for regulating the temperature inside the premises, it is necessary to use heat carrier temperature control in heating networks: central qualitative for the heating load, for the combined load of heating, ventilation and hot water supply - by changing the coolant temperature at the heat source depending on the outside temperature; central qualitative and quantitative for the combined load of heating, ventilation and hot water supply - by regulating both the temperature and the flow of network water at the heat source. Central qualitative and quantitative regulation at the heat source can be supplemented by group quantitative regulation at heating points mainly during the transition period of the heating season, starting from the break point of the temperature graph, taking into account the connection diagrams of heating, ventilation units and hot water supply, pressure fluctuations in the heating system, availability and locations of storage tanks, heat storage capacity of buildings and structures. 7.6 With central qualitative and quantitative regulation of heat supply for heating water in hot water supply systems to consumers, the water temperature in the supply pipeline must be: for closed heat supply systems - at least 70 ° C; for open heat supply systems - at least 60 °C. With central qualitative and quantitative regulation for the combined load of heating, ventilation and hot water supply, the break point of the water temperature graph in the supply and return pipelines should be taken at the outside air temperature corresponding to the break point of the control graph for the heating load. 7.7 In heat supply systems, if the heat consumer in the heating and ventilation systems has individual devices for regulating the air temperature indoors by the amount of network water flowing through the receivers, central qualitative and quantitative regulation should be used, supplemented by group quantitative regulation at heating points in order to reduce fluctuations in hydraulic and thermal regimes in specific quarterly (microdistrict) systems within the limits ensuring the quality and stability of heat supply. 7.8 For separate water heating networks from one heat source to enterprises and residential areas, it is allowed to provide different schedules of coolant temperatures. 7.9 In public and industrial buildings for which it is possible to reduce the air temperature at night and during non-working hours, regulation of the temperature or coolant flow in heating points should be provided. 7.10 In residential and public buildings, if the heating devices do not have thermostatic valves, automatic regulation according to the temperature schedule should be provided to maintain the average internal air temperature in the building. 7.11 It is not allowed to use temperature control schedules for heat supply for heating networks.

Mixtures of water and ethyl alcohol

Very often, mixtures of ethyl alcohol and water are used for this purpose, in which the percentage of alcohol ranges between 40 and 55%. The mixtures crystallize at minus thirty degrees. But there is one BUT: such mixtures are recommended to be used exclusively in closed heating systems equipped with forced circulation of coolant. The fact is that if this does not happen, the alcohol will evaporate very quickly. Yes, and ethyl alcohol boils at 90 degrees, which is not very suitable for standard systems

This is especially important in systems with automation, which calculates the air temperature in the building, and not the coolant temperature

The price of such a mixture is from 65 rubles per liter.

In general, choosing a coolant for heating systems is easy; the main thing is to take into account all the necessary factors.

Everyone should know the standards: coolant parameters for the heating system of an apartment building

During the cold season, residents of apartment buildings often trust already installed central heating batteries to maintain the temperature in their rooms.

This is the advantage of urban high-rise buildings over the private sector - from mid-October to the end of April, public utilities take care of the constant heating of residential premises. But their work is not always flawless.

Many have encountered pipes that are not hot enough in winter frosts, and a real heat attack in the spring. In fact, the optimal temperature of the apartment at different times of the year is determined centrally, and must correspond to the accepted GOST.

Thermal loads - definition and characteristics

What is usually meant by the term “heating load”? This is the amount of heat that is given off by all heating devices installed in the building. To avoid unnecessary expenses on work, as well as the purchase of unnecessary equipment and materials, a preliminary calculation is necessary. With its help, you can adjust the rules for installing and distributing heat throughout all rooms, and this can be done economically and evenly.

But that's not all. Very often, experts carry out calculations relying on exact indicators. They relate to the size of the house and the nuances of construction, which takes into account the variety of elements of the building and their compliance with the requirements of thermal insulation and other things. It is accurate indicators that make it possible to correctly make calculations and, accordingly, obtain options for distributing thermal energy throughout the premises as close to ideal as possible.

But errors in calculations often occur, which leads to ineffective heating operation as a whole. Sometimes it is necessary to redo not only circuits, but also sections of the system during operation, which leads to additional costs.

What parameters influence the calculation of the thermal load as a whole? Here it is necessary to divide the load into several positions, which include:

- Central heating system.

- Underfloor heating system, if one is installed in the house.

- Ventilation system - both forced and natural.

- Hot water supply to the building.

- Branches for additional household needs. For example, for a sauna or bathhouse, for a swimming pool or shower.

Main characteristics

Professionals do not lose sight of any little detail that may affect the correctness of the calculation

Hence, there is a fairly large list of characteristics of the heating system that should be taken into account. Here are just a few of them:

The purpose of the property or its type. It can be a residential building or an industrial one. Heat energy suppliers have standards that are distributed according to the type of building. They are often the basis for calculations. Architectural part of the building. This can include enclosing elements (walls, roofing, ceilings, floors), their overall dimensions, thickness

All kinds of openings must be taken into account - balconies, windows, doors, etc. It is very important to take into account the presence of basements and attics. Temperature conditions for each room separately. This is very important because general temperature requirements for a home do not provide an accurate picture of heat distribution. Purpose of the premises This mainly applies to production workshops where stricter temperature control is required. Availability of special premises

For example, in private residential buildings these could be baths or saunas. Degree of technical equipment. The presence of a ventilation and air conditioning system, hot water supply, and the type of heating used are taken into account. The number of points through which hot water is drawn. And the more such points, the greater the thermal load the heating system is exposed to. The number of people at the site. Criteria such as indoor humidity and temperature depend on this indicator. Additional indicators. In residential premises, you can highlight the number of bathrooms, separate rooms, and balconies. In industrial buildings - the number of shifts of workers, the number of days a year when the workshop itself operates in the technological chain.

Heating standards RF PP No. 354 dated 05/06/2011 and GOST

On May 6, 2011, a Government Decree was issued which is still in effect to this day. According to him, the heating season depends not so much on the time of year, but on the air temperature outside.

Central heating starts to work provided that the external thermometer shows below 8 °C and the cold snap lasts for at least five days.

On the sixth day, the pipes already begin to heat the rooms. If warming occurs during the specified time, the heating season is postponed. In all parts of the country, radiators delight with their warmth from mid-autumn and maintain a comfortable temperature until the end of April.

If frost has set in and the pipes remain cold, this may be the result of a problem in the system. In the event of a global breakdown or unfinished repair work, you will have to use an additional heater until the fault is fixed.

If the problem is due to air pockets filling the batteries, then contact the operating company. Within 24 hours after submitting the application, the plumber assigned to the house will arrive and “blow out” the problem area.

The standard and norms for permissible air temperature values are specified in the document “GOST R 51617-200. Housing and communal services. General technical information". The range of air heating in an apartment can vary from 10 to 25 °C , depending on the purpose of each heated room.

The optimal temperature is considered to be from 19 to 21 °C , but cooling the zone to 18 °C or intense heating to 26 °C is allowed.

The warmth in the house also depends on the time of day. It is officially recognized that a person needs less heat while sleeping. Based on this, lowering the temperature in the rooms by 3 degrees from 00.00 to 05.00 in the morning is not considered a violation.

Source

Data on how to calculate the diameter of a heating pipe

To calculate the diameter of the pipeline, you will need the following data: this is the total heat loss of the home, the length of the pipeline, and the calculation of the power of the radiators in each room, as well as the wiring method. The outlet can be one-pipe, two-pipe, have forced or natural ventilation.

Unfortunately, it is impossible to accurately calculate the pipe cross-section. One way or another, you will have to choose from a couple of options. This point is worth clarifying: a certain amount of heat needs to be delivered to the radiators, while achieving uniform heating of the batteries. If we are talking about systems with forced ventilation, then this is done using pipes, a pump and the coolant itself. All that is needed is to drive the required amount of coolant over a certain period of time.

It turns out that you can choose pipes of a smaller diameter and supply the coolant at a higher speed. You can also make a choice in favor of pipes of a larger cross-section, but reduce the intensity of the coolant supply. The first option is preferable.

Physico-chemical characteristics of the coolant

Specific heat. This is a physical quantity that reflects the amount of heat required to heat a unit mass of coolant by 1 unit. In other words, specific heat capacity reflects how much heat a substance can accumulate in itself. The higher this characteristic, the more efficient the coolant is.

Thermal conductivity. This is the property of a physical body to transfer thermal energy from more heated parts to less heated ones due to the interaction of particles. This parameter is characterized quantitatively through the thermal conductivity coefficient - the higher it is, the more heat the coolant will transfer per unit time.

Density. This is the ratio of the mass of a substance to a unit volume. It characterizes how many molecules or coolant atoms are contained in the space of the heating/cooling circuit. This directly affects thermal conductivity - the higher the density of a substance, the closer its particles are located to each other and the faster the transfer of thermal energy occurs.

Thermal expansion coefficient. This characteristic reflects the degree of increase in the volume of the coolant when the temperature changes by 1 unit. Thermal expansion must be taken into account, since the expanding fluid can cause damage to the heating system piping.

Freezing temperature. It determines at what degrees the coolant turns into a solid. For some substances (for example, glycol solutions), a distinction is made between the temperature of the onset of crystallization and complete solidification, since this process does not occur immediately. This characteristic determines the climatic conditions in which the coolant can be used.

Boiling temperature. This characteristic indicates at what degrees the liquid begins to intensively transform into a gaseous state. The boiling point is of great importance, since this process leads to the formation of air locks and other emergency situations in heating systems.

Viscosity and fluidity. These are mutually opposite characteristics that determine the ability of the coolant fluid to move along the heating/cooling circuit, interact with moving parts of pumping equipment, flow through connections, etc. High viscosity of the working medium leads to premature wear of pumps and increased energy costs for its circulation through the system. Increased fluidity determines the ability of the coolant to seep through the smallest holes.

Selection of circulation pump

The circulation pump helps to identify pressure losses in all sections of the pipeline. To determine the pressure required by the pump to pump coolant through the system, use the formula: P = Rl + Z, where:

- P - decrease in pressure in the line (Pa);

- R - relative resistance to adhesion (Pa/m);

- l is the length of the pipe of one section of the heat pipeline (m);

- Z—pressure reduction in narrow-gauge zones (Pa).

Such calculations are extremely inconvenient and time-consuming, whereas to determine the Rl value of all sections of the pipeline it is enough to use Shevelev’s tables. It must be remembered that pump performance is the total coolant consumption, and not the capacity of the heating system.

Chemical properties of the coolant

Corrosive (chemical) activity. This is the ability of the coolant to react with the materials from which the pipes, connections and pipeline fittings of the system are made. In this case, new connections are formed (for example, rust in metal pipes), and circuit elements are gradually destroyed and clogged, which reduces the efficiency of heat transfer and leads to accidents.

Solubility in water. This is the ability of some substances to form homogeneous (homogeneous) systems with it. Aqueous solutions, as a rule, have the most optimal properties in terms of the efficiency and safety of the heating system.

Safety and environmental friendliness. This is a general characteristic that determines the ability of a substance to negatively affect the body of living beings and the environment as a whole, causing their poisoning and pollution, respectively. It determines in which areas this or that type of coolant can be used.

Comparison of the most common coolants in heating systems

Let us characterize the most common types of coolants used in industry, urban and housing services.

Water. The most common, cheap and accessible coolant. Its advantages are:

Thanks to these advantages, water and water steam are used in centralized heating systems in urban areas, multi-story buildings, administrative, industrial, and public buildings. Its disadvantages include:

Glycol solutions. They are homogeneous mixtures of ethylene or propylene glycol with water, which have the following advantages:

The disadvantages of glycol coolants include:

Glycerin solutions. Historically, the first coolant with antifreeze, which appeared at the beginning of the last century. Then the spread of glycerin coolants was facilitated by:

The gradual abandonment of glycerin solution in favor of glycol coolants was due to:

Today, water and aqueous solutions of glycols are the main coolants used in domestic, industrial and municipal heating. These substances have optimal characteristics that make their use not only effective, but also relatively inexpensive.

Source

How to determine the volume of coolant?

The easiest way is to use a water meter or water flow meter. There is one in almost every house or apartment with a centralized water supply.

Before starting measurements, the heating circuit must be completely emptied. Then readings are taken on the meter, and the system begins to be filled with a small pressure of water. This is necessary to avoid air pockets that distort the readings.

As soon as the heating pipeline is filled with water, you need to take the water meter readings again. You need to remember that 1 cubic meter is 1000 liters, and purchase the appropriate amount of liquid.

The second method is less convenient, but effective when there is no counter. The filled system is emptied through a measuring container (tank or bucket of a certain volume). The main thing is not to go astray with the number of buckets.

Another method is mathematical. The values of the volumes of radiators and expansion tank, pipe diameters, and the volume of the boiler heat exchanger are taken as initial data. Using simple geometric and arithmetic formulas, you can calculate the final volume.

We looked at detailed examples of calculating each of the elements of the heating system in our following articles:

- Calculation of pipe volume: principles of calculations and rules for making calculations in liters and cubic meters

- Expansion tank for open type heating: device, purpose, main types + tips for calculating the tank

How to fill the system: types of coolants and their parameters

The operating principle of most modern heating systems for apartments and private houses requires the presence of a coolant (agent, working fluid). This is the substance through which thermal energy flows from the source to the consumer. Liquids or gases are used in this capacity, but they all have their advantages, but they all also have disadvantages. In order for owners to be able to choose the best option, they first need to consider the main types of coolants and their parameters. Since the Russian climate in many regions is quite harsh, the demands placed on them are serious.

For example, a project for a one-story house of 100 m²

To clearly explain all the methods for determining the amount of thermal energy, we suggest taking as an example a one-story house with a total area of 100 square meters (according to external measurements), shown in the drawing. Let us list the technical characteristics of the building:

- region of construction – temperate climate zone (Minsk, Moscow);

- thickness of external fences – 38 cm, material – sand-lime brick;

- external wall insulation – foam plastic 100 mm thick, density – 25 kg/m³;

- floors – concrete on the ground, no basement;

- ceiling - reinforced concrete slabs, insulated on the cold attic side with 10 cm foam plastic;

- windows – standard metal-plastic with 2 glasses, size – 1500 x 1570 mm (h);

- the entrance door is metal 100 x 200 cm, insulated from the inside with 20 mm extruded polystyrene foam.

The cottage has half-brick (12 cm) interior partitions; the boiler room is located in a separate building. The areas of the rooms are indicated in the drawing, the height of the ceilings will be taken depending on the explained calculation method - 2.8 or 3 m.

A little about heating systems

A heating system is a set of related elements whose purpose is to receive, transport and transfer heat to rooms. There are three main structural elements in any heating system.

The movement of heat through the pipeline is ensured by a coolant - a liquid or gaseous medium. The first medium is water or non-freezing liquid, the second is air, steam, fuel combustion products.

Calculation of system resistance and selection of circulation pump

When calculating the hydraulic resistance of a heating system, the option of natural coolant circulation along its contours is excluded. We consider only the case of forced passage of an extensive network of heating pipes along the thermal circuits. In order for the system to operate with a given efficiency, a sample pump will be required that will certainly guarantee the required pressure. This value is usually presented as the volume of coolant pumped in a selected unit of time.

To determine the total amount of resistance caused by the adhesion of water particles to the internal surfaces of pipes in the mains, the following formula is used: R = 510 4 V 1.9 / d 1.32 (Pa/m). The V sign in this relationship corresponds to the speed of the flow. When carrying out independent calculations, it is always assumed that this formula is valid only for speeds of no more than 1.25 meters/sec. If the user knows the current consumption of hot water, it is possible to use an approximate estimate to determine the internal cross-section of polypropylene pipes.

Upon completion of the basic calculations, you should refer to a special table, which indicates the approximate cross-sections of pipe passages depending on the figures obtained during the calculation. The most difficult and time-consuming procedure is to determine the hydraulic resistance in the following sections of an existing pipeline:

- in the areas where its individual elements meet;

- in valves serving the heating system;

- in valves and control devices.

After all the required parameters regarding the operating characteristics of the coolant have been found, we proceed to determining all other indicators of the system.

Coolant and requirements for it

In winter in Russia it is impossible to live without heating. In our country, as a rule, liquid (water) heating is most common. In such a heating system, water or a special non-freezing liquid is used. When choosing a substance for heat transfer, several important requirements are imposed on it. The first of them is the ability to accumulate and then transfer thermal energy over a given distance. However, there are other criteria.

Last but not least are the characteristics: long service life, reasonable price. Since simple water meets all the requirements, it still remains the most popular coolant, but even this liquid has weaknesses. However, there are no ideals, so home owners have to choose the liquid that, despite all its shortcomings, will be a compromise for a particular heating system.

Heat transfer fluids based on propylene glycol

Propylene glycol compositions and cooling liquids, the mass distribution of which is limited by the expensive basic working component - propylene glycol, have become widespread with the introduction of coolants in food production technologies, as well as in the pharmaceutical industry. Their main advantage over ethylene glycol is that they are safer for humans and the environment.

The following main characteristics can be distinguished:

- does not cause poisoning, aqueous solutions of propylene glycol are explosion- and fire-proof and, accordingly, their vapors practically do not contain the basic active component;

- suitable for heating residential buildings and public buildings;

- has low chemical aggressiveness;

- suitable for materials, and primarily equipment made of metals, on which corrosion occurs upon contact with water;

- prevents water hammer and has a good lubricating effect.

The disadvantages characterizing propylene glycol coolants include:

- the need for replacement every 5 years, coolants with a standard set of additive packages. To increase the period of reliable operation, it is necessary to use a package with carboxylate additives to obtain the “Carbo-ECO-TEN” trademarks;

- high cost;

- at subzero temperatures, coolants have a high viscosity and at the same time are characterized by increased fluidity, so they can easily penetrate through loose connecting parts of the heating system (even where water does not seep through).

Types of coolants and their parameters

The choice of coolant is a primary task, since the appropriate heating system is designed in accordance with it. For this reason, it is necessary to take a closer look at the types of coolants and their parameters, the advantages and disadvantages of the most popular compositions.

Water (SP-V)

It remains a leader, the liquid is universal and available everywhere. It accounts for approximately 70% of all heating systems.

Advantages and disadvantages

A huge advantage of such a coolant is its absolute environmental friendliness. Other benefits of water:

Despite the fairly large list of advantages due to which water is used everywhere in systems, it has several disadvantages. This:

It is possible to combat the “imperfections of ideal” water. To reduce the growth of deposits, use boiled, softened or distilled water. An alternative is to purchase special additives. Such “water-bearing” pipelines and radiators require annual flushing, and the boiler requires scheduled maintenance. During the heating season, it is necessary to adjust the specific resistance of the liquid.

Distilled water

A fully purified liquid is an ideal component for any coolant, since running water contains a large number of substances that negatively affect the elements of the heating system. The distillate has the following characteristics:

The optimal temperature in the heating system is 75°, but this parameter depends more on weather conditions.

Glycol-based antifreezes

In some heating systems, it is necessary to use more reliable antifreeze - coolants that freeze at very low temperatures. In this case, persistent liquids have advantages over water, but there are also disadvantages: in some types they are quite significant.

The main disadvantage of antifreeze is lower heat transfer. They are much inferior to water in this indicator: the difference is 15%. In order to ensure sufficient heating of the premises, owners will have to purchase more radiators. Automatic air vents do not “know how” to work with these liquids, but there is an alternative option - Mayevsky taps.

Another feature of these coolants is their high coefficient of thermal expansion, if this water parameter is considered the standard. Therefore, if the choice is made in favor of antifreeze, then a larger volume of the expansion tank is a prerequisite. How big? Almost twice as much when compared with a heating system that uses water. Radiators and pipes for “anti-freeze” systems must also have a significant volume and diameter.

Ethylene glycol (OC)

Special additives are introduced into the coolant - inhibitors, which reduce the rate of chemical processes in the heat pipeline and in the system as a whole. Ethylene glycol antifreeze is used for automotive heating/cooling systems and for heating rooms not intended for residential use. Disadvantages of this antifreeze:

Antifreeze

So, if you have chosen antifreeze, then you should know that it should not be easily flammable, and it should not contain poisonous or toxic substances.

Important! Do not use antifreeze, ethyl alcohol or transformer oil as a heating fluid! After familiarizing yourself with safety precautions, you will find out for yourself that only those substances that were specially created for this purpose should be used for heating. It is advisable to use a special certified antifreeze, for example, dixis 65 is very popular today. Often, all coolants of this type are made on the basis of two substances:

It is advisable to use a special certified antifreeze, for example, dixis 65 is very popular today. Often, all coolants of this type are made on the basis of two substances:

- Propylene glycol.

- Ethylene glycol.

Selection of coolant

Potential types of coolants and their parameters must be studied before installing the heating system. Choosing the optimal option in advance will help determine the type of suitable boiler equipment and the characteristics of the future pump.

Features of antifreeze

If we talk about antifreeze coolants, they can be called less active participants in heat exchange. For this reason, they require more powerful radiators and pumping equipment.

Compatibility of antifreeze and batteries is the next prerequisite. Since there is always a risk of dangerous chemical reactions, it is not recommended to purchase galvanized pipes. Even special additives in the product will not protect against aggression towards this element of the well-known table.

Another feature of a system working with antifreeze is the need to change the working solution. Any antifreeze needs such an operation after some time, and its frequency depends on the type of liquid used.

Factors to consider

The types of coolants and their parameters need to be studied in order to know the features of a particular composition. Since there are no ideals, the choice depends on the operating conditions of the heating system, on how much the owners are willing to sacrifice.

Home maintenance

If the building is planned to be used year-round, and not intermittently, then the most rational, practical option would be to use ordinary water as a coolant. But even in this case, all potential problems must be considered.

For example, when a building is located far from civilization, power outages may not be the exception, but the rule. In a harsh winter, such an “unpleasant surprise” can be costly: a few hours will be enough for the water to freeze. The consequence will be an accident: the crystallized liquid will rupture the pipeline and/or radiators.

When the cottage is not used constantly, or the owners often go on business trips, the main condition becomes the versatility and all-season availability of the coolant. But in this case, the system must be as reliable as possible, since antifreeze can be toxic and explosive. Due to their fluidity, they are able to find a loophole even where ordinary water will not pass.

Equipment Features

Manufacturers of some boiler models recommend using a certain type of coolant, so owners are required to follow this rule. Otherwise, by choosing the “wrong” fluid, they risk losing all legal rights: both to repair and to warranty service of the unit.

What could be the consequences of narrowing the diameter of the heating pipe?

Narrowing the pipe diameter is extremely undesirable. When wiring around the house, it is recommended to use the same standard size - there is no need to increase or decrease it. The only possible exception would be a large length of the circulation circuit. But even in this case you need to be careful.

But in this same situation, it turns out that the residents who made such a replacement of pipes automatically “stole” approximately 40% of the heat and water passing through the pipes from their neighbors in this riser. Therefore, it is worth understanding that the thickness of pipes that are arbitrarily replaced in a heating system is not a matter of private decision; this cannot be done. If steel pipes are replaced with plastic ones, no matter how you look at it, you will have to widen the holes in the ceilings.

There is such an option in this situation. When replacing risers, you can pass new pieces of steel pipes of the same diameter into the old holes; their length will be 50-60 cm (this depends on such a parameter as the thickness of the ceiling). And then they are connected with couplings to plastic pipes. This option is quite acceptable.

Characteristics of water as a heat conductor

Many heating systems are filled with water as a working medium - the most accessible and versatile coolant. It is freely available, and its reserves in nature are regularly renewed. Up to 70% of heating systems are filled with natural liquid.

The popularity of water is due not only to its availability, but also to environmental safety. Also among its positive features are high density and specific heat capacity. An important performance characteristic is low chemical activity, good heat transfer coefficient, minimal viscosity. Water meets all these requirements. If necessary, its heating temperature can be adjusted.

Among the characteristics of natural liquid, there are also disadvantages. These include:

- low upper heating limit (temperature maximum in the heating system up to 150 °C);

- freezes at 0 °C, turning into a crystalline form with a significant increase in volume, which leads to the destruction of equipment and pipelines of heating systems;

- the possibility of corrosion processes with the formation of metal oxides (rust) and destruction of equipment surfaces;

- scale formation on pipeline surfaces when heated to 80 °C.

If water freezes in the pipes in winter, the entire heating system may become unusable. Often rust and deposits appear on metal pipes and fittings. To minimize the risk of their occurrence, distilled water is used or special additives and alkalis are added to process water.

Heating devices where water serves as a coolant require regular maintenance - flushing heat exchangers and pipelines, periodic boiler repairs, and adjustment of resistivity during the heating season.

What to consider when planning heating

When choosing the most suitable type of heating system, you should definitely take into account the area of the house

This is important because, for example, a single-pipe system with natural circulation works well only in houses whose area does not exceed 100 m2. But in a house whose area is much larger, it will not be able to function due to its rather large inertia

Thus, a preliminary calculation of the pressure in the heating system and planning of the heating system are necessary in order to find and design a system whose use in the house will be most effective. At the preliminary planning stage, it is necessary to try to take into account all the architectural features of the building. In particular, if the building is large enough and, accordingly, the area of the premises that need to be heated is also large, the most appropriate is to introduce a heating system with a pump that will circulate the coolant.

That is, for longer operation of this type of equipment, it should be installed on a return circuit, through which the already cooled coolant is returned to the boiler for reheating.

In this case, there are certain parameters that the circulation pump must meet:

- long service life;

- low energy consumption;

- high power;

- reliability;

- ease of operation;

- noiselessness and absence of vibration during operation.