In order for the heating system to maintain its efficiency and performance for as long as possible, it must be flushed periodically. This simple event allows you to remove scale and various types of debris from the system elements.

Flushing and pressure testing of the heating system

According to the rules, flushing the heating system must be carried out by specially trained people. But if you wish, you can do this yourself. Read the provided guide and get started.

Flushing and pressure testing of the heating system

What is flushing and pressure testing of a heating system?

Flushing the pipes is necessary for the normal operation of the heating system.

Work to prepare and resume the uninterrupted functioning of the heating guarantees trouble-free flow of the coolant.

Flushing

If the radiators in your apartment begin to heat worse than before, there are several reasons:

- poor boiler performance;

- pump failure;

- airing of pipes.

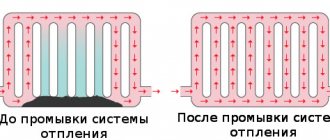

Over many years of operation, debris, scale particles, and rust accumulate in pipes, heating devices, and collectors. Growing inside, they clog the passage hole for the coolant; the porous structure reduces the heat capacity of the metal parts of the heating devices.

Consequences of blockages:

- burnout of the heat exchanger, requiring its replacement;

- temperature difference in batteries;

- noise in the pump with subsequent failure;

- boiler breakdown.

To eliminate and prevent contamination, washing is performed.

Mineral deposits can completely block the movement of coolant

A decrease in heating efficiency occurs for 2 main reasons:

- The appearance of mineral deposits. Non-galvanized pipes readily accept calcium and magnesium salts on the surface. Such problems do not arise with galvanized pipes.

- Sludge growth in pipe sections with low coolant flow rates. Multi-section cast iron radiators are susceptible to this phenomenon. The dependence is proportional to the increase in volume and number of sections.

People do cleaning of simple appliances and heating pipes in private homes on their own. This is easy to do if you have the knowledge and equipment. It is better to entrust heating systems and radiators in apartment buildings to professionals who are responsible for their work and provide a guarantee.

There are 2 ways to clean the system:

- special hydropneumatic equipment;

- chemical reagents.

The basis of chemical reagents is acid.

Crimping

This procedure is designed to check the hydraulic system for weak points. Tests are carried out using overpressure water circuit or pneumatic method.

Installation estimate for heat supply

This selection of components for the future heating system is one of the most important. In practice, problems begin at the stage of selecting the main components of the system - the boiler and radiators.

In an effort to save as much as possible, the cheapest models are purchased. However, their nominal characteristics do not correspond to the calculated ones. As a result, this leads to a significant decrease in system efficiency.

How to avoid such a situation? It is necessary to correctly calculate the costs of organizing heat supply. To do this, you will need an estimate for the installation of heating and the purchase of components. Its correct compilation is only possible if you follow these recommendations:

- Calculation of heating depending on the current parameters of the building (heat losses), type of energy carrier (gas, solid fuel, diesel, etc.). The required heating power for each room in the building is also calculated.

- Based on the data obtained, a list of equipment is compiled - heating boiler, radiators, safety group (air vent, expansion tank, thermostats) and pipelines. The type of the latter largely influences the heating installation estimate. Polymer lines can be installed independently, while steel lines are installed with the help of specialists.

- Market monitoring is carried out, as a result of which heat supply components that are optimal in cost and technical characteristics are selected.

- The cost estimates for the installation of the heating system are filled in: the cost of equipment, transportation costs and installation work.

Accepted samples of heating estimates may have different formats. The main thing is that it is convenient for the compiler to fill them out and subsequently use them as the main financial document for planning purchases.

When involving third parties (organizations) in the installation of heating, it is necessary to agree in advance on all items of the estimate in order to avoid further inconsistencies, both financially and technically.

Equipment for work

To clean the pipes, a pump with a hydropneumatic nozzle is required.

In-place flushing of engineering heating systems with chemical reagents is carried out using an eliminator with manual or automatic reverse. There are imported and Russian samples on the market, differing in pumping volume, type of reverse and other functions. The work is carried out using a washing reagent. Then the action of washing with the neutralizing solution is stopped. Electrical devices create excess pressure and force the chemical solution through.

For hydropneumatic cleaning, you need a pneumatic pump capable of reaching a pressure of up to 6 atm. and higher.

A hand pump is a cuvette with a plunger pump located on the side and a drive handle. Shut-off valves cut off water after heating is filled, others are used to drain the coolant from the device. The plunger pump raises the pressure to 60 bar. The disadvantage when used in private homes is that it takes many hours of work and requires a lot of muscular energy.

Professional washers use automatic devices. They set a pressure limit, upon reaching which the automation turns off the unit. Professional models maintain a pressure of 40-100 bar. Industrial pressure testing stations produce up to 1000 atmospheres.

Test procedure

According to the rules for the technical operation of thermal appliances, tests should be carried out in the following sequence:

- The circuit is filled with water using a pressure tester. The temperature of the liquid should be about 45 degrees. The air must be vented through special vents.

- Next, water is pumped under pressure for at least 10 minutes. During this time, you need to visually inspect all seams, pipe joints, connections of all equipment, and fittings.

- Afterwards, the pressure can be brought to maximum pressure and maintained for 10 minutes. If the pipes are made of polymer materials, then the tests should be carried out for at least half an hour.

- If the pressure does not change during the tests, then we can judge that there are completely no defects.

You can complete the tests and begin directly operating the equipment.

Stages of crimping

The work is carried out at the following frequency:

- when starting a new system;

- annually after the heating season;

- after flushing or repairing the heating main with replacement of pipes.

For apartment buildings, preparation is as follows:

- Inspection of shut-off valves in elevators, central pipes, risers. On cast iron valves, the seals are changed, the paronite gaskets between the connection flanges are renewed, and unusable bolted connections are replaced.

- Using visual observation, pipes and fittings are examined for the presence of cracks, chips, corrosion, and defects. Make repairs if necessary.

- Check the thermal insulation of risers and main pipes in basements.

Pressure testing after pressure cleaning is necessary to identify possible leaks.

Pressure testing procedures and testing are carried out taking into account the parameters of heaters and heating equipment indoors. Regulations allow the use of operating pressures of up to 6 bar for cast iron heating radiators. When they are in the walls, the maximum is 10 bar.

Hydraulic tests are carried out as follows: the system is checked as a whole, then a pressure higher than the working one is applied to the thermal unit.

According to Rules 115 clause 9.2.13., tests are carried out at a pressure not lower than:

- 1 MPa - elevators, heaters for heating and hot water systems;

- 0.6 MPa - cast iron and steel heating radiators;

- 1 MPa - convector, panel heaters;

- working pressure plus 0.5-1 MPa for hot water supply;

- pressure recorded in the manufacturer's instructions for air heaters.

The test pressure in steam systems is selected by the manufacturer from maximum to operating minimum:

- minimum - not lower than 0.2 MPa, but not less than 1.25 working;

- the maximum is established by strength calculations according to standards;

Crimping occurs at temperatures from + 5 degrees. If negative - in emergency cases.

If there is no visible leak, but the pressure drops, the pressure gauge shows problems in hidden places

Crimping stages:

- Filling the system with cold water. During work, the temperature of the liquid is no more than 45 degrees. The pressure increases gradually. Control is carried out using a pressure gauge.

- Once the set pressure is reached, the system remains at rest for about 30 minutes.

- During downtime, an inspection is carried out for leaks in pipes and batteries. Make sure there are no leaks. A method of control is to place toilet paper in dangerous places or wrap pipes with it. When there are leaks, spots of water and silt are visible.

- Control occurs according to the readings of the pressure gauge. The leak occurs in a place inaccessible to observation. A drop in pressure will warn of this.

Upon completion of pressure testing, a certificate of fitness for use is issued.

Tests are carried out by certified companies. In apartment buildings, it is prohibited to carry out heating work yourself. This is done by employees of operating organizations - housing office, management company, housing department, REU. They are required to undergo annual certification at MOEK.

Diagnostic methods

- Water testing is the main method by which all circuits are tested. In this case, water should be pumped into the lower part of the pipes through a tap. It is possible to pump liquid using both automatic and manual pressure testing pumps. The advantage of this method is that it is very simple to complete all the work, and the efficiency of leak detection is high. The fact is that traces of liquid will immediately appear on the pipes.

- Testing with air is not a very effective method, since it is quite difficult to detect leaks. But it is permissible to use this technique at subzero temperatures – the air will not freeze. A compressor is used to force air into the system. It is connected using an adapter to the pipeline. In order to find the leak, you need to listen. Once you find the approximate location of the leak, use a soap solution.

Flushing heating systems

The accumulation of silt and scale in pipes and radiators reduces the quality of heating - just 1 mm of scale reduces the heat transfer of the device by 15%. To normalize the temperature in the house, you will have to increase the heat output of the boiler, which means additional fuel and labor costs. Lime is essentially a heat insulator. Its thermal conductivity is 40 times lower than the metal composition. Therefore, even a thin layer leads to a decrease in heat transfer by the coolant. Scale is aggressive. It interacts with the metal and leads to increased corrosion. The aggressiveness of scale creates fistulas and corrodes welds over several years.

In an apartment building

In an apartment building, flushing is done with a chemical solution to remove scale.

The hydropneumatic method of flushing the heating system is constantly used by utility workers. If you follow the technology, this is an effective way.

The principle of operation is simple - first the water is discharged, then it is supplied back to the heating system by pumps. Under the influence of the coolant flow, scale flakes peel off and come out along with the water when drained.

Step by step sequence:

- Before work, all taps are turned off.

- The end caps of the heating batteries are unscrewed using a special key.

- The return valve closes.

- The air pump is connected to the valve located after the valve.

- The return is reset.

- A pressure of over 6 atm is injected into the pneumatics.

- The valve to which the pneumatic equipment is connected opens.

- The risers are blocked one by one. Up to 10 pieces at a time - this will make the washing procedure effective.

The next step is to switch the system to reset in the opposite direction:

- The discharge closes, the valve connected to the device is closed, and the pneumatics are turned off.

- The open valve is retracted, after which a similar one on the return line is opened.

- The water is discharged - the pneumatic pump is connected through the valve in the opposite direction, the valve opens, and the pneumatics turns on. The liquid will flow in the reverse direction.

The productivity of cleaning is determined visually - if clear liquid begins to come out, washing can be completed. The dirt is poured into the prepared dishes. If possible, a hose is connected and the dirty coolant is discharged into the sewer.

In a private house

Rinsing in a private home is necessary if plain water with hard salts is used.

Rinsing in a private home is difficult to do with your own hands, but it can be done by reading the instructions. Produced in two ways:

- Flow method. Cleaning from slag and deposits using this method involves completely filling all devices with coolant while leaving the air vent valve open. After filling, the valve closes. Simultaneously with the supply of compressed air, the drain hole opens. The water-air mixture continues to flow until clean water appears. The amount of flushing liquid is 3-5 times greater than the working value. Therefore, prepare drainage containers or drains in advance.

- Flushing with filling. The system fills with the valves closed. Air is supplied under pressure for a period of 5-10 minutes. into the inlet pipe, while the outlet is closed. After the end of the compressed air supply, the flushing is drained along with dirt and scale.

The volume of supplied liquid and air is calculated individually. An incorrect calculation will lead to numerous pipe breaks rather than flushing.

In private homes, collectors, shut-off valves, boilers, boilers, joints with appliances, electric circulation pumps, and heated floors are checked.

There is no need to buy washing equipment - it is rented. If it is necessary to draw up official papers and a test report, a special team is called. The estimated cost of services is 1000–2600 rubles/hour.

Is it possible to wash a separate battery?

Now you know how to flush the heating system. However, sometimes it becomes necessary to clean a separate battery. There is a solution for this situation too.

Heating battery cleaning scheme

Important! Flushing a separate heating radiator must be done strictly before the start of the heating season.

Buy a flushing faucet from a plumbing store. Additionally, you need to purchase a rubber hose and a fitting with a thread that matches the diameter of the purchased flushing valve. Install the fitting onto the hose.

Direct washing is carried out in the following sequence.

First step. We connect the flushing tap to the heating radiator.

Second step. We connect a fitting with a hose to the flushing tap.

Third step. We direct the second end of the rubber hose into the toilet.

Fourth step. Open the flush tap and leave for 20-30 minutes. While waiting, hold the hose so that it does not jump out of the toilet.

Important! Although it is recommended to flush individual batteries strictly before the start of the heating season, in some situations the need for flushing arises when heating is in full swing. If this is your case, insert the hose deeper, directly into the riser. Otherwise, the hot coolant may destroy the toilet.

Video - Flushing a heating radiator

Table for selecting reagents for flushing the heating system

Prices for popular models of heating radiators

Heating radiators

Preparation for hydrotesting

4.1.1. Products and their elements subject to hydrotesting must be accepted by the quality control service based on the results of external inspection and non-destructive testing.

The test pressure value for the product should not exceed the maximum permissible pressure value for which the hydraulic stand is designed.

4.1.2. Fasteners and seals used during hydrotesting must be made of materials specified in the working drawings for the product.

4.1.3. Instrumentation, safety devices, fittings, plugs, fasteners, gaskets, etc. must be selected according to the marking for a pressure not lower than the test pressure.

4.1.4. When installing the test product on a hydraulic stand on standard or technological supports, its stable position, free access for inspection and the location of drainage holes (“air vents”) must be ensured at its highest point.

The hydraulic testing scheme, technological process and equipment must ensure complete removal of air when the test product is filled with working fluid.

4.1.5. Installation of communications, installation of the required fittings, instrumentation must be carried out in full accordance with the approved hydrotesting scheme.

All free openings of the product under test must be plugged.

Installation, equipment and inspection of the product at a height of more than 1.5 m should be carried out from special platforms (scaffolding).

4.1.6. When installing flange connections, the threaded elements must be tightened evenly, alternately tightening diametrically opposite ones (“crosswise”), maintaining parallelism of the flanges.

It is prohibited to use wrenches that do not match the size of the nut, non-standard ones and/or with an extension of the handle, as well as a hammer or sledgehammer.

4.1.7. When preparing a working fluid using phosphors, preservatives, as well as when applying indicator coatings to the controlled surfaces of the test product, a general supply and exhaust ventilation system must be turned on at the hydrotesting site.