- July 16, 2020

- Tools and equipment

- Daisy Angel

Relatively recently, the building materials market has been replenished with a new product. Foil insulation today is widely used for noise, hydro and thermal insulation of ceilings, walls, facades and roofs. This material can be used for finishing partitions, baths and pipelines. If you are interested in knowing what foil insulation is called, you should first understand the main types of this thermal insulation.

This is a combined thermal insulation covered with foil, which can be based on different materials. The aluminum component reflects heat, leaving it inside the building. Some studies claim that the reflection effect is as high as 97%. Modern insulation of this kind is thin and has water-repellent characteristics. They don't get damp.

Main types and characteristics

If you, like many consumers, are wondering what insulation with foil is called, you should know that it can be based on different materials. This should include:

- mineral wool;

- expanded polystyrene;

- basalt wool.

There are a huge variety of foil insulation products on sale today. They differ not only in characteristics, but also in application features. When asking yourself the question of what the insulation with foil is called, you should know that if it is based on polyethylene foam, then this name in the store will sound like this: foil polyethylene foam.

This product is sold in rolls, and the layer thickness can vary from 2 to 10 mm. Polyethylene has a foil layer on one or both sides. You can find self-adhesive options. On one side there is an adhesive layer, as well as a protective film. This insulation is used when finishing floors, ceilings or walls, as well as arranging ventilation systems.

Using polyethylene foam foil insulation, you can equip a heated floor, arrange a finishing base for linoleum, or organize thermal insulation in a bathhouse. This material can also be used to create shoe insoles. There are different types of such insulation on sale. If you are interested in knowing what insulation with foil based on polyethylene foam is called, then you should know what to look for in the store:

- ecofol;

- isolon;

- penofol.

The price will depend on the thickness of the insulation.

Advantages of insulating material with foil

Foil insulation has many advantages that other materials often lack. It is these “advantages” that make insulation with foil stand out against the background of a wide variety of insulation products:

- Increased ability to reflect heat. Foil is a wonderful reflector that can repel about 95% of thermal radiation, keeping the house warm and keeping the heat out. By the way, it is for this reason that protective suits for firefighters are made from foil insulation.

- Waterproofing. Foil is a hydrophobic material that repels moisture.

- Ease of use. Foil insulation has a cellular structure, due to which it not only insulates well, but is also easy to install.

- Isolation from external influences. Foil insulation does not allow wind and moisture to pass through, does not freeze in winter and does not dry out in the hot season.

- Noise absorption - the use of insulation with foil allows you to achieve silence in the room and significantly reduce the amount of noise coming from outside.

- Health safety and environmental friendliness. Foil has no harmful effects on the human body, does not emit potentially hazardous substances and does not harm the environment.

- Durability. Reflecting all external influences, the foil can serve for a long time without any signs of rust, rotting or corrosion.

- Elasticity. The foil material can be easily given any desired shape.

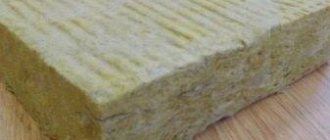

Minvata

This material has a foil layer on only one surface. The product is produced in the form of slabs or rolls. The layer thickness here is slightly greater, and the minimum value is 5 cm. Basalt wool or fiberglass can be used for production.

If you want to know what shiny wall insulation is called, then you should know that in this case we are talking about foiled mineral wool. It has limitations in its use, since cotton wool can negatively affect health. This insulation is used in non-residential premises or for exterior decoration. The products have certain properties that are suitable for thermal insulation of baths, ceilings and walls.

Features of installation of foil insulation

Before purchasing, measurements are taken and the required quantity is calculated based on the fact that the insulation will be fixed not overlapping, but end-to-end. The question of how to properly lay insulation is solved in the same way for both types of metallized coating. When insulating walls, adhere to the following rules:

- Foil thermal insulation is laid with the reflective (shiny) side inside the room.

- Double-sided material is intended for thermal insulation of frame buildings.

- Installation on walls includes the organization of sheathing, the slab insulator is fixed in it between the guides and is additionally strengthened with dowels.

- Installation on the ceiling is carried out using a stapler. The joints are sealed with metallized tape or aluminum adhesive tape. Between the insulation and the final finish, a gap of 2-2.5 cm is created for ventilation.

Fixing joints Source krovlyaikrysha.ru

Application area

Foil insulation is represented by different base materials, which determines the area of their use. For example, foamed foil polyethylene is a self-adhesive material that is used in technological equipment to create a heat-insulating layer in air ducts and pipes.

If you are interested in knowing the correct name for foil insulation, you should pay attention to its base. If it is mineral wool, then this is its foil version. It is available in the form of rolls, cylinders and slabs. Mineral wool has a high degree of fire resistance, so it is widely used for insulation:

- walls;

- saunas;

- chimneys;

- baths;

- roofs

If you see foil polystyrene foam with double-sided coating, you can be sure that the material is resistant to temperature fluctuations over a wide range, which is why it is most often used when constructing heat-insulating layers in heated floors. If you need to insulate the space under the roof, foil polystyrene foam is perfect for you.

Basalt foil insulation is more resistant to aggressive environments than all other types of foil insulation. The properties of this thermal insulation do not change even when exposed to large temperature differences - from -190 to +600 °C. Foil-coated basalt thermal insulator is used in aircraft manufacturing, the heat and power industry and in the construction of gas stations.

Selection of materials

There is a wide range of insulating materials for heat supply lines on sale. To make the right purchase, it is necessary to take into account the characteristics of the room, its parameters and the operating conditions of the heating system.

The main factors influencing the choice of insulation:

- location of the pipeline that needs to be insulated;

- temperature of the coolant moving through the pipes;

- characteristics of the heating main;

- basic properties of materials intended for pipeline insulation.

When choosing, first of all take into account the following performance characteristics of insulation:

- heat resistance;

- thermal conductivity;

- fire safety;

- moisture resistance;

- thickness;

- resistance to decay and microorganisms;

- cost of installation work.

When purchasing materials for pipe insulation, you need to remember that the lower their thermal conductivity, the higher the thermal insulation performance. The degree of moisture resistance is reflected in the quality of protection of metal pipelines from corrosion processes and condensation formation.

The fire resistance of heat insulators must comply with fire safety requirements for heated premises. To calculate the thickness of the material used, special formulas are used.

Why else should you choose this insulation?

Now you know what shiny insulation is called and what its varieties are. Despite the fact that there are differences in the compositions of these materials, they are united by certain technical characteristics, namely:

- moisture-repellent properties;

- high efficiency;

- heat reflection;

- resistance to temperature fluctuations;

- high vapor permeability;

- high sound insulation properties.

As for vapor permeability, this figure is 0.001 mg/(m h Pa). You may also be interested in the ability of the material to reflect thermal radiation. The average thermal conductivity is 0.037 W/(m °C). As for sound insulation properties, sound absorption can reach 68 percent. Foil is also good because it protects the types of insulation materials presented with it from radon and solar radiation. Thermal insulation materials of this type do not require treatment with chemicals, which has a positive effect on environmental cleanliness.

Penofol: application, types and characteristics of the material

Thanks to insulation with foil, it has become possible to protect the house from vapor and liquid moisture. This thermal insulation may consist of polyethylene foam. The two components are connected to each other thanks to thermal welding.

If you are still wondering what insulation with foil on one side is called, you should pay attention to penofol. One-sided foil protection is designated in the specifications by the letter “A”. Such thermal insulation can have a thickness from 0.2 to 4.4 mm. If necessary, you can purchase a foil type of penofol 10 mm thick.

The material is used for external and internal insulation of walls of buildings for various purposes: hangars, attics and basements, heated and unheated warehouses, children's, medical institutions and trade pavilions. If you are interested in knowing what foil insulation for floors is called, you should know that penofol is excellent for this purpose.

Self-installation of thermal insulation

Work on insulating heating pipes using thermal insulating polystyrene foam shells is carried out as follows:

- The halves of the material are put on the pipe and their displacement relative to each other is ensured - this is required for an overlap measuring 10–20 centimeters.

- The half-cylinders should be secured in advance with tape. If a surface protective layer needs to be applied, it is attached at the very end.

- To ensure that the shell adheres more securely to the pipeline, the joints must be taped.

- When it is necessary to insulate heating pipes at turns in the main, shaped types of shells are used.

In many ways, the choice of materials for insulating heating system elements depends on the operating conditions of the heating main and its structural design. Thermal insulation work is simple and can be done by any home craftsman if desired.

Types of foamed foil polyethylene

This insulation is offered for sale in several varieties, which differ in letter marking. If you are wondering what foam with foil is called, you should know that it is polyethylene foam. If you see the letter “A” in the marking, you should know that this is a material with a one-sided coating; it is used with other types of insulation, for example with foam plastic.

The type marked “B” has a double-sided foil coating and is used exclusively independently. If you see materials marked “C”, then this is insulation, on one side of which there is foil, and on the other, polyethylene foam itself with a moisture-resistant contact adhesive mixture. The material can be used without the use of installation tools.

Once you know what insulation with foil and foam rubber is called, it’s time to get acquainted with the main pros and cons of this material. Among the advantages should be highlighted:

- safety and resistance to rodents;

- ease of transportation;

- fire safety;

- ease of installation;

- excellent sound insulation characteristics;

- small thickness.

Nuances of fastening and installation

Installation of insulation is not difficult; it is easy to cut and install. The work on the outside and inside is almost the same.

Main nuances:

- the surface on which the insulation is placed must be clean;

- the material is straightened so that it is smooth, without wrinkles;

- foil prevents heat from escaping, so it is laid with the outer side up;

- the insulator is glued end-to-end, the joints are taped;

- If the insulation does not have a self-adhesive layer, use special glue.

It is important that the glue used for fastening does not emit harmful substances and holds the material firmly.

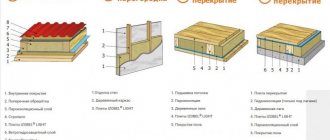

Walls

The slabs are mounted using dowels on vertical surfaces.

Installation of insulation to the wall must be thoroughly thought out. An air gap is left between the material and the subsequent finishing to avoid condensation.

- The membrane is fixed and the insulator is rolled out on top of it.

- The material is fixed with slats. Their thickness should be greater than the main insulation.

- Along the edges of the slats, the insulator is connected with staples.

- The panels are finished over the slats; their thickness provides the necessary air gap.

When insulating with mineral wool, a film is laid to prevent steam and moisture from getting inside.

Floor

The joints are sealed with aluminum tape.

Warm floors, regardless of whether the base is wooden or concrete, are made the same way.

- Clean the floor of debris before applying insulation.

- Cover the base with a primer.

- After drying, roll out the insulation. The strips are laid overlapping and secured with construction tape. You can lay out a backing underneath the linoleum, which will make the floor much warmer.

- A finishing coating is applied on top of the insulating material.

If laying a heated floor is planned, the insulation must be laid with the reflective side up, then the reinforcing mesh, heating elements and finishing cladding.

The choice of insulation materials is quite wide. Each of them has distinctive characteristics. Application depends on which room needs to be insulated.

Minuses

But like every material, it has its drawbacks. Firstly, it is too soft, so it does not have the necessary rigidity. It is not suitable for finishing plastering work or subsequent wallpapering. When pressure is applied to the material, it will bend.

Secondly, sound insulation is quite difficult to attach, with the exception of type “C” with a self-adhesive surface. But to install such insulation you need to use different adhesive mixtures. You cannot nail the sheets, as you will worsen the thermal insulation efficiency.

Thirdly, the effectiveness and versatility of this thermal insulation does not allow it to be used for external buildings. The material can act as an additional layer and reflect incoming thermal energy. In addition, it can only protect the walls from moisture.

The main nuances of using thermal insulators

Before purchasing rolled insulation for heating pipes, you need to make sure that its performance characteristics allow the use of this material in an attic or basement.

When the insulation is rigid and made in the shape of a semicircle, it can be used for pipe products of a certain diameter. A distance of 25 millimeters should be left between the wall and aluminum foil.

The cost of a heat insulator is affected by the thickness of the reflective layer and the material from which its base is made. There is a significant difference between aluminum foil and aluminum coating. The latter option makes the functioning of the heat insulator less effective with low reflectivity.

It is not at all necessary to buy industrially produced foil pipe insulation. You can independently wrap the layer of thermal insulation laid on the pipe with foil if the pipeline is laid in the attic or basement. This material is produced in rolls or in the form of hollow tubes.

The foil is laid face up. A gap of 10-20 millimeters must be left between the foil layer and the pipeline.