They often try to solve the problem of heating a country two-story house by combining stove heating and installing additional heating devices. For example, when the first floor is heated by a fireplace stove, and electric convectors are installed on the second floor. Despite all the positive aspects of this solution, it has one significant drawback - in winter, when the first floor is heated, the second one remains cold. It is possible to heat a two-story house more efficiently by erecting a stove on two floors with one firebox, thus ensuring not only a comfortable temperature, but also significantly saving on fuel costs.

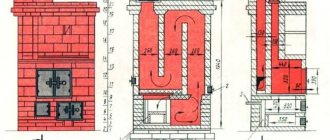

Scheme of construction of a single-fuel two-story furnace

Let's look at how to make a stove that extends over 2 floors. This is a very successful project - efficient and economical.

Construction of the foundation

Such a structure is much heavier than a conventional, single-tier one. Therefore, you need to take care of a strong foundation. It should be slightly larger than the stove base. Since the latter according to the project has dimensions of 900x900 mm, the dimensions of the “pillow” are 1000x1000 mm.

You will need:

- cement/sand/crushed stone;

- formwork boards;

- fittings;

- waterproofing material (for example, roofing felt).

The base can be either level with the floor or rise above it by several centimeters. The layout of the foundation is simple - first they make a sand cushion, then formwork is done and reinforcement is installed, and then the structure is filled with concrete.

After pouring, the foundation should be allowed to stand for about a month. Then the base is waterproofed. To do this, lay a roofing felt sheet - 1 or 2-3. Only after this is the heating stove laid out on two floors. The surface of the “pillow” must be strictly horizontal.

Construction of the furnace

For construction you will need high-quality materials and additional stove elements. The required quantities of both are presented in the tables.

Table 1. Masonry elements

Table 2. Additional elements

Masonry mortar is made from clay and sand. The ratio of components is from 1:1 to 1:2. It all depends on the type and quality of the clay. To determine the exact ratio, make several mortar balls or cakes with different proportions of the components. After this they are left to dry. Those balls that are not cracked demonstrate optimal parameters.

Layout diagram in rows (the numbers correspond to the row number):

- Attaches to the waterproofing layer. First it is laid out dry.

- A blower door is installed on the second and third rows.

- Installation of the firebox chamber. Fireclay bricks are used. The doors of the cleaning chambers are also installed here.

- An asbestos cord is installed on the sides of the bottom of the firebox. Afterwards a grate will be installed over it.

- Install the firebox door.

- From the 7th to the 10th rows - masonry according to the scheme.

- A corner is attached to the front part. Here the firebox is covered with a hob.

- From this to the 16th row, the cooking chamber is built.

- Mount corners that serve as support for solid brickwork.

- This and the next row are solid masonry. The integrity is violated by the three smoke exhaust openings indicated in the diagram.

- The door of the next cleaning chamber is mounted. The drying chamber is laid out along the 23rd row.

- A series of corners on which the chamber ceiling will rest.

- Installation of the cleaning chamber door. Along the 29th row - masonry according to the pattern.

- They brick up a couple of valves.

The diagram shows that after the 38th row there is a new numbering. These rows belong to the next tier. Rows 1-26 – laying according to the pattern. On the 27th, the final valve is installed. 27-30 – everything according to the picture. 31-32 – start of a chimney resting on the ceiling. If the latter is higher, rows are added. The “attic-roof” part of the chimney is laid in a similar way. If there is an attic, the scheme is the same. The output is a two-story attic oven.

Another option is a two-story stove with a hob and fireplace

If heating alone is not enough, but an aesthetic component is also required, this modification will do. It is a stove with one firebox and a fireplace on the first tier and a pair of decorative fireplaces on the next.

The fuel burner and the aesthetic component are located on different sides, so nothing prevents them from functioning at the same time. The connection of smoke exhaust channels starts after installing the fireplace damper. The side part of the structure is equipped with a hob.

The illustration shows the structure of the furnace.

Figure 6. Sectional view of a two-tier stove with a fireplace

The order is effective and efficient. Thanks to original, well-thought-out techniques, oven operation is simplified.

Figure 7. Rows 1-15 Figure 8. Rows 16-26 Figure 9. Rows 27-42 Figure 10. Rows 43-65

The design requires 1100 pcs. red and 1000 pcs. fireclay brick.

Stoves on two floors

The main task of the stove maker when constructing a two-story stove is to, taking into account the characteristics of the room, distribute the heat in such a way that it will not be too hot on the first floor and not too cold on the second. When calculating the stove, you need to remember that warm air rises, which means that heating the second floor requires less heat than the first. Based on this, on the first floor you should not get carried away with the long length of the channels, but it is better to save them for the second floor. If the room on the second floor is not large, then a cap that accumulates heat after passing through the channels of the first floor will be quite sufficient for heating.

Double-deck furnaces should not be equipped with horizontal channels, as this significantly slows down the speed of gas movement, and therefore contributes to increased soot formation. If the smoke channels are excessively long, the temperature of the gases at the outlet of the pipe may drop below 100ᴼ C, which will inevitably lead to the formation of condensation.

The second floor stove must rest entirely on the first floor stove; it is strictly forbidden to place the second floor stove on wooden floor beams, since a wooden house will shrink over time and will tear the masonry at the junction of the stoves. Two-story brick stoves must be equipped with a direct stroke valve to facilitate ignition after a long break between fireboxes. If the design does not allow for a direct stroke valve, you can pre-ignite the furnace through the last cleaning door.

Is stove heating possible in an apartment building? Yes, the designs of furnaces make it possible to heat even fairly large buildings, if they are no more than two floors in height. There are several options for arranging the heating of two-story buildings, and, despite the new types of equipment that have appeared, stove heating is not losing ground. The stove can be used as a hob, as a fireplace, and as a regular solid fuel boiler, if it is equipped with an additional water circuit.

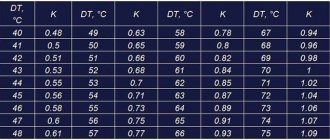

Dimensions

The dimensions of the firebox are designed for a single loading of approximately 50 kg of dry logs 50 cm long and up to 10 cm thick. Moreover, the logs are placed vertically in the firebox. From the firebox, gases rise upward through the first ascending chimney. At a height of about 3.2 m from the floor level, part of the gases is separated into the smoke circulation of the heating panel of the first floor, and the other rises to the top of the stove and enters the smoke circulation of the second floor. In the lowering channels of the smoke circulation of the heating flaps of both floors and in the last lifting channel of the first floor, special heat-exchange nozzles (outlets) are made - bricks protruding from the masonry into the channel. They increase the heat-absorbing surface in the smoke circulation and the rate of heating of the furnace masonry. The last lifting smoke channels of both floors (see rows 60 to 88 in Fig. 1 and 2) have a cross-section of 120x190 mm and end in the upper part of the furnace with a common chamber (rows 89 and 90 in Fig. 2). In this chamber, control bricks are installed, with the help of which the corresponding quantities of flue gases are distributed into the smoke circulation of each floor. These adjustment bricks rest on special protrusions 1.5-2 cm wide, made when laying out the channels in the 88th row. Adjustment of the distribution of flue gases is done once during the first test fires, moving the bricks and achieving uniform heating of the furnace masonry on the lower and upper floors. After the final installation of the adjustment bricks, the side windows of the chamber are tightly closed and covered with clay. The chimney is a mounted one, built directly above the stove. The pipe channel is closed and the draft is controlled by two valves installed in series. In places where soot may accumulate and ash settles in the chimneys, cleaning holes are made, closed with cleaning doors.

Video two-story oven:

Devices

The list of instruments and materials required for the construction of this furnace is given in table. 2. Its design is not particularly complicated, but requires quite high qualifications and accuracy from the performer

Particular attention should be paid to the quality of the masonry not only of the firebox and external walls of the stove, but also of the internal chimney channels, since communication between the stove’s smoke circulations not provided for by the design can lead to its inoperability.

TABLE 1

CHARACTERISTICS OF A TWO-STORY HEATING OVEN WITH SINGLE FUEL

Dimensions of the furnace in plan: fuel section……………………………………..890×1150 mm panel of the 1st floor……………………………………… 770×1020 mm shield of the Nth floor………………………………………. 770×950 mm Furnace height*…………………………………………………………………………………………………………7150 mm Heat-dissipating surface……… …………………………………………………………………………………..20.0 m2 Average heat transfer with a single firing of the furnace per day………………………. 5500 kcal/hour Total daily heat transfer…………………………………………………………..~ 132000 kcal Amount of fuel burned per day (dry firewood)………………… …………………………59 kg Heat transfer time after one fire ……………………………………………………24 hours * The full height of the stove is indicated for the ceiling height 3.4 m. It can be changed by reducing or increasing the number of rows in the masonry from 26 to 46 and from 60 to 82 rows.

TABLE 2 LIST OF DEVICES AND MATERIALS

Solid red brick (selected)……………………………………………………….1900 pcs. Fireproof bricks…………………………………………………………………………………………………………170 pcs. Red clay…………………………………………………………………………………………………………….2.1 m3 Fire-resistant clay………… …………………………………………………………………………………0.2 m3 Sand……………………………………………………… ……………………………………………………………………………………2.3 m3 Fire door 350×350 mm……………………………… ………………………………………………1 PC. Blower door 135×120 mm……………………………………………………………………………………….1 pcs. Cleaning doors 135×120 mm……………………………………………………………………………………………….5 pcs. Furnace valves 130×260 mm……………………………………………………………………………………………….2 pcs. Pre-furnace sheet 500×700 mm……………………………………………………………………………………1 pc. Grate 400×400 mm………………………………………………………………………………………..1 pc.

1. 2. 3. 4. 5. 6. 7.

Heating a two-story cottage with a stove is quite simple, and such a system will not require any special treatment. The only condition that must be observed when using any stove: regular heating. Stove heating of a two-story house is very convenient to use, but the price for this ease will be the complexity of installation, therefore, before constructing a stove heating system, it is necessary to draw up an accurate and specific work plan.

Stove heating can operate autonomously, and in this case there will be no shortage of fuel. True, you should always take into account the fact that the stove occupies a fairly large area, and you need to think about this in advance. In addition, being an excellent decorative element of the house, the operating temperature of the stove is practically impossible to adjust, which is why there is an uneven distribution of thermal energy.

Construction stages

Foundation for a two-story oven

The first thing the work begins with is marking to lay the foundation

It is important to remember that the dimensions of the foundations in any case must be larger than the foundation itself. To set up the structure you will need the following:

- plywood for formwork construction;

- sand and cement;

- fittings;

- crushed stone;

- waterproofing sheet (preferably made of roofing felt).

Stages of work:

- Prepare a place for the foundation, cut out part of the floor boards if necessary.

- Make sure that the future structure will not rest against the load-bearing beams of the ceiling, otherwise you will have to change the layout of the top.

- A pit is dug taking into account the work plan.

- Crushed stone and sand are poured into the bottom and the composition is compacted.

- The formwork frame is constructed so that the concrete does not leak out of the walls.

- Reinforcing mesh is installed. The fittings for a two-story stove are made stronger than for a conventional one.

- A concrete solution is poured and left to dry for several days.

Masonry scheme

Once the foundation is ready, you can begin laying the foundation. The ordering is carried out strictly according to the scheme and includes the following steps:

- The order of laying the first row on the waterproofing sheet is noted.

- The solution for work is mixed.

Next, the rows are built:

| Row No. | Execution of work |

| 1 | Laying out without using a clay mixture to understand the further course of action |

| 2 | Mounting a blower using wire |

| 3 | Formation of the combustion chamber |

| 4 | Laying asbestos strips along the side openings of the fire chamber for further installation of the grate |

| 5 | Installation of a combustion door, similar to the blower door |

| 7—10 | Standard installation scheme |

| 11 | Mounting the hob, installing metal corners |

| 12—16 | Formation of the cooking chamber |

| 17—19 | Laying out continuous brick rows of lines, forming a place for the chimney |

| 20—22 | Installing corners, fixing doors for the cleaning chamber |

| 23—24 | Raising the sides of the drying chamber |

| 25—30 | The filling proceeds without changes, the valves are formed |

| 31—38 | Forming channels for smoke exhaust, expanding the masonry and leading to the ceiling |

The following stages concern construction on the second floor:

- From the 1st to the 26th row, the standard work scheme is used.

- The 27th stage ends with the formation of the valve. And up to 31 everything goes according to plan.

- Rows 31 and 32 are considered to be the beginning of the chimney pipe.

Selection of coolant and method of transporting thermal energy

The most rational solution in two-story houses, in which there are a large number of rooms and there is an overlap between floors, is the implementation of water heating. With a complex building configuration, in the vast majority of cases, there is no alternative to such heating. The system is a looped structure of pipes through which coolant flows, and heat is transferred through radiators or air heaters.

Also, heating using a heated floor can be installed as an additional or sole source of heat. Its operating principle is similar to heating using radiators.

The choice of coolant is extremely important

The use of heated floors powered by electricity throughout the entire house is a theoretically feasible option. However, a number of problems arise in its implementation. Firstly, from an economic point of view, heating organized in this way is not always profitable. Secondly, there is a possibility that it is technically impossible to carry out the task of air heating.

Warm floor

Air can be used as a coolant in multi-level houses. In this case, it is necessary to solve the problem of its transportation. To implement such a project, it becomes necessary to create a system of channels in the space of the building, as well as equip them with fans to force air flow. Only in this way can organized heating ensure the delivery of heat to remote rooms and rooms located on the second floor.

Chimney installation

The chimney plays an important role in the reliable and safe operation of the fireplace. When installing it on the second floor, a problem may arise with the length of the channel, which impairs traction. The photo shows a diagram and standards for installing a chimney on the roof of a house. Compliance with the standards limits the possibility of simply increasing the length of the channel due to the height of the roof outlet.

Reliable draft is ensured when the chimney length is at least 450 cm from the ash pan to the edge of the pipe. If it cannot be ensured by increasing the height, then safety is increased by additional measures. The main methods are to install a deflector at the outlet and place spark arrestors inside the channel.

Heating and cooking two-story stove

This two-story stove can heat two rooms on the ground floor and a room in the attic in small country houses. And the presence of a two-burner stove allows you not only to cook food if necessary, but also to quickly heat one of the rooms on the first floor. The photo shows the process of laying the stove and the stove in its finished form.

Rice. 1. Drawing of horizontal sections (orders) indicating the layout of bricks in each row.

From rows 1 to 4, an ash pit is formed and a blower door is installed.

Cleaning doors are installed on the 4-5th row, a grate is placed on the 5th row, and a combustion door is installed on the 6-8th row.

All doors are attached to the masonry using wire dia. 2 mm, and the frames of the combustion door are also wrapped with asbestos.

Please note that inside the firebox, the threshold and walls can be lined with refractory bricks placed on spoons, which are not tied with the rest. They turn out to be “independent” of the main masonry

During stove repairs, they can be easily replaced by first removing the stove.

A two-burner stove is installed on the 11th row. And since its length is slightly more than two and a half bricks, on the 12th row on the left and right the bricks are hewn or cut off so that the slab can be freely removed during routine repairs of the firebox.

Vertical smoke channels have a size of 13.5×13.5 mm

Particular attention should be paid when laying to thoroughly grouting their internal surfaces.

On the 16th-17th rows, a piece of pipe with a plug is embedded in the masonry or a standard 140x140 mm door is installed to ventilate the cooking chamber, which on the 18th row is covered with bricks resting on steel corners or metal strips.

Rice. 2. General view of the furnace and its sections

In the space from the 20th to the 24th row, you can, if desired, make a niche shelf for various household needs.

On the 20-21st and 25-26th rows, to clean the horizontal sections of the smoke duct, two more cleaning doors should be installed or two halves of brick should be laid instead.

On the 30th row, two valves are installed.

The stove option offered here is designed for a house where the ceiling height on the first floor is 2 m 60 cm, and on the second floor - not lower than 2 m 40 cm.

The design of the stove can be changed so that it can easily fit into a room with other dimensions if you add (or reduce) the number of rows in the masonry.

After completing the laying of the fireproof fluff in the ceiling, proceed to laying the second floor of the furnace by installing a cleaning door on the 2-3rd row, and a valve on the 27th row.

In order to light the stove, all valves must be opened. Hot gases, having passed the hob, begin to move in two directions: along the stove mass of the first floor and along the mass of the second floor. And if you close valve No. 1, only the first floor will heat up. To heat the array of the second floor, valve No. 2 should be closed, but valve No. 1 must be open.

I would like to warn you: it is possible to smoke through the gaps in the frames of valves No. 1 and No. 2. To avoid this, it is recommended to replace these valves with rotary valves (gates).

Rice. 3. Furnace layout plan.

To build such a furnace (excluding pipes and foundations), the following materials and equipment are required:

Red brick M-150—1080 pcs. Clay - 185 kg. Sand - 77 buckets Corner No. (70×70 mm) 80 cm - 2 pcs.; No. 94 (40×40 mm) 80cm - 6 pcs.; No. 4 (40×40 mm) 40 cm - 2 pcs. Furnace casting: fire door - 1 pc. blower door - 1 pc. cleaning door - 5 pcs. valve - 3 pcs. grate - 1 pc. two-burner stove - 1 pc. Steel wire dia. 2 mm - 20 m Asbestos cord dia. 5 mm - 10 m Roofing iron - 1.5 m2

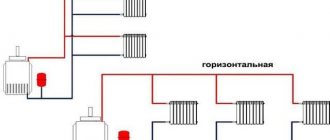

Natural circulation scheme

To understand the principle of operation of the gravity system, study the typical diagram used in two-story private houses. Combined wiring is implemented here: the supply and return of coolant occurs through two horizontal lines, connected by single-pipe vertical risers with radiators.

How gravity heating of a two-story house works:

- The specific gravity of the water heated by the boiler becomes smaller. The colder and heavier coolant begins to displace hot water upward and take its place in the heat exchanger.

- The heated coolant moves along a vertical collector and is distributed along horizontal lines laid with a slope towards the radiators. The current speed is low - about 0.1-0.2 m/s.

- Dividing through the risers, the water enters the radiators, where it successfully releases heat and cools. Under the influence of gravity, it returns to the boiler through a return manifold, which collects coolant from the remaining risers.

- The increase in water volume is compensated by an expansion tank installed at the highest point. Typically, the insulated container is located in the attic of the building.

Schematic diagram of gravity distribution with a circulation pump

In modern designs, gravity systems are equipped with pumps that accelerate circulation and heating of rooms. The pumping unit is placed on a bypass parallel to the supply line and operates when electricity is available. When the light is turned off, the pump is inactive, and the coolant circulates due to gravity.

Scope of application and disadvantages of gravity feeding

The purpose of the gravity circuit is to supply heat to homes without connection to electricity, which is important in remote regions with frequent power outages. The network of gravity pipelines and batteries can work together with any energy-independent boiler or stove (previously they said steam) heating.

Let's look at the negative aspects of using gravity:

- due to the low flow rate, it is necessary to increase the coolant flow by using large-diameter pipes, otherwise the radiators will not warm up;

- in order to “spur” natural circulation, horizontal sections are laid with a slope of 2-3 mm per 1 m of the highway;

- healthy pipes running under the ceiling of the second floor and above the floor of the first floor spoil the appearance of the rooms, which is noticeable in the photo;

- automatic control of air temperature is difficult - for batteries you need to buy only full-bore thermostatic valves that do not interfere with the convective circulation of the coolant;

- the scheme is unable to work with heated floors in a 3-story building;

- An increased volume of water in the heating network implies prolonged heating and high fuel consumption.

To fulfill requirement No. 1 (see the first section) in conditions of unreliable power supply, the owner of a two-story private house will have to bear the costs of materials - pipes of increased diameter and cladding for the manufacture of decorative boxes. The remaining disadvantages are not critical - slow heating is eliminated by installing a circulation pump, lack of efficiency - by installing special thermal heads on radiators and insulating pipes.

Design Tips

If you have taken the development of a gravity heating scheme into your own hands, be sure to consider the following recommendations:

- The minimum diameter of the vertical section coming from the boiler is 50 mm (meaning the internal size of the nominal diameter of the pipe).

- The horizontal distributing and collecting manifold can be reduced to 40 mm, before the last batteries - to 32 mm.

- A slope of 2-3 mm per 1 linear line of the pipeline is made towards the radiators on the supply and the boiler on the return.

- The inlet pipe of the heat generator should be located below the radiators on the first floor, taking into account the slope of the return line. It may be necessary to make a small pit in the boiler room to install a heat source.

- On the connections to heating devices on the second floor, it is better to install a direct bypass of small diameter (15 mm).

- Try to place the upper distribution manifold in the attic so as not to run under the ceilings of the rooms.

- Use an open-type expansion tank with an overflow pipe leading outside and not into the sewer. This makes it easier to monitor when the container is overfilled. The system will not work with a membrane tank.

The calculation and design of gravity heating in a cottage with a complex layout should be entrusted to specialists. And lastly: lines Ø50 mm or more will have to be made of steel pipes, copper or cross-linked polyethylene. The maximum size of metal-plastic is 40 mm, and the diameter of polypropylene will be simply menacing due to the thickness of the walls.

Important points related to the installation of solid fuel heating systems

You should choose the location for the stove with special care. It is advisable that it be erected against a load-bearing wall. This optimizes the operation of this equipment.

When you have to create stove heating for a building consisting of several floors, you should pay close attention to the design of the home. Installation of equipment for heating rooms can only be carried out taking into account the characteristics of the cottage

If the house is built of brick, then the role of the foundation for the furnace can be played by metal beams that are embedded in the masonry. This is done using concrete mortar.

Perhaps you decide to do everything yourself. I would like to warn you against such a step. The fact is that the construction of the furnace must be carried out by professionals. An unskilled approach can seriously affect its properties. To avoid having to overpay, it is better to immediately use the services of a specialist in this field.

Types of fireplaces

Fireplaces of various types can be installed in a living room. The table shows the main options.

Table 1

Types of fireplaces for residential buildings

| № | Name | Peculiarities | |

| Design | Advantages | ||

| 1 | Classic fireplace with open hearth | Brick construction with open firebox, chimney, external cladding and solid foundation. Often a metal frame is mounted. | Can be used to heat the room and provide comfort. Has an attractive appearance. The structure weighs a lot and requires a strong foundation. A full calculation of the strength and structure of the chimney is required. An open firebox increases fire safety requirements |

| 2 | Light version | A firebox is used in the form of a metal chamber with an outlet (chimney). Only a brick facing box is erected at the installation site. | The weight of such a structure starts from 150 kg, which reduces the requirements for the foundation. Installation is greatly simplified and accelerated. Increased fire safety requirements remain. |

| 3 ____ 4 | Cassette fireplace _______________ Closed stove-fireplace | The basis of the design is a finished steel or cast iron firebox, covered with fire-resistant glass. It is equipped with a standard chimney. The firebox is finished on top with decorative bricks or tiles. ______________ The firebox can be brick or metal, but is closed with a door. Heating is provided by installing coolant circuits and air duct routing | The lockable firebox makes it possible to leave the fireplace unattended. Installation is simple and quick. ________________________________________ The main purpose of the design is to heat the room. Installation is complicated, but fire safety is increased. |

Recently, decorative fireplaces have become popular. They are not intended for heating, but only imitate a hearth. The finished design fits harmoniously into any interior. Electric fireplaces are widespread. Do-it-yourself decorative structures are made from plasterboard and covered with tiles, tiles, and carved decorations.

Features of stove heating systems

It is necessary to understand that stove heating is a rather complex system that requires taking into account many nuances. If the craftsmen make one mistake or another, the owner of the house will have to pay. Below we will dwell on common problems that arise due to improper construction of the stove structure.

What are the advantages of heating a private house with wood, peat or coal? It should immediately be noted that they differ in autonomy. The oven can be built anywhere. She does not need access to communications. In some areas this is the only option available.

If there is no gas main at the location of the house, an alternative heating option may be a stove, which can be completely autonomous. Such heating is a classic option for organizing heating in a wooden house.

Undoubtedly, stove heating of a private house also has disadvantages. Firewood can be bought anywhere, but it needs to be stored somewhere. A small closet is clearly not suitable. A separate building will have to be erected. What can we say about space for flammable materials if the stove itself takes up a lot of space? In addition, to warm up a room with this device, you will have to spend a lot of time.

The stove takes up a lot of space in a wooden house. The larger it is, the warmer it is. In other words, it will be truly cozy in a large cottage. For example, it would be advisable to heat a wooden house using a stove if the building has enough space to accommodate it.

The low efficiency of this equipment often becomes the reason for searching for another way to maintain a comfortable temperature in the home. As a rule, the alternative is gas boilers, which we have already mentioned above.

Despite this, many still build such heating systems. Perhaps this is due not only to its good consumer properties, but also to the fact that the stove creates a special comfort that is difficult to put into words. You can only feel it. In addition, food cooked in it acquires a unique taste.

Method of decorating a stove in a kitchen interior

The method of designing the stove structure depends on the chosen design trend. Finishing materials will determine its appearance.

Tile

If you want to create a luxurious atmosphere in a rustic kitchen, the stove can be refined using tiles - special ceramic or clay heat-resistant tiles created specifically for finishing stoves. The unique shape of the tiles makes them easy to install, and the unique pattern will allow you to create a delightful design, unlike others. In the 19th century in Rus', tiled stoves were in fashion among the upper strata of society and were considered an indicator of prosperity and luxury.

Ceramic tiles heat up quickly and retain heat for a long time

A more affordable option for designing a stove structure is to use tiles. It can be of any shape, rectangular, square or imitate various natural fibers.

Tiles will help create a unique stove design

There are tiles that resemble tiles. With its help you can get an exquisite design option, as the following photos demonstrate.

Design of a stove in a private house, decorated with tiles

When choosing tiles, you need to choose fire-resistant samples that can easily withstand high temperatures and have a dense structure. Thanks to these properties, they will last a long time and will not require cosmetic repairs.

Very often, tiling is carried out only in the part where the fire is ignited and maintained.

Stone

Upgrading the surface of a Russian stove with stone allows you to get a unique rustic interior with an antique accent. This option is quite labor-intensive and requires significant financial investments. But by spending time and money, you will get a unique design that will delight more than one generation of your family.

A stone stove will become the main highlight in the house

Plaster

When designing the kitchen of a private house in rustic, Provence, country or Russian styles, plastering with clay mortar is an excellent way to finish the stove. After it hardens, heat-resistant paint is applied to the surface. With its help, the stove can be decorated with an original ornament, ideas for which are suggested in the following photos.

In addition, heat-resistant paint easily withstands any sanitary and hygienic procedures, it is easy to wash it from any dirt, and the appearance of the stove will remain unchanged.

Decorative plaster gives a Russian stove a special charm. It will help you recreate any pattern you like on its surface. The following selection of photos will convince you of this and inspire you to create an extraordinary design.

List of materials

Brickwork is a classic option for a furnace, as the material heats up evenly and slowly.

- single red brick M-200 – 1600 pcs;

- fireclay brick Ш-8 – 250 pcs;

- wedge-shaped fireclay brick Ш-44 – 100 pcs;

- smoke valve 26x26 centimeters – 2 pcs;

- smoke valve 13x26 centimeters – 3 pcs;

- damper (dimensions are determined by location) – 1 piece;

- two-burner hob (dimensions are determined as you go) – 1 piece;

- grate 20x28 centimeters – 5 pcs;

- combustion door 21x25 centimeters – 1 piece;

- blower door 14x25 centimeters – 1 piece;

- cleaning door 7x13 centimeters – 2 pcs;

- steel corner 60x60x5 millimeters - 1.5 m;

- steel strip 50x5 millimeters - 20 m;

- fireclay clay – 100 kg;

- sand, ordinary clay - the amount is determined according to the need for the material.

Operating principle of the bell structure

Previously, before Kuznetsov’s discoveries, heating was ducted, that is, hot air from the firebox rose up inside the device, heating its walls. Giving heat to the bricks, the gases cooled and, under the influence of draft, went into the pipe. Over time, due to uneven heating, cracks appeared and the masonry required repairs. The disadvantages of duct heating are rapid cooling and a large amount of soot.

The movement of gases, according to Kuznetsov’s theory, occurs freely. Hot air inside the structure is retained by two hoods, located either one above the other or side by side. There are options with holes in the middle of the domes. Both elements are connected through a so-called “dry seam” - free space necessary for the circulation of gases.

Gas flow diagram in a bell-type furnace

When the fuel burns, hot gases enter the first hood, which is connected directly to the firebox. Expanding, they cannot move upward and stop in a limited space, where they cool over time, or flow downward, reducing draft and delaying the combustion process. Thus, the temperature and combustion power are adjusted independently.

The second hood creates additional draft, as a result of which complete combustion of solid fuel occurs first, and the resulting heat is retained thanks to the pyrolysis gases accumulated under the roof. Due to the fact that hot air does not evaporate instantly, but circulates inside the device, the efficiency of the heat source reaches 93%. In addition, there is a noticeable saving in fuel (briquettes, firewood or coal), and soot deposition is reduced to a minimum.

Advantages and disadvantages of stove heating

But the stove heating system also has a number of disadvantages. Firstly, dimensions and weight: a stove installed in the house will look good, but a significant reduction in usable space will still be noticeable. The large weight of furnace structures necessitates laying a foundation. Secondly, the system warms up for a long time. Of course, this quality works both ways, because prolonged heating subsequently leads to equally long cooling. The efficiency of stoves is also their disadvantage, since most of the heat will go either into the chimney or to heat the walls.

The hood of the first tier must be closed, but the holes for cleaning it and cleaning the lower passages are located on the second floor. The furnace and lining are usually made of fireclay bricks, and basalt cardboard must be laid between them. This solution helps prevent the possible occurrence of cracks in the masonry.

Video about stove heating:

Features of operation

A characteristic feature of Dutch stoves is that due to the considerable length of the flue, during reheating, flue gases are not completely removed through the chimney and some of them, including poisonous carbon monoxide, can enter the room. To avoid such phenomena, during operation it is necessary to monitor the temperature in the middle of the front surface (forehead) - it should not exceed 60 degrees. This is a temperature that is tolerable for the palm, but not for the back of the hand.

Main types of brick kilns

So, depending on the functions performed, brick stoves in country houses are divided into the following main types:

- Heating stoves. As is clear, such a device is intended exclusively for heating indoor air. It can heat one room or the whole house if it is built into the wall.

- Cooking stoves are created for purely utilitarian purposes for cooking. In addition, you can dry mushrooms, berries and fruits on a brick cooking stove. Often such stoves are installed in summer kitchens.

- Cooking and heating furnaces. A classic structure that can not only heat a room or the entire house, but also be used for cooking food. A multifunctional multicooker with a solid history.

The technology of building brick stoves, proven over centuries, allows you to create a highly efficient device that will quickly heat the room, be safe to use and become the center of attraction of the entire house.

heating and cooking stove

Types of two-tier ovens

The main classification of such structures involves dividing stoves into designs with one firebox and with two. Division can be based on different criteria. There are options with cookers, beds, and fireplaces. * In single-fire structures, the firebox is always located on the first floor. Heavy outbuildings are also located there. A working or decorative fireplace is sometimes installed on the next tier. The first contributes to faster heating of the room, and the second - more efficient heat transfer.

Models with one firebox are more economical in terms of fuel consumption. Why do double the work and spend twice as much money on firewood if you only need to load logs on the first floor? This logic works in the short term. But some experts are opposed to such a modification. Flue gases, when cooled, contribute to the formation of condensation, which reduces the service life of the masonry.

Advantages of stoves with two fireboxes:

- more efficient heating of floors;

- possibility of heating the tiers separately.

Which solution to choose depends on personal preferences, objectives and design features of the building.

Important! Single- and double-furnace designs have advantages and disadvantages. You need to focus on the option whose advantages outweigh in your individual case.

Russian stove with heating, ordering and finishing

Creating Drawings

A Russian stove with a fireplace is quite a rarity. The scheme that will be considered combines a Russian stove with a firebox and a fireplace. If the stove is laid according to the attached drawings, the stove can easily heat approximately 40-50 square meters of living space.

The stove is built using a “two-tier hood” system and heats evenly on all sides.

A modern Russian heater (stove) with a heating element meets some household requirements. On a cast iron stove it is possible to cook a wide variety of food, and in the crucible - dishes of traditional Russian cuisine. The oven is quite convenient for drying various fruits, mushrooms and berries.

This design provides a very comfortable bed, on which, if wooden floors are attached, there may be enough space for two adults.

A variant of the Russian stove, in which there are arched ceilings of the openings.

The drawing contains the facade of a Russian stove (an option in which there are arched ceilings of the openings).

On the side of the stove at the base of the furnace there is a very large oven niche, which is heated from above and from the sides. First of all, it is done so that the stove has greater heat transfer - additional heat will flow into the room from it. In winter, our ancestors warmed young domestic animals in a similar oven.

Wood chips, which are built on the sides of the fireplace, will store wood chips so that the stove can be lit. In different places of the array, seven stoves of various sizes are provided, in which it is possible to quite conveniently store or dry small items. In addition, the stoves decorate the stove: together with a cascade of shelves and arches, they will give the fireplace an elegant look.

If desired, some of the arches can be replaced with straight jumpers. The stove can also be decorated by laying shelves and arches made of bricks of a different color or a more intense color.

Furnace operating modes

Externally, “Teplushka” is almost no different from an ordinary Russian stove. except that there is a firebox in one of the corners.

The Russian heated vehicle can be heated in two modes. With a traditional (Russian) firebox, you will need to remove the damper and open the valve. In order to switch to the second mode, in which the furnace will heat up somewhat more intensely, you will need to open the valves, then the combustion door of the hob. In this case, one of the valves will have to be closed, and the valve will close the crucible. In such a case, the combustion door will act as a blower.

From the furnace, flue gases through the valves, which are open, will be directed into the chimney.

The cooking stove can be heated in three modes. Firewood must be burned on firebox grates. In the first mode, hot smoke gases will directly enter the chimney through open valves and chimneys, heating only the stove and bricks of the combustion chamber.

The mouth must be closed with a damper so that the flue gases flow from the furnace into the lower heating chamber of the furnace.

In order for the heater to switch to the second mode, in which the stove bed and furnace will warm up, you will need to open one of the valves and close the other. The furnace is closed with a damper. Hot smoke gases will change their direction and enter the furnace through the window. After it warms up, gases will flow into the chimney through the open valves.

To switch to the third mode, simply close the valve. The hot smoke gases in front of the window will change their direction and descend into the smoke circulation of the lower heating of the stove. Having passed along the entire perimeter of the lower mass of the stove and given off heat in this place, the flue gases will enter the chimney through the window, after which they will escape into the atmosphere through the open valve. In the third mode, the lower part of the outer perimeter and the oven niche will be intensively heated.

Interior of a village house with a stove

The rustic style almost never completely went out of style. Even having their own huge dacha, stuffed with ultra-modern equipment and perfect, economical heating devices, people strive to build something on their site in the old style - a small gazebo or sauna. But many, having acquired a country house, want to completely transform it, turning it into something like an old Russian hut with a real stove. There are almost no specialists left who are engaged in planning a village house with a stove, because people even in distant villages have switched en masse to coal or gas. We will try to delve a little into this problem to help our readers.

Country house design with stove

Traditional Russian stoves come in several types - simple and with a stove, with a heating shield. Later they began to make metal structures, but the classic design of a stove in a private house implies a brick structure. It can be whitewashed and painted with folk ornaments or covered with tiles. Now there are excellent clinker tiles that are resistant to high temperatures, but you can also use high-quality majolica with painted glaze.

It is quite natural that in ancient Russian huts a large stove was the center of the entire interior. But you need to understand that in a house with a Russian stove, where everything is kept strictly according to ancient standards, there is no water heating, and the heat in the room is distributed unevenly. Furniture should be arranged so that in winter it is not very cold away from the stove. Being too close to a hot heat source will also not be very comfortable. It is advisable to choose the right middle in each case. Also, do not forget that the stove itself is quite large and bulky; it takes much longer to cool down and heat up than modern heating devices.

It is not at all necessary to use exclusively expensive natural materials for a house made of timber with a stove. Try to keep the decor itself in a classic rustic style - the type and size of the windows, the height of the ceilings, the design of the furniture. But various small things or interior details that will not be conspicuous can be purchased from plastic or artificial stone. They are visually almost indistinguishable from things made of natural brick. granite or wood. There is a third option for the interior of a village house with a stove - from the outside the building looks like an old log house, but inside the whole furnishings are designed in a modern style. You see that you can, if you wish, choose the most successful option for yourself in order to simultaneously feel like you are in an ancient setting and not be deprived of the benefits of civilization.

Stove heating of a two-story house

Today, Yuri Mikhailovich Kishulko, a hereditary stove maker, gives us advice on stove heating. Yuri Mikhailovich's father, a self-taught stove maker from the Vitebsk region, spent his entire life improving his skills. The son helped his father from early childhood, absorbing the wisdom of the stove business. Today Yuri Mikhailovich is a virtuoso and a true enthusiast of his craft, easily building complex stoves capable of heating a two-story house and fireplaces in small living rooms.

When arranging stoves indoors, you should strive to ensure that they are located primarily near the internal main walls. It is not recommended to install stoves near external walls, as this complicates and increases the cost of building chimneys. If possible, the stove should be open and freely heat the room. To heat the kitchen, living rooms and utility rooms, stoves should be grouped into a so-called thermal unit. In this case, the chimneys are combined into one brick riser.

Compact stoves and hearths up to 700 kg can be installed directly on a solid floor. If this is not enough, the floors are reinforced with additional beams. Furnaces weighing more than 700 kg are placed on a foundation. The foundation is buried into the ground at least 0.5 - 0.6 m for one-story furnaces without mounted pipes and at least 1 m for two-story furnaces and main pipes. The foundation of the furnace cannot be tied to the masonry (foundation) of the building wall, as different shrinkage is possible.

If you have two floors...

The designs of the bases for the furnaces of the upper floors are chosen depending on the structures of the building walls, the relative position of the main walls and the orientation of the furnaces themselves. The simplest solution is to install the upper floor furnace on top of the lower floor furnace, however, when repairing the furnace on the first floor, it becomes difficult to maintain the upper furnace. To more evenly distribute the load on the lower furnace, a reinforced concrete slab is laid on it (at the level of the interfloor ceiling). Sometimes, during laying, racks made of square, round or profiled steel are embedded into the mass of the lower furnace (in the corners), and the lower ends of the racks are embedded in a solid foundation. A solid platform is made from channels and corners on top, on which the upper stove is installed.

In brick buildings, it is widely used to install products on rails or steel beams of various profiles embedded in brickwork to a depth of at least 38 cm (one and a half bricks). To prevent the brick from collapsing, sealing is done using spacers. The space between the beams is filled with lightweight concrete or brickwork. When laying out the stoves themselves, it is better to use a clay mortar; when heated and cooled, it will work in unison with the brick, which means your stove will remain intact and functional for many years. The brick is laid in the form of a vault. The beams are fastened with ties. If you have a dacha, the most practical way to heat the second floor is to install a small hood or shield fired by a stove located on the first floor. Sometimes the shield can be interlocked with a small fireplace (if the height of the chimney allows). If stove heating is the main heating system in your home, then you need an option with stoves on the first and second floors, which can be heated separately. Based on this, a house design is made, rooms are assigned, etc.

Let's take a closer look at a heating two-tier thick-walled stove with heat output on the first floor - 3.7 kW and on the second - 2.7 kW, its dimensions are 64x115 cm. If desired, on the first floor you can install a heating-cooking stove with a stove and an oven, or, if necessary, a heating larger oven with built-in oven.

Fire-resistant bricks (fireclay) are not produced in Belarus. Only imported bricks from neighboring countries are sold. The average price for it is 2000 rubles per piece. Tiles for cladding stoves in Belarus are produced by the only enterprise, KUP Volkovyskstroy-materials. Ceramic tiles are intended for cladding and laying the front surfaces of heating household stoves, kitchen stoves and fireplaces.

The design of the tiles is strong, durable, and securely attached to the brickwork. Tiles are sold in ready-made sets, their cost starts from 800 thousand Belarusian rubles for the simplest option.

A brief excursion into history

Our ancestors noticed the heating effect of open fire when they lit fires in caves. Bonfires were replaced by partially enclosed hearths, and then by the first inefficient fireplaces, most of the heat from which went up the chimney.

The Russian stove, laid using channel technology, in contrast to the famous “blacksmithing”, is only 30-40% efficient

Over time, they came up with a kind of cap that traps hot gases inside the structure, and learned to separate the hot air into several streams. A turning point in technology occurred when I. S. Podgorodnikov, a well-known heating engineer in our country, took up the issue. He invented a “two-story hood,” which organized the exit of flue gases in a slightly different way. However, practice was not enough, and the idea was finally brought to life thanks to I.V. Kuznetsov.

Option of a bell-type device for a wood-burning stove with an oven

Igor Viktorovich created a powerful theoretical basis for bell-type combustion, which he was able to successfully put into practice. Only thanks to his work did stove heating become truly effective. He has developed more than 150 different standards and collected dozens of standard solutions and schemes. The most advanced modifications became popular, hundreds of craftsmen adopted Kuznetsov’s bell-type furnaces. Let's try to figure out how “blacksmithing” works.

Air heating

In this category we include all methods of heating without the mediation of a coolant - water, oil, antifreeze and any others. The air in the room is heated through direct contact with the heating element.

Buleryan

The stove is a firebox surrounded by thick pipes with open ends up and down. The pipes heat up and provide convective mixing of the air in the room.

Directing them in different directions speeds up the process. If it is necessary to heat several isolated rooms from the buleryan, air ducts with natural or forced circulation are installed.

Advantages:

- Existing furnaces ensure almost complete combustion of fuel due to the fact that they provide long-term smoldering with a limited supply of oxygen. This ensures efficiency that is unattainable for traditional stoves.

- Buleryan does not take up much space and does not require its own premises. A stove for heating two floors can easily fit in the living room or dining room. There will be no soot or odors.

- Installing air ducts will cost less than installing a water heating system. Although, taking into account the necessary thermal insulation, not by much.

Flaws:

- It is almost impossible to lay air ducts after finishing the final renovation without spoiling the aesthetics of the room. The heating plan for a two-story house - both the heat source and the wiring - will have to be thought out in advance.

- Any stove heating of a two-story house is associated with the need to store reserves of firewood, coal, pellets or peat briquettes.

In the photo there is a buleryan stove in the living room.

Brick oven

An ordinary Russian stove usually has very impressive dimensions.

It occupies up to a third of the house’s area and is quite capable of heating several rooms. It is clear, however, that two-story heating stoves are somewhat more complex structures.

In general, there are almost no standards in the field of designing brick kilns. The specific implementation depends on the size of the room, the location of the stove, the imagination of the stove maker, or, alternatively, the order of a ready-made solution found on the Internet that was invented by someone else.

A typical two-story heating stove has a firebox located below and a cap or duct chimney that makes several turns on the second floor.

Execution options can be varied. For example, it is enough to place a cast-iron stove on the firebox, laying an asbestos cord under it to isolate the room from combustion products - and you will get a heating and cooking stove on two floors.

The stove can be placed in the middle of the room or in the corner; finally, if desired, you can even organize water heating of a two-story house with natural circulation by simply placing a coil in the firebox.

Dignity:

In the absence of gas, stove heating is the cheapest heating method. A brick stove pleases its owners with its great thermal inertia: it is usually heated once a day for 2-3 hours, and the rest of the time it releases the accumulated heat.

Flaws:

- Again, you will need a supply of fuel, which will take up a fair amount of space in the yard.

- Folding a stove so that condensation does not seep through the masonry, so that the stove does not crack and smoke into the room is an art that is gradually being lost.

If you are not afraid of experiments, you can try to do this work yourself; but in the absence of any experience, it is better to be prepared for various surprises.

Selecting the optimal heating scheme

First, let's determine what type of heating system we need - with natural or forced circulation. If you have a large two-story cottage, then you definitely need to choose a system with a pump. But if you have a small dacha in an area remote from central highways, a gravity-flow system that can operate without electricity may be suitable for you.

When making a final decision, it is important to remember that most homeowners prefer a two-pipe scheme with a forced operating principle