When planning an open fireplace in your country house, do not forget to create an additional source of heat, since a fireplace in this design (due to low efficiency and high fire hazard) is more of an interior solution and an element “for the soul.”

By the way, the photo below on the left shows an integrated approach to creating a fireplace. This structure includes both

an open fireplace (on the right side) and a traditional stove (on the left).

A very smart decision. If you want to admire the fire, we light the fireplace; if you want to leave the fire overnight, we light the stove.

As a rule, pragmatism takes over and our clients more often order closed stoves (see photo below). However, nothing beautiful is alien to them, and a stove door with a heat-resistant glass insert can serve as a compromise option. This will also allow you to continue to admire the fire, but in safer conditions.

Don't let the mess around the stoves scare you. The fact is that a stove or fireplace, as a rule, is built at the very initial stages of interior decoration of a country house. Therefore, in the future, after the construction of floors and ceilings, the finishing of walls, the bricks in the fireplace or stove washed and coated with a special varnish, everything will shine in a completely different light.

The photo below shows stoves that not only heat, but also allow you to cook incomparable dishes over an open fire. Unfortunately, a situation where there is no light and the gas has run out or has frozen (in a cylinder on the street) is quite possible and you will more than once remember with a kind word your “a la Dutch oven”.

A stove or fireplace is an important element of your future country house, no matter whether it is wooden or caracas. Therefore, even at the stage of designing a house, you need to decide, as a first approximation, the location of the future stove or fireplace, the type of stove, think about where the chimney, air ducts, etc. will go.

It is best if you already at this stage talk with the master stove maker and together determine the parameters of the future stove. Don't forget about the foundation for the stove. Unlike cassette fireplaces, brick stoves require a more powerful foundation, which it is advisable to “untie” from the main foundation of the house.

Private houses used for permanent residence require high-quality and complete heating. It can be done using completely different equipment. Stove heating in a wooden house is considered traditional and common. The fact is that buildings made of timber, SIP panels or other types of wood are considered environmentally friendly and traditional, just like heating created using a stove. If a cooking and heating structure is created, then you can use it not only to heat a room or the entire building, but also for cooking. A fireplace can be made instead of a stove, but it must be correctly located.

Laying the foundation for stove heating

The need and purpose of the foundation was discussed above.

Installing a stove is only possible if the foundation for it is ready, and the process of creating it takes some time. When laying the foundation, you must follow some rules that will help create a reliable foundation for the stove. The foundation can only be laid on dense soils. Semi-rocky or rocky soils are ideal. If the soil is bulk, then it must be thoroughly compacted so that its total thickness does not exceed 20 cm. When laying a foundation on loose soil, it is also necessary to compact it so that the base of the foundation can go deeper. When planning and arranging the foundation, it is necessary to make it with a small margin so that the stove does not stand end-to-end. In addition, increasing the area of the foundation will reduce the load on it.

The distance from the foundation to the walls of the house should be at least 5 cm, and the free space can be filled with sand. In addition, under no circumstances should you combine the foundations of the building and the stove, otherwise deformations may occur in the future not only of the stove, but of the entire house.

Choosing a heating system depending on the size of the house

- For small, well-insulated houses, consisting of one or two rooms and a kitchen, one heating and cooking stove made of brick will be sufficient.

- For larger buildings, it is necessary to carefully consider the heating system so that the entire house can be heated from one stove. For this purpose, heating is used using a water or steam circuit.

- For a one-story building, such a circuit can be connected to a brick stove or one made of cast iron. When installing a system in a two- or three-story house, a cast iron stove-boiler is more suitable.

The next thing you need to decide is the type of fuel. The system can be heated with wood, coal, peat, gas, diesel, electricity or several of these. This choice will determine which heating stove to purchase.

How does a heating stove work on two floors?

To fully understand how a stove works in a two-story house, you can pay attention to the photo. If the house is made of brickwork, then the stove can be installed on steel beams, which were initially built into the walls of the building

When installing beams, you need to use spacers that will soften the effect of weight on the walls and thereby prevent their deformation. The space between the beams is filled with ordinary mortar, but clay mortar is used to reliably cement the furnaces.

When installing stoves for heating a cottage, it is necessary to maintain the independence of the systems: each stove in a two-story cottage must be able to operate separately from the other. If desired, a fireplace can be installed into the erected structure, which will add an additional dose of comfort. If you choose a heating and cooking option as the main stove, located on the lower floor, then this design will provide the house with everything necessary.

Fire protection

Another most important question that you should think carefully about at the same time as how to determine the correct location of the stove in a wooden house is how to protect it from fire. Proper and careful handling of heating appliances is not always enough.

Fire is an unpredictable and difficult to control element. And if by some chance he broke free, then it is very difficult to stop him. That is why you should initially consider security measures.

- Firstly, this issue should also be addressed at the design stage. Different types of wood used in the construction of residential buildings have different flammability classes. Naturally, you need to choose the safest one.

- In addition, walls, especially in the immediate vicinity of the stove, can be treated with special substances. So-called fire retardants are not expensive, but they can bring a lot of benefits. It must be said right away that they will not make the wall completely impervious to fire. But they will significantly reduce the flammability threshold and slow down the combustion process itself.

- It would be a good idea to cover the walls and floor near the stove with special fire-resistant finishing materials. Asbestos, cement or gypsum plaster, facing brick are great for this purpose, turning the stove area not only into a safe, but also a beautiful space.

- But the use of vinyl and polymer finishing materials in these places is not only not recommended, but is also considered dangerous. They have the very unpleasant property of releasing very toxic chemicals when burned, which leads to severe poisoning and even death.

Stove heating of a two-story house

Today, Yuri Mikhailovich Kishulko, a hereditary stove maker, gives us advice on stove heating. Yuri Mikhailovich's father, a self-taught stove maker from the Vitebsk region, spent his entire life improving his skills. The son helped his father from early childhood, absorbing the wisdom of the stove business. Today Yuri Mikhailovich is a virtuoso and a true enthusiast of his craft, easily building complex stoves capable of heating a two-story house and fireplaces in small living rooms.

When arranging stoves indoors, you should strive to ensure that they are located primarily near the internal main walls. It is not recommended to install stoves near external walls, as this complicates and increases the cost of building chimneys. If possible, the stove should be open and freely heat the room. To heat the kitchen, living rooms and utility rooms, stoves should be grouped into a so-called thermal unit. In this case, the chimneys are combined into one brick riser.

Compact stoves and hearths up to 700 kg can be installed directly on a solid floor. If this is not enough, the floors are reinforced with additional beams. Furnaces weighing more than 700 kg are placed on a foundation. The foundation is buried into the ground at least 0.5 - 0.6 m for one-story furnaces without mounted pipes and at least 1 m for two-story furnaces and main pipes. The foundation of the furnace cannot be tied to the masonry (foundation) of the building wall, as different shrinkage is possible.

If you have two floors...

The designs of the bases for the furnaces of the upper floors are chosen depending on the structures of the building walls, the relative position of the main walls and the orientation of the furnaces themselves. The simplest solution is to install the upper floor furnace on top of the lower floor furnace, however, when repairing the furnace on the first floor, it becomes difficult to maintain the upper furnace. To more evenly distribute the load on the lower furnace, a reinforced concrete slab is laid on it (at the level of the interfloor ceiling). Sometimes, during laying, racks made of square, round or profiled steel are embedded into the mass of the lower furnace (in the corners), and the lower ends of the racks are embedded in a solid foundation. A solid platform is made from channels and corners on top, on which the upper stove is installed.

In brick buildings, it is widely used to install products on rails or steel beams of various profiles embedded in brickwork to a depth of at least 38 cm (one and a half bricks). To prevent the brick from collapsing, sealing is done using spacers. The space between the beams is filled with lightweight concrete or brickwork. When laying out the stoves themselves, it is better to use a clay mortar; when heated and cooled, it will work in unison with the brick, which means your stove will remain intact and functional for many years. The brick is laid in the form of a vault. The beams are fastened with ties. If you have a dacha, the most practical way to heat the second floor is to install a small hood or shield fired by a stove located on the first floor. Sometimes the shield can be interlocked with a small fireplace (if the height of the chimney allows). If stove heating is the main heating system in your home, then you need an option with stoves on the first and second floors, which can be heated separately. Based on this, a house design is made, rooms are assigned, etc.

Let's take a closer look at a heating two-tier thick-walled stove with heat output on the first floor - 3.7 kW and on the second - 2.7 kW, its dimensions are 64x115 cm. If desired, on the first floor you can install a heating-cooking stove with a stove and an oven, or, if necessary, a heating larger oven with built-in oven.

Fire-resistant bricks (fireclay) are not produced in Belarus. Only imported bricks from neighboring countries are sold. The average price for it is 2000 rubles per piece. Tiles for cladding stoves in Belarus are produced by the only enterprise, KUP Volkovyskstroy-materials. Ceramic tiles are intended for cladding and laying the front surfaces of heating household stoves, kitchen stoves and fireplaces.

The design of the tiles is strong, durable, and securely attached to the brickwork. Tiles are sold in ready-made sets, their cost starts from 800 thousand Belarusian rubles for the simplest option.

Types of foundations for a stove in a wooden house

When choosing a suitable foundation, consider the following:

- Installation cost – the price of building materials, installation and preparatory work is taken into account.

- Characteristics of the foundation and soil characteristics - the choice is based on the total weight of the structure, the type of soil (clayey, sandy, black soil, stone).

- Dimensions of the foundation for the stove in the house - depending on the area occupied by the stove equipment, the total weight of the structure, the required type of foundation is calculated.

All existing foundations are usually classified into several groups:

- On stilts and pillars.

- Concrete bases.

Foundations on piles and pillars

The base is made in three ways:

If you want to make a foundation for a stove in a wooden house with your own hands, without involving outside help, it is better to choose a pile structure, which is easy to install and does not require (with the exception of a screw device) serious material investments.

During installation, the foundation is insulated, thereby preventing the appearance of condensation on the walls of the furnace or cladding. Pillars without insulation will be “cold bridges,” which will negatively affect the operation of furnace equipment.

Concrete bases

Advantages of the device: ability to withstand heavy loads of strength, possibility of self-production, relatively low financial costs.

Cons: time required for installation and excavation work.

Concrete foundations are made in two ways:

The foundation gains strength gradually. Installation of a metal furnace and lining it with stone begins no earlier than 28-30 days after pouring the concrete.

Floor placement (floor installation)

Existing building codes for installing a home heating stove in a wooden house allow the installation of equipment that does not have cladding directly on a wooden floor. When installing on the second floor, you will need to strengthen the logs with metal corners and channels.

To prevent fire, the tree is protected with a metal sheet or a clay-brick layer. Otherwise, installing a wood-burning stove in a wooden house yourself is not difficult.

Manufacturers of heating equipment must provide detailed installation instructions. By following the recommendations and the step-by-step installation plan specified in the technical documentation, you can independently install the stove and connect it to the chimney.

Heating scheme for a two-story cottage using a stove

Heating scheme for a two-story cottage using a stove.

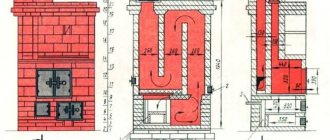

Image 1 shows what a stove installed in a two-story house should look like. If the house has brickwork, the stoves can be installed on rails or steel beams, which should be mounted into the brickwork. When sealing such beams, it is imperative to use special gaskets that will help prevent destruction. Lightweight concrete will have to be poured between the beams, and it is preferable to seal the ovens themselves using clay, this is due to the fact that clay interacts well with brick.

It is important to remember that both furnaces should be built so that they can be put into operation separately. A two-story house will be heated not only by a stove, but also by a fireplace if it is built into the overall structure

The stove heating with which the house will be equipped will become more functional if the stove placed on the ground floor is used for cooking, and for this it will only need to be installed in the kitchen space

A two-story house will be heated not only by a stove, but also by a fireplace if it is built into the overall structure. The stove heating with which the house will be equipped will become more functional if the stove placed on the ground floor is used for cooking, and for this it will only need to be installed in the kitchen space.

7c8c1156860600fd6610565a47975954.jpe

Furnace-heater Miracle

Such a heating device provides high-quality heating for premises of any purpose for a long time, while little fuel is wasted.

Device

This device is an all-welded steel structure. The transfer sheet divides the combustion chamber into two compartments. The top contains nozzles and an injector. At the bottom there is smoldering fuel.

The heater is covered with a special steel casing: it reduces the heating temperature of the walls of the device and allows the heat to escape evenly. Thanks to this element, it is impossible to get burned on the stove.

Principle of operation

The process of gas generation is the smoldering of fuel with minimal access to oxygen. Re-burning of the gas occurs using special nozzles.

Such a device can be heated with firewood, garbage, dry manure, and peat. One load of fuel material provides the structure with continuous operation for 6-8 hours.

Application area

The “Miracle” stove-heater can be used for heating summer cottages, large cottages, industrial buildings, outbuildings, garages, and greenhouses.

Advantages

Such a heating device begins heating immediately after kindling. Warmth will come to the house in about 20-30 minutes. In addition, its advantages include independence from gas, oil, electricity, uniform heating of the entire room, work with any type of fuel (with the exception of coal), and high efficiency.

The Miracle oven is an economical and easy-to-use device that does not require special maintenance or care. Its combustion process can be controlled. Installation of such equipment will be inexpensive. You can cook food and heat water on it.

Two-story oven with fireplace and hob

Functional model with one firebox and open fireplace on the first floor, and two decorative fireplaces on the second. The stove and fireplace are located on different sides and can operate simultaneously. The combination of gas flows begins above the fireplace damper. The design of the fireplace insert is simplified; there is no smoke tooth. There is a hob on the side, but no oven.

Cross-section of a two-level stove with a fireplace

Two-level model diagram

The principle of masonry and the movement of gases

The author of the order used modern techniques to increase efficiency and simplify operation. When using a fire door with glass, it is recommended to leave a through gap in front of the grate in the firebox floor. This trick prevents soot from forming on the door.

The order of masonry from 1 to 15 rows

Ordinal scheme from 16 to 26 rows

Laying walls from 27 to 42 rows

Construction requires 1000 pieces of fireclay bricks (highlighted in yellow in the diagram) and 1100 pieces of single solid red brick. The choice of refractory bricks for the construction of the walls of the stove and fireplace is based on the desire of the customer.

Important! Any finished arrangement of a stove on 2 floors requires modification, taking into account the characteristics of a particular house, its area, and ceiling height. Before purchasing materials, consult with an experienced stove maker

If necessary, he will make constructive changes to the circuit and give practical advice.

Before purchasing materials, consult with an experienced stove maker. If necessary, he will make constructive changes to the circuit and give practical advice.

744eab03586ee883b551923abc3fc0db.jpe

Selection of coolant and method of transporting thermal energy

The most rational solution in two-story houses, in which there are a large number of rooms and there is an overlap between floors, is the implementation of water heating. With a complex building configuration, in the vast majority of cases, there is no alternative to such heating. The system is a looped structure of pipes through which coolant flows, and heat is transferred through radiators or air heaters.

Also, heating using a heated floor can be installed as an additional or sole source of heat. Its operating principle is similar to heating using radiators.

The choice of coolant is extremely important

The use of heated floors powered by electricity throughout the entire house is a theoretically feasible option. However, a number of problems arise in its implementation. Firstly, from an economic point of view, heating organized in this way is not always profitable. Secondly, there is a possibility that it is technically impossible to carry out the task of air heating.

Warm floor

Air can be used as a coolant in multi-level houses. In this case, it is necessary to solve the problem of its transportation. To implement such a project, it becomes necessary to create a system of channels in the space of the building, as well as equip them with fans to force air flow. Only in this way can organized heating ensure the delivery of heat to remote rooms and rooms located on the second floor.

How to protect a country house from fire when installing a stove

- Use of thermal insulation materials with a high degree of fire resistance to protect walls and ceilings at the installation site.

- Application of fire protection: impregnations and mastics.

Fire retardant treatment of wooden structures

Mastics and impregnations have been developed for protection. The former provide better fire protection, the latter are almost colorless.

The order of installation regarding fire safety measures specified by the manufacturer is specified in the technical documentation. Fire protection work is carried out by representatives of the Ministry of Emergency Situations. You can take measures to prevent fire yourself, but before putting the stove into operation, you will need to obtain a certificate from the inspector of the Ministry of Emergency Situations about the fulfillment of all requirements of the safety regulations.

Detailed parameters for installing a solid fuel heating country stove are described in the technical documentation attached to the heaters of leading European and Russian factories. Compliance with the described rules is mandatory.

Since ancient times, it was believed that the stove in the house was the main property. It doesn’t just heat and makes it possible to cook tasty and healthy food. She is a symbol of comfort, a home that should be preserved and protected. Therefore, skilled stove makers have always been considered a privileged caste. After all, the home nurse had to be built in such a way that it could be quickly and hotly heated, so that in the most severe frost the whole house would be warm and cozy, and the sizzling of the cooking food and the aroma of pies would spread from room to room. But before you start building, you need to calculate the location of the stove in the house. So that not a single molecule of heat is wasted.

The first and immutable requirement when choosing a furnace location is the complete design of the house. That is, the location of the stove in the house should be planned simultaneously with the walls. In this case, it will not happen that one room will be unbearably hot, and the other will be bitterly cold. And it’s much easier to pour the foundation under it before the floors are laid.

But there are other rules that should be followed.

Under no circumstances should the foundation for the stove be connected to a common foundation. Over time, the house will definitely shrink and the least that will happen is that the stove will become covered with cracks, from which wisps of smoke will constantly curl, making it impossible and even dangerous to stay in the room. Well, at most it will simply warp and require a lot of repairs. The location must be selected in such a way that the chimney is in close proximity to the internal main wall

It will be possible to support the pipe on the ceiling beam. Be sure to take into account the layout of the house. Number of rooms and windows

The need to heat the second floor, if there is one. And the material from which the house is built. Next, the approximate heat loss of the entire structure is calculated. From here the heat transfer of all surfaces of the stove is calculated. The design of the furnace itself must also be thought out in advance. Well, one last thing. If the house is too large and one heating device is not enough, you should calculate how many stoves will need to be installed and in what places.

Many years and even centuries of experience show that building too many chimneys means consuming an increased amount of firewood. There is no need to make a separate stove for each room. This is why it is called an ideal location, because with a minimum of space, the largest possible area is heated.

And one more important fact

A stove, no matter what type of fuel it is heated with, is a device around which some amount of garbage, dirt, ash, soot and other dirty substances always accumulate. Therefore, it is better to make the firebox hole in the room that is closest to the front door

Then you won’t have to carry firewood, buckets and bags of ash across the whole house. Believe me, after these voyages the rooms will definitely have to be cleaned.

Devices

The list of instruments and materials required for the construction of this furnace is given in table. 2. Its design is not particularly complicated, but requires quite high qualifications and accuracy from the performer

Particular attention should be paid to the quality of the masonry not only of the firebox and external walls of the stove, but also of the internal chimney channels, since communication between the stove’s smoke circulations not provided for by the design can lead to its inoperability

TABLE 1

CHARACTERISTICS OF A TWO-STORY HEATING OVEN WITH SINGLE FUEL

Dimensions of the furnace in plan: fuel section……………………………………..890×1150 mm panel of the 1st floor……………………………………… 770×1020 mm shield of the Nth floor………………………………………. 770×950 mm Furnace height*…………………………………………………………………………………………………………7150 mm Heat-dissipating surface……… …………………………………………………………………………………..20.0 m2 Average heat transfer with a single firing of the furnace per day………………………. 5500 kcal/hour Total daily heat transfer…………………………………………………………..~ 132000 kcal Amount of fuel burned per day (dry firewood)………………… …………………………59 kg Heat transfer time after one fire ……………………………………………………24 hours * The full height of the stove is indicated for the ceiling height 3.4 m. It can be changed by reducing or increasing the number of rows in the masonry from 26 to 46 and from 60 to 82 rows.

TABLE 2 LIST OF DEVICES AND MATERIALS

Solid red brick (selected)……………………………………………………….1900 pcs. Fireproof bricks…………………………………………………………………………………………………………170 pcs. Red clay…………………………………………………………………………………………………………….2.1 m3 Fire-resistant clay………… …………………………………………………………………………………0.2 m3 Sand……………………………………………………… ……………………………………………………………………………………2.3 m3 Fire door 350×350 mm……………………………… ………………………………………………1 PC. Blower door 135×120 mm……………………………………………………………………………………….1 pcs. Cleaning doors 135×120 mm……………………………………………………………………………………………….5 pcs. Furnace valves 130×260 mm……………………………………………………………………………………………….2 pcs. Pre-furnace sheet 500×700 mm……………………………………………………………………………………1 pc. Grate 400×400 mm………………………………………………………………………………………..1 pc.

1. 2. 3. 4. 5. 6. 7.

Heating a two-story cottage with a stove is quite simple, and such a system will not require any special treatment. The only condition that must be observed when using any stove: regular heating. Stove heating of a two-story house is very convenient to use, but the price for this ease will be the complexity of installation, therefore, before constructing a stove heating system, it is necessary to draw up an accurate and specific work plan.

Stove heating can operate autonomously, and in this case there will be no shortage of fuel. True, you should always take into account the fact that the stove occupies a fairly large area, and you need to think about this in advance. In addition, being an excellent decorative element of the house, the operating temperature of the stove is practically impossible to adjust, which is why there is an uneven distribution of thermal energy.

How to help the stove burn more efficiently

How can you “make” a metal stove heat up longer and perform the function of heating a house more efficiently? Let's look at some options:

Some summer residents recommend covering a metal stove with bricks. In their opinion, the building will first heat the bricks, and they, in turn, giving off heat, will warm the house. This is the operating principle of a conventional stone stove. Theoretically, this is true, but there are a few caveats. Firstly, the brick will still not heat up as much as in a traditional oven, which means you will not achieve the desired effect. Secondly, you will also reduce the service life of your stove. Due to the lack of free space, the metal case will not cool well. For this reason, the metal will burn out faster. And finally, due to the strong heating of the case, the risk of fire increases. By the way, some people line a metal stove with bricks (about 2/3) for safety reasons. in the lower part, such devices get quite hot. Another option used by summer residents is a water tank. Suitable for ovens with a horizontal top surface. Place a container filled with water on top. During strong combustion, the water will heat up, and then it will gradually give off its heat to the room

This method cannot be called very effective, but the heat of the heated water will be enough for some time. It is also important what kind of firewood you use for heating. Here, pay attention to 2 criteria: combustion temperature and the amount of tar, tar, oils, etc. released during combustion. – substances that contribute to the formation of soot. Soot is formed when burning any wood.

However, most of the substances that clog the chimney are present in coniferous firewood (resin), in birch logs with bark (it contains tar) and in fuel briquettes, which consist of seed husks (oil). Therefore, they should be avoided whenever possible. We recommend using hardwood firewood for heating: they produce a lot of heat and few soot-forming products. The quality of the fuel you “feed” your stove is also of great importance. Under no circumstances should you burn waste left over from repairs in a stove: remnants of fiberboard, chipboard, laminated chipboard, etc. This will harm not only the heating device, but also your health. We also do not recommend burning branches, tree trimmings and similar debris without first drying them, because firewood (or the material that replaces it) must be as dry as possible (according to the instructions for such stoves, their humidity level should not exceed 20%). When undried wood burns, moisture evaporates. Water vapor rises. There they encounter small particles of ash, which are formed during combustion, and glue them together. The resulting pieces settle on the walls in the form of soot and soot. Thus, wet wood clogs your stove. Thirdly, when using such firewood it is not possible to reach the same temperature as when burning dry firewood. Metal stoves are not designed to hold heat at all. They only heat while they are burning. Therefore, in order for the device to warm the air for as long as possible, it is necessary to properly organize the combustion mode. Such stoves have a long burning mode. It is quite economical, because... does not require the use of large amounts of fuel.

Summer residents who have been using similar heating devices for many years recommend the following algorithm of actions:

- Light the stove and heat it well.

- When the wood burns with a bright flame, add an armful of dry firewood to the firebox - about 2/3 of its volume. Some add firewood in combination with fuel briquettes, some add only briquettes (not made from seeds).

- Close the valve and the vent. Due to the lack of oxygen, the firewood will not burn with a strong flame, but will only smolder. Thanks to this, one bookmark can last for 7-8 – or even more – hours. This method saves fuel and your energy, and also provides a constant comfortable temperature in the room.

Each heating device requires special treatment. If you study all its whims and fulfill all its wishes, it will thank you with its warmth.

Dimensions

The dimensions of the firebox are designed for a single loading of approximately 50 kg of dry logs 50 cm long and up to 10 cm thick. Moreover, the logs are placed vertically in the firebox. From the firebox, gases rise upward through the first ascending chimney. At a height of about 3.2 m from the floor level, part of the gases is separated into the smoke circulation of the heating panel of the first floor, and the other rises to the top of the stove and enters the smoke circulation of the second floor. In the lowering channels of the smoke circulation of the heating flaps of both floors and in the last lifting channel of the first floor, special heat-exchange nozzles (outlets) are made - bricks protruding from the masonry into the channel. They increase the heat-absorbing surface in the smoke circulation and the rate of heating of the furnace masonry. The last lifting smoke channels of both floors (see rows 60 to 88 in Fig. 1 and 2) have a cross-section of 120x190 mm and end in the upper part of the furnace with a common chamber (rows 89 and 90 in Fig. 2). In this chamber, control bricks are installed, with the help of which the corresponding quantities of flue gases are distributed into the smoke circulation of each floor. These adjustment bricks rest on special protrusions 1.5-2 cm wide, made when laying out the channels in the 88th row. Adjustment of the distribution of flue gases is done once during the first test fires, moving the bricks and achieving uniform heating of the furnace masonry on the lower and upper floors. After the final installation of the adjustment bricks, the side windows of the chamber are tightly closed and covered with clay. The chimney is a mounted one, built directly above the stove. The pipe channel is closed and the draft is controlled by two valves installed in series. In places where soot may accumulate and ash settles in the chimneys, cleaning holes are made, closed with cleaning doors.

Disadvantages of long-burning stoves

The disadvantages of such furnaces include:

The need to install a metal chimney that must be thoroughly insulated

This requirement is usually silent from equipment sellers. Meanwhile, it is very important, since operation without compliance with this condition is simply impossible. Previously, it was said about incomplete combustion of flue gases during gas generation mode. Getting into a cold pipe, they instantly form soot and condensation, similar to tar, foul-smelling and flowing down the walls of the pipe.

- This publication is devoted to the use of fireplace stoves with a water circuit.

- Review material about Bavaria fireplace stoves is waiting for you at this link.

If you use a prefabricated pipe, then the upper assembly part must be inserted into the lower one, and not vice versa. The pipe must be at least 1.5 meters above the roof ridge, since this combustion mode produces a large amount of soot that pollutes the roof.

The need to install such a pipe, taking into account the ceiling cuts, passage through the roof, umbrella, etc., often more than doubles the cost of the stove itself.

This will have to be done at least once every 3 months when the furnace is constantly operating. Signs of the need for cleaning are smoke coming out when the firebox is opened, the absence of a hum when the stove is ignited, and increased wood consumption. That is why it is better to make the chimney dismountable - this will make it much easier to clean it from tar and soot.

Use only in premises with temporary occupancy

Manufacturers, as a rule, are silent about the negative impact of metal stoves on health. It is explained by dust in the air and burning on stove surfaces. Combustion products are easily spread throughout the room, and inhaling them is unsafe for health.

In Soviet times, regulatory documents regulated the surface area of stoves with a temperature of 120 degrees or more (in residential premises it was prohibited to operate stoves with 5% or more of this area). This norm has not been canceled since then, but it is not customary to mention it among manufacturers of furnace equipment. Such stoves should not be installed in bedrooms and rooms where children stay for long periods of time.

Incomplete combustion of fuel has a harmful effect on the environment

In damp, windless weather, chimney smoke falls down, enveloping nearby houses. And a gas generator stove, unlike a brick stove, has to be fired constantly.

The choice of a stove for a summer house or country house should be approached individually, taking into account the characteristics of the home, the time spent in it, the availability of sufficient fuel and other factors. If possible, the classic, time-tested brick oven remains the preferred option. A long-burning furnace can be considered as an auxiliary one. As the main one, it should be used only when there is a periodic need for heating the home.

Stoves on two floors

The main task of the stove maker when constructing a two-story stove is to, taking into account the characteristics of the room, distribute the heat in such a way that it will not be too hot on the first floor and not too cold on the second. When calculating the stove, you need to remember that warm air rises, which means that heating the second floor requires less heat than the first. Based on this, on the first floor you should not get carried away with the long length of the channels, but it is better to save them for the second floor. If the room on the second floor is not large, then a cap that accumulates heat after passing through the channels of the first floor will be quite sufficient for heating.

Double-deck furnaces should not be equipped with horizontal channels, as this significantly slows down the speed of gas movement, and therefore contributes to increased soot formation. If the smoke channels are excessively long, the temperature of the gases at the outlet of the pipe may drop below 100ᴼ C, which will inevitably lead to the formation of condensation.

The second floor stove must rest entirely on the first floor stove; it is strictly forbidden to place the second floor stove on wooden floor beams, since a wooden house will shrink over time and will tear the masonry at the junction of the stoves. Two-story brick stoves must be equipped with a direct stroke valve to facilitate ignition after a long break between fireboxes. If the design does not allow for a direct stroke valve, you can pre-ignite the furnace through the last cleaning door.

Is stove heating possible in an apartment building? Yes, the designs of furnaces make it possible to heat even fairly large buildings, if they are no more than two floors in height. There are several options for arranging the heating of two-story buildings, and, despite the new types of equipment that have appeared, stove heating is not losing ground. The stove can be used as a hob, as a fireplace, and as a regular solid fuel boiler, if it is equipped with an additional water circuit.

Consider air circulation.

To effectively heat a room, consider air circulation: warm air rises and cold air descends.

Therefore, when choosing a stove or fireplace, think about their placement. You may need to purchase a ceiling fan or other appliances. If the fireplace is located on the first floor, and the second floor is also planned to be heated, you need to look at how warm air will be supplied there. The first option is free circulation. But then the heating will be uneven: distant rooms are colder and take longer to warm up. And if the rooms are isolated (the door is closed), they will not warm up at all, or the heating will take a very long time. The second option is to separate the hoses with warm air, when warm air from the heating device goes through the air duct and enters the room through the ventilation grille. Here you need to take into account how long the sleeves need to be pulled - if the length is long, you may need a special fan.

Air heating

In this category we include all methods of heating without the mediation of a coolant - water, oil, antifreeze and any others. The air in the room is heated through direct contact with the heating element.

Buleryan

The stove is a firebox surrounded by thick pipes with open ends up and down. The pipes heat up and provide convective mixing of the air in the room.

Directing them in different directions speeds up the process. If it is necessary to heat several isolated rooms from the buleryan, air ducts with natural or forced circulation are installed.

Advantages:

- Existing furnaces ensure almost complete combustion of fuel due to the fact that they provide long-term smoldering with a limited supply of oxygen. This ensures efficiency that is unattainable for traditional stoves.

- Buleryan does not take up much space and does not require its own premises. A stove for heating two floors can easily fit in the living room or dining room. There will be no soot or odors.

- Installing air ducts will cost less than installing a water heating system. Although, taking into account the necessary thermal insulation, not by much.

Flaws:

- It is almost impossible to lay air ducts after finishing the final renovation without spoiling the aesthetics of the room. The heating plan for a two-story house - both the heat source and the wiring - will have to be thought out in advance.

- Any stove heating of a two-story house is associated with the need to store reserves of firewood, coal, pellets or peat briquettes.

In the photo there is a buleryan stove in the living room.

Brick oven

An ordinary Russian stove usually has very impressive dimensions.

It occupies up to a third of the house’s area and is quite capable of heating several rooms. It is clear, however, that two-story heating stoves are somewhat more complex structures.

In general, there are almost no standards in the field of designing brick kilns. The specific implementation depends on the size of the room, the location of the stove, the imagination of the stove maker, or, alternatively, the order of a ready-made solution found on the Internet that was invented by someone else.

A typical two-story heating stove has a firebox located below and a cap or duct chimney that makes several turns on the second floor.

Execution options can be varied. For example, it is enough to place a cast-iron stove on the firebox, laying an asbestos cord under it to isolate the room from combustion products - and you will get a heating and cooking stove on two floors.

The stove can be placed in the middle of the room or in the corner; finally, if desired, you can even organize water heating of a two-story house with natural circulation by simply placing a coil in the firebox.

Dignity:

In the absence of gas, stove heating is the cheapest heating method. A brick stove pleases its owners with its great thermal inertia: it is usually heated once a day for 2-3 hours, and the rest of the time it releases the accumulated heat.

Flaws:

- Again, you will need a supply of fuel, which will take up a fair amount of space in the yard.

- Folding a stove so that condensation does not seep through the masonry, so that the stove does not crack and smoke into the room is an art that is gradually being lost.

If you are not afraid of experiments, you can try to do this work yourself; but in the absence of any experience, it is better to be prepared for various surprises.

Gas convectors

Another way in which you can do air heating of a private two-story house with minimal time and money is by installing gas convectors.

Each device is a closed burner with air intake from the street and combustion products discharged there through a coaxial pipe. The heat exchanger heats the air in the room. The devices can operate from both main gas and bottled gas.

2163d27d9b0f7a448f842769831b5843.jpe

6abc3571ae8d0fcb3349ee3d83cd8e79.jpe 70d1ae7f8983b60d60e7b2d69c801397.jpe 81fa333c2bc668042adc3d10b0c088ea.jpe

Advantages:

- Full autonomy of heating for each room in the house.

- Low project cost. The price of each convector is 4-8 thousand rubles. Considering that you do not need a boiler and wiring from it, this will mean significant savings.

Flaws:

- Unfortunately, mains gas is not available everywhere.

- Installation of convectors is possible only on the external wall of the house.

- Drilling wide holes for a coaxial pipe in, for example, reinforced concrete is still a pleasure.

- look here.

What criteria should a stove for a summer cottage have?

Many consider the best option for heating a dacha to be a traditional brick stove (Russian, Swedish or Dutch). However, such devices are intended for constant use and are not very suitable for irregular heating, because... take too long to heat up. Sometimes, depending on the weather, they sometimes need more than a day to raise the temperature in the house.

To quickly warm up a room that has not been heated for weeks, not traditional, but modern metal stoves - Buleryan, Breneran, Butakova - are better suited. They provide a comfortable temperature much faster – within a few hours

What else is important when choosing a means of heating a summer house?

- Easy to install. Not everyone is ready to spend a lot of effort and money on building a reliable and massive brick stove in a small country house.

- Fast heating of the room. A summer resident, having decided to visit his dacha on the weekend, does not agree to sit in a cold house for a long time - he wants to quickly find himself in the warmth.

- Furnace burning time. Getting up at night, in the cold, to add wood to the firebox is not a job for the faint of heart. And during daylight hours, you don’t want to spend the whole day working on the stove. What kind of vacation is this?

- Fire safety. Many country houses are made of wood, so the issue of reliability and safety of heating equipment comes first.

Construction stages

Foundation for a two-story oven

The first thing the work begins with is marking to lay the foundation

It is important to remember that the dimensions of the foundations in any case must be larger than the foundation itself. To set up the structure you will need the following:

- plywood for formwork construction;

- sand and cement;

- fittings;

- crushed stone;

- waterproofing sheet (preferably made of roofing felt).

Stages of work:

- Prepare a place for the foundation, cut out part of the floor boards if necessary.

- Make sure that the future structure will not rest against the load-bearing beams of the ceiling, otherwise you will have to change the layout of the top.

- A pit is dug taking into account the work plan.

- Crushed stone and sand are poured into the bottom and the composition is compacted.

- The formwork frame is constructed so that the concrete does not leak out of the walls.

- Reinforcing mesh is installed. The fittings for a two-story stove are made stronger than for a conventional one.

- A concrete solution is poured and left to dry for several days.

Masonry scheme

Once the foundation is ready, you can begin laying the foundation. The ordering is carried out strictly according to the scheme and includes the following steps:

- The order of laying the first row on the waterproofing sheet is noted.

- The solution for work is mixed.

Next, the rows are built:

| Row No. | Execution of work |

| 1 | Laying out without using a clay mixture to understand the further course of action |

| 2 | Mounting a blower using wire |

| 3 | Formation of the combustion chamber |

| 4 | Laying asbestos strips along the side openings of the fire chamber for further installation of the grate |

| 5 | Installation of a combustion door, similar to the blower door |

| 7—10 | Standard installation scheme |

| 11 | Mounting the hob, installing metal corners |

| 12—16 | Formation of the cooking chamber |

| 17—19 | Laying out continuous brick rows of lines, forming a place for the chimney |

| 20—22 | Installing corners, fixing doors for the cleaning chamber |

| 23—24 | Raising the sides of the drying chamber |

| 25—30 | The filling proceeds without changes, the valves are formed |

| 31—38 | Forming channels for smoke exhaust, expanding the masonry and leading to the ceiling |

The following stages concern construction on the second floor:

- From the 1st to the 26th row, the standard work scheme is used.

- The 27th stage ends with the formation of the valve. And up to 31 everything goes according to plan.

- Rows 31 and 32 are considered to be the beginning of the chimney pipe.

Protective screens near or around the oven

Such a system will need to be implemented when installing a potbelly stove in the corner of the room. You can mount or lay out several screens from brick, installed at a short distance from each other. In this case:

- The first screen protects a person from touching the iron stove and getting burned. It is usually made of refractory or fireclay bricks;

- To protect walls made of flammable material, a second layer of protection is provided. It can be made of brick or covered with a barrier made of sheet steel with a mirror-like front surface. In this case, heat waves will be reflected from the mirror and spread faster throughout the room;

- if the foundation is insufficient in size or it is impossible to manufacture it, it will be necessary to lay a protective screen made of durable fire-resistant material on the wooden floor. This can be a sheet of steel or a decorative layer of heat-resistant clinker tiles or porcelain stoneware. The surface will first have to be covered with a layer of thermal insulation.

Installation of metal screens

This is the easiest way to make surface protection. It is better to use sheets with a polished front surface. Before fastening, the wall surface at the required level along the height of the screen is covered with a layer of thermal insulation. In this way, we protect the surface of the walls from the effects of heat.

You can lay a layer of thermal insulation or fasten the metal with self-tapping screws with inserted ceramic spacers. But it is better to attach the screen to strips or a metal profile treated with a layer of protection. In this option, the air gap will not allow heat to pass freely to the walls, and reliable insulation of the stove from the wooden wall is ensured.

A special gap is made at the bottom of the wall for the passage of cold air, ventilation of the wall and screen. When arranging a wall with a layer of thermal insulation, a number of longitudinal guides are installed on the surface. The space between them is filled with a layer of mineral wool or other material. Then sheets of metal are installed and screwed to the sheathing with self-tapping screws.

In this design, there is no need to leave a gap at the bottom. The air will not be able to pass through calmly, but the wall will be reliably protected from high temperatures. To protect the floor of the house, a slab made of non-flammable durable material can be used.

Brick screens

This protection option is usually installed near the stove. Thus, you can protect not only the wall, but also the person from burns. By installing a brick wall, you can reduce the distance from the stove to the wall. For laying, it is better to use ceramic or fire-resistant bricks.

The work is carried out in several stages:

- you will need to make a small foundation or remove boards from the floor along the marking lines for laying the screen and, by drilling holes in the concrete of the base of the building, insert metal rods to fasten the bottom of the wall and the foundation;

- Having leveled the floor surface, lay out a layer of mortar and lay the first row of bricks; you need to place the bricks in the same plane without distortions. This determines how level your entire wall will be. Do not forget to make small grooves for ventilation; for this you can move several bricks of the bottom row.

- checking the level and pulling the twine for laying each subsequent row, all bricks are laid on a mortar of clay and sand. Having raised the wall to the required height, the top is sealed with a layer of mortar or covered with a board. This way you can make a shelf for decorative ornaments and all sorts of little things.

The brick is laid no higher than the top of the furnace at a distance of at least 40-100 mm from it.

Using both types of protective screens, you can reduce the distance from the oven to 500 mm.

Examples of installation of protective brick screens in the photo:

How does stove heating work in a two-story house?

Any stove is heavy, so it should be located next to solid internal walls, which will make it possible to balance its operation. If the total estimated weight of the stove is no more than 700 kilograms, then it can be installed directly on the floor, but only if it initially has high strength. If the total weight of the stove is too large, then it becomes necessary to lay a foundation. The foundation must be laid to a depth of at least one meter.

If stove heating in the house is the main one, then a separate stove must be installed on each floor. In general, it would be best to design and calculate the stove masonry before building the house. A stove installed on the second floor should be located directly above the stove, which is located on the floor below. This is done to reduce the load on the floor between floors. In addition, reinforced concrete slabs are often used to provide greater reliability and rigidity.

Let's sum it up

So, there are not so many options for the correct location of a brick or iron wood-burning stove. They depend on the layout of the house and the design of the stove itself. It is necessary to choose a location at the design stage and it is better to have a real specialist do this, who can calculate both the heat loss of the house and the heat transfer of the furnace located in one place or another.

But no matter what option you choose, wall-mounted, corner, in an interior partition, with a hob or fireplace, fire safety measures should not be neglected under any circumstances.

And then your home will be warm, cozy, fun and festive, no matter what bad weather is raging outside the window.

Advantages of stove-type heating

Stove heating, which can be used to equip a two-story house, may also be the only possible solution, since a cottage located outside the city may not have electricity or a gas pipeline. In addition, heating a two-story house with a stove is quite cheap; you will only need to buy coal or firewood.

However, such heating also has some disadvantages, including the significant weight of the heating system, as well as its dimensions. Heating and all its benefits can be started to be used a long time after the start of heating, since the stoves are inertial: they heat up for a long time, but cool down just as long. When heating a house, the stove can lose quite a lot of heat, which escapes through the chimney. The efficiency of stove heating is low and is only 25 percent, which means that before the stove begins its immediate duties, it will warm up the walls.

Application of protective screens

Screens are shields made of brick or metal that protect walls from intense thermal radiation. Similar protection is used when installing metal stoves.

- Metal screens are made from steel or cast iron sheets, these

casings surround the heat source with a distance of 3-5cm.

Advice! When purchasing a metal sauna stove, you should give preference to a model equipped with a metal casing. Its cost is not much higher, but the issues of wall insulation are eliminated.

Additional frontal or front shielding, which is located on the walls depending on the location of the stove, will not hurt. The protection guarantees the wood from overheating, reducing the temperature by 100 degrees or more, and provides the opportunity to save space in the steam room. A stove protected by a casing can be installed at a distance of 50-55cm from the wall.

Installation of screens is simple. The casing, equipped with legs, is secured to the floor by side or front screens - with galvanized nails or self-tapping screws.

- Brick screens are masonry used to cover the stove with

on all sides, the same casing, only made of brick. Another method is to lay half a brick between the firebox and a wall made of solid fireclay bricks laid on a solution of clay and cement. The width of the wall should be 120mm, although there is an opinion that it is permissible to put 60mm in a quarter of a brick, but it should be remembered that in this case the thermal insulation value is reduced by exactly half. It is recommended to raise the height of the masonry 20-30 cm above the surface of the firebox, but if you raise it to the ceiling, it will not be worse.

The screen should be placed at a distance of 10-15cm from the wall, 5-15cm from the stove, that is, the space saving is 30-40cm

Important! Functional openings for heat exchange should be made at the bottom of the masonry. Protective screens are effective, they reduce the temperature to a level acceptable when using high-temperature fuel units

The same function is performed by wall cladding made of non-combustible materials.

Protective screens are effective; they reduce the temperature to a level acceptable when using high-temperature fuel units. The same function is performed by wall cladding made of non-combustible materials.

Features of a heating stove on two floors

It is important to know exactly what the weight of the future heating system will be. To build a reliable structure, it is necessary to pour the foundation

It must be deepened into the ground by at least 1 meter, and the ceiling between the first and second floors must be very strong. A reinforced concrete slab can support this weight. Installation of such structures should be carried out along internal load-bearing walls.

0f9144b4c66791468fef78ad9393f49f.jpe

A two-story stove can be of two types - a stove with one firebox or with two. The main firebox in such structures can only be on the ground floor, as well as all heavy extensions - a stove bench or stove. A fireplace may be installed on the second floor - sometimes false, but more often functional. A false design will increase the heat transfer of the heating system, and the current one will allow you to warm up the room faster. Such systems include two-channel chimneys.

Stove with one firebox

A heating system with one firebox may last less than two fireboxes. This happens due to the specific design of the system itself.

On the top floor there should always be channels located vertically. In order to separate the heating of the floors, dampers are installed.

Their function is to block the movement of flue gases. After this, the cooling gases in the chimneys of the second floor form condensate. thus, the masonry begins to gradually collapse. The design of a stove in the house with two fireboxes can provide faster heating.

On average, the size of the firebox of such a stove is designed for a single loading of up to 50 kg of dry firewood. Typically, for stoves with one firebox, the logs are stacked vertically. This allows for faster heat transfer. The gases rise up the first ascending chimney, then, at a height of about 3 meters, the gases are separated into the distribution chimneys of the first or second floor. There may be bricks protruding inward inside the vertical channels. They allow you to increase the surface area that absorbs heat.

In places where there may be an accumulation of soot or ash deposition, special openings for cleaning should be provided, but closed with doors. A heating system with a single firebox has a big advantage. You only need to heat on the first floor. No need to carry firewood upstairs and do the same thing twice.

How to build a stove with your own hands - drawings and construction technology: step-by-step instructions, video

Despite the fact that many private houses today are equipped with one or another heating system, brick heating structures do not lose their popularity. On the contrary, engineers and craftsmen are developing more and more new models of stoves, more compact, including various functions. Indeed, stove heating will never be superfluous for a private home, as it can help out the owners in different situations. For example, in autumn or spring, when the nights are cold, but it seems too early to turn on the autonomous heating, a heated stove will create a cozy atmosphere in the rooms and relieve them of excess humidity. The stove will help maintain an optimally favorable atmosphere and temperature balance in the house that is comfortable for humans.

How to build a stove with your own hands drawings

Therefore, the search query about how to build a stove with your own hands, the drawings of which will tell in detail about the correct sequence of masonry work, does not leave the pages of the Internet. Today, even those people who have no experience as a stove maker at all show a desire to try their hand at this craft. If you decide to install a stove in your house on your own, then beginners are advised to choose a simple version of this structure with a clear procedure.

In addition to the availability of the design, when choosing a stove model, you should pay attention to its heat capacity, that is, how much area it is designed to heat. It is important to take into account the functionality of the structure and decide what you would like to get from it.

Types of brick kilns

There are several main types of stoves - some of them perform only one main task - heating the house, others are used only for cooking, and others include several functions at once in their “set of capabilities”. Therefore, in order to decide on the right model, you need to know what each of the varieties is.

- A heating and cooking structure can not only heat one or two rooms, but also help cook food and boil water. If the model is equipped with an oven and a drying niche, then it becomes possible to bake bread and dry vegetables and fruits for the winter.

The most versatile are heating and cooking stoves.

A heating and cooking stove is often built into a wall or acts as a wall itself - for this, it is turned with the stove and firebox towards the kitchen, and with the back wall towards the living area of the house. You can solve two problems at once - heating the premises and making it possible to cook food in a separate room.

If the structure is additionally equipped with a fireplace, then the stove will work not only as a functional structure, but will also become a decorative decoration of the house.

- The heating type of stoves is designed only for heating the premises of the house. Some models have not only a combustion chamber, but also a fireplace. Thus, the oven can operate in two modes - when only one of the functions is used, or they are both activated simultaneously. Most often, heating stoves are built into the wall between rooms or installed in the middle of one large room, dividing it into zones.

Heating stove

A similar structure is erected both for the main heating of the house and as an additional one, which is used in the spring and autumn to maintain normal temperature and humidity in the rooms. Heating stoves are usually installed when the kitchen has already realized its own cooking capabilities, or in a house with a large total area, where several stoves are being built that perform different functions.

On a summer cottage in a small house, it is better to install a multifunctional structure that can help out in several situations at once.

- The cooking stove is built in the kitchen, and its design is designed specifically for quick cooking. However, this function does not deprive it of its heating capabilities, since its entire body, back wall and cast iron stove are well heated, releasing heat into the room.

The main function of this stove is cooking.

The cooking stove is usually compact, so it is perfect for installing it in a country house or in a small kitchen of a private house.

Having such a compact but functional unit, you can eliminate the risk of freezing or being left without dinner and hot tea even if the electricity and gas supply is turned off.

Many different models of all listed types of furnaces have been developed. They can be very miniature and occupy a large area. Therefore, having settled on one of the models, before stocking up on materials for its construction, you need to measure and draw its base on the floor of the room in which it is planned to be installed. This way you can visually determine how much free space will remain in the room.

How to choose the right place to install the stove?

In order for the stove to work efficiently and transfer maximum heat to the premises of the house, and also be fireproof, it is necessary to choose the right location for it.

It is especially important to think through this point if the stove is built into a finished building, since the chimney pipe must pass between the ceiling beams and not accidentally bump into them, so the installation option must be calculated as accurately as possible.

A brick stove structure can be installed in different places in a room or between two rooms. Which place is better to choose will be discussed further.

- To get the maximum effect from the stove, you should not install it near the outside wall of the building, as it will cool down quickly and is unlikely to heat more than one room.

- Some stove models are installed in the center of the room or offset from it to one side or the other. This location is chosen if the room needs to be divided into separate zones. Moreover, different sides of the stove structure may have different decorative finishes, made in a style that matches the design of a specific area of the room.

- Quite often, the stove is built into a wall between two or even three rooms, which allows for the most efficient use of the generated heat. In this case, for fire safety purposes, it is very important to provide reliable insulation of the walls, ceiling and attic floor where the chimney pipe passes.

- When choosing an installation location, it is also necessary to ensure that each side of the foundation for the furnace should be 100÷150 mm larger than the base of the furnace itself.

- To accurately determine the size of the base and height of the stove, it is recommended to always choose a model that comes with an order diagram.

Having chosen the stove model and the place for its installation, you can purchase all the necessary materials and prepare the necessary tools. The amount of materials will depend on the size and functional features of the stove model, and the tools for masonry are always the same.

Tools required for masonry work

To work you will need to prepare a very “solid” set of tools

Tools for laying bricks and pouring the foundation will require:

- Rule - This tool is used to level the surface of a concrete foundation.

- A hammer-pick is necessary for splitting and trimming bricks.

- Veselka is a wooden spatula that is used for grinding clay and lime mortar.

- A stove hammer is used to split bricks and remove dried mortar that has protruded beyond the masonry.

- A broom made from sponge is intended for cleaning the internal channels of the furnace from sand and solution that has got into them.

- A lead scriber is needed for markings if the stove is finished with tiles.

- A building level is necessary to control the evenness of the rows and the surface of the walls.

- A scriber is a rod used for markings.

- A plumb line is a cord with a weight designed to check the verticality of the output surfaces.

- A construction angle with a ruler to check the correctness of external and internal angles, as they must be perfectly straight.

- Pliers are used for bending and biting off wire to secure cast iron stove elements in masonry seams.

- Rasp - this tool is used to remove beads and grind in lumps in dried masonry.

- The chisel is used for splitting bricks and dismantling old masonry.

- A rubber hammer is necessary to level the bricks laid on the mortar using the tapping method.

- Trowels (trowels) of different sizes are used to apply mortar when laying bricks and remove the mixture protruding from the seams.

- Joining is a tool for leveling mortar in masonry joints. It is used if the masonry is done “for jointing”, without further cladding.

- Manual tamping will be required to compact the soil and backfill layers into the foundation pit.

- Containers for mixing solution and clean water.

- A sieve with a metal mesh for sifting sand.

Goats will make it easier to lay out the top rows

- A stand for the convenience of working at heights, called “goats”. The surface of this device is of sufficient size not only for comfortable movement of the master, but also for installing a container filled with solution.

Arrangement of the foundation for a brick stove

The foundation for the stove is usually prepared together with the foundation of the house, but they should not be in contact with each other, much less be combined into a single structure. New foundations tend to shrink, which can lead to deformation of one of them, which will lead to damage to the other. That is why they must be installed separately from each other.

If you are building a stove in an already built house with a wooden floor, you will have to do quite a lot of work. In the place where the stove will be installed, the floor boards will have to be removed by cutting a hole to the size of the future foundation.

If the foundation under the house is monolithic, and the selected stove model is not too massive, then the structure can be erected on it, having previously laid waterproofing material on the installation site.

The foundation should have the shape of the base of the furnace, however, as mentioned above, each of its sides is made larger than the side of the furnace by 100 ÷ 150 mm.

- If the floor in the house is wooden, markings are made on it along which the boards will be cut.

- Then a pit is dug in the subfloor soil according to the shape of the future foundation, the depth of which can vary from 450 to 700 mm, depending on the composition of the soil.

- The bottom of the pit is compacted, and its walls are lined with plastic film or roofing felt.

A pit with a layer of waterproofing on the walls and a sand and gravel cushion at the bottom

- Then, a sand cushion 100÷150 mm thick is laid on the bottom, depending on the depth of the pit, and compacted well using a hand tamper.

- The next layer, on top of the sand, is filled with crushed stone, which is also compacted, if possible. This layer can be from 150 to 200 mm.

- Next, wooden formwork in the form of a box is installed along the perimeter of the pit. Moreover, polyethylene or roofing felt remains inside it, and then is fixed to the walls using a stapler and staples. This waterproof material will preserve the mortar poured into the formwork, preventing moisture from leaving it, which will give the slab the opportunity to dry and harden evenly.

- The foundation should have a height of approximately 250 mm below the level of the “clean” floor, that is, two rows of bricks will need to be laid on the finished foundation so that it rises flush with the floor surface.

- Some craftsmen, on the contrary, raise the foundation above the floor by 80÷100 mm in order to save bricks. The convenience of this solution also lies in the simpler joining of the side walls of the foundation with the surface of the floor covering.

- The next step is to install a reinforcement grid made of steel reinforcement 4÷6 mm thick into the formwork, to its entire height. The rods are tied together with wire twists.

- Next, in the lower part of the formwork, to a thickness of 250÷300 mm, you can pour a coarse concrete solution mixed with cement and gravel in the proportions 1: 3, or cement, crushed stone of the middle fraction with the addition of sand, in the ratio 1: 2: 1. But, in principle, you can use a regular concrete solution of sand and cement.

- If a coarse mixture is poured down, then immediately, without waiting for it to set, a finely mixed solution is laid out on top.

- The poured concrete mixture is leveled according to the rule along the upper edges of the formwork boards, after which it is recommended to lay and sink 15÷20 mm into the solution a reinforcing mesh with cells of 50 mm.

The upper reinforcing belt can simply be sunk into freshly poured concrete mortar

- The surface of the foundation is leveled again, and if necessary, concrete mortar is added to the formwork, on top of the mesh.

- Next, the foundation is left to harden and gain strength - this process will take from three weeks to a month, depending on the thickness of the layers of the poured mortar. To make the concrete more durable, it is recommended to spray it with water every day during the first week, starting from the second day.

- Waterproofing is laid on top of the frozen foundation, consisting of two or three sheets of roofing material, which are laid one on top of the other.

Laying will be carried out only on the layer of laid waterproofing (roofing felt)

- To begin laying the first row, it is recommended to make markings on the waterproofing material, indicating the location of the stove base. Thanks to the outlined perimeter of the base, it will be much easier to install the first row of bricks and maintain the evenness of the sides and corners.

After these preparatory works, you can proceed to the masonry.

Dry masonry

Even experienced craftsmen, when starting to lay a previously unfamiliar structure, first do it dry, that is, without mortar. This process helps to understand the intricacies of the internal channels of the furnace and not make mistakes during the main masonry. The entire structure is raised dry, and each of the rows must be laid out in accordance with the order applied to the stove model.

When performing dry masonry, it is necessary to maintain the thickness of the horizontal and vertical rows. To keep this parameter the same throughout the entire masonry, you can use slats 5 mm thick. Of course, it will be difficult to measure vertical seams with small pieces of slats when laying dry, so they will have to be determined visually, but for horizontal seams, slats must be used. By applying them, after laying out the last row of the structure, you can see the actual height of the stove.

As an example of using slats, you can consider this photo.

Maintaining the width of horizontal and vertical seams using calibration slats

It is especially important to adhere to a uniform thickness of the seams if the masonry is being made for jointing and will not be finished with additional decorative materials in the future.

When making dry masonry, it is important to understand the configuration of the channel through which the smoke will leave the firebox and rise to the chimney. If a mistake is made when laying out this passage, then you will have to reposition part or even the entire structure of the stove, since backdraft may form and smoke will flow into the room during kindling.

Having raised the stove dry before laying the chimney pipe, the structure is dismantled. Moreover, if not only whole bricks were used in the rows, but also their small fragments, then when disassembling each of the rows can be folded into a separate stack, putting the row number on one of the bricks. Sometimes, in addition, the number of the brick in each row is also indicated. Such a system will speed up the work, since all the material will be adjusted and laid out in the required order, and all that remains is to soak it one by one and place it in the rows of the oven, but already on the solution.

When performing the main laying, two slats are installed on the edges of the previous row, between which a solution 60÷70 mm thick is applied. Then the brick of the top row is placed on it, leveled and tapped until it rests against the slats. It is necessary to have such calibration devices for three rows, since it can be pulled out of the seam only after the solution has set. So, having laid out three rows, the slats are pulled out from the lowest seam, cleaned and laid on the fourth - and so on. If you are not sure that the vertical seams will be the same thickness, you can also prepare a short strip for them, which will be rearranged into the next seam immediately after leveling the two adjacent bricks.

It is optimal to have a set of calibration slats for three rows

After pulling the calibration strips out of the seam, there will be a fairly deep gap between the bricks. It is filled with mortar, the excess of which is removed with a trowel, and then put in order using jointing.

Processing seams for jointing

If the calibration slats were laid on both edges of the brick, then on the inside of the wall there will also be recesses between the seams. They also need to be carefully sealed, since the seams must be sealed, filled with mortar across the entire width of the brick.

It is very important, when laying on mortar, to check each of the laid rows with a building level so that the entire structure does not warp.

Such simple auxiliary devices as calibration slats will help to carry out the laying accurately with the same width of the seams. Therefore, the entire surface of the stove will look as if the design was made by a professional craftsman.

These nuances will help simplify the process of constructing a furnace structure and avoid mistakes that may lead to the need to redo the entire work.

Schemes for the construction of brick kilns

Yu. Proskurin's stove with heating and cooking functions and a drying chamber