Heating systems for country cottages with a height of 2 or more floors are usually designed by heating engineers. But owners of houses with a simple layout with an area of up to 200 m² do not have to turn to specialists - they can think through and organize the heating of the building themselves. The purpose of this publication is to explain which heating scheme for a two-story house is best combined with specific operating conditions, boiler equipment and radiators. We invite you to consider the existing options and choose the best one.

Types of heating systems

Practice shows that most homeowners put forward 3 basic requirements for the heating system of a two-story house:

- The house should always be warm.

- Minimum energy consumption - natural gas, firewood, electricity, and so on.

- Beauty. It is advisable to remove pipes, fittings and heating devices from view so as not to spoil the interior.

The requirements are listed in order of importance from the users' point of view. We will talk about installation costs when reviewing the systems.

The wishes are quite understandable, but they should be linked to technical capabilities. For example, in remote regions there are power outages or there is no main gas supply. Hence the advice: first determine the main fuel and backup energy carrier, select a boiler and heating devices. Reflect your wishes on paper - sketch out a rough draft with your own hands.

It is not always possible for the owner of a house to arrange utility networks himself - to develop diagrams, install equipment and pipes. In this case, it makes sense to contact the specialists of an engineering company that deals with the listed work. For example, in the central region of the Russian Federation, services for installing boilers and installing heating systems are provided.

Such a thorough approach will allow you to install a heating circuit for a two-story house, which will not have to be redone later. There are 5 system options to choose from:

- gravity (also known as gravitational and convection);

- single-pipe;

- two-pipe;

- radial (otherwise known as collector);

- water underfloor heating circuits called underfloor heating.

Note. The first scheme involves natural circulation of coolant through pipes and an expansion tank communicating with the atmosphere. The rest implement the principle of forced circulation using a pump and work under pressure (a closed membrane tank is used).

An example of a draft heating project for a 2-story mansion.

The indicated systems can be combined with each other. For example, make heated floors on the first floor, and assemble a radial circuit on the second. Now let's take a closer look at each option separately.

Features of a single-pipe heating system

The choice of one- or two-pipe heating does not depend on the number of floors of the house - both types are suitable, but for buildings with 2 or more floors, the installation of a circulation pump is required.

Heating with a liquid coolant (water or antifreeze) is considered the most effective, while for small one-story houses, for example, summer cottages, other options can be considered.

Operating principle and distinctive features

Heating radiators, according to a single-pipe scheme, are connected in series, that is, the coolant first enters one device closest to the boiler, from it through a pipeline to another, etc. The looped circuit, which is a network, is also suitable for a 2-story house, since it is conveniently located along the perimeter walls.

The simplest single-pipe heating scheme for a 2-story building: from the supply riser, the coolant flows into heating radiators connected in series order

The presence of shut-off valves can improve the use of the system. For example, the Mayevsky faucet is designed to remove air “locks” that often occur during downtime, that is, in the summer. In addition to it, various models of balancing valves, ball valves, and special regulators are used.

The forced circulation method in a single-pipe structure in the event of a temporary absence of electricity can be replaced by a natural one, but this requires the installation of a membrane tank and the placement of horizontal pipes at an angle of up to 5º.

Assessing disadvantages and advantages

The main advantage of single-pipe networks is considered to be easier drafting of the project and the installation itself. A minimum of pipes allows you not to rely on a complex room layout, but simply lay the pipeline strictly along the perimeters of both floors. Savings on purchasing fewer elements for a single main line - pipes, taps - are also appreciated.

One pipe takes up much less space than two, so it can be disguised under the floor covering, laid unnoticed in doorways, that is, installed without disturbing the interior.

One of the main disadvantages of a single-pipe system, relevant for a house with 2 floors, is the rapid cooling of the coolant during sequential movement through the radiators (+)

The disadvantages include the need to purchase a more powerful circulation pump, as a result of which the cost of electricity increases. It is more difficult to regulate the temperature level in a design with a serial connection: when the heating intensity in the nearest radiator decreases, the temperature in the entire line will automatically decrease.

Natural circulation scheme

To understand the principle of operation of the gravity system, study the typical diagram used in two-story private houses. Combined wiring is implemented here: the supply and return of coolant occurs through two horizontal lines, connected by single-pipe vertical risers with radiators.

Reference. There are other ways to organize gravity flow on two floors, for example, by dividing the risers directly from the expansion tank with pipes of a smaller diameter. The circuit is material-intensive, looks like a spider, and installation will cause a lot of trouble.

How gravity heating of a two-story house works:

- The specific gravity of the water heated by the boiler becomes smaller. The colder and heavier coolant begins to displace hot water upward and take its place in the heat exchanger.

- The heated coolant moves along a vertical collector and is distributed along horizontal lines laid with a slope towards the radiators. The current speed is low - about 0.1-0.2 m/s.

- Dividing through the risers, the water enters the radiators, where it successfully releases heat and cools. Under the influence of gravity, it returns to the boiler through a return manifold, which collects coolant from the remaining risers.

- The increase in water volume is compensated by an expansion tank installed at the highest point. Typically, the insulated container is located in the attic of the building.

Schematic diagram of gravity distribution with a circulation pump.

In modern designs, gravity systems are equipped with pumps that accelerate circulation and heating of rooms. The pumping unit is placed on a bypass parallel to the supply line and operates when electricity is available. When the light is turned off, the pump is inactive, and the coolant circulates due to gravity.

Scope of application and disadvantages of gravity feeding

The purpose of the gravity circuit is to supply heat to homes without connection to electricity, which is important in remote regions with frequent power outages. The network of gravity pipelines and batteries can work together with any energy-independent boiler or stove (previously they said steam) heating.

Let's look at the negative aspects of using gravity:

- due to the low flow rate, it is necessary to increase the coolant flow by using large-diameter pipes, otherwise the radiators will not warm up;

- in order to “spur” natural circulation, horizontal sections are laid with a slope of 2-3 mm per 1 m of the highway;

- healthy pipes running under the ceiling of the second floor and above the floor of the first floor spoil the appearance of the rooms, which is noticeable in the photo;

Due to the too large distance from the ceilings, it is very difficult to hide the pipe behind the cladding - automatic control of air temperature is difficult - for batteries you need to buy only full-bore thermostatic valves that do not interfere with the convective circulation of the coolant;

- the scheme is unable to work with heated floors in a 3-story building;

- An increased volume of water in the heating network implies prolonged heating and high fuel consumption.

Comment. The last negative point does not play a special role - the energy spent on heat production will not go anywhere. It will return as the pipelines cool.

To fulfill requirement No. 1 (see the first section) in conditions of unreliable power supply, the owner of a two-story private house will have to bear the costs of materials - pipes of increased diameter and cladding for the manufacture of decorative boxes. The remaining disadvantages are not critical - slow heating is eliminated by installing a circulation pump, lack of efficiency - by installing special thermal heads on radiators and insulating pipes.

Design Tips

If you have taken the development of a gravity heating scheme into your own hands, be sure to consider the following recommendations:

- The minimum diameter of the vertical section coming from the boiler is 50 mm (meaning the internal size of the nominal diameter of the pipe).

- The horizontal distributing and collecting manifold can be reduced to 40 mm, before the last batteries - to 32 mm.

- A slope of 2-3 mm per 1 linear line of the pipeline is made towards the radiators on the supply and the boiler on the return.

Even large pipes can be laid hidden (pictured on the right). On the left is a typical installation with open communications - The inlet pipe of the heat generator should be located below the radiators on the first floor, taking into account the slope of the return line. It may be necessary to make a small pit in the boiler room to install a heat source.

- On the connections to heating devices on the second floor, it is better to install a direct bypass of small diameter (15 mm).

- Try to place the upper distribution manifold in the attic so as not to run under the ceilings of the rooms.

- Use an open-type expansion tank with an overflow pipe leading outside and not into the sewer. This makes it easier to monitor when the container is overfilled. The system will not work with a membrane tank.

Important point. Don’t forget to carefully insulate all elements of the gravity circuit located in the attic of a two-story house so as not to heat up the cold roof.

The calculation and design of gravity heating in a cottage with a complex layout should be entrusted to specialists. And lastly: lines Ø50 mm or more will have to be made of steel pipes, copper or cross-linked polyethylene. The maximum size of metal-plastic is 40 mm, and the diameter of polypropylene will be simply menacing due to the thickness of the walls.

What should you consider when choosing heating wiring diagrams in a two-story house?

The “golden mean” can confidently be considered a two-pipe system.

However, it is impossible to say unequivocally that in any case it will be better than a single-pipe one - a lot depends on the type of house and the location of the premises in it.

If the floor area is not large in size, and the rooms are arranged in descending order of comfort (for example, children's room - bedroom - living room - kitchen), then a single-pipe system will be more appropriate.

As for the collector system, due to the significant costs of purchasing materials and installation, it can currently only be recommended in exceptional cases. An example of this is houses, some of which are rented out or where servants live in addition to the family. That is, where the homeowner has limited access to certain rooms, as a result of which he cannot directly regulate the heat transfer of the radiators installed there.

Pros and cons of a single-pipe scheme

A single-pipe heating system for a two-story private house can function normally only with forced circulation from a pump. The design is as follows: one main line runs along the perimeter of the floor, where all the batteries are connected. That is, the collector simultaneously plays the role of supply and return.

The Leningradka system is compact and works perfectly with a small number of heating devices

The operation of the single-pipe circuit, called “Leningradka”, is quite complex:

- If the pipelines are calculated correctly, then approximately 1/3 of the hot water flows into each radiator. The remaining 2/3 of the volume moves further along the highway.

- The coolant that has passed through the battery gets rid of the heat and returns back to the collector, lowering the flow temperature by 1-2 °C.

- The cooled water flows to the next radiator, where the process of separation and merging of flows is repeated. The temperature of the coolant in the collector drops again. How many batteries are connected to the ring main, the number of times the water will cool.

- Having passed the last heating device, the cold coolant returns to the boiler.

An important condition for the normal operation of the system: the diameter of the main line must be sufficient to supply heat to all batteries. In fact, pipes measuring 25–32 mm (DN 20–25) are used with radiator inlets Ø15 mm (internal diameter DN10).

Supporters of the “Leningradka” call its main advantage the low cost of materials and installation. We agree with the statement, but with a caveat: if the assembly is made with cheap polypropylene.

Single-pipe wiring is easier to install in building structures

A one-pipe heating circuit made in a two-story house from metal-plastic, cross-linked polyethylene or metal will cost more than a two-pipe one due to the price of fittings. Our expert Vladimir Sukhorukov will provide the exact calculation in the video below.

The disadvantages of the Leningradka look like this:

- since each subsequent radiator receives cooler coolant, it is necessary to increase the number of sections to heat distant rooms;

- in order not to select the number of sections at random, you need to calculate the cooling of the water;

- the maximum number of efficiently operating batteries on one branch is 5-6 pieces, otherwise the diameter of the distribution pipe will have to be increased to 40-50 mm;

- a looped highway is more difficult to route through the house - doorways get in the way, especially on the second floor;

- heating devices influence each other, which makes it difficult to organize automatic control.

Example. Imagine that all radiators have thermal heads installed. If the air in the first room has warmed up to the set temperature, the thermostat will close the coolant passage into the battery. Then hotter water will flow to the remaining appliances, which will force the remaining radiator valves to operate.

A small plus of single-pipe wiring: it is easier to hide one branch in a wall or under the floors than two. The heating network can be easily combined with other types of forced circulation systems.

Common installation mistakes

Above are “Leningrad” diagrams of horizontal single-pipe floor circuits with radiators connected to a common main line by two tees. Only part of the total volume of coolant circulating through the circuit flows through each device. You may encounter an erroneous connection without a main pipe (see the outline of the first floor in the figure below).

Types of connection of radiators in horizontal single-pipe circuits.

This method of connecting heating radiators is extremely cheap. Each radiator has one fitting for connecting a DN20 or DN25 metal-plastic pipe and a section of pipe between adjacent devices. Can't think of anything cheaper. But the price to pay for the cheapness is poor performance of half the radiators. The first of them (in the direction of the coolant movement) is heated to a temperature of 55 ° C, and the last one at N = 6-8 is heated to only 35 ° C, since the coolant, passing through the radiators, intensively cools down in them.

Two-pipe wiring - simple and reliable

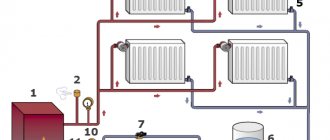

There is no need to describe the algorithm of operation of the two-pipe circuit, since it is outrageously simple. 2 pipelines are laid past all heating devices - supply and return. According to the first, the hot coolant enters the batteries, where it is cooled and returned to the boiler through the second. The connection is appropriate - one connection is embedded in the supply, the second - in the return.

Classic dead-end wiring. Shown here is 1 shoulder on each floor; if necessary, their number can be increased to 2-3

In two-story country houses, 2 types of two-pipe systems are used:

- Deadlock or shoulder. The supply and return lines end at the last radiator; in fact, the coolant changes direction and flows back to the boiler.

- Passing (ring, Tichelman loop). The supply pipe ends at the last battery, and the return pipe starts from the very first radiator, passes through the remaining heaters and returns to the heat source. The direction of water movement does not change, hence the name.

Note. Both systems are powered by a pump and in the vast majority of cases operate under a pressure of 1-2.5 Bar. There is no point in making them open; it is easier and more convenient to install a membrane expansion tank next to the boiler.

In the Tichelman loop, water does not turn around after leaving the battery, but flows in the same direction (classical hitchhiking).

Two-pipe schemes are almost flawless, so let's start by listing the disadvantages:

- extended branches with a large number of heating devices require deep balancing, but when the number of batteries is 5-6 pcs. there will be no problems;

- the pipelines of the Tichelman loop inevitably encounter doorways that have to be rounded in different ways;

- a heating network assembled from polypropylene will cost more than a similar single-pipe system;

- All.

There are really few downsides to two-pipe schemes: they are reliable, stable in operation, easy to automatically adjust and function equally well with heated floors, radiators and other types of heaters. Dead-end wiring arms can be made of different lengths and loads according to the number of batteries, and the Tichelman loop is an example of hydraulic balance that does not require balancing.

For reference. In a country cottage with an area of up to 200 m², it will be possible to get by with pipe diameters of 10-20 mm (internal), no more.

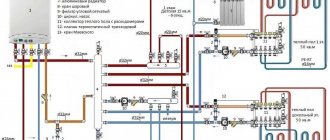

Heating with heated floors

Warm floors are installed on the first floor, and batteries with collector wiring are installed on the second floor. Only the living area of the house is taken into account; the balcony and porch are not taken into account. This arrangement of equipment is intended for permanent residence of residents in the house. At the dacha, radiators are also installed on the ground floor, since additional radiators will warm up the room faster. The boiler comes with a safety group, expansion tank, circulation pump and the necessary components.

The principle of collector distribution of coolant

The beam circuit is a modern type of two-pipe distribution that satisfies all new and old requirements: efficiency, cost-effectiveness due to automated control, completely hidden pipe laying, and so on. What are the features of the system:

- The coolant from the boiler is directed to the main distribution unit - the collector.

- The radiators are connected by DN10-15 connections to the comb according to a two-pipe circuit, each to its own pair of fittings on the supply and return manifolds. There are no highways.

- The supply pipes are insulated and laid hidden along any convenient route - under the floor covering, behind suspended ceilings or in the walls.

- With the help of manifold flow meters (rotameters), manual adjustment of the amount of water directed to the battery is available. If the comb is equipped with servo drives connected to the room thermostat, the coolant flow will be controlled automatically.

The perfection of collector heating schemes for two-story houses is somewhat overshadowed by the high price of materials. Combs with rotameters, pipe insulation, servos - all of these elements cost a lot of money. The second disadvantage: such a system is difficult to assemble in residential premises without making repairs. To hide a bundle of pipelines, you will have to dismantle the floors or remove the ceiling lining.

Common connection options

If you decide to install a single-pipe system, you will have to choose between two types:

- simple circuit without regulation;

- "Leningradka" with the ability to turn off individual radiators.

In terms of control method, the first option is clearly inferior to the second; its only advantage is its budget cost.

Installation of a simple single-pipe system of horizontal or vertical type is simple and reliable, but temperature control in the network is impossible (+)

Installing the Leningradka will cost a little more, since in addition to the pipes you need to purchase a set of shut-off valves. Using bypasses and valves, you can reduce/increase the amount of coolant supplied to the radiator.

Diagram of the Leningradka device: using shut-off valves, you can temporarily turn off individual unnecessary radiators without changing the functional qualities of the entire system as a whole (+)

"Leningradka" is recognized by professional heating engineers as the best option for a single-pipe system for a 2-story residential building.

Complete set and installation of equipment

Standard equipment for system assembly:

- circulation pump;

- gas or electric boiler (power depends on the size of the house, characteristics of the coolant, etc.);

- expansion tank;

- pipes 20 mm and 25 mm;

- adapters, gaskets, plugs;

- set of radiators;

- Mayevsky cranes.

Along with steel pipes, polymer or metal-plastic pipes can be used, with the latter being preferred.

In heating circuits with closed expansion tanks, air is bled using automatic bleeders equipped with shut-off valves and floats, or Mayevsky valves supplying each radiator

First, they find a suitable place for the boiler and install it, then assemble the pipeline leading to the radiators. Tees are fixed in places of radiator branches and bypasses. The pump is installed on the return line, next to the inlet to the boiler, and connected to the power supply.

The installation location of an open expansion tank is the highest point of the system; a closed one can be mounted in any convenient place, for example, in a boiler room. Radiators are suspended from the walls using special fasteners and equipped with plugs and taps.

Underfloor heating circuits

Like the collector circuit, a water-heated floor is installed during the construction or renovation of a two-story house. There are 2 ways to install underfloor heating:

- embedding pipe coils in a cement-sand screed;

- layout of heating circuit pipes in heat-distributing metal plates without pouring screed.

For reference. Concreting of pipelines is usually done on the first floors of residential buildings. The second method is used for laying inside wooden floors.

The ends of pipes Ø16 x 2 mm, laid with a snake or snail, are connected to the comb, which was mentioned above and described in detail in a separate publication. A manifold with a mixing unit or RTL thermal heads ensures the supply of coolant to the circuits with a temperature not exceeding 50 °C.

The advantages of heated floors are obvious - real energy savings of 15-20% due to heating the surface to a temperature of 20-25 ° C and comfort for those living in the house. Now about the negative points:

- Installing a heated floor in a two-story home is not a cheap undertaking. In terms of the cost of materials and installation, this is the most expensive option for space heating.

- Heating circuits, especially in cement screeds, are very inert in terms of adjustment. Imagine, a cold monolith reaches operating mode within 24 hours. To prevent the room from overheating, a third of the required heating power should be supplied by batteries that quickly respond to changes in air temperature.

- In the event of a malfunction or water leak in the circuit, the concrete screed will have to be broken.

A method for installing heated floors without a cement screed

Despite the problems listed above, heated floors are being used by homeowners more and more often - the heating is too comfortable and the fuel savings are noticeable. Unlike other heating systems, heating circuits do not spoil the interior of the premises at all.

Two-pipe heating system for a 2-story house

Truly comfortable living conditions can only be achieved by installing a two-pipe heating system. Its design allows you to regulate the temperature in individual rooms and save energy resources.

How does a two-way circuit work?

Unlike a single-pipe circuit, a two-pipe circuit consists of a pair of lines with different purposes: one of them supplies coolant, the second returns it back. The radiators are connected not in series order, but in parallel. One circuit, with heated coolant, extends from the riser to the radiators of both floors, the second is mounted to the boiler outlet and is also distributed to both floors.

Radiators are equipped with thermostatic valves that allow you to set a comfortable temperature. If desired, you can reduce the heating intensity partially or completely block the flow of water into the device.

Some devices are fundamentally embedded in the return line, for example, a membrane tank that regulates pressure, a circulation pump and a safety valve are traditionally installed in front of the boiler

In modern 2-story houses, two-pipe structures are used, since they are much more efficient than single-pipe ones:

- reduce pressure loss;

- do not require a powerful pump;

- keep the coolant temperature the same for each radiator;

- allow you to use many different thermal devices within one system (for example, radiators, convectors and “warm floors”);

- make it possible to repair and replace parts without compromising overall functionality.

The main disadvantage is the difficulty of self-installation - during assembly, consultation and supervision of professionals is required.

Successful solutions for installing a two-pipe system

There are many incarnations of various schemes, but when drawing up a project you should start from individual requirements.

The simplest diagram for arranging a heating system in a 2-story house. It is characterized by the following points: 2 circuits for heating and hot water production, liquid coolant, forced circulation (+)

A number of universal schemes are suitable for providing heat to houses of various sizes and number of floors.

Detailed diagram of two-pipe wiring for a one-story house with a fully equipped basement. The problem of thermal insulation of the floor in the basement was solved by connecting a water-based “warm floor” system

If you install additional equipment, such as a membrane tank, the capabilities of the heating system will expand.

A and B – two variants of the wiring device, upper and lower type. Additional equipment: expansion tank, Mayevsky taps, overhead line (+)

The following diagram combines the three most popular wiring diagrams.

Level 1 – dead-end wiring with parallel installation of both circuits; Level 2 – counter wiring, characterized by two-way radiator connection; 3 – collector wiring with improved balancing

All of the above schemes are suitable for heating a 2-story building.

Choosing a suitable scheme

After familiarizing yourself with the heating systems used in two-story houses, it’s time to return to your draft project, where the types of radiators and boiler are selected, the arrangement of this equipment is determined, and wishes are listed. Next, select a scheme in accordance with the recommendations:

- If there are frequent power outages, the choice is small - you need a gravity system. If the house is heated with a brick stove, you should use it as a heat source and not buy a boiler.

- If you still don’t understand what you want, feel free to assemble a closed-type two-pipe dead-end circuit. It can be easily adapted to different conditions and equipment. Subsequently, install a solid fuel, gas or electric boiler - there is no difference, the heating will work.

- If you have increased requirements for interior design, start with manifold wiring. In order not to make a mistake with the size of the pipes, pull the diameter of 32 mm to the comb, and make connections to the batteries Ø16 x 2 mm (outer).

Joint connection of a radiator network and underfloor heating circuits controlled by room thermostats - Warm floors are installed if there are funds and desire. It is better to combine them with any system other than gravity.

Advice. Underfloor heating without a radiator network is not suitable for everyone. To warm a room with a warm floor, its surface will have to be brought to 30 °C or more. A long stay in such a room causes a feeling of stuffiness and discomfort for many.

In a small country house with 2 floors, it is worth making a one-pipe system from PPR pipes. With 3-4 batteries on each branch it will work flawlessly. We do not recommend using Leningradka in a large cottage. For more information about choosing a wiring, watch the video from an expert:

pros

Single-pipe systems also have advantages, which determines their popularity. The most important advantage is the low cost of installation due to the reduction in the number of pipes and time.

Important! This scheme is suitable for houses of different heights and with different layouts. Regardless of the architectural features of the house, it will completely cover all rooms.

During installation, it is allowed to lay the deck chair in the floor screed. For underfloor heating systems, a single-pipe design is the ideal choice. The pipeline can also be laid on the floor surface. In this case, it is necessary that the sun lounger goes as low as possible.

About compatibility with various boilers

When choosing a heating scheme for a two-story house, you need to take into account the type of heat source. For example, all systems except gravity can work with a wall-mounted gas boiler. If there is a power outage, the heat generator will simply stop. The best option for gravity feeding is a non-volatile floor unit or a brick oven with a water circuit (tank - boiler, but not a coil!).

Direct connection of gravity wiring to a solid fuel boiler is extremely undesirable, although homeowners do it anyway.

Due to the low speed of movement and slow heat extraction, the heating unit will overheat and boil, and sooner or later an accident will occur. A buffer tank is definitely needed, taking away excess energy, and connected according to all the rules of gravity flow - with large diameters and with slopes. The structure will be bulky and ugly.

Closed systems of two-story houses are compatible with any boilers, including double-circuit ones. The only recommendation: when connecting to solid fuel units, it is better to use a heat accumulator, which will prevent the coolant from boiling and prevent an accident.

Heating with gas boiler

Gas boilers are the main source of energy in most modern heating systems. They guarantee high performance at relatively low energy costs, are highly reliable and safe, of course, subject to all installation standards and regulations.

However, in recent years there has been a trend of constant growth in prices for natural gas, which will soon equate the unit costs of its purchase with the costs of maintaining an electric heating system. And two-story houses are most often built with large areas. As long as gas availability remains, we recommend heating your two-story house with a gas boiler.

Independent calculation of the heating scheme

To calculate the scheme, it is necessary to collect the following initial data:

- Dimensions of all internal premises;

- Overall, external dimensions of the structure;

- Dimensions of door and window openings;

- Region – average temperature in winter;

- Required indoor temperature;

- Positioning of the cottage according to the cardinal directions;

- Height and material of construction of external walls;

- Type and thickness of insulation on walls, roof, and basement.

Ultimately, at the stage of purchasing equipment and materials, you will mainly need knowledge of the power of the boiler and radiators, based on calculations of the heat loss of the building, as well as a number of hydraulic parameters for selecting a pump, expansion tank and pipelines.

General operating principle

The operation of any heating system is to convert the energy of burned gas, solid (liquid) fuel or electricity into heat. Heated water (antifreeze) flows through pipes into radiators, where it releases heat into the space.

Gravity system

Pipe slope during natural circulation in the heating system

The operation is based on the laws of physics. If the contours provide for the natural movement of water, then such a scheme is called gravitational.

It is extremely difficult to create a heated floor circuit in gravity systems without the use of additional pumps. A difference of several millimeters in the pipes in the floor leads to airing and cessation of coolant movement.

The density of the heated coolant is lower than that of the cold one. Due to the difference in density, water/antifreeze from the boiler rises upward along the supply riser (diameter 60 - 80 mm). An open or closed expansion tank is installed at the top of the entire system.

The upper circuit of the wiring is laid along the perimeter of the second floor premises. A pipe with a diameter of 40-50 mm is installed with a slope of 2-3 cm per meter of length. In places where radiators are installed, pipes with a diameter of 16 - 25 mm are welded into the wiring. The liquid flows through them into the radiators. The coolant then enters the radiators on the ground floor.

At the level of the boiler or slightly lower, along the perimeter of the building, a lower circuit (return) is laid, into which the cooled water is collected.

The circuit is used in places where the electricity needed to operate the pumps is often cut off. Gas boilers in this case are equipped with non-volatile safety devices.

The same scheme is needed for systems with solid fuel boilers. In the event of a power outage, circulation stops, and wood/coal continues to heat the water. You can stop the operation of a solid fuel boiler only by quickly removing the burning fuel, which is extremely problematic. Increased pressure occurs, which can destroy pipes and radiators.

What does forced circulation provide?

All the advantages of water heating systems, where the coolant circulates with forced impulse, are provided by one simple element - the pump. It is placed on the supply or return pipeline directly next to the boiler, as a result of which the speed of water movement through the pipes significantly increases. If during gravity flow the coolant speed is 0.1–0.3 m/s, then after installing the pump it increases to 0.7–1 m/s. This provides a lot of benefits.

So, let’s look at all the advantages of a forced circulation system:

- the speed of water has increased - its flow rate has increased, which means that the diameter of the pipe can be reduced;

- the warm-up time of all radiators is reduced, there is no inertia;

- large length of branches and highways, choice of a convenient method for laying them. The main thing is that the pump develops the required pressure;

- The slopes of the routes can be kept to a minimum. They are only needed to empty pipelines;

- when a closed type system is installed, the expansion tank can be placed in the boiler room.

The list of other advantages is very extensive; there is no need to list them all. Is it worth mentioning an important point: a forced circulation system allows you to install a type of heating such as heated floors in private homes. But there are only 2 shortcomings, but one of them plays an important role. This is the dependence of building heating on the availability of electricity. They turned it off - the pump stopped - the batteries cooled down.

There is also a worse case scenario. After a power outage, a solid fuel boiler will quickly overheat and boil, and then there will be an explosion. Therefore, forced circulation must always be provided by uninterruptible power supplies or a generator so that the heating system continues to function normally.

The second disadvantage is that the running pump consumes a small amount of electricity and sometimes makes noise. But these nuances are insignificant compared to the number of options for heating schemes that forced movement of the coolant allows you to implement. Here is their list:

- single-pipe;

- two-pipe;

- collector (radial);

- water heated floors.

Horizontal layout

The horizontal type of pipe routing, in turn, is divided into:

- beam (collector);

- consistent.

The collector circuit, which, as the most popular, will be described in more detail below, is characterized by the presence of a separate supply for each radiator.

The sequential method implies the existence of a single branch extending from the riser, running along the perimeter of all floors and containing supply and return pipes.

Advantages of horizontal wiring:

- high level of hydraulic stability;

- the ability to automatically set and maintain the temperature in each individual room;

- when using the scheme, it is allowed to install separate heat meters, either two or more;

- Wiring of this type can be placed discreetly without spoiling the appearance of the rooms with pipeline parts.

Disadvantages of wiring:

- a complicated heating startup scheme: to ensure uninterrupted operation, gently release the air from it first;

- on all radiators it is required to install taps to release air pockets;

- the cost of a project involving a collector is quite high, since more building materials need to be purchased for the arrangement.