But for the latter to become possible, orderly and reliable information is needed. Today, together with specialists from the Royal Thermo industrial group, we decided to collect complete information about what steel panel radiators are, highlight the most reliable facts from it, discard all unnecessary things and convey the essence to the reader in an easy-to-read form. This will help:

- Get a complete understanding of the features of steel panel radiators, as well as how they differ from similar heating devices.

- Find out how to choose the right steel radiators.

- Get information about how panel radiators are connected to various heating systems.

First, let's look at the features of panel radiators, without affecting the characteristics of the material from which they are made.

Features of panel radiators

Structurally, a panel radiator is quite simple: it is based on panels (most often there are two of them), inside which the coolant circulates. Each panel is made of two profiled plates connected to each other by contact and roller welding. Most often, convection elements and decorative grilles are installed between the panels; in some cases, these parts are missing (it all depends on the type of design).

Double-row and three-row panel radiators equipped with convection elements combine the functions of both a radiator and a convector.

Let's look at the differences:

- A radiator is a heating device that accumulates heat and transfers it to surrounding objects through thermal (infrared) radiation. It is also called radiant heat.

- A convector is a heating device that primarily heats the air. Air flows heat up as they pass through the fins and other convective elements of the device. What makes them move is the temperature difference in the room (warm air rises, cold air falls down).

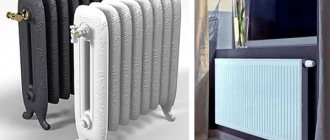

Classic radiators (for example, cast iron) heat the room to a greater extent due to infrared radiation, and to a lesser extent due to convection light. In systems with convective heating, everything is the other way around.

Since a panel radiator combines such universal capabilities, it means it can heat a room more efficiently. In practice, this looks like quick and uniform heating of the room throughout the entire volume (both below and under the ceiling).

Konstantin VitalievHead of steel panel radiators Royal Thermo, .

A convection element installed between two thermal panels of a steel radiator provides approximately 50% of the heat, the remaining 50% is radiant heat from the panels.

Panel heaters that do not have convection elements are more closely related to classic radiators.

Such devices do not provide effective indoor convection, but they have another, very significant, advantage. Their design does not have hard-to-reach areas where dust and other contaminants accumulate. Such radiators are very easy to clean and maintain, which allows the devices to be used in facilities with special requirements for indoor hygiene: hospitals, schools, social centers, and so on. In this regard, panel radiators without convection elements compare favorably with other heating devices, be they classic convectors, cast iron radiators or other types of heating equipment.

Minimum required thermal power

Typically, thermal calculations of houses are done infrequently, so calculations have to be done room by room. The power of all radiators should be 20% higher than the power of the boiler. For a house insulated according to GOST, heat loss is 10 kW per 100 sq. m. with a ceiling height of up to 2.7 m.

Determining the number of radiators in each room by area is not always reasonable. Heat loss depends on walls, windows, doors. You shouldn't hang too many batteries either. But there should be enough of them so that the system is not hot (>70°C).

Here is an example of power distribution:

- The inner room is heated by the neighboring ones and can be equipped with a minimum number of radiators.

- External wall and window – 1 kW per 10 m2.

- A long outer wall and two windows - multiply the previous figure by 1.2.

- Two external walls and a window - multiply by 1.3.

- Two external walls and two windows - we multiply the primary data by 1.4 or 1.5.

This definition of power is relative. Much depends on other characteristics of the house: layout, size of external walls and windows. But for more than 90% of standard Russian houses, such a simple calculation is quite enough.

Steel panels: good or bad

Most steel radiators are affordable. Steel itself is cheap, and this is a fact, and the ease of its processing only plays into the hands of the consumer.

This feature mainly concerns panel radiators. Tubular steel radiators, for example, are difficult to manufacture and therefore have a higher cost.

Steel has good heat transfer. It is lower than that of aluminum, but on a five-point scale it can be rated at 5 (for aluminum it will be 5+).

From the point of view of environmental friendliness, steel radiators have no equal: in accordance with sanitary and environmental requirements, they can be used in almost any facility (even in hospitals and kindergartens).

Steel heaters are not without their disadvantages, but all their disadvantages are very controversial.

For example, the chemical properties of steel are such that corrosion is its faithful companion. This fact, according to ordinary people, “puts an end to” steel radiators (at least their use in centralized heating systems). In accordance with their logic, autonomous heating can be filled with non-freezing liquids and independently control the quality of the coolant. But let's turn to the opinion of a specialist.

Konstantin Vitaliev

A steel panel radiator can be used in absolutely any modern heating systems. Modern apartment buildings use closed (independent) heating systems. This means that the coolant in the heating circuit of an apartment building is heated through a heat exchanger installed in the ITP (individual heating point). The heat exchanger, in turn, is heated by coolant from the external boiler room. Thus, the heating system of the building is isolated and uses only its own coolant, the quality of which is easier to monitor.

Another disadvantage that is mistakenly attributed to all steel radiators is that these products are not designed for high pressure in the system. Indeed, a heater with a wall thickness of half a millimeter cannot withstand the same pressure as a panel radiator with a wall of 1.25 mm. Therefore, always pay attention to the specifications of the product, and problems will bypass you.

Additional restrictions on the operation of a steel radiator are, again, related to the electrochemical properties of steel. It is prohibited to drain coolant from a system in which steel radiators are installed (except in situations related to accidents or the need for preventive maintenance). If it is not difficult for owners of autonomous systems to comply with this requirement, then residents of apartment buildings can ignore it altogether.

Konstantin Vitaliev

In modern apartment buildings, the coolant has not been drained from the heating system for a long time. Therefore, there is no problem complying with the manufacturer’s requirements.

Prices: summary table

| Model | Height, mm | Working pressure, atm. | price, rub. |

| Buderus Logatrend K-Profil 11 300 2000 | 300 | 10 | 6 930 |

| Kermi FKO 22 200 2000 | 200 | 10 | 8 599 |

| Purmo Ventil Compact 200 2000 | 200 | 10 | 11 400 |

| Radena CS 150 16 sections | 150 | 25 | 10 100 |

| Loten Gray Z 750 180 mm | 180 | 16 | 9 189 |

| Rettig Column H-2×200×700 | 200 | 10 | 7 800 |

Steel panel radiators: overall characteristics

Combining the design features of panel radiators and the characteristics of the material from which they are made (in our case, steel), we get the following picture.

Konstantin Vitaliev

Steel panel heating radiators are the lowest cost per kilowatt of heat among heating devices. Therefore, they are widely used in mass construction (apartment buildings, administrative buildings).

And here are the qualities this popularity is based on:

- if we do not take into account the budget segment (products of very questionable quality), then steel panel radiators can be used as part of both autonomous and centralized heating systems;

- the same applies to the requirements for the characteristics of the coolant: high-quality steel panels work on any coolant (water, non-freezing liquids with a pH of 8 to 9.5, etc.);

- steel panel radiators provide uniform heating of the room throughout the entire volume and demonstrate high efficiency, regardless of the temperature of the coolant.

Konstantin Vitaliev

It has long been proven that when using low-temperature coolant, steel panel radiators are the most efficient heating devices. Even at a coolant temperature of 45°C - 50°C, the radiator is able to effectively transfer heat to the room.

Reviews of low heating devices: advantages and disadvantages

| Advantages | Flaws |

| Small dimensions allowing installation of devices under any windows, as well as in rooms with insufficient free space | Greater cost compared to standard products. For one narrow battery you have to pay 2-3 times more |

| More comfortable heating, the lower and longer the heating device, the more even the room temperature and the better the entire volume of air is heated | Less efficient, since with the same width they have a smaller heat exchange area, and it is not always possible to install extremely wide radiators |

| Models with a height of 200 mm have a wide selection (any material, almost any manufacturer, various colors) | More demanding on the quality of the coolant. According to owner reviews, some models with complex designs clog quickly. This leads to air pockets |

| Stylish and modern appearance, most models do not need to be hidden from view | Shorter service life |

| The small volume of coolant (with the exception of tubular steel) makes the system more inert and functional | Slightly more complex installation |

Criteria for choosing steel panel radiators

Considering the almost complete versatility of steel panel radiators, the key criterion for their selection should be the quality of the product. Of all possible options, the budget segment should be excluded. The fact is that its true quality is unknown even to sellers. Product compliance with the international standard ISO 9001 should be a key focus for the buyer. On the territory of the Russian Federation it is confirmed by a certificate of conformity to GOST 31311-2005.

But the international standard is a concept very detached from Russian realities. No one is more familiar with the operating features of heating appliances in our country than domestic manufacturers. Therefore, one, but proven, domestic manufacturer is always better than two foreign ones.

Also, the main selection criteria include:

- heating system pressure;

- type of coolant used;

- radiator dimensions: for example, the width of the radiator installed under the window should cover from 50% to 75% of the width of the window opening (50% for ordinary residential premises, 75% for social institutions);

- features of the location of the heating wiring (if the wiring is in the floor, the radiator must have lower outlets for connection, if the wiring is built according to the classical scheme, the radiator outlets must be located on the sides).

The permitted pH level of the coolant, the permissible pressure in the system, as well as other equally important parameters are always reflected in the product data sheet.

For many, the aesthetic component is important, so we shouldn’t forget about it either. The color, which should match the overall style of the room, the presence of decorative grilles - all this can be of great importance if you care not only about comfort, but also about beauty.

Type

They produce panel and tubular batteries made of steel. Panel models are distinguished by their low price and large heat transfer area, which is especially effective in two-layer models. Most of the series have a laconic design, which does not always suit fans of sophisticated interiors. The equipment is reliable, but is recommended for installation in private homes with heating systems with low operating pressure.

Tubular ones attract with a variety of formats, sophisticated design, and soft thermal radiation. The batteries can withstand high pressure and are often well equipped, but this is compensated by the price.

Number of sections

The greater the number of sections, the higher the heat transfer. This allows you to use fewer heating devices when heating a large room. The number of sections affects the dimensions: for panel ones the depth increases, for tubular ones the width increases. Multi-section models are material-intensive, which affects the price of products.

Size

Before purchasing batteries, it is recommended to measure the space under the window or on the wall where the gadget will be placed. There should be a space of 10-15 cm from the top edge to the window sill so as not to interfere with air exchange. The bottom of the battery should not rest on the floor. The width is chosen 10-15% less than the window size. When installed on a wall, the impact on the interior is visually assessed.

Power

Building regulations determine the required power of heating devices: 41 W per cubic meter for panel houses, 34 W per unit volume for brick buildings. Based on these recommendations, you can choose the power of the installed device. Technical characteristics are indicated in the passport. It is enough to calculate the volume of the room and compare it with the battery power. Such calculations are preliminary, especially for private housing construction. This is due to the different thermal characteristics of the materials used in construction and the presence of additional thermal insulation. It is better to entrust the calculation of power to heating engineers - this will help you save either on the purchase of heating equipment or on energy for the boiler during the heating season.

Features of installing panel radiators

Installing a panel radiator, as well as connecting it to the heating circuit, are activities that are not particularly difficult. If the radiator is chosen correctly and its outlets are located in accordance with the characteristics of the heating wiring, its installation takes a minimum of time.

Among models with bottom connections, wrap-around radiators are very convenient to install. There are no welded brackets in their design, so the product can be connected to the wiring on both the left and right sides.

In models with side connection, convenient connection to the system is provided by four inlet/outlet holes, which are located on the sides of the product.

If the delivery set includes original brackets and fittings from the manufacturer, as well as additional fittings (Mayevsky taps, thermostatic valves, etc.), then quick connection, as well as the tightness of the connections, will be guaranteed throughout the entire period of operation.

Cast iron

Cast iron radiators are a classic, the most popular heating devices over the last hundred years. Long accordions of seven or eight sections can be seen in many retro photographs of Soviet apartments. Even then they were reliable, like a rock, withstanding any external mechanical impact and high pressure from the inside; they served for 50 years, got so hot that you couldn’t touch them, were resistant to corrosion and did not stop working even when they were “poorly heated” and the coolant temperature was low.

They are made from cast iron grade SCH 12-28, which is quite resistant to corrosion, using gaskets made of heat-resistant rubber - thanks to them, the products maintain tightness even when heated to 130 degrees.

But “cast iron” somehow looks antediluvian, they have a high heat capacity, many people talk about the sharp corners of the sections and the rough, unaesthetic casting surface. The best models of cast iron heating radiators are devoid of these shortcomings and will decorate any private home, some of them are even quite elegant, with smooth front surfaces and factory primer, with two- and three-column sections, which allows you to optimally reduce the width of the radiator for a given heat transfer.

TeploNetUser FORUMHOUSE

Cast iron radiators will never go out of style. Only the appearance will change.

A modern cast iron battery consists of several hollow sections, usually seven or eight, hermetically assembled together, with horizontal channels through which the coolant passes. Radiators can be one-, two- and three-channel. Their sizes are regulated by special GOST 8690-94 Cast iron heating radiators, according to which

- the distance between nipple holes should be from 300 to 800 mm;

- product height from 400 to 900 mm;

- depth from 100 to 160 mm.

Technical characteristics are given in the product labeling: this is how the MS-140-580-0.9-7 labeling is read: this is a product with a depth of 140 mm, a height of 580 mm, with a working pressure of 0.9 MPa, which consists of seven sections. This radiator fully complies with GOST.

The number of sections is simply calculated based on the area of the room (although there are also precise, complex and labor-intensive calculation methods that take into account many circumstances, from the region - winter is one thing in Moscow, and another in Irkutsk - to the number of windows in the room). A simple calculation is done like this: to heat a square meter of area, you need 100 W, therefore, by multiplying the area of the room by 100, we will find out how much heat is needed. Then we divide this value by the thermal power of one section of the selected model from the selected manufacturer.

The formula for calculating the number of sections of a cast iron battery is: multiply the area of the room by one hundred and divide by the thermal power of the section.

For a room of 21 square meters. meters according to this formula you will need 7.5 sections of a 160W radiator. It's better to round to eight than to seven.

There is nothing particularly difficult about installing cast iron batteries. Like all types of radiators, they must be installed at a certain distance from the wall, floor and window sill. These distances are regulated by SP 73.13330.2012 “SNiP 3.05.01-85. Internal sanitary systems of buildings."

- From the floor 60 mm;

- From the bottom surface of the window sill – 50 mm;

- 25 mm from the wall plaster surface (but the manufacturer may specify other dimensions).

RoaromaFORUMHOUSE user

The radiator will not operate at full capacity if the distance between it and the wall is not maintained. They passed, it’s not even discussed.

A cast-iron radiator is hung from the wall on metal supports, but sometimes, due to the design features of the house and the heavy weight of the device, it is placed on legs. Floor radiators are often stylized as antique ones, decorated with intricate castings; such products, even domestically produced, have a refreshingly high cost, but fit perfectly into a classic interior.

But when deciding on cast iron radiators, you should remember this important feature: they have high thermal inertia; They both heat up and cool down slowly. It will not be possible to quickly change the temperature in a room heated by cast iron radiators.

But in houses that are heated by solid fuel boilers, the disadvantages of cast iron become advantages: the large heat capacity in this case is rather a plus.

Lord LLC User FORUMHOUSE

Aluminum convectors quickly heat the air, but also quickly cool themselves. This is the reason for my choice of cast iron. If there was gas, I would install aluminum.

VashnovoselFORUMHOUSE user

Well, cast iron takes longer to heat up, well, inertia, so this is better with a solid fuel boiler and permanent residence!

And for houses connected to main gas, cast iron batteries, according to reviews from our users, are not the best choice.

TraksFORUMHOUSE User

My neighbor last year threw out cast iron and installed aluminum. Now pay less for gas. His house is well insulated; at a temperature of -25 degrees outside there is no need to heat the coolant to 90 degrees, 50-60 is enough.

Rules for the location of batteries in the house

In order for the system to work properly, installation rules must be strictly followed. Although the installation technology is not complicated, it has its own nuances, so the work must be carried out by specialists.

Important! If radiators are installed incorrectly, they are not covered by the warranty.

In order to avoid heat loss and uneven heating of the room, when installing devices it is necessary to observe indentations and choose the correct location:

- The most suitable option for the battery is considered to be a place under the window, i.e. where the heat loss is the most significant. The radiator width must be at least 70% of the window width. Mounted clearly in the middle.

Correct placement of the battery Source koffkindom.ru

- Leave at least 10 cm from the battery to the windowsill, as well as to the floor. The optimal distance between the floor and the radiator is 12 cm. It is not recommended to leave more than 15 cm.

- The battery is fixed at a distance of 5 cm from the wall.

- You can stick heat-reflecting material behind the radiator - then some of the heat will not go into the wall, but will return to the room.

- If the radiator is planned to be placed not under the window sill, but on the wall, then the distance between them should be at least 20 mm.