At the same time, like any other equipment, over time, even in these reliable boilers, certain problems arise. And since their design is quite complex, the variety of potential failures here is quite impressive. However, Baxi tried to make life as easy as possible for buyers of its products and developed its own self-diagnosis system. High-precision electronics analyze the characteristics of work processes, compare them with nominal indicators and, if a problem is detected, display information about it on the LCD display.

But information about errors is displayed in encoded form in the format E## or ##E, where E is an abbreviation for Error, and ## is a two- or three-digit digital value. Knowing the code and what problem it shows, you can try to fix it yourself or at least assess the extent of the problem. However, we strongly do not recommend trying to fix it on your own - this procedure should be trusted only to experienced specialists who comply with established regulations and take into account the design features of the equipment.

The explanation of error codes in some cases can be found in the manual for your boiler model. However, it will be much more reliable to have at hand a complete list of possible problems and their coded meanings.

Decoding

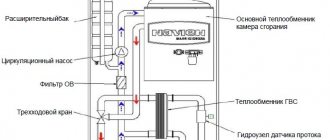

The factory interpretation of error E25—reduced coolant circulation—does not provide a complete understanding of the essence of the problem. In the instructions for various models of the Baxi boiler, the emphasis is on blocking the pump. But this is not the only reason such a fault code appears on the display.

Control panel for gas boiler Baxi LUNA 3 comfort

Error e25 indicates an intense increase in temperature in the heating circuit. This parameter in Baksi units is determined by the difference in readings from sensors installed at the inlet and outlet of the boiler heat exchanger. When it grows at a speed above 1 0С/sec, the operation of the unit is blocked by the protection circuit. A decrease in fluid circulation is caused by several factors, therefore there is no clear recommendation for eliminating error E25. The algorithm of actions given in the article will allow you to figure out the reason for the appearance of this fault code in a short period of time.

How to fix the error. Instructions

- Before starting work, you need to turn off the boiler, turn off its power and shut off the gas supply.

- It is necessary to check the filter located on the return line of the heating system. It is necessary to close the taps and drain the water from the boiler. To do this, place the drain pipe on the tap fitting on the left and turn it to drain the water. After this, the drain valve is closed.

- Next, you need to check the filter, which is located on the return line of the heating system. Unscrew the plug, inspect the mesh that is located inside, and if necessary, rinse and clean it. Then the filter is put in place and fixed.

- Then the boiler is disassembled. To remove the front panel, use a Phillips screwdriver and remove the two screws from the bottom. The panel is pulled towards itself and removed from the fasteners.

- It is recommended to check the filter on the heating system. Expand the control panel. The filter is located in the hydraulic group under the circulation pump. Dismantle the electric drive for the directional valve: remove the bracket and take out the electric drive itself. Then you need to carefully pull out the capillary of the heating system pressure gauge. Next you need to remove the bracket that secures the filter itself. Then, by prying from below with a small screwdriver, you can remove the filter element. If the filter is dirty, it needs to be cleaned. Before installing the filter back, it is recommended to lubricate the o-ring with a special lubricant - this will help avoid problems during further dismantling if the filter has to be removed again.

- After lubrication, the filter is put back and secured with a bracket. The pressure gauge is also connected to its original place, the valve drive is installed and fixed.

- Next, open the taps for the heating system and feed the boiler. Pressure is raised to feed the boiler. Close the tap.

- After the work has been done, you need to check the circulation in the boiler. Fix the control panel, open the gas supply valve, connect the power supply and turn on the boiler. After starting the fan and turning on the pump, the boiler will start working and it will be possible to check its circulation. If the boiler works well and does not display an error, the problem is solved and the operation of the device is restored.

Thus, the error for the Baxi E25/E26 gas boiler model is associated with clogged filters. To eliminate it, you need to dismantle the device and clean the clogged areas. After this, the boiler’s operation will be restored.

The most common causes of errors during operation

Errors in Baksi gas boilers are displayed on the display as coded messages. To decipher the message, you need to use the correspondence table. It is worth noting that each model has its own, so it cannot be used as a universal one. This can lead to an incorrect diagnosis and the prescription of useless actions that will not be aimed at eliminating problems.

Malfunctions of Baksi wall-mounted gas boilers with one working circuit will affect exclusively the heating system. Moreover, electronics break down more often, because mechanical parts are made of durable metal, which undergoes additional processing and hardening. As a result, it can last for many decades without even showing visible signs of wear.

When cleaning the combustion chamber, you need to remove the naga very carefully so as not to damage the protective inner layer. If this happens, the wear rate will increase many times and the boiler will not be able to work for the entire announced period of time. You should behave in the same way when cleaning the burner. The diameter of the tool should be smaller than the holes so that they do not become loose, otherwise the device will become unusable and will have to be replaced.

Malfunctions of Baksi double-circuit gas boilers will already affect both the heating and water heating systems. There are many more options for breakdowns here, since the system is more complex than a single-circuit model. Diagnostics can take more time, and repair work is much more difficult. So in this matter, it would be better to trust the professionals so that they take on all the troubles themselves.

To avoid breakdowns and extend the life of the unit, you need to correctly configure the Baxi gas heating boiler. This is quite easy to do if you use the practical recommendations from the instructions. In addition, the “smart” automatic control system itself will prompt the user with the optimal parameters that are best suited for his system. In general, you need to carefully monitor the automation readings, as they can tell you about impending problems. Timely diagnosis increases the chances of success.

Gas prospects

The use of gas for heating houses and apartments is one of the most promising trends in the development of engineering communications today. Manufacturers of boiler equipment have offered so many options that you can choose the right unit for absolutely any room. An example is BAXI boilers.

BAXI gas boilers can be installed in any room. They are suitable for installation in apartments and for organizing heating of a large country house. Naturally, the room where the mini-boiler room is installed must meet existing requirements:

- The room must be at least 15 cubic meters in volume.

- Ceiling height is at least 2.2 meters.

- Good ventilation, capable of providing three air changes.

Existing requirements for the organization of a chimney can be ignored if you choose a BAXI boiler with a closed combustion chamber to heat your home. Such a unit is a full-fledged mini-boiler room, which has all the necessary elements and does not harm the ecology of the house. Models from this manufacturer differ in power ratings, so BAXI boiler units can be used to heat and supply hot water to a wide variety of rooms.

Content

- Instructions for installing a baxi boiler What needs to be done

- Error E 01

It has already been proven that the safest and most effective heating occurs through the condensation of water vapor generated during the combustion of hydrocarbons. Gas boilers that operate using such a system are called condensers. This is exactly what Baxi belongs to, which is designed for the conditions of post-Soviet countries. In Russia, Ukraine and Belarus, it is important to use energy-saving technologies, which is what the manufacturer of gas boilers Baksi does.

Baxi boiler error 25. Heating circuit temperature sensor

Regardless of the reasons for the error, it is detected by the temperature sensor, so its malfunction is also possible. There may not be actual overheating - the sensor simply provides incorrect values to the control unit. Typically, sensors are thermistors with a certain dependence of resistance on temperature. Therefore, it is quite easy to check the serviceability of the sensor - measure its resistance with a multimeter. At room temperature it should be approximately 10 kOhm, at 40 degrees approximately 5 kOhm. In some boiler models, the heating and hot water temperature sensors are the same, so they can be swapped for testing (for testing only!). If necessary, buy a new temperature sensor.

Other malfunctions and solutions

In addition to those described above, other codes may appear on the display during operation:

- E111 - appears when the supply fluid is heated above 95 degrees. Press and hold the Reset button for a couple of seconds. If the value does not disappear, you need to call service.

- E129 - fan speed is below the minimum permissible. You need to contact a service center for repairs.

- E153 - accidental pressing of the “Reset” button. What you need to do to set the previous mode is just press and hold this button until the settings are restored.

- E154 - lack of flow circulation. To resolve the problem, contact customer service.

We invite you to watch a video about eliminating error E03 on a Baksi boiler:

BAXI Forum

The largest professional forum BAXI in Russia

- Unanswered topics

- Active topics

- Search

- Users

- our team

- Acknowledgments

- 04/16/2021 — The conference has been moved to a separate subdomain. Now we are at forum.baxi.ru.

- 11/15/2019 — A separate section on the forum has been allocated for discussion of the ZONT device.

- 07/19/2019 — The BAXI seminar book 3Q was published. 2019 (119 MB). Download

- 06/20/2019 — BAXI Energy voltage stabilizers are on sale.

- 04/16/2019 — Sales of BAXI Eco Nova boilers have started.

- 11/16/2018 — The BAXI 4Q seminar notebook was published. 2018 (8 MB). Download

Useful observations

- To ensure uninterrupted operation of the Baxi boiler, connect it to the network via a UPS. The UPS contains a charger, stabilizer and battery group. This ensures continued operation of the device even in emergency situations. The number of additional working hours can be determined by the total capacity of all batteries.

- If the boiler is controlled by an electronic board, before operating it you need to check in the settings whether the type of heating device is selected correctly. An incorrect choice can trigger error E25.

- The Baxi boiler may display error E25 after changing the heating circuit. An installed radiator can cause a large load on the pump. The hydraulic resistance increases, which reduces the circulation in the boiler - this is how fault E25 occurs. This point must be taken into account before reconstructing the heating system. To prevent the problem, you can include an additional pumping device in the circuit, determining the correct characteristics and a suitable installation location.

- If the heating system needs to increase the pressure from time to time by topping up, the problem is caused by a small leak of liquid due to a crack - therefore, the coolant level decreases gradually. If the pressure drops and diagnostics do not yield results, you need to look for a hidden leak.

- When replacing a unit, check the identity of the numbers and letters on the panel. When replacing the board with a universal unit, you need to adjust the boiler settings.

- When installing the NTC, you should change the gasket and apply fresh thermal paste to the internal circuit tube.

Errors E25 and E26 for the Baxi boiler are similar, but they can be caused by different reasons. If you find it difficult to identify the problem yourself, it is better to seek help from specialists. Sometimes even experienced professionals cannot immediately accurately determine the problem - it takes time and checking possible options.

Preventative recommendations and boiler maintenance

What is included in the list of seasonal maintenance operations:

- checking for leaks and gas leaks at connections (soap solution)

- examine the condition of the combustion chamber, remove dirt, check the position of the flame electrode

- the position of the group of nozzles in the boiler body, it must be securely fastened to the body, there should be no gaps

- gas valve check

- checking the pressure on the pressure gauge

- pressure control in the expansion tank

- cleaning filters from dirt

One of the most important and expensive parts of any boiler is the heat exchanger, and taking into account the fact that the hardness of the water used often does not meet the standards, its prevention should be considered. You can do the cleaning yourself, but dirt can be removed more effectively using special installations (boosters) and professional washing products.

As a rule, in the summer, the boiler is used exclusively in DHW mode, and the components responsible for heating are idle, so it is advisable to carry out maintenance and testing of the boiler in the “winter” operating mode well before the onset of the heating period.

Damage to the Venturi device

This malfunction most likely occurs on boilers from other manufacturers and boilers, but I think it is necessary to describe it too. Since the plastic tubes themselves are located near the gas burner, there is a possibility of exposure to high temperatures.

This mainly happens due to the presence of other malfunctions, for example, a primary heat exchanger clogged with scale or prolonged operation of the boiler at maximum power. The tubes of the device simply melt, and any, even the slightest, deformation leads to the entire system not working correctly and the unit stopping.

If the information from this article was useful and helped you, you can share it with your friends using the social buttons below.

Almost everything described above can also be viewed in the video, which describes error e 03 in detail: