The “warm floor” system has long been firmly established in our everyday life, and such a floor has a long history. Even in ancient Rome, the principle of floor heating in baths was the same as in the operation of modern systems. Happy owners of country houses often install heated floors in their homes for additional heating. This is not surprising - after all, a pleasant feeling of comfort is primarily associated with the optimal temperature. Without it, the house is not only uncomfortable, but even dangerous to health. In this case, the heated floor can be water or electric. Let's try to figure out which of these systems is optimal for your home, what the operating principle of electric and water floors is, and how to make a warm floor with your own hands. It is quite possible to install heated floors yourself, even without special skills in construction and repair.

Water heated floor: general information

Water is supplied through a network of pipes in the “lower” heating system, which is heated to 35 degrees.

The structure is installed both in urban residential premises and in private homes. After all, heated floors can be powered by a gas boiler and heat pump. This system differs from radiator and convector systems in that the heat is distributed evenly. Feet get cold due to cold air both in apartments and in private houses, which often leads to health problems. This unpleasant circumstance is eliminated by a heating system that warms the air below. Buying a water heated floor for large rooms is also a profitable solution, since the price for electricity is higher than for other heat carriers. In addition, the system does not need to be regularly maintained, as is the case with radiators and convectors.

From a design point of view, water-heated floors are a good option for those who like spaciousness in the room, because the pipes are hidden from view.

Despite the many advantages, water heated floors can cause inconvenience. It is possible to obtain the minimum heating temperature by installing a mixing unit and connecting it to a pump for forced circulation of water in the pipes. Install such devices only with the permission of the responsible authorities who have the authority to give consent or recommendations. Before you buy a water heated floor, you should consult with the management company or installation specialists.

Choosing a heating boiler

If there is a gas main in the region, then the question of fuel for the boiler simply does not arise - gas units will be both affordable and economical. In addition, gas will in any case be cheaper than electricity or solid fuel. However, if the settlement is not gasified, then the only option will be a solid fuel or liquid fuel unit.

Gas combi boilers, which can also operate on liquefied gas (the nozzle needs to be replaced), can be a good option in case of gas supply interruptions. However, liquefied gas itself is not advisable to use, since it is quite expensive and is consumed quickly.

Provided that diesel fuel is purchased at wholesale prices and in large quantities, it would be quite logical to purchase an oil-fuel boiler. It is quite capable of heating a large house. In all other cases, the best option would be to connect heated floors and radiators to a solid fuel boiler - coal, wood, pellets.

Please note that when developing a diagram for connecting underfloor heating and radiators, it is worth considering that floor heating is more efficient and economical. However, you don’t need to think that radiators are of no use. These devices help retain heat inside the house and prevent its loss through windows, doors and cold walls. Therefore, a well-designed project and selected components, as well as reasonable control, will allow you to create an effective and at the same time economical heating system.

The most profitable option for heating equipment would be a condensing boiler. Fuel consumption in such installations is more economical, due to which the efficiency of the units reaches values much higher than those of other boilers. Condensing boilers are equipped with automatic electronic ignition and require a circulation pump. Therefore, such units require electricity.

How does it work

A water-heated floor heats the room using small-diameter pipes through which the coolant circulates. The water temperature should not exceed 50 degrees - the key rule of the system. With a pipe diameter of 80 mm, the length of the heating circuit reaches 80 m, with a diameter of 20 mm - no more than 120 m. Pipes of maximum length are heated by a circulation pump with a pressure of 6 or 8 m. Otherwise, the system will not create sufficient heating.

The boiler heats the coolant up to 80 degrees if the same water is used by radiators. For a water floor, the temperature is needed twice as low: up to 50 degrees. For this reason, a mixing unit with a mixing valve and a circulation pump are installed in the system. The valve mixes water from the return and return collectors. In this way, a temperature suitable for a water floor is achieved. Water enters the distribution unit and is directed through the return manifold into pipes under the floor. The coolant makes a circle and returns through the return manifold to the boiler, and this cycle continues as long as the pump is running.

Malfunctions and repairs

The water floor structure is simple in structure, which causes few problems. Heating may deteriorate as a result of:

- no noise from the circulation pump when power is supplied;

- lack of system functioning. The distribution panel should be checked on each circuit where the shut-off valves should be in the open position;

- air intake.

Troubleshooting:

- Removing air from the heating structure. The operation of underfloor heating may be defective even with high-quality installation.

The main problem is airing due to a sharp drop in pressure in the heating circuit, excessive heating, leaks and leaky connections, and improper installation.

The manifold may be installed incorrectly, the pipes may be sloping, there may be no valves to eliminate excess pressure, or air may not be pumped out of the manifold assembly during initial start-up. The system will not heat up due to the small thickness of the pipelines.

The problem is solved by overlapping all and leaving one contour, after which each branch is run separately.

In this case, the circulation pump turns on at low speeds, the pressure in the system increases to 1 kg and operates in this mode for some time at a temperature of 55 degrees.

By lowering the flow meter, the performance of the structure improves. A separator can be used to automatically remove air from pipes.

- Setting up the system. To set it up correctly, you should study the principles of operation of the collector that directs the flow of waste and warm liquid. Typically, the operation of the circuits is adjusted in accordance with the balancing table.

At the same time, the cap is removed from the valve and it is closed. Using the table, the speed in each circuit is determined by turning the valve so many times.

- Low temperature due to insufficient boiler power , which needs to be cleaned, preventive maintenance carried out or temperature sensors checked.

Heat transfer is reduced in the presence of furniture and carpets or due to poor insulation (rework and installation of high-quality insulation may be necessary).

- Uneven heating. If the system has been de-aired, but the floor does not warm up, the reason may be an inadequate vapor barrier or its absence. You can check this factor by gluing polyethylene to the floor.

If condensation appears on it within 24 hours, the system must be replaced.

- Mechanical damage (during covering installation) . First, the water is turned off, the damaged area is protected, and access to the pipeline is cleared.

The damaged area is cut, the ends are unraveled, a press coupling is put on the pipe and secured with press pliers. The tightness is checked using internal hydraulics.

- Incorrect installation.

Incorrect installation of the floor is possible with low door openings, incorrect location of the collector, installation using the “snake” technology, increased pipe spacing, and incorrect calculation of heat loss.

This is possible with an unprepared base, insufficient insulation thickness, or short pipeline length.

Conditions and rules that are important to follow

Whatever the cost of a water heated floor, the purchase is advisable only when certain conditions and rules are observed.

Problems will arise if they are not followed: either the floor will be too hot, or the service life of the pipes will be halved. These are just a few of the undesirable consequences that imprudence entails. Rooms for different purposes require different temperatures:

- in the bedroom - 18 degrees;

- in the bathroom - 25 degrees;

- in the hall - 22 degrees;

- in the kitchen - 20 degrees.

Servo

creates a suitable temperature for each room separately. The device is installed on the return collector sockets. Such equipment smoothly opens and closes passages in the circuits at the command of room thermostats.

Rules that will help you avoid mistakes when installing heated floors:

- Do not exceed a certain number of circuits that are connected to the collector;

- Do not exceed the maximum length of contours;

- Pipe diameter - no more than 80 or 20 mm;

- Before operation, you need to calculate the appropriate pump power;

- Make an installation plan in advance and prepare all the necessary tools.

How to achieve maximum savings

Any underfloor heating system must perform its functions as efficiently as possible. When choosing a specific model, first of all, pay attention to the power characteristics and installation specifics. However, during operation problems may arise with excess energy consumption.

This is often due to ineffective heating control systems. It is different for each type of heated floor, so it is impossible to give general recommendations - you need to consider all the examples.

Power

To install a water heated floor in an apartment, it is useful to know what the energy consumption of the system depends on. Power is determined by the temperature of the coolant: the higher the temperature, the greater the power output. When using such a heating system, it is important to remember: the water temperature should not exceed 50, and the power from 1 sq. m - no more than 140 W. When a water-heated floor in an apartment is the only source of heating, it is recommended to cover most of the room.

A private house

Water-heated floors in a private home allow you to save on electricity. In addition, such a heating system in the house works smoothly. Engineers recommend taking into account the heating system before construction begins, at the planning stage. This will make calculations easier in the future.

This design is installed due to the cold inside the room. The cold climate forces people in Simferopol to buy water heated floors and use it with other heating sources.

It is also possible to install a heated water floor in a private house after construction is completed. However, it is important to comply with certain conditions. First you need to understand whether the house is suitable for installing such a heating system. If the room does not have thermal insulation, it is useless to install such a system - heat loss should not exceed 100 W/sq. m. A water-heated floor in a concrete house will subtract 15-20 cm from the total height of the room. Therefore, during installation, it is important to ensure that the dimensions of the doorways are maintained.

Pipe deformations and leaks occur due to an uneven and weak base surface. Therefore, before installing such a heating system, it is recommended to use special building mixtures.

Minuses

A water floor is suitable for furnishing private houses and cottages. For multi-apartment buildings with central heating, such a system will not be suitable, since it will be necessary to collect a lot of documents to obtain permission.

Other design disadvantages include:

- The need to perform complex calculations for installation;

- The need to raise the floor level by a few centimeters, reducing the height of the doors.

- If there are leaks on a concrete floor, you will have to open the base. The system is heavy and not suitable for old objects.

Therefore, first familiarize yourself with the advantages and disadvantages. It is better to install the floor in a house under construction, making the necessary calculations during the design, which will reduce installation costs.

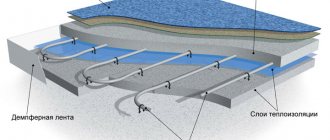

Pie recipe"

Each element of the heating system performs a special function. In order to buy and install a heated water floor in a private home, you need the following “ingredients”:

:

- cement mixture;

- plastic film with a thickness of at least 0.1 mm;

- thermal insulation material;

- plasticizers;

- reinforcing mesh 50x50 or 100x100, rod thickness - 3-5 mm;

- heat-resistant floor covering.

A thin layer of polyethylene film is laid on the base, soil or concrete slab. Then the floor is covered with heat-insulating material: density from 40 kg/m3, thickness from 300 mm.

Plasticizers

added to cement fill for elasticity of the material. Inside this layer there will be water-heated floor pipes. The screed is reinforced with a reinforcing mesh, and then a heat-resistant floor covering is applied. Installing a water floor under tiles or laminate is a good idea, since these building materials have sufficient thermal conductivity.

Thermal conductivity of floor coverings

There are a large number of different types of flooring, ranging from ceramic tiles to wood. All of them have their own specific properties, among which one of the main ones is thermal conductivity. Before we get acquainted with the thermal conductivity indicators of floor coverings, let’s figure out what kind of concept this is – thermal conductivity. In simple words, it is the ability of bodies or materials to transfer heat . The higher it is, the faster the material heats up, but also cools down faster.

Table. Thermal conductivity coefficients.

| Name of coating | Coefficient value, W/m*k |

| Tile | 1,05 |

| Linoleum | 0,2 |

| Parquet board | 0,15 |

| Carpet, carpeting | 0,12 |

| Laminate | 0,1 |

| Cork | 0,034 |

The lower the thermal conductivity, the longer the coating retains heat. Based on the table, we can conclude that the material that retains heat the longest is cork. Tiles retain thermal energy the worst, but they heat up quickly.

Cork floor

In order for floor heating to be as effective as possible, the finishing material must conduct heat quickly and well. Ceramic tiles are the leader here, although they require fairly powerful heating.

Advice! Solving the problem with heating power is simple - just buy more powerful heaters; The pipe is also laid at more frequent intervals. Heaters with a power rating of at least 200 W/m2 are purchased for tiles.

Floor covering for heated floors

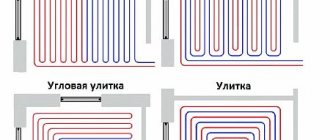

Water heated floor: snakes and snails

The heating system is installed according to one of 4 schemes: “snail”, “snake”, “corner snake” and “double snake”. The pipes, which are laid according to the “snail” pattern, evenly distribute heat in the room. This installation method is used when you do not want to divide the room into warm and cool zones.

The “snake” scheme is the simplest solution for installing a water-heated floor. An unpleasant feature of this scheme is that there is a noticeable difference in coolant temperatures at the inlet and outlet.

Differences in temperature will not be noticeable if you combine both patterns. Often, pipes are laid in the shape of a “snail” in the center of the room, and in a “snake” on the sides.

Advantages and disadvantages of ETP

The advantages of ETP are:

- ease of installation of the structure.

This is especially true for heating mats and infrared film. They simply need to be laid out on the base and connected according to the instructions; this does not require any special knowledge; Easy to install - high reliability and durability.

Provided the insulation is intact, the heating wire or mats embedded in the screed have an almost unlimited service life; High reliability and durability - high autonomy.

ETP does not require connecting the house to the water supply and even works from an electric generator. This allows it to be used in village houses and cottages. Versatility. These floors can be installed in any room

The disadvantages of this heating method include:

- relatively high cost of heating a room. EHP consumes quite a lot of power, especially if it is the only heating method;

- Due to the relatively low temperature of the floor surface, the air in the room warms up rather slowly. This is relevant if the EHP is the only source of heat and does not operate constantly. For example, in a country house in winter;

- Since heating elements are prohibited from being placed under massive furniture, global rearrangement of the furniture will not be possible after the work is completed.

Pipe for water heated floor

In order for the heating system to work, you need to choose and buy the right pipe for a water heated floor. Reliability is an abstract concept, but it is what determines the efficiency of heating. A pipe for water heated floors must have the following characteristics

:

- Heat resistance

Resistance to temperatures in pipes is an important parameter, even taking into account the fact that a warm water floor does not warm up above 50 degrees. This is due not so much to the temperature as to the constant exposure to hot water. The structure of some materials crystallizes and collapses under the influence of 30-40 degrees, so “random” pipes are not suitable for water heated floors.

- Strength

The pipe for underfloor heating must withstand the internal water pressure, the weight of the concrete or cement screed and the effects of erosion. Before you buy and install a water heated floor in a private house, it is important to remember that the pressure in the pipes is 2 atm, but the heating system must withstand 6 atm. This indicator includes any load.

- Protection against chemical processes

Serious damage is caused by chemical and oxygen corrosion. Therefore, it is important that the pipe for water heated floors is resistant to these processes.

- Length

Leaks occur at pipe joints, and to avoid troubles, it is recommended to make calculations in advance.

- Material quality

It is not difficult to check the reliability of pipe manufacturing: any heating equipment and its components undergo mandatory certification. The brand and the level of trust in it among other users also play a role.

Design and Build Rules

The basic rule says: a cottage heating system with water-heated floors is always designed for a specific object!

Absolutely all objects are unique, and the same appearance of cottages does not guarantee the same preferences of residents. There are a number of design rules, between which there is no strict gradation; they are all important, and without taking them into account, the system will not work in the desired mode. But the calculations begin by calculating the safety margin of the floor and the heat loss of the house. This allows you to decide on the type of construction: “screed” or “dry”. And also decide on additional thermal insulation of the building (this action is never superfluous for a private house in Russia).

It is important to remember that in almost all calculations of underfloor heating, the principle of sequence “from simple to complex” or “from large to small” does not work. It is impossible to first select pipes, a collector for them, a boiler for them, etc., and designing water floors in the reverse order does not work.

Professional designers complete the system in such a way that if some parameter changes, then other points are simultaneously adjusted.

The nuances of installing heated floors for a private home and its difference from installation in an apartment

Equipment for a water heated floor system using a “wet scheme” requires filling the coolant circuit with a screed. The minimum thickness of the screed is 4 cm (above the pipe) + 2 cm the height of the pipe. 1 m2 of screed is 1 cm thick, weighs about 17 kg. 6 cm of screed will give ≈100 kg/m2. The load on the floor in a room with an area of 20 m2 will exceed 2 tons.

For an apartment in a multi-story building, these are excess loads, so water-heated floors in such facilities are installed only using “dry” technology.

It is prohibited by law to connect a water underfloor heating system in an apartment to a regular riser.

In some houses built according to modern designs, engineers specifically included the possibility of parallel connection of a separate apartment through a special riser. In other cases, approximately the following scheme is allowed for an apartment: “dry installation” + electric boiler + UNIBOX.

Schematic diagram of a water heated floor in a private house

The heating scheme for a private house based on water-heated floors can be presented in the following sequence:

- Boiler.

- Security group. Needed to relieve high pressure in the system.

- Expansion tank.

Further the route will bifurcate. Because high-temperature coolant is supplied to the radiators, and for the floor circuit it must be diluted.

- Radiator.

- Control and adjustment unit, including: Pumping and mixing unit.

- Collector.

Comments: the entire circuit can be roughly divided into three nodes: boiler (1, 2, 7) + wall heating (3, 4) + floor heating (5, 6). All types of heating are controlled and operate independently of each other.

The system operates according to the following protocol:

- Hot water (HW) from the boiler enters the main riser.

- From the riser, part of the hot water passes into the radiators. The expansion tank is part of this branch. The cooled water returns to the boiler through the return line.

- The main part of the hot water enters the pumping and mixing unit (PMU), where in a three-way valve it is mixed with the return from the floor circuit to regulate the temperature.

- Then the hot water is pumped through the collector along the underfloor heating circuits. Cold water (CW) is returned through the same collector. In the NSU, part of the cold water is used to regulate the temperature. Most of it enters the boiler through the return line.

The room temperature sensor transmits a signal to the collector thermostat. The temperature of the coolant in the underfloor heating system is adjusted up to the collector.

The reason is explained with a simple example. Let's say there are 3 rooms in a cottage, each of them has its own floor covering: carpet, tile and laminate. Each room must have an air temperature of +24˚C. But each floor covering has its own thermal conductivity. And if a coolant with a temperature of 40˚C is sufficient for a room with tiles, then in a room with carpet it will need to be raised by several degrees.

Experienced designers in such cases operate with several parameters at once: pipe diameter, pitch and type of installation.

The inconvenience of thermal engineering calculations lies precisely in the difficulty of combining different parameters in one project to obtain the optimal result for the agreed amount.

Calculation of the water floor. General views

The thermal power of the floor is calculated to heat the cottage during the 5 coldest days of the year. These are different constants for each region. Therefore, the norm of one region is not at all applicable in another.

Deviations are allowed here. For example, in Moscow the average temperature of the coldest month, February, is -9.8˚C. Every year for 3-5 days it drops to -18˚C. And in the cottage the air temperature must be maintained at +24˚C. When designing a heating system, the power of the floor circuit may not be enough on these frosty days, and there are two options. You can either lower the temperature in the room to +21-22 degrees, or add another circuit with wall-mounted radiators.

The other part of the calculations concerns each room. For example, there is a corner room in a cottage with an area of 4x5 m and a height of 2.5 m. Two walls with an area of 22.5 m2 face the street. There are two windows with a total area of 5 m2. Ventilation is also taken into account, and what is located under and above the room, and the purpose of the room (bedroom, kitchen or living room). It is necessary to calculate with what minimum configuration it is possible to ensure a comfortable air temperature in the room.

In the project, the power of thermal radiation can be adjusted by changing the diameter of the pipes, the type of installation of the circuit, the speed and temperature of the coolant.

The calculations even take into account the material of the enclosing structures, which is considered layer by layer, and the thermal characteristics of each layer are entered into the project as a separate line.

The power and productivity of the pump and boiler are also calculated separately.

IMPORTANT: amateur calculations of a heated floor should be compared with the diagnosis that a psychic gave to a sick person. Data obtained in this way can be studied, but used in practice is dangerous. It is necessary that the project calculations are carried out only by specialists.

Methods for installing water circuits

In total, there are only 5 ways of laying pipes in an underfloor heating circuit, of which the first 2 are basic, and the rest are derivatives:

- Snail.

- Snake.

- Double snail.

- Double snake.

- Combined.

You only need to compare the basic types of installation, and the difference between them is very noticeable:

| Snake | Snail | |

| Complexity | It is very simple to design, but difficult to implement, since the circuit is built on pipe bends at an angle of 180˚. | Noticeably more difficult to design, but easy to install. Due to the absence of 180˚ bends, the hydraulic resistance of the circuit is reduced by 5-10%. |

| Uniformity of heating | In the standard version and with poor design, the “zebra effect” is clearly visible. | Warming up is uniform. |

| Material consumption | Higher than that of a snail, by 7-10%. | Optimal. |

The “snail” has an objective advantage, but the shortcomings of the “snake” are leveled out by an experienced engineer at the design stage. For example, you can reduce the temperature difference or the laying step. And on sloping floors, “snake” installation is preferable.

IMPORTANT: a combination of different types of styling, even within the same contour, is a common practice. For example, immediately after the collector, the pipe is laid in a “snake” along the outer walls in order to concentrate heat in the “boundary zone”. Then you can use the snail style.

There are two immutable rules:

- The length of pipes in each circuit should not exceed 100 m.

- They try to keep the length of the pipes the same for all circuits.

Design for concrete and wood floors: differences

The limiting factor is the bearing capacity of the foundation. Only a floor underfloor water heating system is allowed on a wooden base. It works partly as a system in a screed. But to lighten the load, the cement-sand mortar was replaced with a structure made of polymers, composites and wood.

Scheme of deck structure

A mat with bosses and pipes are sequentially laid on a wooden base. They are covered from above with a special sheet material with high thermal conductivity, and then there is a floor covering.

The weight of 1 m2 of water-heated floor, assembled using “dry technology” from proprietary materials, is about 10-12 kg, and the height of the room will decrease by no more than 7-8 cm, of which 3.5 cm is the heat insulator included in the structural mat . This property allows you to install a floor heating structure in a residential building without major repairs.

Disadvantages of “dry technology” water floor

Lack of inertia is the main flaw of this scheme. After all, the entire volume of the cement-sand screed was responsible for the inertia of the water-heated floor. But this same disadvantage can be interpreted as an advantage, because the room should be heated faster.

But here the rate of heat transfer from the pipe to the flooring interferes. In a screed, this process occurs due to direct heat transfer - the pipe is completely enveloped and in contact with the screed material. In the flooring system, special aluminum radiators are installed to increase the efficiency of heat transfer between the mat and the pipe.

This metal fits more tightly to the pipe, and heat transfer through it is much more efficient than through a screed. But still, even in the best systems, it is not possible to remove more than 50-55 W/m2 from a water-heated floor.

This option can work well in the south of Russia, and in the Moscow region it is suitable as an additional source of heat to create comfort.

There is experience in the successful use of water-heated floors in cottages using “dry technology” in the Moscow region and the North-Western Federal District. These houses were originally designed as low energy buildings. The thermal insulation technique was taken from “passive houses”.

Typology of pipes for water heated floors

In order for the system to last for a long time, it is important to install a suitable pipe for water heated floors. You can buy a structure from the following materials: copper, metal-plastic, polypropylene, stainless steel, PEX polyethylene, heat-resistant polyethylene PE-RT. You should take a closer look at these materials so as not to make a mistake in your choice.

Copper is a non-ferrous metal that is constantly used in the production of various devices. For modern heated floors, copper pipes are used both in pure form and with a PVC sheath.

Advantages of copper pipes for water heated floors:

- withstand regular exposure to elevated temperatures;

- convenient bend radius;

- are not susceptible to oxygen corrosion due to the oxide film;

- tolerate pressure up to 80 atm;

- smooth inner surface;

- high thermal conductivity.

The disadvantages are the following:

- susceptibility to electrochemical corrosion;

- do not tolerate the effects of ammonia additives;

- tendency to mechanical deformation.

Important: for safety, you need to ground metal and copper pipes for water heated floors and remove oxygen inside.

Corrugated pipe

made of stainless steel is a ribbed product. Elasticity depends on the manufacturing method - annealed or not annealed. Such pipes are used in a private house or apartment when connecting hot or cold water supply.

An auxiliary polyethylene shell protects corrugated pipes from external unwanted influences.

Advantages:

- not susceptible to many types of corrosion;

- withstand temperatures up to 100 degrees at a pressure of 14 atm;

- high level of thermal conductivity.

Flaws:

- vulnerability to electrical and chemical corrosion processes;

- kinks destroy the structure.

Corrosion resistance of corrugated pipes

for a water heated floor is formed by the following factors:

- system grounding;

- lack of oxygen and active chemical additives.

Polypropylene pipes are more elastic than their polyethylene counterparts. Therefore, such products have thick walls. This factor affects the characteristics of the pipes and makes them less suitable for heated floors in an apartment or private house. But when there is demand, there is also supply: some pipes are modified and given heat resistance, reinforced with an anti-oxygen layer.

A polypropylene pipe for water heated floors has the following advantages:

- affordable price;

- ease of installation, docking;

- resistance to destructive corrosion processes;

- does not react with chemicals, with the exception of aggressive oxidizing agents;

- dielectric.

Minuses:

- the period of influence of high temperatures and pressures on the structure;

- it is undesirable to bend and deform;

- at the junction there is reduced permeability;

- high degree of thermal expansion;

- rapid wear due to the influence of oxygen.

Engineers do not recommend using the elasticity of polypropylene pipes when installing water heated floors. Due to bends, the surface becomes rough, the walls become thinner and the cross-sections become smaller, which can lead to the destruction of the pipe.

However, such products for heated floors can be used for installation in bathrooms, hallways and kitchens. Inside this product there is a 0.3 mm thick duralumin foil to strengthen the structure, form bends and protect against oxygen diffusion. The outer and inner layers consist of a polymer coating that ensures the tightness and rigidity of the pipe. These layers are made of heat-resistant, cross-linked or regular polyethylene.

For heated floors, a pipe made of heat-resistant and cross-linked polyethylene is the best option.

Advantages of metal-plastic pipes:

- affordability;

- service life 50 years;

- elastic and smooth surface;

- temporarily maintain a temperature of 90 degrees at a pressure of 7 atm;

- no electrical conductivity;

- holds the fold shape well.

Flaws:

- expand due to high temperature, which reduces the reliability of the collet connection;

- high price of fittings;

- service life depends on the combination of pressure and temperature, and the frequency of their exposure;

- inadmissibility of kinks and fractures;

- low level of thermal conductivity.

All the disadvantages of metal-plastic pipes for heated floors can be leveled out. To do this, it is enough to adhere to the basic rules for installing and operating a heating system.

If none of the options are suitable, it is recommended to buy a PEX pipe

for heated floors.

The class of cross-linked polyethylene products includes three-layer metal-plastic. But this is only one type of structure. Among them there are products made from one or two layers, since the main load in pipes for heated floors falls on polyethylene. The third layer often performs an auxiliary function: it prevents the diffusion of oxygen. EVOH

polymer (Ethylene-vinyl alcohol is a copolymer of ethylene and vinyl alcohol) is used.

Constructions made of ordinary polyethylene

(PE) have less strength and resistance to heat. Polyethylene is cross-linked using four methods: peroxide (PEX-a), silane (PEX-b), radiation (PEX-c) and nitrogen (PEX-d). Modifications PEX-a and PEX-b are popular, and pipes PEX-c and PEX-d are considered unsafe for health in European countries.

The toxicity of polyethylene is significantly reduced in closed heating systems, so you can buy pipes of any type for heated floors.

Note:

the quality of the product is checked in the oven at 130 degrees for 10 minutes.

High-quality polyethylene will not change its structure, but ordinary material will melt. Advantages of PEX pipes for heated floors:

- if the operating rules are followed, the service life is 50 years;

- resistance to elevated temperatures at a pressure of 6 atm;

- sufficient level of thermal conductivity;

- do not conduct electricity;

- strength and flexibility;

- compression connections ensure reliable assembly;

- sufficient length for seamless styling;

- affordability.

Minuses:

- significant elongation due to high temperatures;

- large bend radius;

- single-layer modifications are subject to oxygen diffusion.

Pipes for heated floors made of polyethylene RE-RT

have high heat resistance. The difference between this polymer and the usual one is the branched bonds between the molecules. Such pipes are more homogeneous, since the bonds are not cross-linked, but are formed directly during the synthesis process.

Advantages of RE-RT pipes for heated floors:

- price;

- heat resistance;

- durability;

- surface smoothness.

Flaws:

- quickly fail if the temperature regime is not observed;

- intense diffusion of oxygen;

- expansion of the material when heated.

Use of electrical energy in the heating system (electric underfloor heating)

Electric underfloor heating is a reliable heating system that is used in residential premises not only for floor heating, but also as a main heating system.

How does an electric heated floor work?

An electric underfloor heating system consists of heating elements and heat regulators. Heating elements are placed under the floor. They can be placed inside a concrete screed, filled with mortar or laid directly in tile adhesive. This design ensures the durability, strength and safety of the system.

Heating sections are electrical cables (single-core and double-core), as well as couplings.

Types of electric heated floors

For a long time, electric floors were of two types: based on cables and based on heating mats. Their operating principle was absolutely identical, and the consumer’s choice depended only on the characteristics of the room in which the heated floor system was installed.

However, relatively recently a new type of electric heated floor has appeared, the basis for which is infrared film. And, since many people are interested in the question of which floor to choose, they often settle on infrared heated floors. The main argument in this case is the confidence in the benefits of infrared spectrum radiation for the human body. We all know that medicine has long established the healing properties of such radiations, which are used, for example, in physiotherapy. However, when listening to this argument from the sellers, you should remember from the physics course that many materials do not transmit such radiation, being opaque to them. These materials also include the materials from which floor coverings are made - laminate, ceramics, linoleum. And no one can guarantee that your flooring will transmit these beneficial radiations. Therefore, assurances about the benefits of infrared heated floors can safely be called a common marketing ploy.

Attention! Another undeniable advantage of infrared film is that it consumes approximately 20% less electricity than its cable counterparts.

This is explained by the fact that there is no screed on top of the film, and, accordingly, there is no energy loss. But, on the other hand, the screed is a protective protective layer. It not only protects the film from damage, but also protects us from electric shock. And in the absence of such a screed, we walk along the current conductor on which the floor covering lies.

Another advantage is that parts of the film can be easily replaced in case of malfunction. However, the connection of the heating elements, through which this lightness is achieved, is the most unreliable part of the heating system. But the cable is a solid conductor. And it fails much less often.

A warm electric film-type floor is indispensable in cases where you are not planning major repairs. When installing it, you can simply lift the covering, lay down the film, and install the covering back. All. It also makes sense when, for some reason, it is not possible to raise the floor level when screeding.

However, in the nursery on the loggia or in the hallway it is preferable to use a cable that is better insulated and, accordingly, safer. In addition, the tiles, with which electric heated floors are so successfully combined, are more convenient to lay on a concrete screed.

Film heated floor

Therefore, despite all the promise of infrared heated floors, many consumers prefer to use heating cable systems.

Advantages and disadvantages of electric heated floors

Let's now talk about the pros and cons of a warm electric floor compared to a water one.

The advantages of a warm electric floor are very impressive, and they can be listed for a long time:

- the temperature is distributed evenly throughout the height of the room. This is its main difference from water heating systems; the difference in air temperature near the floor and ceiling is insignificant, since there are no convection currents;

- you can adjust the heating depending on your desire in each room;

- the “electric heated floor” system is easy to install and is considered budget-friendly;

- with proper operation, the service life of heating elements is several decades;

- such a floor does not steal useful space in our already not very large apartments and does not spoil the interior;

- this heating does not create any problems or inconveniences for people with upper respiratory tract diseases, since such floors do not dry out the air and create a pleasant microclimate in the house;

- rooms in which electric heated floors are installed warm up quickly.

However, electric heated floors also have disadvantages:

- Electrical energy is a fairly expensive type of fuel. Therefore, the most significant disadvantage is the high electricity consumption;

- The “electric heated floor” system is quite an expensive purchase. And its installation requires the purchase of additional elements;

- if there is a warm electric floor in the house, it is necessary to use a thermostat, which is not always convenient;

- under the influence of an electric heating system, a coating such as parquet dries out quite quickly, which affects its appearance;

- installing an electric floor requires replacing the old wiring, since the additional load is quite significant;

- This type of heating is not recommended in large industrial premises, since it is simply unprofitable.

Before you buy pipes for heated floors

The severity of winter, heat loss in the living space, the area and number of rooms, the design of the heating system and the type of flooring are the determining factors when installing heated floors. Studying the conditions of the heated environment will allow you to find out what affects the temperature, pressure and length of the pipe circuits.

For example, the frame structure reduces the load on the pipeline. Therefore, in such cases, a protective sheath for the pipes is not necessary. Because the thermal conductivity of air is lower than that of the concrete surface. To avoid this problem, it is recommended to buy pipes for heated floors made of stainless steel or copper.

For floor screed, metal-plastic pipes

.

List of important parameters for purchase:

- strength, permissible pressure in the system;

- ability to tolerate elevated temperatures;

- service life within the operating rules;

- thermal conductivity qualities;

- ability or inability to conduct electricity;

- for polymers, the presence of an anti-oxygen layer is important;

- chemical and corrosive activity, list of unacceptable substances;

- installation features;

- manufacturer rating.

Guarantee

The durability of the structure depends on the quality of the materials, the novelty of the technologies, the professionalism of the installation of the system and the correctness of the design.

If the warranty period for the operation of an electric heated floor is designed for a period of 25 years, then for a water system it will be longer; the duration depends on the selected pipe manufacturer and the quality of the pipelines.

The warranty for equipment and materials is provided by the manufacturer. It is important to comply with the technical conditions. Please review the list before use.

The installation is guaranteed by the installers. Warranty obligations will be considered valid subject to compliance with the operating conditions that are listed in the annex to the contract.

The warranty period for work performed is from 12 months to 5 years from the date of drawing up and approval of the work completion certificate. Its duration depends on the elements used.

After the expiration of the warranty period for service, a contract may be concluded to extend the service on individual terms.

When using a water floor, attention is paid to its effectiveness (do not place it under furniture, cabinets, sanitary equipment), insulation of floors or the foundation of the 1st floor.

Under tiles

Tiles are installed in those spaces where the influence of the external environment is most aggressive. It is recommended to install heated water floors under tiles in the kitchen, bath, and bathrooms. After all, the surface of the tile is colder to the touch than, for example, laminate.

A heated water floor under the tiles is installed taking into account the following nuances: it is important to level the surface, and the base must adhere well to the tile adhesive.

When making a plan, it is important to remember:

- the heating circuit is made from solid pipe sections;

- the pipeline is not installed under household appliances or furniture;

- the manifold cabinet is positioned so that the length of the pipes is the same;

- under the box, space is freed up for connecting all the pipes;

- the length of one circuit is no more than 100 m, otherwise the hydraulic resistance will increase;

- the distance between the pipes is 15 cm, the distance from the wall is 25 cm;

- pipes with the hottest coolant are laid in cool areas of the building.

The methods for installing a water heated floor under tiles are as follows: with laying a concrete screed, a floor covering system, laying on a wooden subfloor.

The choice of installation method is influenced by the characteristics of the building and individual premises. For example, a concrete screed is suitable for homes with a solid foundation. The flooring installation method is used in rooms with low ceilings, since in this case the height of the heated floor is minimal. In private wooden houses, the method of laying on a subfloor is often used.

It is not difficult to install a heated water floor under a tile using the screed method: the structure is filled with cement mortar, and the contours are fixed to the base, reinforcing mesh or heat-insulating tile.

When laying flooring, polyurethane foam boards are used as a thermal insulation layer. The advantage of such slabs is that they can withstand heavy weight loads. This method involves another option for the arrangement of pipes: they install slabs with grooves on which sheets of gypsum fiber or mounting mesh are laid.

To use the subfloor installation method, you will need a suitable thermal insulation material: polystyrene or mineral wool. A thermal insulation layer is laid between the boards, and then DPS modules with ready-made lines are installed under the pipes.

If the foundation of the house is strong enough, then the tiled structure can be laid on duralumin slabs. This facilitates the process of fixing the circuit and also improves thermal conductivity. Floor screed is a popular but complex method of laying pipes. Water-heated floors under tiles are laid using the screed method only on a solid base. After all, for 1 sq. m of “pie” accounts for a quarter of a ton.

The sequence of this installation method is as follows:

- Remove the old screed from the rough base and level the surface.

- Repair mortar is used to eliminate defects, cracks and depressions.

- To install a water-heated floor under the tiles, it is important to level the surface using a level.

- Install a manifold cabinet with a distribution unit.

- Mount the cabinet into the wall and make a 20 cm recess for it, if possible.

- Lay the first layer - waterproofing, polyethylene film 0.3 mm thick.

- A damper tape is distributed around the perimeter to compensate for expansion of the screed due to exposure to high temperatures.

- Apply thermal insulation material (expanded polystyrene boards or foil backings).

- Lay the pipeline according to the chosen pattern (snail or snake). Start with less warm areas of the room. At the same time, fix the contour.

- A leak test is performed. The pipes are connected to the distribution unit, water is released through the channels and left for 24 hours.

- The screed is poured using the same method as cement mortar. To compensate for the expansion of concrete, an expansion joint is made on the coating. To do this, use a damper tape before the stage of laying the solution.

- The tiles are laid with the heating system turned off. The work uses glue for heated floors.

Installation of cable system

In order to save energy, the cable system should be installed on top of thermal insulation. As in the previous instructions, you can use polystyrene foam for this. It is imperative to lay a special backing with foil on top of the polystyrene foam to reflect heat.

After this, you need to determine the location where the thermostat will be installed. The device should be fixed on one of the walls at approximately a height of 30-80 cm. A groove is made from the regulator to the floor, in which a cable and several wires from the temperature sensor will be placed.

The wire is placed on the substrate in the form of a snake or spiral. The second end of the single-core cable must be connected to the thermostat. It is unacceptable to superimpose one turn on another. Mounting tapes for fixing the wire are laid out perpendicular to the turns with an approximate pitch of 500 mm. To allow fixation on the tape, special clips are provided. You also need to remember about damper tapes, which are laid out under the wall around the perimeter of the room.

To reduce heat consumption and high-quality heating of the floor, some experts recommend raising the wire by installing it on a reinforced mesh, which, in turn, is located at a height of 1-1.5 cm from the thermal insulation. This way the wire will be completely filled with concrete. The thickness of the fill is always determined by the laying technology and the diameter of the wire used. The resistance of the heating system must be checked several times.

More information on installing cable heated floors can be obtained by watching this video:

Water-heated floor under laminate

For installation on a heated water floor, a moisture-resistant laminate is suitable, which is mounted on a synthetic substrate. In this case, the use of materials that absorb moisture is unacceptable. Water-heated flooring can be laid under laminate with class 33 grade. Thermal resistance - 0.15 sq. m K/W.

A heated water floor under a laminate can be installed using the methods listed above, the main thing is to follow safety precautions and monitor the condition of the pipes.

The thinner the surface, the higher its thermal conductivity. Therefore, the coating for water heated floors must be durable and resistant to wear. It is convenient if the laminated panel has a “Click” system, since the tongue-and-groove material needs a perfectly flat surface.

Mats for water heated floors

It is recommended to buy mats for water heated floors in situations where there are difficulties in choosing a suitable heat-insulating layer. These mounting coatings are based on foam plastic with a density of 40 kg/cubic meter. m. Mats for water heated floors are made using the hydropellent embossing method. Thanks to this, the material withstands mechanical stress, is resistant to aggressive conditions, and also retains its appearance. It is convenient to insert pipes with a diameter of up to 18 mm into the relief base. Mats for water heated floors do not require the cost of additional fasteners, and installation of pipes is convenient.

Advantages:

- polystyrene foam in the composition makes the material durable;

- the top layer of the mat is covered with an additional protective film;

- installation markings on the mats increase the efficiency of thermal conductivity.

Flaw

Expanded polystyrene mats for heated floors have one problem: during the combustion process, the material produces substances hazardous to health.

Heating with solid fuel boiler

Combined heating with a solid fuel boiler is a closed gravity system with a heat storage device. Both one-pipe and two-pipe wiring are allowed. To increase efficiency, it is worth installing chokes on each of the heating devices.

During operation of a solid fuel boiler, a large amount of heat is generated. It is better not to interfere with this process, but to redirect the excess heat to the heat generator. Then the fuel will be consumed efficiently, and the system will not quickly cool down after the fuel burns out in the boiler.

When the coolant in the main circuit begins to cool, hotter water from the heat generator will be supplied to the system. If the electricity goes out, the water supply from the heat storage tank stops and the bypass opens.

One of the best options for solid fuel boilers will be a unit with a pyrolysis type of combustion. The fuel in it is burned in two stages, which releases more heat and less carbon monoxide. Almost only carbon dioxide and steam remain at the boiler outlet.

Each consumer makes the final choice of a heating boiler, radiators, pipes for connecting them and for heated floors, as well as the wiring diagram, taking into account many factors. Among them are not only the costs of arranging the system, purchasing fuel and the principle of operation, but also personal preferences. If necessary, all work on system design can be ordered from professionals.

Kinds

Mats for water heated floors vary in function and quality, design and production method.

Foil products.

Foil foam is the main component of these mats. Mats with foil are used in heated rooms as an additional heat source. The pipes are placed on the side covered with foil. To do this, you need to purchase additional fasteners.

Mats with bosses.

On the surface of such products there are shaped protrusions (bobs). The production of mats with bosses is based on hydropellet stamping.

Mats for water heated floors with film.

The products consist of three layers - polystyrene foam, foil and film. The density of such a mat is 30-35 kg per cubic meter, which is enough for a water-heated floor. The advantage of this product is the markings, which facilitate the installation process.

Flat mats made of polystyrene foam.

The thickness of the material of such a mat is 50 mm, and the density is up to 40 kg per cubic meter. Thanks to this feature, the product is able to maintain its shape and size under external influences. Special plastic brackets are suitable as fasteners for a flat mat.

Before buying mats for water heated floors, you should check for certificates of conformity. Respectable manufacturers do not hide their product documents.

Features of film systems

If you need accelerated heating of a living space, you can always use a special infrared film. Such products are distinguished by their durability and do not take much time to install. Everyone has the opportunity to purchase a mobile heating device in the most simplified version and hide it under the carpet and hang it on a cold wall. The surface temperature of such a product is controlled using a thermostat. In such systems, sensors are installed that determine the floor temperature.

There are two main types of film floors:

- Infrared system;

- Bimetallic.

As the name suggests, such systems differ in manufacturing technology, as well as in the heating principle. Infrared systems generate heat that is approximately 90% longitudinal waves. It should be noted that infrared radiation has a beneficial effect on the human body. It is not recommended to install the film system in places where furniture will be located. In close contact with some materials, the temperature of the heater fragment may reach a critical level, which will lead to failure of part of the system.

The width of the produced rolls can range from 50 to 100 cm. Experts have different opinions about what the thickness of the film should be. Some say that material that is too thin is not suitable for an underground system because it can quickly fail. Other experts insist that, thanks to the thin film, the height of the living space does not decrease.

The advantages of film systems include the following:

- Installation does not require special equipment;

- Such heaters can be installed under various types of floor coverings;

- No need to fill the screed;

- Saving energy resources.

The disadvantages of infrared systems include the low operational life of thermostats. On average, manufacturers provide a 10-year warranty on such devices.